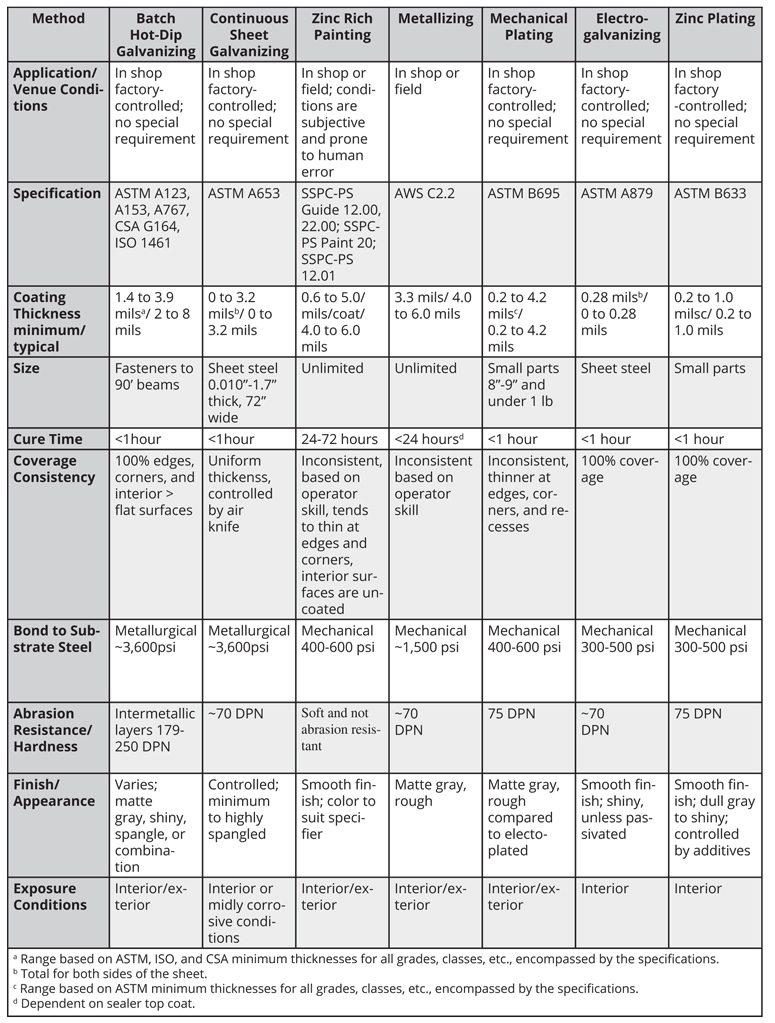

Zinc Coatings . zinc painting, zinc spray metallizing, mechanical plating, electrogalvanizing, and zinc plating; This process is a form is. Electroplating provides a uniform and attractive finish that lasts for many years. learn about the different types, characteristics, and applications of zinc coatings for steel products. sherardizing, less common but effective, employs zinc dust applied to a metal surface and heated to form a diffusion layer. To help architects, engineers, and other specifiers assess. zinc electroplating is one of the most cost effective metal finishings for corrosion resistance. electroplating these parts with a blue zinc coating can help parts attain their need for enhanced protection against corrosion, without breaking the bank.

from

zinc painting, zinc spray metallizing, mechanical plating, electrogalvanizing, and zinc plating; zinc electroplating is one of the most cost effective metal finishings for corrosion resistance. electroplating these parts with a blue zinc coating can help parts attain their need for enhanced protection against corrosion, without breaking the bank. Electroplating provides a uniform and attractive finish that lasts for many years. This process is a form is. sherardizing, less common but effective, employs zinc dust applied to a metal surface and heated to form a diffusion layer. To help architects, engineers, and other specifiers assess. learn about the different types, characteristics, and applications of zinc coatings for steel products.

Zinc Coatings To help architects, engineers, and other specifiers assess. learn about the different types, characteristics, and applications of zinc coatings for steel products. zinc electroplating is one of the most cost effective metal finishings for corrosion resistance. zinc painting, zinc spray metallizing, mechanical plating, electrogalvanizing, and zinc plating; To help architects, engineers, and other specifiers assess. electroplating these parts with a blue zinc coating can help parts attain their need for enhanced protection against corrosion, without breaking the bank. This process is a form is. sherardizing, less common but effective, employs zinc dust applied to a metal surface and heated to form a diffusion layer. Electroplating provides a uniform and attractive finish that lasts for many years.

