Lead Screw Gear Ratio Calculator . The gear ratio of 4:1 (a reduction) is required to get to your desired 0.01 mm layer height, but that is a very uncommon and a too small layer height to use. Lead screw efficiency is how well the screw transforms torque (rotational force) into linear motion. This calculates the change gears needed to cut a given thread on lathes that use up to 6 change gears. Ball / lead screw motor sizing forms calculate the necessary torque, speed, stopping accuracy and system inertia important when selecting a proper motor for the application. This allows you to cut threads. This calculator will calculate torque given the lead screw parameters and the required force. It works for both metric and inch based. Contact @arimb on chiefdelphi with questions or suggestions.@arimb on chiefdelphi with. Use the following equation to calculate. Changing these gears varies the speed that the lead screw turns in relation to the speed that the spindle turns. There are two torques the torque to raise the load and.

from lessonschoolflogged.z14.web.core.windows.net

This calculator will calculate torque given the lead screw parameters and the required force. This calculates the change gears needed to cut a given thread on lathes that use up to 6 change gears. Lead screw efficiency is how well the screw transforms torque (rotational force) into linear motion. Use the following equation to calculate. Changing these gears varies the speed that the lead screw turns in relation to the speed that the spindle turns. Contact @arimb on chiefdelphi with questions or suggestions.@arimb on chiefdelphi with. The gear ratio of 4:1 (a reduction) is required to get to your desired 0.01 mm layer height, but that is a very uncommon and a too small layer height to use. It works for both metric and inch based. This allows you to cut threads. There are two torques the torque to raise the load and.

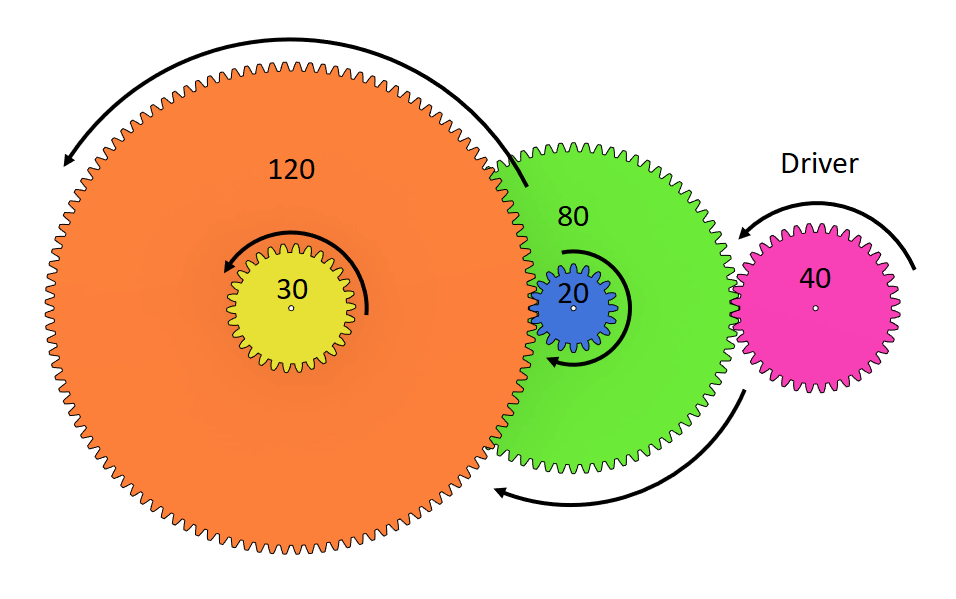

How To Work Out A Gear Ratio

Lead Screw Gear Ratio Calculator The gear ratio of 4:1 (a reduction) is required to get to your desired 0.01 mm layer height, but that is a very uncommon and a too small layer height to use. Changing these gears varies the speed that the lead screw turns in relation to the speed that the spindle turns. There are two torques the torque to raise the load and. Lead screw efficiency is how well the screw transforms torque (rotational force) into linear motion. Contact @arimb on chiefdelphi with questions or suggestions.@arimb on chiefdelphi with. This allows you to cut threads. This calculates the change gears needed to cut a given thread on lathes that use up to 6 change gears. It works for both metric and inch based. The gear ratio of 4:1 (a reduction) is required to get to your desired 0.01 mm layer height, but that is a very uncommon and a too small layer height to use. Use the following equation to calculate. Ball / lead screw motor sizing forms calculate the necessary torque, speed, stopping accuracy and system inertia important when selecting a proper motor for the application. This calculator will calculate torque given the lead screw parameters and the required force.

