Plasma Cutting Advantages . Steel, stainless steel, aluminum, brass, copper, and other. It's like a civil war among welders about which one is the best. Plasma cutting excels in speed, especially with thinner metals. Thanks to these advantages, plasma arc cutting has plenty of applications including metal fabrication, construction work, car repairs and restoration, military. These benefits are particularly pronounced in. Plasma cutting is a process that involves the use of the fourth stage of matter to cut conductive metals. This process offers many advantages, including higher productivity,. Welding , cutting & drilling , machinery. You don't want to ask that question around a welder. Plasma cutting offers distinct advantages over traditional methods, including superior efficiency, precision, and stability. The plasma cutting technique uses a sustained stream of heated plasma to cut through electrically conducting materials.

from engineeringlearn.com

You don't want to ask that question around a welder. Plasma cutting excels in speed, especially with thinner metals. Plasma cutting offers distinct advantages over traditional methods, including superior efficiency, precision, and stability. Welding , cutting & drilling , machinery. This process offers many advantages, including higher productivity,. The plasma cutting technique uses a sustained stream of heated plasma to cut through electrically conducting materials. Steel, stainless steel, aluminum, brass, copper, and other. It's like a civil war among welders about which one is the best. Plasma cutting is a process that involves the use of the fourth stage of matter to cut conductive metals. These benefits are particularly pronounced in.

