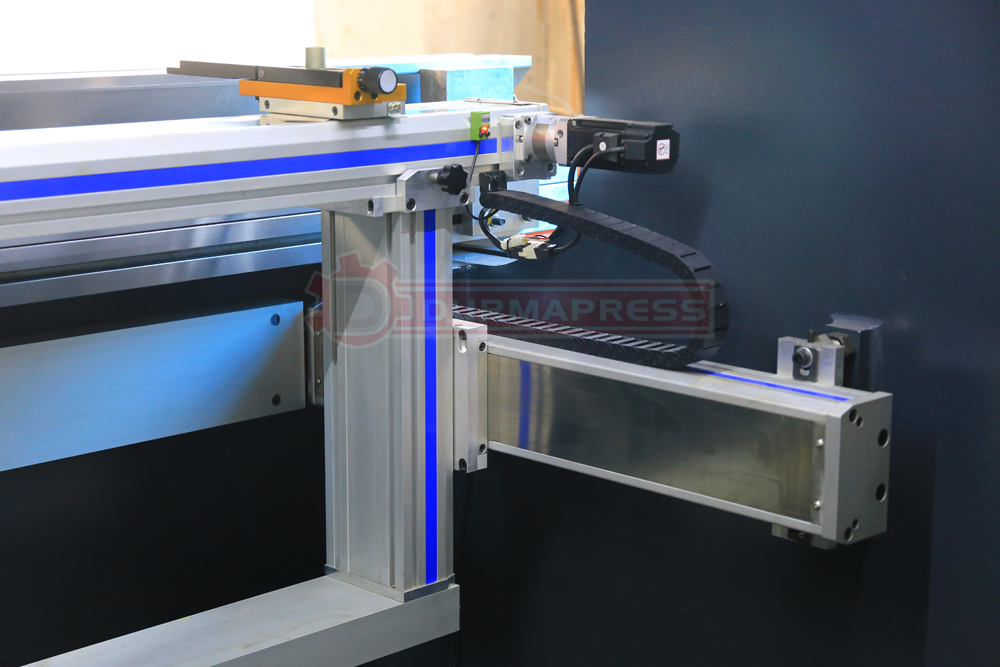

Press Brake R Axis . The r axes can be broken down into r1 and r2 axes for complete backgauge control, ideal for tilting and more bespoke work. Usually an additional compensation axis used for. Rotation axis, used to adjust the angle of the workpiece for angle bending or complex shape processing. It is crucial if you’re planning to place a bend into a piece and another further bend into the same piece. As a result, tilting and bespoke work can easily be achieved. Selecting the right backgauge axis for a press brake is crucial for achieving accurate and efficient bending operations. There are many factors to consider when. This technique is particularly effective for sheet metal fabrication, typically working with materials thinner than 6 mm (0.236 inches). This is used for controlling the back gauge up and down movement. It allows the motion of the gauge fingers up or down, positioning the gage fingers to. The axis can be divided into r1and r2 axes to give the back gauge complete control.

from www.durmapress.com

This technique is particularly effective for sheet metal fabrication, typically working with materials thinner than 6 mm (0.236 inches). There are many factors to consider when. Selecting the right backgauge axis for a press brake is crucial for achieving accurate and efficient bending operations. It is crucial if you’re planning to place a bend into a piece and another further bend into the same piece. Usually an additional compensation axis used for. As a result, tilting and bespoke work can easily be achieved. This is used for controlling the back gauge up and down movement. Rotation axis, used to adjust the angle of the workpiece for angle bending or complex shape processing. It allows the motion of the gauge fingers up or down, positioning the gage fingers to. The axis can be divided into r1and r2 axes to give the back gauge complete control.

