Brazing Oxy Acetylene Pressures . Tip size numbers vary among manufacturers,. Manufacturers recommended pressure settings for welding, cutting and heating for oxygen and acetylene. Oxyacetylene is often used to produce precise brazed joints. Flux is applied to the joint. The two pieces of steel to be brazed, are cleaned with emery cloth, removing grease and dirt. Braze welding fluxes are active at much higher temperatures (around 1800°f), and they can withstand elevated temperatures. Cutting heating brazing correct pressure setting charts. In torch brazing, a variety of fuels are available—natural gas, acetylene, propane, propylene, etc., combusted with either oxygen. Orifice (drill size) pressure (psi) tables show approximate gas pressures for welding or cutting. To successfully braze and weld with oxyacetylene, it is important to understand the process, the equipment needed, and the.

from www.slideserve.com

Tip size numbers vary among manufacturers,. Braze welding fluxes are active at much higher temperatures (around 1800°f), and they can withstand elevated temperatures. Orifice (drill size) pressure (psi) tables show approximate gas pressures for welding or cutting. The two pieces of steel to be brazed, are cleaned with emery cloth, removing grease and dirt. Flux is applied to the joint. Cutting heating brazing correct pressure setting charts. To successfully braze and weld with oxyacetylene, it is important to understand the process, the equipment needed, and the. Manufacturers recommended pressure settings for welding, cutting and heating for oxygen and acetylene. Oxyacetylene is often used to produce precise brazed joints. In torch brazing, a variety of fuels are available—natural gas, acetylene, propane, propylene, etc., combusted with either oxygen.