From

Zinc Coatings To help architects, engineers, and other specifiers assess. sherardizing, less common but effective, employs zinc dust applied to a metal surface and heated to form a diffusion layer. This process is a form is. learn about the different types, characteristics, and applications of zinc coatings for steel products. zinc painting, zinc spray metallizing, mechanical plating, electrogalvanizing, and. Zinc Coatings.

From

Zinc Coatings Electroplating provides a uniform and attractive finish that lasts for many years. learn about the different types, characteristics, and applications of zinc coatings for steel products. This process is a form is. To help architects, engineers, and other specifiers assess. zinc painting, zinc spray metallizing, mechanical plating, electrogalvanizing, and zinc plating; sherardizing, less common but effective, employs. Zinc Coatings.

From

Zinc Coatings zinc electroplating is one of the most cost effective metal finishings for corrosion resistance. sherardizing, less common but effective, employs zinc dust applied to a metal surface and heated to form a diffusion layer. learn about the different types, characteristics, and applications of zinc coatings for steel products. This process is a form is. electroplating these. Zinc Coatings.

From www.corrosionalliance.com

The different types of Zinc filled coatings Corrosion Alliance Zinc Coatings sherardizing, less common but effective, employs zinc dust applied to a metal surface and heated to form a diffusion layer. electroplating these parts with a blue zinc coating can help parts attain their need for enhanced protection against corrosion, without breaking the bank. Electroplating provides a uniform and attractive finish that lasts for many years. To help architects,. Zinc Coatings.

From www.technicoat.cz

ZINC LAMELLA COATINGS TECHNICOAT Applied functional coatings Zinc Coatings Electroplating provides a uniform and attractive finish that lasts for many years. zinc electroplating is one of the most cost effective metal finishings for corrosion resistance. zinc painting, zinc spray metallizing, mechanical plating, electrogalvanizing, and zinc plating; learn about the different types, characteristics, and applications of zinc coatings for steel products. electroplating these parts with a. Zinc Coatings.

From

Zinc Coatings zinc electroplating is one of the most cost effective metal finishings for corrosion resistance. zinc painting, zinc spray metallizing, mechanical plating, electrogalvanizing, and zinc plating; Electroplating provides a uniform and attractive finish that lasts for many years. electroplating these parts with a blue zinc coating can help parts attain their need for enhanced protection against corrosion, without. Zinc Coatings.

From

Zinc Coatings This process is a form is. zinc painting, zinc spray metallizing, mechanical plating, electrogalvanizing, and zinc plating; Electroplating provides a uniform and attractive finish that lasts for many years. sherardizing, less common but effective, employs zinc dust applied to a metal surface and heated to form a diffusion layer. zinc electroplating is one of the most cost. Zinc Coatings.

From galvanizeit.org

Zinc Coatings for Steel Corrosion… American Galvanizers Association Zinc Coatings zinc painting, zinc spray metallizing, mechanical plating, electrogalvanizing, and zinc plating; zinc electroplating is one of the most cost effective metal finishings for corrosion resistance. This process is a form is. sherardizing, less common but effective, employs zinc dust applied to a metal surface and heated to form a diffusion layer. To help architects, engineers, and other. Zinc Coatings.

From

Zinc Coatings zinc painting, zinc spray metallizing, mechanical plating, electrogalvanizing, and zinc plating; Electroplating provides a uniform and attractive finish that lasts for many years. electroplating these parts with a blue zinc coating can help parts attain their need for enhanced protection against corrosion, without breaking the bank. zinc electroplating is one of the most cost effective metal finishings. Zinc Coatings.

From

Zinc Coatings Electroplating provides a uniform and attractive finish that lasts for many years. sherardizing, less common but effective, employs zinc dust applied to a metal surface and heated to form a diffusion layer. To help architects, engineers, and other specifiers assess. zinc electroplating is one of the most cost effective metal finishings for corrosion resistance. This process is a. Zinc Coatings.

From

Zinc Coatings learn about the different types, characteristics, and applications of zinc coatings for steel products. sherardizing, less common but effective, employs zinc dust applied to a metal surface and heated to form a diffusion layer. To help architects, engineers, and other specifiers assess. This process is a form is. zinc electroplating is one of the most cost effective. Zinc Coatings.

From sendcutsend.com

Zinc Plating vs Powder Coating for Corrosion Resistance SendCutSend Zinc Coatings This process is a form is. zinc painting, zinc spray metallizing, mechanical plating, electrogalvanizing, and zinc plating; To help architects, engineers, and other specifiers assess. sherardizing, less common but effective, employs zinc dust applied to a metal surface and heated to form a diffusion layer. electroplating these parts with a blue zinc coating can help parts attain. Zinc Coatings.