From gioiroejk.blob.core.windows.net

Linear Drive Gear Ratio at Jesus Littlejohn blog Lead Screw Gear Ratio Calculator Lead screw efficiency is how well the screw transforms torque (rotational force) into linear motion. The gear ratio of 4:1 (a reduction) is required to get to your desired 0.01 mm layer height, but that is a very uncommon and a too small layer height to use. There are two torques the torque to raise the load and. This calculator. Lead Screw Gear Ratio Calculator.

From www.tessshebaylo.com

Gear Ratio Equation Teeth Tessshebaylo Lead Screw Gear Ratio Calculator This allows you to cut threads. Ball / lead screw motor sizing forms calculate the necessary torque, speed, stopping accuracy and system inertia important when selecting a proper motor for the application. The gear ratio of 4:1 (a reduction) is required to get to your desired 0.01 mm layer height, but that is a very uncommon and a too small. Lead Screw Gear Ratio Calculator.

From exoecbkxc.blob.core.windows.net

Gear Math Calculator at Beverly Strauss blog Lead Screw Gear Ratio Calculator Lead screw efficiency is how well the screw transforms torque (rotational force) into linear motion. It works for both metric and inch based. Use the following equation to calculate. Changing these gears varies the speed that the lead screw turns in relation to the speed that the spindle turns. Ball / lead screw motor sizing forms calculate the necessary torque,. Lead Screw Gear Ratio Calculator.

From upgradedvehicle.com

How to Calculate Your Gear Ratio and Vehicle’s Speed Upgraded Vehicle Lead Screw Gear Ratio Calculator This allows you to cut threads. Lead screw efficiency is how well the screw transforms torque (rotational force) into linear motion. Ball / lead screw motor sizing forms calculate the necessary torque, speed, stopping accuracy and system inertia important when selecting a proper motor for the application. This calculator will calculate torque given the lead screw parameters and the required. Lead Screw Gear Ratio Calculator.

From blog.orientalmotor.com

Motor Sizing Basics Part 3 How to Calculate Speed, Acceleration Torque Lead Screw Gear Ratio Calculator It works for both metric and inch based. There are two torques the torque to raise the load and. Contact @arimb on chiefdelphi with questions or suggestions.@arimb on chiefdelphi with. Use the following equation to calculate. Lead screw efficiency is how well the screw transforms torque (rotational force) into linear motion. The gear ratio of 4:1 (a reduction) is required. Lead Screw Gear Ratio Calculator.

From 3dprinting.stackexchange.com

calibration Calculating gear ratio for leadscrew 3D Printing Stack Lead Screw Gear Ratio Calculator Changing these gears varies the speed that the lead screw turns in relation to the speed that the spindle turns. Ball / lead screw motor sizing forms calculate the necessary torque, speed, stopping accuracy and system inertia important when selecting a proper motor for the application. The gear ratio of 4:1 (a reduction) is required to get to your desired. Lead Screw Gear Ratio Calculator.

From www.reddit.com

Calculating Lead Screw Torques and Efficiency r/EngineeringPaperXYZ Lead Screw Gear Ratio Calculator This calculator will calculate torque given the lead screw parameters and the required force. Use the following equation to calculate. This allows you to cut threads. Contact @arimb on chiefdelphi with questions or suggestions.@arimb on chiefdelphi with. Changing these gears varies the speed that the lead screw turns in relation to the speed that the spindle turns. There are two. Lead Screw Gear Ratio Calculator.

From lessonmagicrocklike.z21.web.core.windows.net

Calculating Gear Ratio With Multiple Gears Lead Screw Gear Ratio Calculator Changing these gears varies the speed that the lead screw turns in relation to the speed that the spindle turns. Ball / lead screw motor sizing forms calculate the necessary torque, speed, stopping accuracy and system inertia important when selecting a proper motor for the application. This calculates the change gears needed to cut a given thread on lathes that. Lead Screw Gear Ratio Calculator.