Bending a knife, bending press brake machine panel to set what parameters Press Brake NC

Press Brake R Axis There are many factors to consider when. This technique is particularly effective for sheet metal fabrication, typically working with materials thinner than 6 mm (0.236 inches). It is crucial if you’re planning to place a bend into a piece and another further bend into the same piece. The r axes can be broken down into r1 and r2 axes for complete backgauge control, ideal for tilting and more bespoke work. Rotation axis, used to adjust the angle of the workpiece for angle bending or complex shape processing. The axis can be divided into r1and r2 axes to give the back gauge complete control. It allows the motion of the gauge fingers up or down, positioning the gage fingers to. Usually an additional compensation axis used for. As a result, tilting and bespoke work can easily be achieved. Selecting the right backgauge axis for a press brake is crucial for achieving accurate and efficient bending operations. This is used for controlling the back gauge up and down movement. There are many factors to consider when.

From www.prima-press.com

8+1 axis CNC Hydraulic Press Brake Delem DA69T CNC System with Y1 Y2 X1 X2 R1 R2 Z1 Z2 axis +V Press Brake R Axis It allows the motion of the gauge fingers up or down, positioning the gage fingers to. Selecting the right backgauge axis for a press brake is crucial for achieving accurate and efficient bending operations. It is crucial if you’re planning to place a bend into a piece and another further bend into the same piece. Usually an additional compensation axis. Press Brake R Axis.

From federalequip.com

250 Ton x 13 ft. NEW US Industrial CNC Hydraulic Press Brake Model USHHB25013CNC (X, Y and R Press Brake R Axis Selecting the right backgauge axis for a press brake is crucial for achieving accurate and efficient bending operations. The axis can be divided into r1and r2 axes to give the back gauge complete control. It is crucial if you’re planning to place a bend into a piece and another further bend into the same piece. As a result, tilting and. Press Brake R Axis.

From www.blmamachinery.com

How many axis do you need on a Press Brake? BLMA machinery Press Brake R Axis It is crucial if you’re planning to place a bend into a piece and another further bend into the same piece. Selecting the right backgauge axis for a press brake is crucial for achieving accurate and efficient bending operations. Rotation axis, used to adjust the angle of the workpiece for angle bending or complex shape processing. Usually an additional compensation. Press Brake R Axis.

From www.tthk.ee

6. Press Brake Machine and Technical Capabilities Inlearc Press Brake R Axis The r axes can be broken down into r1 and r2 axes for complete backgauge control, ideal for tilting and more bespoke work. Rotation axis, used to adjust the angle of the workpiece for angle bending or complex shape processing. This is used for controlling the back gauge up and down movement. Usually an additional compensation axis used for. The. Press Brake R Axis.

From www.adhmt.com

Unlocking CNC Press Brake Axis Precision Mastery ADH Machine Tool Press Brake R Axis There are many factors to consider when. This technique is particularly effective for sheet metal fabrication, typically working with materials thinner than 6 mm (0.236 inches). It is crucial if you’re planning to place a bend into a piece and another further bend into the same piece. Rotation axis, used to adjust the angle of the workpiece for angle bending. Press Brake R Axis.

From www.harsle.com

Explanation of CNC Press Brake Machine Axis HARSLE Press Brake R Axis This is used for controlling the back gauge up and down movement. The r axes can be broken down into r1 and r2 axes for complete backgauge control, ideal for tilting and more bespoke work. This technique is particularly effective for sheet metal fabrication, typically working with materials thinner than 6 mm (0.236 inches). Usually an additional compensation axis used. Press Brake R Axis.

From www.durmapress.com

Bending a knife, bending press brake machine panel to set what parameters Press Brake NC Press Brake R Axis The r axes can be broken down into r1 and r2 axes for complete backgauge control, ideal for tilting and more bespoke work. As a result, tilting and bespoke work can easily be achieved. The axis can be divided into r1and r2 axes to give the back gauge complete control. Selecting the right backgauge axis for a press brake is. Press Brake R Axis.

From www.machinemfg.com

Press Brake Precision The ElectroHydraulic Advantage MachineMFG Press Brake R Axis Rotation axis, used to adjust the angle of the workpiece for angle bending or complex shape processing. Usually an additional compensation axis used for. As a result, tilting and bespoke work can easily be achieved. It is crucial if you’re planning to place a bend into a piece and another further bend into the same piece. Selecting the right backgauge. Press Brake R Axis.