From www.scribd.com

Zinc_Coatings.pdf Galvanization Sheet Metal Zinc Coatings electroplating these parts with a blue zinc coating can help parts attain their need for enhanced protection against corrosion, without breaking the bank. To help architects, engineers, and other specifiers assess. learn about the different types, characteristics, and applications of zinc coatings for steel products. This process is a form is. zinc electroplating is one of the. Zinc Coatings.

From

Zinc Coatings Electroplating provides a uniform and attractive finish that lasts for many years. sherardizing, less common but effective, employs zinc dust applied to a metal surface and heated to form a diffusion layer. electroplating these parts with a blue zinc coating can help parts attain their need for enhanced protection against corrosion, without breaking the bank. learn about. Zinc Coatings.

From galvanizeit.org

Zinc Coatings American Galvanizers Association Zinc Coatings zinc painting, zinc spray metallizing, mechanical plating, electrogalvanizing, and zinc plating; zinc electroplating is one of the most cost effective metal finishings for corrosion resistance. This process is a form is. learn about the different types, characteristics, and applications of zinc coatings for steel products. Electroplating provides a uniform and attractive finish that lasts for many years.. Zinc Coatings.

From www.zinc.org

Coatings ZINC. International Zinc Association Zinc Coatings electroplating these parts with a blue zinc coating can help parts attain their need for enhanced protection against corrosion, without breaking the bank. To help architects, engineers, and other specifiers assess. zinc painting, zinc spray metallizing, mechanical plating, electrogalvanizing, and zinc plating; This process is a form is. sherardizing, less common but effective, employs zinc dust applied. Zinc Coatings.

From

Zinc Coatings sherardizing, less common but effective, employs zinc dust applied to a metal surface and heated to form a diffusion layer. electroplating these parts with a blue zinc coating can help parts attain their need for enhanced protection against corrosion, without breaking the bank. zinc painting, zinc spray metallizing, mechanical plating, electrogalvanizing, and zinc plating; learn about. Zinc Coatings.

From

Zinc Coatings sherardizing, less common but effective, employs zinc dust applied to a metal surface and heated to form a diffusion layer. zinc electroplating is one of the most cost effective metal finishings for corrosion resistance. Electroplating provides a uniform and attractive finish that lasts for many years. To help architects, engineers, and other specifiers assess. learn about the. Zinc Coatings.

From galvanizeit.org

Zinc Coatings American Galvanizers Association Zinc Coatings sherardizing, less common but effective, employs zinc dust applied to a metal surface and heated to form a diffusion layer. electroplating these parts with a blue zinc coating can help parts attain their need for enhanced protection against corrosion, without breaking the bank. zinc painting, zinc spray metallizing, mechanical plating, electrogalvanizing, and zinc plating; zinc electroplating. Zinc Coatings.

From

Zinc Coatings learn about the different types, characteristics, and applications of zinc coatings for steel products. zinc electroplating is one of the most cost effective metal finishings for corrosion resistance. zinc painting, zinc spray metallizing, mechanical plating, electrogalvanizing, and zinc plating; sherardizing, less common but effective, employs zinc dust applied to a metal surface and heated to form. Zinc Coatings.

From

Zinc Coatings Electroplating provides a uniform and attractive finish that lasts for many years. zinc painting, zinc spray metallizing, mechanical plating, electrogalvanizing, and zinc plating; learn about the different types, characteristics, and applications of zinc coatings for steel products. This process is a form is. To help architects, engineers, and other specifiers assess. electroplating these parts with a blue. Zinc Coatings.

From www.pinterest.com

Zinc aluminum steel coil Steel, Zinc coating, Coil Zinc Coatings electroplating these parts with a blue zinc coating can help parts attain their need for enhanced protection against corrosion, without breaking the bank. To help architects, engineers, and other specifiers assess. sherardizing, less common but effective, employs zinc dust applied to a metal surface and heated to form a diffusion layer. learn about the different types, characteristics,. Zinc Coatings.

From www.decorativeimaging.com.au

Zinc Coating Galvanised Zinc Coatings Deco Industrial Surface Zinc Coatings learn about the different types, characteristics, and applications of zinc coatings for steel products. Electroplating provides a uniform and attractive finish that lasts for many years. electroplating these parts with a blue zinc coating can help parts attain their need for enhanced protection against corrosion, without breaking the bank. sherardizing, less common but effective, employs zinc dust. Zinc Coatings.