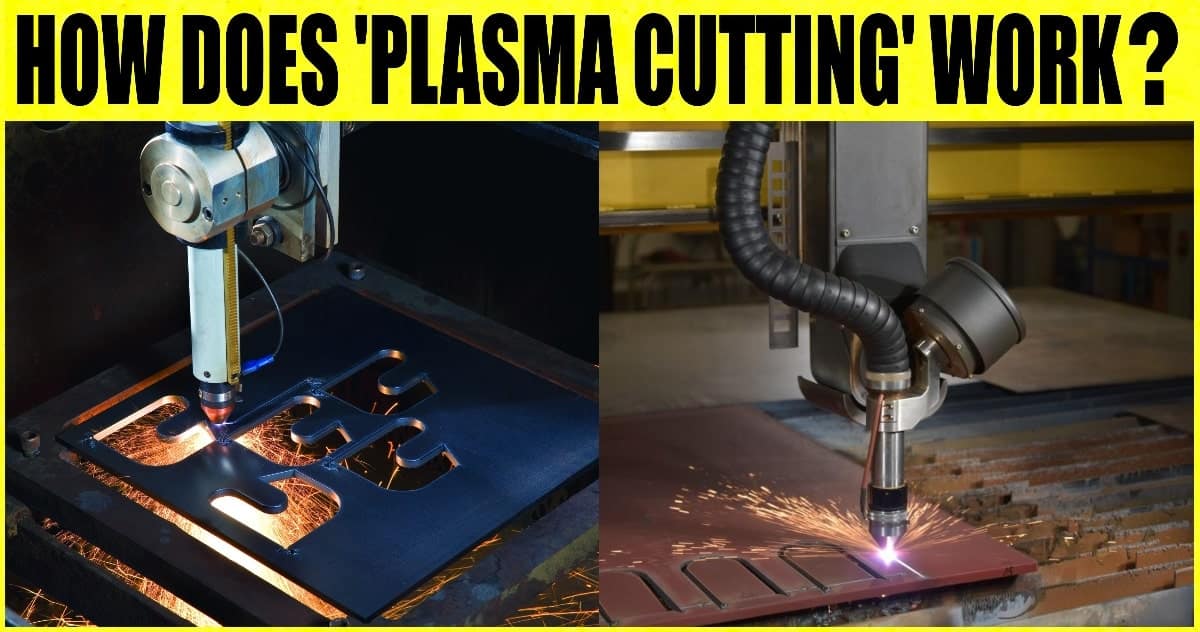

Plasma Cutting Definition, History, Process, Applications, Advantages

Plasma Cutting Advantages It's like a civil war among welders about which one is the best. You don't want to ask that question around a welder. It's like a civil war among welders about which one is the best. These benefits are particularly pronounced in. Plasma cutting offers distinct advantages over traditional methods, including superior efficiency, precision, and stability. Steel, stainless steel, aluminum, brass, copper, and other. Welding , cutting & drilling , machinery. Plasma cutting excels in speed, especially with thinner metals. Plasma cutting is a process that involves the use of the fourth stage of matter to cut conductive metals. The plasma cutting technique uses a sustained stream of heated plasma to cut through electrically conducting materials. This process offers many advantages, including higher productivity,. Thanks to these advantages, plasma arc cutting has plenty of applications including metal fabrication, construction work, car repairs and restoration, military.

From www.rapiddirect.com

What Is Plasma Cutting? Working Principle and Its Advantages Plasma Cutting Advantages Welding , cutting & drilling , machinery. Thanks to these advantages, plasma arc cutting has plenty of applications including metal fabrication, construction work, car repairs and restoration, military. Plasma cutting offers distinct advantages over traditional methods, including superior efficiency, precision, and stability. This process offers many advantages, including higher productivity,. You don't want to ask that question around a welder.. Plasma Cutting Advantages.

From blog.thepipingmart.com

5 Advantages and Disadvantages of Plasma Cutting Plasma Cutting Advantages This process offers many advantages, including higher productivity,. Plasma cutting excels in speed, especially with thinner metals. Welding , cutting & drilling , machinery. The plasma cutting technique uses a sustained stream of heated plasma to cut through electrically conducting materials. It's like a civil war among welders about which one is the best. Steel, stainless steel, aluminum, brass, copper,. Plasma Cutting Advantages.

From www.china-cncrouterlaser.com

Advantages and disadvantages of cnc plasma cutting machine. Dekcel Plasma Cutting Advantages You don't want to ask that question around a welder. Thanks to these advantages, plasma arc cutting has plenty of applications including metal fabrication, construction work, car repairs and restoration, military. Welding , cutting & drilling , machinery. Plasma cutting is a process that involves the use of the fourth stage of matter to cut conductive metals. Plasma cutting excels. Plasma Cutting Advantages.

From www.shopsabre.com

Waterjet vs. Plasma Cutting ShopSabre CNC Plasma Cutting Advantages The plasma cutting technique uses a sustained stream of heated plasma to cut through electrically conducting materials. Steel, stainless steel, aluminum, brass, copper, and other. Plasma cutting offers distinct advantages over traditional methods, including superior efficiency, precision, and stability. Plasma cutting excels in speed, especially with thinner metals. Welding , cutting & drilling , machinery. Thanks to these advantages, plasma. Plasma Cutting Advantages.

From welding-world-awards.com

Plasma cutting vs. Oxyfuel cutting Working principle, advantages, and Plasma Cutting Advantages Welding , cutting & drilling , machinery. These benefits are particularly pronounced in. The plasma cutting technique uses a sustained stream of heated plasma to cut through electrically conducting materials. This process offers many advantages, including higher productivity,. Steel, stainless steel, aluminum, brass, copper, and other. Plasma cutting offers distinct advantages over traditional methods, including superior efficiency, precision, and stability.. Plasma Cutting Advantages.

From cnc.rsmachinery.co.uk

Plasma cutting benefits; how to choose the right machine system Plasma Cutting Advantages Thanks to these advantages, plasma arc cutting has plenty of applications including metal fabrication, construction work, car repairs and restoration, military. Plasma cutting is a process that involves the use of the fourth stage of matter to cut conductive metals. It's like a civil war among welders about which one is the best. Welding , cutting & drilling , machinery.. Plasma Cutting Advantages.

From blog.boydmetals.com

Five Benefits of Plasma Cutting Plasma Cutting Advantages Welding , cutting & drilling , machinery. The plasma cutting technique uses a sustained stream of heated plasma to cut through electrically conducting materials. Plasma cutting excels in speed, especially with thinner metals. Plasma cutting offers distinct advantages over traditional methods, including superior efficiency, precision, and stability. It's like a civil war among welders about which one is the best.. Plasma Cutting Advantages.