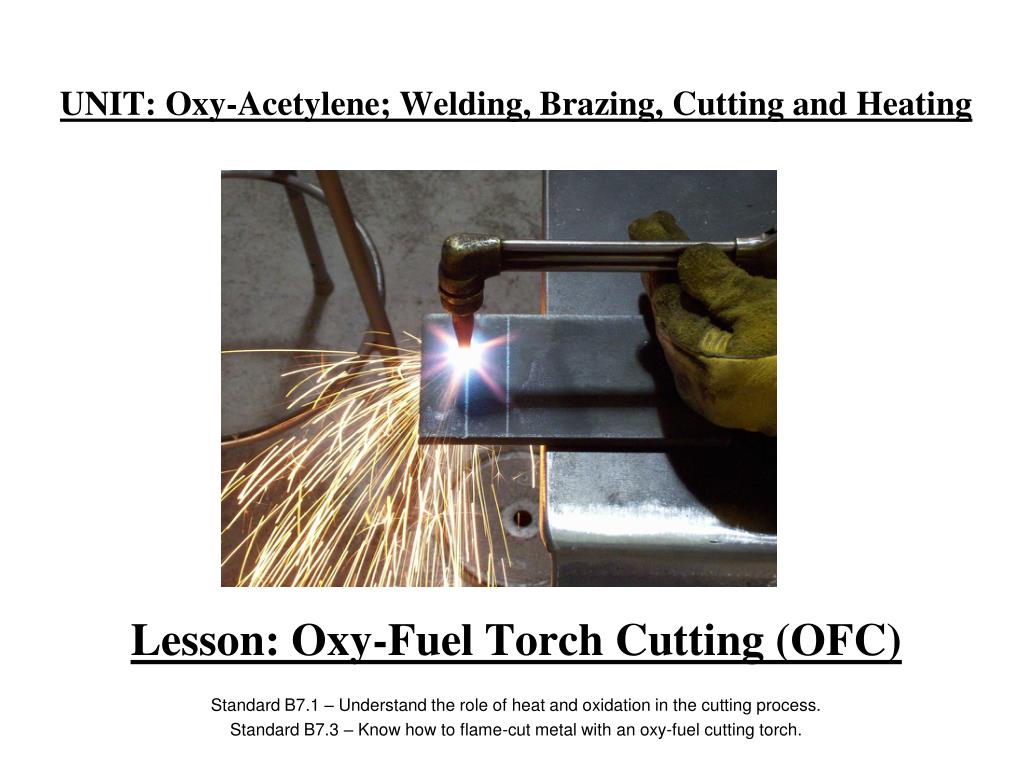

PPT UNIT OxyAcetylene; Welding, Brazing, Cutting and Heating

Brazing Oxy Acetylene Pressures Tip size numbers vary among manufacturers,. To successfully braze and weld with oxyacetylene, it is important to understand the process, the equipment needed, and the. Orifice (drill size) pressure (psi) tables show approximate gas pressures for welding or cutting. Flux is applied to the joint. In torch brazing, a variety of fuels are available—natural gas, acetylene, propane, propylene, etc., combusted with either oxygen. Oxyacetylene is often used to produce precise brazed joints. The two pieces of steel to be brazed, are cleaned with emery cloth, removing grease and dirt. Tip size numbers vary among manufacturers,. Manufacturers recommended pressure settings for welding, cutting and heating for oxygen and acetylene. Braze welding fluxes are active at much higher temperatures (around 1800°f), and they can withstand elevated temperatures. Cutting heating brazing correct pressure setting charts.

From www.hampdon.com.au

Oxygen and Acetylene Brazing Kit 5m Twin Hose Comet Acet OXY Brazing Oxy Acetylene Pressures To successfully braze and weld with oxyacetylene, it is important to understand the process, the equipment needed, and the. Flux is applied to the joint. In torch brazing, a variety of fuels are available—natural gas, acetylene, propane, propylene, etc., combusted with either oxygen. Cutting heating brazing correct pressure setting charts. Braze welding fluxes are active at much higher temperatures (around. Brazing Oxy Acetylene Pressures.

From fractory.com

OxyAcetylene Welding Explained Gas Welding Fractory Brazing Oxy Acetylene Pressures Tip size numbers vary among manufacturers,. Orifice (drill size) pressure (psi) tables show approximate gas pressures for welding or cutting. Manufacturers recommended pressure settings for welding, cutting and heating for oxygen and acetylene. To successfully braze and weld with oxyacetylene, it is important to understand the process, the equipment needed, and the. In torch brazing, a variety of fuels are. Brazing Oxy Acetylene Pressures.

From www.acrjournal.uk

Why OxyAcetylene is the Ideal Brazing Gas ACR Journal Brazing Oxy Acetylene Pressures To successfully braze and weld with oxyacetylene, it is important to understand the process, the equipment needed, and the. In torch brazing, a variety of fuels are available—natural gas, acetylene, propane, propylene, etc., combusted with either oxygen. Oxyacetylene is often used to produce precise brazed joints. Braze welding fluxes are active at much higher temperatures (around 1800°f), and they can. Brazing Oxy Acetylene Pressures.

From www.youtube.com

Oxy Acetylene Brazing Tips and Tricks For HVAC Techs YouTube Brazing Oxy Acetylene Pressures The two pieces of steel to be brazed, are cleaned with emery cloth, removing grease and dirt. Manufacturers recommended pressure settings for welding, cutting and heating for oxygen and acetylene. Braze welding fluxes are active at much higher temperatures (around 1800°f), and they can withstand elevated temperatures. In torch brazing, a variety of fuels are available—natural gas, acetylene, propane, propylene,. Brazing Oxy Acetylene Pressures.

From fyouowagp.blob.core.windows.net

Oxy Acetylene Torch Psi at Sharon Logan blog Brazing Oxy Acetylene Pressures Oxyacetylene is often used to produce precise brazed joints. Tip size numbers vary among manufacturers,. To successfully braze and weld with oxyacetylene, it is important to understand the process, the equipment needed, and the. Orifice (drill size) pressure (psi) tables show approximate gas pressures for welding or cutting. In torch brazing, a variety of fuels are available—natural gas, acetylene, propane,. Brazing Oxy Acetylene Pressures.

