How Much Interference For A Press Fit . Input hole and shaft diameters to determine the interference fit. My understanding is that the 'rule of thumb' for press fits is about 0.001 per inch of bore. This interference, or tightness of fit or friction fit, ensures a secure. Generally steel in steel press fits range from 0.0003 per inch of diameter for light press fits to 0.0013 for heavy. Calculate press fit interference easily with our online tool. The specified interference is more than 6 times that rule of thumb value (6.3 thou per inch. Joint pressure in the friction surface is necessary for the torque. The critical element in press fit assembly is the amount of interference between the hole and shaft. Tolerance in press fit ensures the components of an assembly match the specified functional requirements without jeopardizing the joint’s integrity. This calculator will show you the percentage of interference between the two components and help you ensure a tight fit for your press.

from slideplayer.com

Joint pressure in the friction surface is necessary for the torque. The specified interference is more than 6 times that rule of thumb value (6.3 thou per inch. The critical element in press fit assembly is the amount of interference between the hole and shaft. My understanding is that the 'rule of thumb' for press fits is about 0.001 per inch of bore. Input hole and shaft diameters to determine the interference fit. This calculator will show you the percentage of interference between the two components and help you ensure a tight fit for your press. Generally steel in steel press fits range from 0.0003 per inch of diameter for light press fits to 0.0013 for heavy. This interference, or tightness of fit or friction fit, ensures a secure. Tolerance in press fit ensures the components of an assembly match the specified functional requirements without jeopardizing the joint’s integrity. Calculate press fit interference easily with our online tool.