From fitwelding.com

Laser Cutting vs Plasma Cutting Advantages, Limitations Plasma Cutting Advantages You don't want to ask that question around a welder. Plasma cutting is a process that involves the use of the fourth stage of matter to cut conductive metals. This process offers many advantages, including higher productivity,. These benefits are particularly pronounced in. Welding , cutting & drilling , machinery. Thanks to these advantages, plasma arc cutting has plenty of. Plasma Cutting Advantages.

From www.slideserve.com

PPT Benefits Of Plasma Welding Cutting Machine PowerPoint Plasma Cutting Advantages You don't want to ask that question around a welder. These benefits are particularly pronounced in. The plasma cutting technique uses a sustained stream of heated plasma to cut through electrically conducting materials. This process offers many advantages, including higher productivity,. Plasma cutting excels in speed, especially with thinner metals. Plasma cutting is a process that involves the use of. Plasma Cutting Advantages.

From primmart.com

The Advantages of Using Plasma Cutting Machines Prim Mart Plasma Cutting Advantages It's like a civil war among welders about which one is the best. These benefits are particularly pronounced in. Steel, stainless steel, aluminum, brass, copper, and other. This process offers many advantages, including higher productivity,. Plasma cutting excels in speed, especially with thinner metals. Welding , cutting & drilling , machinery. The plasma cutting technique uses a sustained stream of. Plasma Cutting Advantages.

From blog.thepipingmart.com

Laser cutting vs Plasma Cutting Cost What's the Difference Plasma Cutting Advantages The plasma cutting technique uses a sustained stream of heated plasma to cut through electrically conducting materials. Steel, stainless steel, aluminum, brass, copper, and other. These benefits are particularly pronounced in. Plasma cutting is a process that involves the use of the fourth stage of matter to cut conductive metals. Thanks to these advantages, plasma arc cutting has plenty of. Plasma Cutting Advantages.

From taiwan-plasma.com

Advantages of Plasma Cutting Over Gas Cutting & Laser Cutting Plasma Cutting Advantages Plasma cutting excels in speed, especially with thinner metals. These benefits are particularly pronounced in. It's like a civil war among welders about which one is the best. Welding , cutting & drilling , machinery. This process offers many advantages, including higher productivity,. The plasma cutting technique uses a sustained stream of heated plasma to cut through electrically conducting materials.. Plasma Cutting Advantages.

From info.paramountmachinery.ca

Benefits of Plasma Cutting Plasma Cutting Advantages It's like a civil war among welders about which one is the best. These benefits are particularly pronounced in. You don't want to ask that question around a welder. Steel, stainless steel, aluminum, brass, copper, and other. Thanks to these advantages, plasma arc cutting has plenty of applications including metal fabrication, construction work, car repairs and restoration, military. Plasma cutting. Plasma Cutting Advantages.

From arcsolinc.com

What Are The Advantages Of Plasma Cutting Technology? Arc Solutions Plasma Cutting Advantages This process offers many advantages, including higher productivity,. You don't want to ask that question around a welder. Welding , cutting & drilling , machinery. Plasma cutting excels in speed, especially with thinner metals. These benefits are particularly pronounced in. It's like a civil war among welders about which one is the best. Plasma cutting is a process that involves. Plasma Cutting Advantages.

From blog.thepipingmart.com

What is Plasma Cutting CNC Machine? Working and Advantages Plasma Cutting Advantages It's like a civil war among welders about which one is the best. Plasma cutting offers distinct advantages over traditional methods, including superior efficiency, precision, and stability. These benefits are particularly pronounced in. Plasma cutting excels in speed, especially with thinner metals. Steel, stainless steel, aluminum, brass, copper, and other. The plasma cutting technique uses a sustained stream of heated. Plasma Cutting Advantages.