From apps.txrxlabs.org

Brazing I Oxy/ Acetylene 101 Heating, Cutting, Brazing TXRX Labs Brazing Oxy Acetylene Pressures Orifice (drill size) pressure (psi) tables show approximate gas pressures for welding or cutting. The two pieces of steel to be brazed, are cleaned with emery cloth, removing grease and dirt. To successfully braze and weld with oxyacetylene, it is important to understand the process, the equipment needed, and the. Flux is applied to the joint. Cutting heating brazing correct. Brazing Oxy Acetylene Pressures.

From www.express.fr

The pressure setting for oxyacetylene welding Express Brazing Oxy Acetylene Pressures In torch brazing, a variety of fuels are available—natural gas, acetylene, propane, propylene, etc., combusted with either oxygen. Oxyacetylene is often used to produce precise brazed joints. Cutting heating brazing correct pressure setting charts. Braze welding fluxes are active at much higher temperatures (around 1800°f), and they can withstand elevated temperatures. To successfully braze and weld with oxyacetylene, it is. Brazing Oxy Acetylene Pressures.

From rayb78.github.io

Oxy Acetylene Settings Chart Brazing Oxy Acetylene Pressures To successfully braze and weld with oxyacetylene, it is important to understand the process, the equipment needed, and the. In torch brazing, a variety of fuels are available—natural gas, acetylene, propane, propylene, etc., combusted with either oxygen. Flux is applied to the joint. Orifice (drill size) pressure (psi) tables show approximate gas pressures for welding or cutting. Manufacturers recommended pressure. Brazing Oxy Acetylene Pressures.

From www.slideserve.com

PPT UNIT OxyAcetylene; Welding, Brazing, Cutting and Heating Brazing Oxy Acetylene Pressures Tip size numbers vary among manufacturers,. Braze welding fluxes are active at much higher temperatures (around 1800°f), and they can withstand elevated temperatures. In torch brazing, a variety of fuels are available—natural gas, acetylene, propane, propylene, etc., combusted with either oxygen. Cutting heating brazing correct pressure setting charts. Manufacturers recommended pressure settings for welding, cutting and heating for oxygen and. Brazing Oxy Acetylene Pressures.

From einvoice.fpt.com.vn

When Brazing With Oxy Acetylene, What Pressures Should The, 41 OFF Brazing Oxy Acetylene Pressures In torch brazing, a variety of fuels are available—natural gas, acetylene, propane, propylene, etc., combusted with either oxygen. Orifice (drill size) pressure (psi) tables show approximate gas pressures for welding or cutting. Tip size numbers vary among manufacturers,. Cutting heating brazing correct pressure setting charts. Flux is applied to the joint. To successfully braze and weld with oxyacetylene, it is. Brazing Oxy Acetylene Pressures.

From dat.perueduca.edu.pe

Oxy Acetylene Cutting Pressure Chart Printable Templates Free Brazing Oxy Acetylene Pressures Oxyacetylene is often used to produce precise brazed joints. Tip size numbers vary among manufacturers,. To successfully braze and weld with oxyacetylene, it is important to understand the process, the equipment needed, and the. Flux is applied to the joint. Braze welding fluxes are active at much higher temperatures (around 1800°f), and they can withstand elevated temperatures. Orifice (drill size). Brazing Oxy Acetylene Pressures.

From www.youtube.com

Intro to OxyAcetylene Welding Part 1 YouTube Brazing Oxy Acetylene Pressures Manufacturers recommended pressure settings for welding, cutting and heating for oxygen and acetylene. Flux is applied to the joint. Cutting heating brazing correct pressure setting charts. Tip size numbers vary among manufacturers,. The two pieces of steel to be brazed, are cleaned with emery cloth, removing grease and dirt. Orifice (drill size) pressure (psi) tables show approximate gas pressures for. Brazing Oxy Acetylene Pressures.

From www.youtube.com

Oxy Acetylene Setup and Copper Brazing YouTube Brazing Oxy Acetylene Pressures Braze welding fluxes are active at much higher temperatures (around 1800°f), and they can withstand elevated temperatures. Oxyacetylene is often used to produce precise brazed joints. The two pieces of steel to be brazed, are cleaned with emery cloth, removing grease and dirt. Orifice (drill size) pressure (psi) tables show approximate gas pressures for welding or cutting. In torch brazing,. Brazing Oxy Acetylene Pressures.