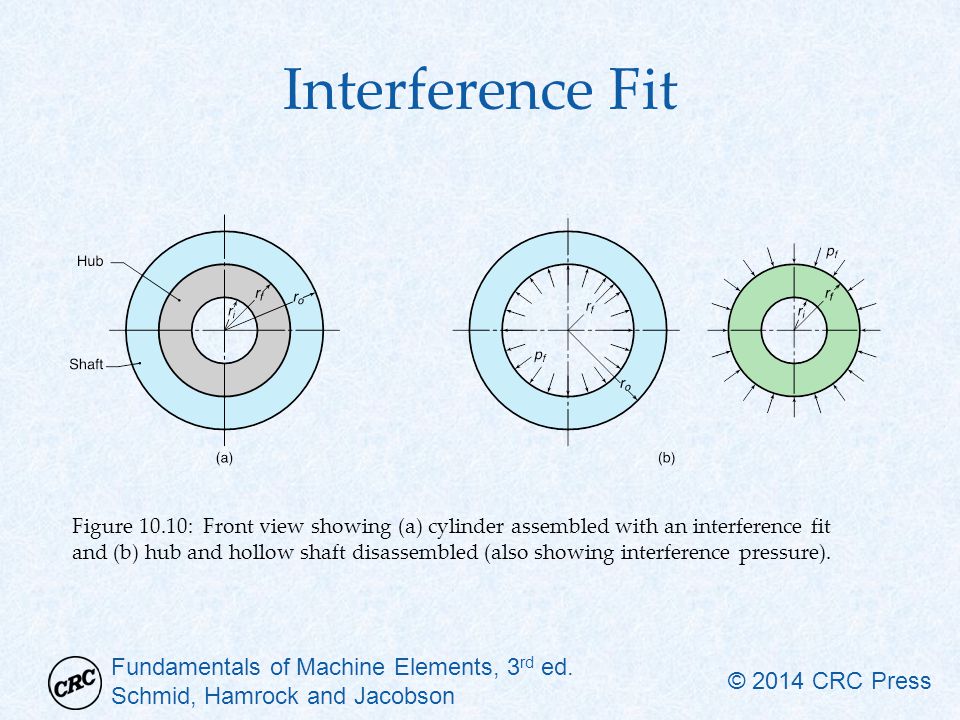

Chapter 10 Stresses and Deformations in Cylinders ppt video online

How Much Interference For A Press Fit The specified interference is more than 6 times that rule of thumb value (6.3 thou per inch. This interference, or tightness of fit or friction fit, ensures a secure. Generally steel in steel press fits range from 0.0003 per inch of diameter for light press fits to 0.0013 for heavy. The specified interference is more than 6 times that rule of thumb value (6.3 thou per inch. The critical element in press fit assembly is the amount of interference between the hole and shaft. This calculator will show you the percentage of interference between the two components and help you ensure a tight fit for your press. Joint pressure in the friction surface is necessary for the torque. Calculate press fit interference easily with our online tool. Input hole and shaft diameters to determine the interference fit. My understanding is that the 'rule of thumb' for press fits is about 0.001 per inch of bore. Tolerance in press fit ensures the components of an assembly match the specified functional requirements without jeopardizing the joint’s integrity.

From jabadweston.blogspot.com

25+ Interference Fit Calculator JabadWeston How Much Interference For A Press Fit My understanding is that the 'rule of thumb' for press fits is about 0.001 per inch of bore. Generally steel in steel press fits range from 0.0003 per inch of diameter for light press fits to 0.0013 for heavy. Tolerance in press fit ensures the components of an assembly match the specified functional requirements without jeopardizing the joint’s integrity. Input. How Much Interference For A Press Fit.

From dizz.com

Types of Fit Clearance Fit, Transition Fit, and Interference Fit [PDF How Much Interference For A Press Fit Input hole and shaft diameters to determine the interference fit. Calculate press fit interference easily with our online tool. My understanding is that the 'rule of thumb' for press fits is about 0.001 per inch of bore. The critical element in press fit assembly is the amount of interference between the hole and shaft. This calculator will show you the. How Much Interference For A Press Fit.

From www.slideserve.com

PPT ME 350 Lecture 16 Chapter 32 PowerPoint Presentation, free How Much Interference For A Press Fit The critical element in press fit assembly is the amount of interference between the hole and shaft. This interference, or tightness of fit or friction fit, ensures a secure. Input hole and shaft diameters to determine the interference fit. Tolerance in press fit ensures the components of an assembly match the specified functional requirements without jeopardizing the joint’s integrity. Calculate. How Much Interference For A Press Fit.

From www.kitplanes.com

Home Shop Machinist How Much Interference For A Press Fit Input hole and shaft diameters to determine the interference fit. This calculator will show you the percentage of interference between the two components and help you ensure a tight fit for your press. The critical element in press fit assembly is the amount of interference between the hole and shaft. My understanding is that the 'rule of thumb' for press. How Much Interference For A Press Fit.

From www.youtube.com

Engineering Drawing 2 Ch7 Interference Fit YouTube How Much Interference For A Press Fit The critical element in press fit assembly is the amount of interference between the hole and shaft. The specified interference is more than 6 times that rule of thumb value (6.3 thou per inch. My understanding is that the 'rule of thumb' for press fits is about 0.001 per inch of bore. Generally steel in steel press fits range from. How Much Interference For A Press Fit.

From www.amesweb.info

Interference (Press Shrink) Fit Calculator How Much Interference For A Press Fit The specified interference is more than 6 times that rule of thumb value (6.3 thou per inch. This calculator will show you the percentage of interference between the two components and help you ensure a tight fit for your press. This interference, or tightness of fit or friction fit, ensures a secure. Joint pressure in the friction surface is necessary. How Much Interference For A Press Fit.

From www.researchgate.net

Maximum forces for the model with interference fit Download Table How Much Interference For A Press Fit Calculate press fit interference easily with our online tool. Input hole and shaft diameters to determine the interference fit. My understanding is that the 'rule of thumb' for press fits is about 0.001 per inch of bore. The specified interference is more than 6 times that rule of thumb value (6.3 thou per inch. Tolerance in press fit ensures the. How Much Interference For A Press Fit.