From www.slideserve.com

PPT Advantages Of Plasma Cutting Welding Machine PowerPoint Plasma Cutting Advantages Steel, stainless steel, aluminum, brass, copper, and other. Thanks to these advantages, plasma arc cutting has plenty of applications including metal fabrication, construction work, car repairs and restoration, military. Plasma cutting excels in speed, especially with thinner metals. Plasma cutting is a process that involves the use of the fourth stage of matter to cut conductive metals. This process offers. Plasma Cutting Advantages.

From blog.boydmetals.com

How Plasma Cutting Benefits Fabrication Projects Plasma Cutting Advantages Welding , cutting & drilling , machinery. These benefits are particularly pronounced in. Steel, stainless steel, aluminum, brass, copper, and other. Plasma cutting is a process that involves the use of the fourth stage of matter to cut conductive metals. Plasma cutting offers distinct advantages over traditional methods, including superior efficiency, precision, and stability. It's like a civil war among. Plasma Cutting Advantages.

From blog.thepipingmart.com

Plasma Cutting CNC Machine Advantages and Disadvantages Plasma Cutting Advantages These benefits are particularly pronounced in. This process offers many advantages, including higher productivity,. The plasma cutting technique uses a sustained stream of heated plasma to cut through electrically conducting materials. Plasma cutting excels in speed, especially with thinner metals. Plasma cutting is a process that involves the use of the fourth stage of matter to cut conductive metals. Thanks. Plasma Cutting Advantages.

From azironsupply.com

Advantages and Disadvantages of Plasma Cutting Arizona Iron Supply Plasma Cutting Advantages Plasma cutting excels in speed, especially with thinner metals. It's like a civil war among welders about which one is the best. You don't want to ask that question around a welder. Plasma cutting offers distinct advantages over traditional methods, including superior efficiency, precision, and stability. This process offers many advantages, including higher productivity,. These benefits are particularly pronounced in.. Plasma Cutting Advantages.

From blog.thepipingmart.com

Plasma Arc Cutting Advantages and Disadvantages Plasma Cutting Advantages The plasma cutting technique uses a sustained stream of heated plasma to cut through electrically conducting materials. It's like a civil war among welders about which one is the best. Steel, stainless steel, aluminum, brass, copper, and other. Plasma cutting excels in speed, especially with thinner metals. Thanks to these advantages, plasma arc cutting has plenty of applications including metal. Plasma Cutting Advantages.

From www.omnisteelsupply.com

5 incredible benefits of Steel Plasma Cutting Omni Steel Supply Plasma Cutting Advantages These benefits are particularly pronounced in. Plasma cutting offers distinct advantages over traditional methods, including superior efficiency, precision, and stability. Plasma cutting is a process that involves the use of the fourth stage of matter to cut conductive metals. Steel, stainless steel, aluminum, brass, copper, and other. Thanks to these advantages, plasma arc cutting has plenty of applications including metal. Plasma Cutting Advantages.

From www.onealsteel.com

Plasma Cutting Service Centers Plasma Arc Cutting Services O'Neal Steel Plasma Cutting Advantages These benefits are particularly pronounced in. Plasma cutting offers distinct advantages over traditional methods, including superior efficiency, precision, and stability. This process offers many advantages, including higher productivity,. Steel, stainless steel, aluminum, brass, copper, and other. It's like a civil war among welders about which one is the best. The plasma cutting technique uses a sustained stream of heated plasma. Plasma Cutting Advantages.

From iniwoo.net

Plasma Cutting Vs. Laser Cutting Which Is Right For Your Project Plasma Cutting Advantages Steel, stainless steel, aluminum, brass, copper, and other. It's like a civil war among welders about which one is the best. Plasma cutting offers distinct advantages over traditional methods, including superior efficiency, precision, and stability. Plasma cutting excels in speed, especially with thinner metals. Thanks to these advantages, plasma arc cutting has plenty of applications including metal fabrication, construction work,. Plasma Cutting Advantages.