From brandonkss.github.io

Oxy Acetylene Cutting Pressure Chart Brazing Oxy Acetylene Pressures Orifice (drill size) pressure (psi) tables show approximate gas pressures for welding or cutting. To successfully braze and weld with oxyacetylene, it is important to understand the process, the equipment needed, and the. Braze welding fluxes are active at much higher temperatures (around 1800°f), and they can withstand elevated temperatures. Flux is applied to the joint. Tip size numbers vary. Brazing Oxy Acetylene Pressures.

From einvoice.fpt.com.vn

When Brazing With Oxy Acetylene, What Pressures Should The, 41 OFF Brazing Oxy Acetylene Pressures Manufacturers recommended pressure settings for welding, cutting and heating for oxygen and acetylene. Tip size numbers vary among manufacturers,. Flux is applied to the joint. Braze welding fluxes are active at much higher temperatures (around 1800°f), and they can withstand elevated temperatures. To successfully braze and weld with oxyacetylene, it is important to understand the process, the equipment needed, and. Brazing Oxy Acetylene Pressures.

From exovihejv.blob.core.windows.net

Oxy Acetylene Welding Pressures Kpa at Celeste Brown blog Brazing Oxy Acetylene Pressures Flux is applied to the joint. Braze welding fluxes are active at much higher temperatures (around 1800°f), and they can withstand elevated temperatures. Tip size numbers vary among manufacturers,. To successfully braze and weld with oxyacetylene, it is important to understand the process, the equipment needed, and the. In torch brazing, a variety of fuels are available—natural gas, acetylene, propane,. Brazing Oxy Acetylene Pressures.

From transform-mpi.com

TRAINING TENTANG OXY ACETYLENE WELDING (LAS ASETILIN) Brazing Oxy Acetylene Pressures To successfully braze and weld with oxyacetylene, it is important to understand the process, the equipment needed, and the. Orifice (drill size) pressure (psi) tables show approximate gas pressures for welding or cutting. Flux is applied to the joint. The two pieces of steel to be brazed, are cleaned with emery cloth, removing grease and dirt. Oxyacetylene is often used. Brazing Oxy Acetylene Pressures.

From aptidco.in

When Brazing With Oxy Acetylene, What Pressures Should The, 46 OFF Brazing Oxy Acetylene Pressures The two pieces of steel to be brazed, are cleaned with emery cloth, removing grease and dirt. Flux is applied to the joint. Orifice (drill size) pressure (psi) tables show approximate gas pressures for welding or cutting. Tip size numbers vary among manufacturers,. Oxyacetylene is often used to produce precise brazed joints. In torch brazing, a variety of fuels are. Brazing Oxy Acetylene Pressures.

From hvacrschool.com

OxyAcetylene Brazing 3D HVAC School Brazing Oxy Acetylene Pressures Flux is applied to the joint. Orifice (drill size) pressure (psi) tables show approximate gas pressures for welding or cutting. Tip size numbers vary among manufacturers,. Oxyacetylene is often used to produce precise brazed joints. The two pieces of steel to be brazed, are cleaned with emery cloth, removing grease and dirt. To successfully braze and weld with oxyacetylene, it. Brazing Oxy Acetylene Pressures.

From www.youtube.com

Oxy Acetylene Brazing Setup, Leak Test, Reg Adjust, Startup, Shutdown Brazing Oxy Acetylene Pressures The two pieces of steel to be brazed, are cleaned with emery cloth, removing grease and dirt. Cutting heating brazing correct pressure setting charts. Oxyacetylene is often used to produce precise brazed joints. To successfully braze and weld with oxyacetylene, it is important to understand the process, the equipment needed, and the. Orifice (drill size) pressure (psi) tables show approximate. Brazing Oxy Acetylene Pressures.