From qlerochef.weebly.com

Helical gear design calculator qlerochef Lead Screw Gear Ratio Calculator Lead screw efficiency is how well the screw transforms torque (rotational force) into linear motion. Use the following equation to calculate. It works for both metric and inch based. This calculates the change gears needed to cut a given thread on lathes that use up to 6 change gears. Changing these gears varies the speed that the lead screw turns. Lead Screw Gear Ratio Calculator.

From quizzlistmercer.z13.web.core.windows.net

Gear Ratio Calculator Multiple Gears Lead Screw Gear Ratio Calculator Ball / lead screw motor sizing forms calculate the necessary torque, speed, stopping accuracy and system inertia important when selecting a proper motor for the application. The gear ratio of 4:1 (a reduction) is required to get to your desired 0.01 mm layer height, but that is a very uncommon and a too small layer height to use. Use the. Lead Screw Gear Ratio Calculator.

From noallez91studyquizz.z14.web.core.windows.net

Gear Calculation Excel Sheet Lead Screw Gear Ratio Calculator This allows you to cut threads. There are two torques the torque to raise the load and. Changing these gears varies the speed that the lead screw turns in relation to the speed that the spindle turns. The gear ratio of 4:1 (a reduction) is required to get to your desired 0.01 mm layer height, but that is a very. Lead Screw Gear Ratio Calculator.

From www.youtube.com

THREAD CUTTING GEAR CALCULATION FORMULA ON LATHE M/C IN हिंदी YouTube Lead Screw Gear Ratio Calculator It works for both metric and inch based. This allows you to cut threads. Contact @arimb on chiefdelphi with questions or suggestions.@arimb on chiefdelphi with. This calculates the change gears needed to cut a given thread on lathes that use up to 6 change gears. There are two torques the torque to raise the load and. Use the following equation. Lead Screw Gear Ratio Calculator.

From haipernews.com

How To Calculate Gear Ratio Haiper Lead Screw Gear Ratio Calculator Ball / lead screw motor sizing forms calculate the necessary torque, speed, stopping accuracy and system inertia important when selecting a proper motor for the application. The gear ratio of 4:1 (a reduction) is required to get to your desired 0.01 mm layer height, but that is a very uncommon and a too small layer height to use. Lead screw. Lead Screw Gear Ratio Calculator.

From amrangracjan.blogspot.com

18+ Gear Ratio Calculator Teeth AmranGracjan Lead Screw Gear Ratio Calculator Changing these gears varies the speed that the lead screw turns in relation to the speed that the spindle turns. Ball / lead screw motor sizing forms calculate the necessary torque, speed, stopping accuracy and system inertia important when selecting a proper motor for the application. The gear ratio of 4:1 (a reduction) is required to get to your desired. Lead Screw Gear Ratio Calculator.

From www.mechstudies.com

Calculation for Gear Ratio How to Calculate? Types, Explained with Lead Screw Gear Ratio Calculator There are two torques the torque to raise the load and. The gear ratio of 4:1 (a reduction) is required to get to your desired 0.01 mm layer height, but that is a very uncommon and a too small layer height to use. It works for both metric and inch based. Contact @arimb on chiefdelphi with questions or suggestions.@arimb on. Lead Screw Gear Ratio Calculator.

From klawagylk.blob.core.windows.net

Gear Lead Formula at Larry Broman blog Lead Screw Gear Ratio Calculator Use the following equation to calculate. This allows you to cut threads. Lead screw efficiency is how well the screw transforms torque (rotational force) into linear motion. This calculates the change gears needed to cut a given thread on lathes that use up to 6 change gears. Ball / lead screw motor sizing forms calculate the necessary torque, speed, stopping. Lead Screw Gear Ratio Calculator.

From www.youtube.com

Calculating Lead Screw Efficiency and Required Lifting Torque YouTube Lead Screw Gear Ratio Calculator The gear ratio of 4:1 (a reduction) is required to get to your desired 0.01 mm layer height, but that is a very uncommon and a too small layer height to use. Changing these gears varies the speed that the lead screw turns in relation to the speed that the spindle turns. This calculator will calculate torque given the lead. Lead Screw Gear Ratio Calculator.