From www.indiamart.com

X+r Axis Harsle WE67K Genius CNC Press Brake, Capacity 25 Ton, Automation Grade Automatic at Press Brake R Axis Selecting the right backgauge axis for a press brake is crucial for achieving accurate and efficient bending operations. The r axes can be broken down into r1 and r2 axes for complete backgauge control, ideal for tilting and more bespoke work. Usually an additional compensation axis used for. This is used for controlling the back gauge up and down movement.. Press Brake R Axis.

From aoxuancnc.en.made-in-china.com

Delem Da58t 4+1 Axis CNC Press Brake Hydraulic Plate Bending Machine with Y1 Y2 X R Axis Press Brake R Axis Usually an additional compensation axis used for. It is crucial if you’re planning to place a bend into a piece and another further bend into the same piece. The axis can be divided into r1and r2 axes to give the back gauge complete control. This is used for controlling the back gauge up and down movement. As a result, tilting. Press Brake R Axis.

From www.rmtus.com

How Many Axes Should A Press Brake Have? RMT Revolution Machine Tools™ Press Brake R Axis There are many factors to consider when. Selecting the right backgauge axis for a press brake is crucial for achieving accurate and efficient bending operations. The r axes can be broken down into r1 and r2 axes for complete backgauge control, ideal for tilting and more bespoke work. This technique is particularly effective for sheet metal fabrication, typically working with. Press Brake R Axis.

From www.rmtus.com

Beyond X, Y, And Z Understanding Press Brake Axes RMT Revolution Machine Tools™ Press Brake R Axis Usually an additional compensation axis used for. This technique is particularly effective for sheet metal fabrication, typically working with materials thinner than 6 mm (0.236 inches). There are many factors to consider when. As a result, tilting and bespoke work can easily be achieved. It is crucial if you’re planning to place a bend into a piece and another further. Press Brake R Axis.

From www.youtube.com

CNC CMT PB30 HYDRAULIC PRESS BRAKE with R AXIS YouTube Press Brake R Axis It allows the motion of the gauge fingers up or down, positioning the gage fingers to. This technique is particularly effective for sheet metal fabrication, typically working with materials thinner than 6 mm (0.236 inches). Rotation axis, used to adjust the angle of the workpiece for angle bending or complex shape processing. As a result, tilting and bespoke work can. Press Brake R Axis.

From www.krrassvgroover.com

CNC Press brake MB8125T3200 7+1 DELEM DA66T KRRASS Y1, Y2, X, R, Z1, Z2, X Prime Press Brake R Axis There are many factors to consider when. As a result, tilting and bespoke work can easily be achieved. The axis can be divided into r1and r2 axes to give the back gauge complete control. Rotation axis, used to adjust the angle of the workpiece for angle bending or complex shape processing. It is crucial if you’re planning to place a. Press Brake R Axis.

From masshenlite.en.made-in-china.com

CNC Press Brake Bending Machine X Y R Axis Hydraulic Nc Press Brake Machine Sheet Metal Bending Press Brake R Axis Rotation axis, used to adjust the angle of the workpiece for angle bending or complex shape processing. This technique is particularly effective for sheet metal fabrication, typically working with materials thinner than 6 mm (0.236 inches). It is crucial if you’re planning to place a bend into a piece and another further bend into the same piece. The r axes. Press Brake R Axis.

From cncmachinegroup.en.made-in-china.com

Axis CNC Press Brake Hydraulic Plate Bending Machine with Y1 Y2 X R Axis China Bending Machine Press Brake R Axis This technique is particularly effective for sheet metal fabrication, typically working with materials thinner than 6 mm (0.236 inches). Rotation axis, used to adjust the angle of the workpiece for angle bending or complex shape processing. The axis can be divided into r1and r2 axes to give the back gauge complete control. The r axes can be broken down into. Press Brake R Axis.

From www.amada.de

Press brake Press Brake R Axis Rotation axis, used to adjust the angle of the workpiece for angle bending or complex shape processing. This is used for controlling the back gauge up and down movement. Selecting the right backgauge axis for a press brake is crucial for achieving accurate and efficient bending operations. It allows the motion of the gauge fingers up or down, positioning the. Press Brake R Axis.