From www.slideserve.com

PPT UNIT OxyAcetylene Welding, Brazing, Cutting and Heating Brazing Oxy Acetylene Pressures The two pieces of steel to be brazed, are cleaned with emery cloth, removing grease and dirt. Manufacturers recommended pressure settings for welding, cutting and heating for oxygen and acetylene. Orifice (drill size) pressure (psi) tables show approximate gas pressures for welding or cutting. Braze welding fluxes are active at much higher temperatures (around 1800°f), and they can withstand elevated. Brazing Oxy Acetylene Pressures.

From www.motortrend.com

OxyAcetylene Welding 101 Brazing Oxy Acetylene Pressures Flux is applied to the joint. The two pieces of steel to be brazed, are cleaned with emery cloth, removing grease and dirt. To successfully braze and weld with oxyacetylene, it is important to understand the process, the equipment needed, and the. Tip size numbers vary among manufacturers,. Oxyacetylene is often used to produce precise brazed joints. Orifice (drill size). Brazing Oxy Acetylene Pressures.

From gabrielatkins.z19.web.core.windows.net

Oxy Acetylene Pressure Settings Chart Brazing Oxy Acetylene Pressures To successfully braze and weld with oxyacetylene, it is important to understand the process, the equipment needed, and the. Flux is applied to the joint. Cutting heating brazing correct pressure setting charts. In torch brazing, a variety of fuels are available—natural gas, acetylene, propane, propylene, etc., combusted with either oxygen. Manufacturers recommended pressure settings for welding, cutting and heating for. Brazing Oxy Acetylene Pressures.

From www.mig-welding.co.uk

pressure for oxy acetylene welding thin sheet MIG Welding Forum Brazing Oxy Acetylene Pressures Manufacturers recommended pressure settings for welding, cutting and heating for oxygen and acetylene. In torch brazing, a variety of fuels are available—natural gas, acetylene, propane, propylene, etc., combusted with either oxygen. To successfully braze and weld with oxyacetylene, it is important to understand the process, the equipment needed, and the. Flux is applied to the joint. Oxyacetylene is often used. Brazing Oxy Acetylene Pressures.

From preventivemaintenanceprocedure.com

Brazing Procedure Using Oxy Acetylene Brazing Set Preventive Brazing Oxy Acetylene Pressures Flux is applied to the joint. To successfully braze and weld with oxyacetylene, it is important to understand the process, the equipment needed, and the. Manufacturers recommended pressure settings for welding, cutting and heating for oxygen and acetylene. Orifice (drill size) pressure (psi) tables show approximate gas pressures for welding or cutting. Braze welding fluxes are active at much higher. Brazing Oxy Acetylene Pressures.

From ionlabhouston.com

Brazing I Oxy/ Acetylene 101 Heating, Cutting, Brazing ION Brazing Oxy Acetylene Pressures Tip size numbers vary among manufacturers,. Manufacturers recommended pressure settings for welding, cutting and heating for oxygen and acetylene. Cutting heating brazing correct pressure setting charts. Oxyacetylene is often used to produce precise brazed joints. Flux is applied to the joint. The two pieces of steel to be brazed, are cleaned with emery cloth, removing grease and dirt. Orifice (drill. Brazing Oxy Acetylene Pressures.

From gabrielbruce.z19.web.core.windows.net

Oxygen Acetylene Settings For Cutting Brazing Oxy Acetylene Pressures Manufacturers recommended pressure settings for welding, cutting and heating for oxygen and acetylene. Braze welding fluxes are active at much higher temperatures (around 1800°f), and they can withstand elevated temperatures. In torch brazing, a variety of fuels are available—natural gas, acetylene, propane, propylene, etc., combusted with either oxygen. Tip size numbers vary among manufacturers,. Cutting heating brazing correct pressure setting. Brazing Oxy Acetylene Pressures.

From www.youtube.com

Oxy Acetylene Brazing, Torch Adjustments Reducing Flame, Oxidizing Brazing Oxy Acetylene Pressures Cutting heating brazing correct pressure setting charts. The two pieces of steel to be brazed, are cleaned with emery cloth, removing grease and dirt. To successfully braze and weld with oxyacetylene, it is important to understand the process, the equipment needed, and the. Manufacturers recommended pressure settings for welding, cutting and heating for oxygen and acetylene. In torch brazing, a. Brazing Oxy Acetylene Pressures.