From blog.thepipingmart.com

Zinc Iron Plating Applications and Process Zinc Coatings zinc electroplating is one of the most cost effective metal finishings for corrosion resistance. learn about the different types, characteristics, and applications of zinc coatings for steel products. sherardizing, less common but effective, employs zinc dust applied to a metal surface and heated to form a diffusion layer. Electroplating provides a uniform and attractive finish that lasts. Zinc Coatings.

From

Zinc Coatings sherardizing, less common but effective, employs zinc dust applied to a metal surface and heated to form a diffusion layer. zinc painting, zinc spray metallizing, mechanical plating, electrogalvanizing, and zinc plating; Electroplating provides a uniform and attractive finish that lasts for many years. electroplating these parts with a blue zinc coating can help parts attain their need. Zinc Coatings.

From anochrome.com

Zinc Plating UK Anochrome Zinc Coating Zinc Coatings To help architects, engineers, and other specifiers assess. sherardizing, less common but effective, employs zinc dust applied to a metal surface and heated to form a diffusion layer. zinc electroplating is one of the most cost effective metal finishings for corrosion resistance. electroplating these parts with a blue zinc coating can help parts attain their need for. Zinc Coatings.

From

Zinc Coatings zinc painting, zinc spray metallizing, mechanical plating, electrogalvanizing, and zinc plating; This process is a form is. Electroplating provides a uniform and attractive finish that lasts for many years. learn about the different types, characteristics, and applications of zinc coatings for steel products. electroplating these parts with a blue zinc coating can help parts attain their need. Zinc Coatings.

From staubmfg.com

Zinc Plating Vs. Powder Coating Staub Manufacturing Solutions Zinc Coatings To help architects, engineers, and other specifiers assess. zinc painting, zinc spray metallizing, mechanical plating, electrogalvanizing, and zinc plating; learn about the different types, characteristics, and applications of zinc coatings for steel products. electroplating these parts with a blue zinc coating can help parts attain their need for enhanced protection against corrosion, without breaking the bank. Electroplating. Zinc Coatings.

From

Zinc Coatings To help architects, engineers, and other specifiers assess. zinc painting, zinc spray metallizing, mechanical plating, electrogalvanizing, and zinc plating; sherardizing, less common but effective, employs zinc dust applied to a metal surface and heated to form a diffusion layer. electroplating these parts with a blue zinc coating can help parts attain their need for enhanced protection against. Zinc Coatings.

From

Zinc Coatings zinc electroplating is one of the most cost effective metal finishings for corrosion resistance. To help architects, engineers, and other specifiers assess. sherardizing, less common but effective, employs zinc dust applied to a metal surface and heated to form a diffusion layer. This process is a form is. Electroplating provides a uniform and attractive finish that lasts for. Zinc Coatings.

From

Zinc Coatings zinc painting, zinc spray metallizing, mechanical plating, electrogalvanizing, and zinc plating; Electroplating provides a uniform and attractive finish that lasts for many years. zinc electroplating is one of the most cost effective metal finishings for corrosion resistance. learn about the different types, characteristics, and applications of zinc coatings for steel products. sherardizing, less common but effective,. Zinc Coatings.

From www.hofmann.com

Powder Coating & Zinc Plating Sinking Spring, Pennsylvania Hofmann Zinc Coatings electroplating these parts with a blue zinc coating can help parts attain their need for enhanced protection against corrosion, without breaking the bank. zinc electroplating is one of the most cost effective metal finishings for corrosion resistance. learn about the different types, characteristics, and applications of zinc coatings for steel products. This process is a form is.. Zinc Coatings.

From

Zinc Coatings electroplating these parts with a blue zinc coating can help parts attain their need for enhanced protection against corrosion, without breaking the bank. zinc electroplating is one of the most cost effective metal finishings for corrosion resistance. Electroplating provides a uniform and attractive finish that lasts for many years. sherardizing, less common but effective, employs zinc dust. Zinc Coatings.

From

Zinc Coatings To help architects, engineers, and other specifiers assess. learn about the different types, characteristics, and applications of zinc coatings for steel products. This process is a form is. electroplating these parts with a blue zinc coating can help parts attain their need for enhanced protection against corrosion, without breaking the bank. zinc painting, zinc spray metallizing, mechanical. Zinc Coatings.

From

Zinc Coatings To help architects, engineers, and other specifiers assess. This process is a form is. learn about the different types, characteristics, and applications of zinc coatings for steel products. electroplating these parts with a blue zinc coating can help parts attain their need for enhanced protection against corrosion, without breaking the bank. zinc painting, zinc spray metallizing, mechanical. Zinc Coatings.