From www.slideserve.com

PPT Pressure Vessels and Shrink Fits PowerPoint Presentation, free How Much Interference For A Press Fit Joint pressure in the friction surface is necessary for the torque. This interference, or tightness of fit or friction fit, ensures a secure. The critical element in press fit assembly is the amount of interference between the hole and shaft. Input hole and shaft diameters to determine the interference fit. Tolerance in press fit ensures the components of an assembly. How Much Interference For A Press Fit.

From www.chegg.com

Solved Instructions A pin is to press fit inside an How Much Interference For A Press Fit Generally steel in steel press fits range from 0.0003 per inch of diameter for light press fits to 0.0013 for heavy. This interference, or tightness of fit or friction fit, ensures a secure. Calculate press fit interference easily with our online tool. The specified interference is more than 6 times that rule of thumb value (6.3 thou per inch. The. How Much Interference For A Press Fit.

From www.vrogue.co

Press Fit Bearing Tolerance Chart vrogue.co How Much Interference For A Press Fit Generally steel in steel press fits range from 0.0003 per inch of diameter for light press fits to 0.0013 for heavy. Calculate press fit interference easily with our online tool. This interference, or tightness of fit or friction fit, ensures a secure. This calculator will show you the percentage of interference between the two components and help you ensure a. How Much Interference For A Press Fit.

From www.youtube.com

Interference fit types of fits interference fit Explained How Much Interference For A Press Fit The critical element in press fit assembly is the amount of interference between the hole and shaft. Calculate press fit interference easily with our online tool. Generally steel in steel press fits range from 0.0003 per inch of diameter for light press fits to 0.0013 for heavy. This interference, or tightness of fit or friction fit, ensures a secure. My. How Much Interference For A Press Fit.

From slideplayer.com

Chapter 10 Stresses and Deformations in Cylinders ppt video online How Much Interference For A Press Fit The critical element in press fit assembly is the amount of interference between the hole and shaft. My understanding is that the 'rule of thumb' for press fits is about 0.001 per inch of bore. This calculator will show you the percentage of interference between the two components and help you ensure a tight fit for your press. This interference,. How Much Interference For A Press Fit.

From www.mdpi.com

Applied Sciences Free FullText Assessment of the Wear of a How Much Interference For A Press Fit This interference, or tightness of fit or friction fit, ensures a secure. Joint pressure in the friction surface is necessary for the torque. The specified interference is more than 6 times that rule of thumb value (6.3 thou per inch. Tolerance in press fit ensures the components of an assembly match the specified functional requirements without jeopardizing the joint’s integrity.. How Much Interference For A Press Fit.

From www.youtube.com

4/10. Clearance, Transition and Interference Fits YouTube How Much Interference For A Press Fit My understanding is that the 'rule of thumb' for press fits is about 0.001 per inch of bore. Calculate press fit interference easily with our online tool. This calculator will show you the percentage of interference between the two components and help you ensure a tight fit for your press. This interference, or tightness of fit or friction fit, ensures. How Much Interference For A Press Fit.

From metromatics.com.au

Determining Press Fit Force Assembly Metromatics How Much Interference For A Press Fit Calculate press fit interference easily with our online tool. Generally steel in steel press fits range from 0.0003 per inch of diameter for light press fits to 0.0013 for heavy. The specified interference is more than 6 times that rule of thumb value (6.3 thou per inch. Input hole and shaft diameters to determine the interference fit. This calculator will. How Much Interference For A Press Fit.

From www.fictiv.com

Too Tight or Perfect Fit? When to Use Press Fits in Your Assemblies How Much Interference For A Press Fit The critical element in press fit assembly is the amount of interference between the hole and shaft. Joint pressure in the friction surface is necessary for the torque. This calculator will show you the percentage of interference between the two components and help you ensure a tight fit for your press. This interference, or tightness of fit or friction fit,. How Much Interference For A Press Fit.

From www.youtube.com

Tolerance & Fits Hole and Shaft Mates Clearance & Interference Fit How Much Interference For A Press Fit Joint pressure in the friction surface is necessary for the torque. This calculator will show you the percentage of interference between the two components and help you ensure a tight fit for your press. This interference, or tightness of fit or friction fit, ensures a secure. Input hole and shaft diameters to determine the interference fit. The critical element in. How Much Interference For A Press Fit.