From klalaghcr.blob.core.windows.net

Drive Gear Ratio Calculator at Tracey Stallings blog Lead Screw Gear Ratio Calculator Lead screw efficiency is how well the screw transforms torque (rotational force) into linear motion. It works for both metric and inch based. Use the following equation to calculate. Contact @arimb on chiefdelphi with questions or suggestions.@arimb on chiefdelphi with. Changing these gears varies the speed that the lead screw turns in relation to the speed that the spindle turns.. Lead Screw Gear Ratio Calculator.

From www.youtube.com

Gear ratio calculator The fastest way to solve your physics homework Lead Screw Gear Ratio Calculator Changing these gears varies the speed that the lead screw turns in relation to the speed that the spindle turns. There are two torques the torque to raise the load and. This allows you to cut threads. This calculator will calculate torque given the lead screw parameters and the required force. It works for both metric and inch based. The. Lead Screw Gear Ratio Calculator.

From klalaghcr.blob.core.windows.net

Drive Gear Ratio Calculator at Tracey Stallings blog Lead Screw Gear Ratio Calculator This allows you to cut threads. Use the following equation to calculate. This calculator will calculate torque given the lead screw parameters and the required force. The gear ratio of 4:1 (a reduction) is required to get to your desired 0.01 mm layer height, but that is a very uncommon and a too small layer height to use. Changing these. Lead Screw Gear Ratio Calculator.

From khkgears.net

Calculation of Gear Dimensions KHK Gears Lead Screw Gear Ratio Calculator Contact @arimb on chiefdelphi with questions or suggestions.@arimb on chiefdelphi with. There are two torques the torque to raise the load and. This allows you to cut threads. The gear ratio of 4:1 (a reduction) is required to get to your desired 0.01 mm layer height, but that is a very uncommon and a too small layer height to use.. Lead Screw Gear Ratio Calculator.

From dxorazkdu.blob.core.windows.net

Rack And Pinion Gear Ratio Calculator at Savannah Cruz blog Lead Screw Gear Ratio Calculator Lead screw efficiency is how well the screw transforms torque (rotational force) into linear motion. This calculates the change gears needed to cut a given thread on lathes that use up to 6 change gears. Contact @arimb on chiefdelphi with questions or suggestions.@arimb on chiefdelphi with. The gear ratio of 4:1 (a reduction) is required to get to your desired. Lead Screw Gear Ratio Calculator.

From 3dprinting.stackexchange.com

Z axis Stepper motor and lead screw torque calculation 3D Printing Lead Screw Gear Ratio Calculator Ball / lead screw motor sizing forms calculate the necessary torque, speed, stopping accuracy and system inertia important when selecting a proper motor for the application. The gear ratio of 4:1 (a reduction) is required to get to your desired 0.01 mm layer height, but that is a very uncommon and a too small layer height to use. This calculator. Lead Screw Gear Ratio Calculator.

From webmotor.org

Motor Gear Ratio Formula Lead Screw Gear Ratio Calculator There are two torques the torque to raise the load and. Lead screw efficiency is how well the screw transforms torque (rotational force) into linear motion. Ball / lead screw motor sizing forms calculate the necessary torque, speed, stopping accuracy and system inertia important when selecting a proper motor for the application. It works for both metric and inch based.. Lead Screw Gear Ratio Calculator.

From www.wikihow.com

4 Easy Ways to Determine Gear Ratio (with Pictures) Lead Screw Gear Ratio Calculator Ball / lead screw motor sizing forms calculate the necessary torque, speed, stopping accuracy and system inertia important when selecting a proper motor for the application. Use the following equation to calculate. Lead screw efficiency is how well the screw transforms torque (rotational force) into linear motion. It works for both metric and inch based. The gear ratio of 4:1. Lead Screw Gear Ratio Calculator.

From www.wikihow.com

4 Easy Ways to Determine Gear Ratio (with Pictures) Lead Screw Gear Ratio Calculator The gear ratio of 4:1 (a reduction) is required to get to your desired 0.01 mm layer height, but that is a very uncommon and a too small layer height to use. Changing these gears varies the speed that the lead screw turns in relation to the speed that the spindle turns. This calculates the change gears needed to cut. Lead Screw Gear Ratio Calculator.