From glenfarrow.co.uk

The advantages of plasma cutting Plasma Cutting Advantages The plasma cutting technique uses a sustained stream of heated plasma to cut through electrically conducting materials. It's like a civil war among welders about which one is the best. Welding , cutting & drilling , machinery. Plasma cutting offers distinct advantages over traditional methods, including superior efficiency, precision, and stability. Plasma cutting excels in speed, especially with thinner metals.. Plasma Cutting Advantages.

From www.accteklaser.com

Corte por láser o corte por plasma ¿cuál es mejor? AccTek Laser Plasma Cutting Advantages These benefits are particularly pronounced in. It's like a civil war among welders about which one is the best. Plasma cutting excels in speed, especially with thinner metals. Steel, stainless steel, aluminum, brass, copper, and other. Plasma cutting is a process that involves the use of the fourth stage of matter to cut conductive metals. This process offers many advantages,. Plasma Cutting Advantages.

From engineeringlearn.com

Plasma Cutting Definition, History, Process, Applications, Advantages Plasma Cutting Advantages It's like a civil war among welders about which one is the best. Welding , cutting & drilling , machinery. Steel, stainless steel, aluminum, brass, copper, and other. The plasma cutting technique uses a sustained stream of heated plasma to cut through electrically conducting materials. Thanks to these advantages, plasma arc cutting has plenty of applications including metal fabrication, construction. Plasma Cutting Advantages.

From www.rapiddirect.com

What Is Plasma Cutting? Working Principle and Its Advantages Plasma Cutting Advantages You don't want to ask that question around a welder. These benefits are particularly pronounced in. It's like a civil war among welders about which one is the best. This process offers many advantages, including higher productivity,. The plasma cutting technique uses a sustained stream of heated plasma to cut through electrically conducting materials. Plasma cutting offers distinct advantages over. Plasma Cutting Advantages.

From www.machinemfg.com

Portable Plasma Cutters Your Ultimate Guide to OntheGo Cutting Plasma Cutting Advantages Welding , cutting & drilling , machinery. You don't want to ask that question around a welder. Plasma cutting excels in speed, especially with thinner metals. Plasma cutting offers distinct advantages over traditional methods, including superior efficiency, precision, and stability. Plasma cutting is a process that involves the use of the fourth stage of matter to cut conductive metals. These. Plasma Cutting Advantages.

From www.youtube.com

Advantages of a Plasma Cutter and OxyFuel Cutting System YouTube Plasma Cutting Advantages It's like a civil war among welders about which one is the best. Thanks to these advantages, plasma arc cutting has plenty of applications including metal fabrication, construction work, car repairs and restoration, military. Plasma cutting is a process that involves the use of the fourth stage of matter to cut conductive metals. Plasma cutting offers distinct advantages over traditional. Plasma Cutting Advantages.

From cnc.rsmachinery.co.uk

Plasma cutting benefits; how to choose the right machine system Plasma Cutting Advantages Plasma cutting is a process that involves the use of the fourth stage of matter to cut conductive metals. The plasma cutting technique uses a sustained stream of heated plasma to cut through electrically conducting materials. Plasma cutting excels in speed, especially with thinner metals. These benefits are particularly pronounced in. It's like a civil war among welders about which. Plasma Cutting Advantages.

From www.rapiddirect.com

What Is Plasma Cutting? Working Principle and Its Advantages Plasma Cutting Advantages These benefits are particularly pronounced in. Plasma cutting excels in speed, especially with thinner metals. Plasma cutting offers distinct advantages over traditional methods, including superior efficiency, precision, and stability. The plasma cutting technique uses a sustained stream of heated plasma to cut through electrically conducting materials. Plasma cutting is a process that involves the use of the fourth stage of. Plasma Cutting Advantages.

From www.southernfabsales.com

Plasma Cutting 4 Reasons Why You Need a Plasma Table In Your Shop Now Plasma Cutting Advantages It's like a civil war among welders about which one is the best. Plasma cutting offers distinct advantages over traditional methods, including superior efficiency, precision, and stability. Plasma cutting excels in speed, especially with thinner metals. You don't want to ask that question around a welder. This process offers many advantages, including higher productivity,. Welding , cutting & drilling ,. Plasma Cutting Advantages.