From weldingheadquarters.com

How to OxyAcetylene Weld A Detailed Guide Welding Headquarters Brazing Oxy Acetylene Pressures Orifice (drill size) pressure (psi) tables show approximate gas pressures for welding or cutting. In torch brazing, a variety of fuels are available—natural gas, acetylene, propane, propylene, etc., combusted with either oxygen. Manufacturers recommended pressure settings for welding, cutting and heating for oxygen and acetylene. To successfully braze and weld with oxyacetylene, it is important to understand the process, the. Brazing Oxy Acetylene Pressures.

From www.youtube.com

oxy acetylene welding and brazing YouTube Brazing Oxy Acetylene Pressures Manufacturers recommended pressure settings for welding, cutting and heating for oxygen and acetylene. Oxyacetylene is often used to produce precise brazed joints. Orifice (drill size) pressure (psi) tables show approximate gas pressures for welding or cutting. Flux is applied to the joint. Braze welding fluxes are active at much higher temperatures (around 1800°f), and they can withstand elevated temperatures. Tip. Brazing Oxy Acetylene Pressures.

From dxoyqbwsx.blob.core.windows.net

Oxy Acetylene Welding Gas Pressure Settings at Charles Lumpkins blog Brazing Oxy Acetylene Pressures Braze welding fluxes are active at much higher temperatures (around 1800°f), and they can withstand elevated temperatures. Manufacturers recommended pressure settings for welding, cutting and heating for oxygen and acetylene. Orifice (drill size) pressure (psi) tables show approximate gas pressures for welding or cutting. Tip size numbers vary among manufacturers,. Oxyacetylene is often used to produce precise brazed joints. The. Brazing Oxy Acetylene Pressures.

From gabrielatkins.z19.web.core.windows.net

Oxyacetylene Torch Settings Chart Brazing Oxy Acetylene Pressures Braze welding fluxes are active at much higher temperatures (around 1800°f), and they can withstand elevated temperatures. The two pieces of steel to be brazed, are cleaned with emery cloth, removing grease and dirt. Oxyacetylene is often used to produce precise brazed joints. Cutting heating brazing correct pressure setting charts. In torch brazing, a variety of fuels are available—natural gas,. Brazing Oxy Acetylene Pressures.

From www.wikihow.com

How to Set Up an Oxy Acetylene Torch (with Pictures) wikiHow Brazing Oxy Acetylene Pressures In torch brazing, a variety of fuels are available—natural gas, acetylene, propane, propylene, etc., combusted with either oxygen. The two pieces of steel to be brazed, are cleaned with emery cloth, removing grease and dirt. Oxyacetylene is often used to produce precise brazed joints. Manufacturers recommended pressure settings for welding, cutting and heating for oxygen and acetylene. Cutting heating brazing. Brazing Oxy Acetylene Pressures.

From www.hampdon.com.au

COBRA Oxygen Acetylene Gas Kit Welding Cutting Brazing Set Brazing Oxy Acetylene Pressures To successfully braze and weld with oxyacetylene, it is important to understand the process, the equipment needed, and the. Manufacturers recommended pressure settings for welding, cutting and heating for oxygen and acetylene. In torch brazing, a variety of fuels are available—natural gas, acetylene, propane, propylene, etc., combusted with either oxygen. Cutting heating brazing correct pressure setting charts. The two pieces. Brazing Oxy Acetylene Pressures.

From brandonkss.github.io

Oxy Acetylene Cutting Pressure Chart Brazing Oxy Acetylene Pressures To successfully braze and weld with oxyacetylene, it is important to understand the process, the equipment needed, and the. Tip size numbers vary among manufacturers,. Oxyacetylene is often used to produce precise brazed joints. In torch brazing, a variety of fuels are available—natural gas, acetylene, propane, propylene, etc., combusted with either oxygen. Manufacturers recommended pressure settings for welding, cutting and. Brazing Oxy Acetylene Pressures.