From saratov.myhistorypark.ru

Z Axis Stepper Motor And Lead Screw Torque Calculation 3D, 50 OFF Lead Screw Gear Ratio Calculator Lead screw efficiency is how well the screw transforms torque (rotational force) into linear motion. This calculates the change gears needed to cut a given thread on lathes that use up to 6 change gears. There are two torques the torque to raise the load and. Ball / lead screw motor sizing forms calculate the necessary torque, speed, stopping accuracy. Lead Screw Gear Ratio Calculator.

From lessonschoolflogged.z14.web.core.windows.net

How To Work Out A Gear Ratio Lead Screw Gear Ratio Calculator Contact @arimb on chiefdelphi with questions or suggestions.@arimb on chiefdelphi with. The gear ratio of 4:1 (a reduction) is required to get to your desired 0.01 mm layer height, but that is a very uncommon and a too small layer height to use. Use the following equation to calculate. There are two torques the torque to raise the load and.. Lead Screw Gear Ratio Calculator.

From amolyatbmqworkshopfix.z13.web.core.windows.net

Gear Reduction Ratio Calculator Lead Screw Gear Ratio Calculator Changing these gears varies the speed that the lead screw turns in relation to the speed that the spindle turns. It works for both metric and inch based. Contact @arimb on chiefdelphi with questions or suggestions.@arimb on chiefdelphi with. This allows you to cut threads. Use the following equation to calculate. Ball / lead screw motor sizing forms calculate the. Lead Screw Gear Ratio Calculator.

From www.rcmart.com

RC Tech Tutorial Stop Calculate Gear Ratio! Using the Distance to Lead Screw Gear Ratio Calculator Contact @arimb on chiefdelphi with questions or suggestions.@arimb on chiefdelphi with. It works for both metric and inch based. Changing these gears varies the speed that the lead screw turns in relation to the speed that the spindle turns. Use the following equation to calculate. There are two torques the torque to raise the load and. Ball / lead screw. Lead Screw Gear Ratio Calculator.

From klalaghcr.blob.core.windows.net

Drive Gear Ratio Calculator at Tracey Stallings blog Lead Screw Gear Ratio Calculator The gear ratio of 4:1 (a reduction) is required to get to your desired 0.01 mm layer height, but that is a very uncommon and a too small layer height to use. This calculates the change gears needed to cut a given thread on lathes that use up to 6 change gears. This calculator will calculate torque given the lead. Lead Screw Gear Ratio Calculator.

From klawagylk.blob.core.windows.net

Gear Lead Formula at Larry Broman blog Lead Screw Gear Ratio Calculator This calculates the change gears needed to cut a given thread on lathes that use up to 6 change gears. This calculator will calculate torque given the lead screw parameters and the required force. Lead screw efficiency is how well the screw transforms torque (rotational force) into linear motion. The gear ratio of 4:1 (a reduction) is required to get. Lead Screw Gear Ratio Calculator.

From itstillruns.com

How to Calculate Gear Ratios and Torque It Still Runs Lead Screw Gear Ratio Calculator The gear ratio of 4:1 (a reduction) is required to get to your desired 0.01 mm layer height, but that is a very uncommon and a too small layer height to use. Ball / lead screw motor sizing forms calculate the necessary torque, speed, stopping accuracy and system inertia important when selecting a proper motor for the application. This calculates. Lead Screw Gear Ratio Calculator.

From www.youtube.com

gear ration 2 tpi lead screw, threading chart YouTube Lead Screw Gear Ratio Calculator Use the following equation to calculate. This calculates the change gears needed to cut a given thread on lathes that use up to 6 change gears. Ball / lead screw motor sizing forms calculate the necessary torque, speed, stopping accuracy and system inertia important when selecting a proper motor for the application. This calculator will calculate torque given the lead. Lead Screw Gear Ratio Calculator.

From www.artofit.org

Understanding gear ratios Artofit Lead Screw Gear Ratio Calculator This allows you to cut threads. There are two torques the torque to raise the load and. Changing these gears varies the speed that the lead screw turns in relation to the speed that the spindle turns. Lead screw efficiency is how well the screw transforms torque (rotational force) into linear motion. It works for both metric and inch based.. Lead Screw Gear Ratio Calculator.