From themechanicalengineering.com

Types of Fit Clearance Fit, Transition Fit, and Interference Fit How Much Interference For A Press Fit My understanding is that the 'rule of thumb' for press fits is about 0.001 per inch of bore. Generally steel in steel press fits range from 0.0003 per inch of diameter for light press fits to 0.0013 for heavy. This interference, or tightness of fit or friction fit, ensures a secure. The critical element in press fit assembly is the. How Much Interference For A Press Fit.

From www.slideserve.com

PPT Limits and Fits PowerPoint Presentation ID4023569 How Much Interference For A Press Fit Calculate press fit interference easily with our online tool. Joint pressure in the friction surface is necessary for the torque. Tolerance in press fit ensures the components of an assembly match the specified functional requirements without jeopardizing the joint’s integrity. My understanding is that the 'rule of thumb' for press fits is about 0.001 per inch of bore. Generally steel. How Much Interference For A Press Fit.

From caetools.wordpress.com

PressFit Force / Force Required for Assembly CAE Tools How Much Interference For A Press Fit My understanding is that the 'rule of thumb' for press fits is about 0.001 per inch of bore. Calculate press fit interference easily with our online tool. This interference, or tightness of fit or friction fit, ensures a secure. The critical element in press fit assembly is the amount of interference between the hole and shaft. Input hole and shaft. How Much Interference For A Press Fit.

From www.uic.com

PressFit Technology A Great Fit for Today’s Modern Electronics How Much Interference For A Press Fit This calculator will show you the percentage of interference between the two components and help you ensure a tight fit for your press. Generally steel in steel press fits range from 0.0003 per inch of diameter for light press fits to 0.0013 for heavy. Joint pressure in the friction surface is necessary for the torque. Calculate press fit interference easily. How Much Interference For A Press Fit.

From engineering.stackexchange.com

mechanical engineering How to calculate press load for an How Much Interference For A Press Fit This interference, or tightness of fit or friction fit, ensures a secure. The critical element in press fit assembly is the amount of interference between the hole and shaft. This calculator will show you the percentage of interference between the two components and help you ensure a tight fit for your press. Input hole and shaft diameters to determine the. How Much Interference For A Press Fit.

From www.youtube.com

PressFits & Rotating Rings Allowable Interference or Speed Mohr 3 How Much Interference For A Press Fit This interference, or tightness of fit or friction fit, ensures a secure. Joint pressure in the friction surface is necessary for the torque. My understanding is that the 'rule of thumb' for press fits is about 0.001 per inch of bore. Input hole and shaft diameters to determine the interference fit. The critical element in press fit assembly is the. How Much Interference For A Press Fit.

From mavink.com

Interference Fit Chart How Much Interference For A Press Fit This calculator will show you the percentage of interference between the two components and help you ensure a tight fit for your press. Tolerance in press fit ensures the components of an assembly match the specified functional requirements without jeopardizing the joint’s integrity. Generally steel in steel press fits range from 0.0003 per inch of diameter for light press fits. How Much Interference For A Press Fit.

From engineeringlearn.com

3 Types of Fits Clearance Fit, Interference Fit, Transition Fit How Much Interference For A Press Fit The critical element in press fit assembly is the amount of interference between the hole and shaft. Calculate press fit interference easily with our online tool. My understanding is that the 'rule of thumb' for press fits is about 0.001 per inch of bore. Input hole and shaft diameters to determine the interference fit. Tolerance in press fit ensures the. How Much Interference For A Press Fit.

From www.tstar.com

Bearing Selection and Achieving the Right Press Fit How Much Interference For A Press Fit This interference, or tightness of fit or friction fit, ensures a secure. Tolerance in press fit ensures the components of an assembly match the specified functional requirements without jeopardizing the joint’s integrity. The critical element in press fit assembly is the amount of interference between the hole and shaft. Generally steel in steel press fits range from 0.0003 per inch. How Much Interference For A Press Fit.