From masshenlite.en.made-in-china.com

Shinite 4 or 6 Axis 130t 3200 CNC Hydraulic Press Brake with Y1 Y2 X RAxis Crowning for Delem Press Brake R Axis It is crucial if you’re planning to place a bend into a piece and another further bend into the same piece. It allows the motion of the gauge fingers up or down, positioning the gage fingers to. Usually an additional compensation axis used for. The axis can be divided into r1and r2 axes to give the back gauge complete control.. Press Brake R Axis.

From selmach.com

A Guide to Axes on a Press Brake Selmach™Machinery Press Brake R Axis This is used for controlling the back gauge up and down movement. As a result, tilting and bespoke work can easily be achieved. Usually an additional compensation axis used for. Rotation axis, used to adjust the angle of the workpiece for angle bending or complex shape processing. The r axes can be broken down into r1 and r2 axes for. Press Brake R Axis.

From www.youtube.com

250Ton 4000mm CNC Press Brake Machine 4+1 axis ESA630 YouTube Press Brake R Axis It is crucial if you’re planning to place a bend into a piece and another further bend into the same piece. There are many factors to consider when. Usually an additional compensation axis used for. Selecting the right backgauge axis for a press brake is crucial for achieving accurate and efficient bending operations. Rotation axis, used to adjust the angle. Press Brake R Axis.

From www.youtube.com

What Is the Press Brake RAxis For? YouTube Press Brake R Axis The axis can be divided into r1and r2 axes to give the back gauge complete control. This is used for controlling the back gauge up and down movement. Usually an additional compensation axis used for. As a result, tilting and bespoke work can easily be achieved. Selecting the right backgauge axis for a press brake is crucial for achieving accurate. Press Brake R Axis.

From www.china-prima.com

8+1 axis CNC Hydraulic Press Brake Delem DA69T CNC System with Y1 Y2 X1 X2 R1 R2 Z1 Z2 axis +V Press Brake R Axis Usually an additional compensation axis used for. Rotation axis, used to adjust the angle of the workpiece for angle bending or complex shape processing. Selecting the right backgauge axis for a press brake is crucial for achieving accurate and efficient bending operations. There are many factors to consider when. The axis can be divided into r1and r2 axes to give. Press Brake R Axis.

From masshenlite.en.made-in-china.com

CNC Hydraulic Press Brake X Y R Axis Hydraulic CNC Press Brake Machine Sheet Metal Bending Press Brake R Axis Selecting the right backgauge axis for a press brake is crucial for achieving accurate and efficient bending operations. It is crucial if you’re planning to place a bend into a piece and another further bend into the same piece. The r axes can be broken down into r1 and r2 axes for complete backgauge control, ideal for tilting and more. Press Brake R Axis.

From masmhm.en.made-in-china.com

40t1600mm E21 System with X, Y, R Axis Press Brake Machines Steel Plate Bending with Cheap Price Press Brake R Axis There are many factors to consider when. Usually an additional compensation axis used for. This is used for controlling the back gauge up and down movement. It allows the motion of the gauge fingers up or down, positioning the gage fingers to. The axis can be divided into r1and r2 axes to give the back gauge complete control. Rotation axis,. Press Brake R Axis.

From www.youtube.com

Press Brake Axis Explained YouTube Press Brake R Axis Rotation axis, used to adjust the angle of the workpiece for angle bending or complex shape processing. It allows the motion of the gauge fingers up or down, positioning the gage fingers to. The axis can be divided into r1and r2 axes to give the back gauge complete control. There are many factors to consider when. The r axes can. Press Brake R Axis.

From www.harsle.com

WE67K200T/3200 X+R Axis Press Brake Machine with DA53T from China manufacturer HARSLE Press Brake R Axis The axis can be divided into r1and r2 axes to give the back gauge complete control. This technique is particularly effective for sheet metal fabrication, typically working with materials thinner than 6 mm (0.236 inches). Usually an additional compensation axis used for. The r axes can be broken down into r1 and r2 axes for complete backgauge control, ideal for. Press Brake R Axis.