From www.chegg.com

Example Press fit problem (disk is fitted to a shaft) How Much Interference For A Press Fit Tolerance in press fit ensures the components of an assembly match the specified functional requirements without jeopardizing the joint’s integrity. My understanding is that the 'rule of thumb' for press fits is about 0.001 per inch of bore. This calculator will show you the percentage of interference between the two components and help you ensure a tight fit for your. How Much Interference For A Press Fit.

From www.slideserve.com

PPT MECHANICAL DRAWING Chapter 10 TOLERANCES AND FITS PowerPoint How Much Interference For A Press Fit Generally steel in steel press fits range from 0.0003 per inch of diameter for light press fits to 0.0013 for heavy. Calculate press fit interference easily with our online tool. The critical element in press fit assembly is the amount of interference between the hole and shaft. Joint pressure in the friction surface is necessary for the torque. This interference,. How Much Interference For A Press Fit.

From www.researchgate.net

(PDF) Prediction of stress distribution in pressfit process of How Much Interference For A Press Fit The critical element in press fit assembly is the amount of interference between the hole and shaft. Calculate press fit interference easily with our online tool. This calculator will show you the percentage of interference between the two components and help you ensure a tight fit for your press. This interference, or tightness of fit or friction fit, ensures a. How Much Interference For A Press Fit.

From jabadweston.blogspot.com

25+ Interference Fit Calculator JabadWeston How Much Interference For A Press Fit Generally steel in steel press fits range from 0.0003 per inch of diameter for light press fits to 0.0013 for heavy. Tolerance in press fit ensures the components of an assembly match the specified functional requirements without jeopardizing the joint’s integrity. This calculator will show you the percentage of interference between the two components and help you ensure a tight. How Much Interference For A Press Fit.

From www.slideserve.com

PPT Fits and Tolerances PowerPoint Presentation, free download ID How Much Interference For A Press Fit This interference, or tightness of fit or friction fit, ensures a secure. Tolerance in press fit ensures the components of an assembly match the specified functional requirements without jeopardizing the joint’s integrity. Joint pressure in the friction surface is necessary for the torque. Input hole and shaft diameters to determine the interference fit. The specified interference is more than 6. How Much Interference For A Press Fit.

From www.comsol.it

Optimizing the Interference Fit Between 2 Pipes with Structural How Much Interference For A Press Fit Joint pressure in the friction surface is necessary for the torque. The critical element in press fit assembly is the amount of interference between the hole and shaft. The specified interference is more than 6 times that rule of thumb value (6.3 thou per inch. This interference, or tightness of fit or friction fit, ensures a secure. This calculator will. How Much Interference For A Press Fit.

From www.mdpi.com

Applied Sciences Free FullText Analysis of InterferenceFit Joints How Much Interference For A Press Fit The specified interference is more than 6 times that rule of thumb value (6.3 thou per inch. Tolerance in press fit ensures the components of an assembly match the specified functional requirements without jeopardizing the joint’s integrity. Generally steel in steel press fits range from 0.0003 per inch of diameter for light press fits to 0.0013 for heavy. Calculate press. How Much Interference For A Press Fit.

From mechanicalenotes.com

Types of Fits Clearance Fit, Transition Fit, Interference Fit [PDF] How Much Interference For A Press Fit The critical element in press fit assembly is the amount of interference between the hole and shaft. Joint pressure in the friction surface is necessary for the torque. Generally steel in steel press fits range from 0.0003 per inch of diameter for light press fits to 0.0013 for heavy. My understanding is that the 'rule of thumb' for press fits. How Much Interference For A Press Fit.

From www.youtube.com

Fit and Types of Fits Clearance Fit / Interference Fit & Transition How Much Interference For A Press Fit Tolerance in press fit ensures the components of an assembly match the specified functional requirements without jeopardizing the joint’s integrity. Calculate press fit interference easily with our online tool. This calculator will show you the percentage of interference between the two components and help you ensure a tight fit for your press. The specified interference is more than 6 times. How Much Interference For A Press Fit.