From www.krrassgroup.com

How Many Axis Do I Need on a Press Brake? Press Brake R Axis The r axes can be broken down into r1 and r2 axes for complete backgauge control, ideal for tilting and more bespoke work. This technique is particularly effective for sheet metal fabrication, typically working with materials thinner than 6 mm (0.236 inches). It allows the motion of the gauge fingers up or down, positioning the gage fingers to. It is. Press Brake R Axis.

From www.youtube.com

ZYMT Torsion bar Press Brake With NC E300 Angle program and R axes YouTube Press Brake R Axis It allows the motion of the gauge fingers up or down, positioning the gage fingers to. Rotation axis, used to adjust the angle of the workpiece for angle bending or complex shape processing. This is used for controlling the back gauge up and down movement. The axis can be divided into r1and r2 axes to give the back gauge complete. Press Brake R Axis.

From www.fabtechsolutions.com

Model Series A Wysong Press Brakes FABTECH SOLUTIONS Press Brake R Axis Usually an additional compensation axis used for. There are many factors to consider when. It allows the motion of the gauge fingers up or down, positioning the gage fingers to. This technique is particularly effective for sheet metal fabrication, typically working with materials thinner than 6 mm (0.236 inches). It is crucial if you’re planning to place a bend into. Press Brake R Axis.

From www.youtube.com

ZYMT ZYB175T3200 CNC press brake 4+1(X,Y1,Y2,R+V)axes with Da66t Working video YouTube Press Brake R Axis It is crucial if you’re planning to place a bend into a piece and another further bend into the same piece. As a result, tilting and bespoke work can easily be achieved. There are many factors to consider when. The axis can be divided into r1and r2 axes to give the back gauge complete control. This technique is particularly effective. Press Brake R Axis.

From www.nargesa-usa.com

MP3003CNC 10 Foot x 140 Ton Hydraulic Press Brake with R Axis — Nargesa USA Press Brake R Axis There are many factors to consider when. The axis can be divided into r1and r2 axes to give the back gauge complete control. This is used for controlling the back gauge up and down movement. The r axes can be broken down into r1 and r2 axes for complete backgauge control, ideal for tilting and more bespoke work. It allows. Press Brake R Axis.

From www.blmamachinery.com

CNC Press Brake structure BLMA machinery Press Brake R Axis Rotation axis, used to adjust the angle of the workpiece for angle bending or complex shape processing. Usually an additional compensation axis used for. The axis can be divided into r1and r2 axes to give the back gauge complete control. Selecting the right backgauge axis for a press brake is crucial for achieving accurate and efficient bending operations. As a. Press Brake R Axis.

From www.fabtechsolutions.com

Model Series A Wysong Press Brakes FABTECH SOLUTIONS Press Brake R Axis As a result, tilting and bespoke work can easily be achieved. It is crucial if you’re planning to place a bend into a piece and another further bend into the same piece. Rotation axis, used to adjust the angle of the workpiece for angle bending or complex shape processing. Usually an additional compensation axis used for. It allows the motion. Press Brake R Axis.

From fabricaitonmachines.com

CNC Press Brake Metal Fabrication Equipment Sinobender Press Brake R Axis This is used for controlling the back gauge up and down movement. This technique is particularly effective for sheet metal fabrication, typically working with materials thinner than 6 mm (0.236 inches). As a result, tilting and bespoke work can easily be achieved. The r axes can be broken down into r1 and r2 axes for complete backgauge control, ideal for. Press Brake R Axis.

From www.harsle.com

WE67K200T/3200 X+R Axis Press Brake Machine with DA53T from China manufacturer HARSLE Press Brake R Axis It allows the motion of the gauge fingers up or down, positioning the gage fingers to. The axis can be divided into r1and r2 axes to give the back gauge complete control. There are many factors to consider when. Usually an additional compensation axis used for. This technique is particularly effective for sheet metal fabrication, typically working with materials thinner. Press Brake R Axis.