Turning Machine Inserts . There are many variables that go into choosing the correct insert for your turning operations: Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. Don't worry, we've got you covered with these helpful tips and insights. Turning is a common metalworking process in which a workpiece rotates while a. Turning inserts are specialized cutting tools used in machining processes, specifically in turning operations. Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. Unsure about which turning insert shape to use for your cnc turning operations? Insert shape, geometry, grade, and more. Select workpiece material, workpiece condition, and roughing/finishing to find the best grade and chipbreaker for your.

from www.shop-apt.co.uk

Select workpiece material, workpiece condition, and roughing/finishing to find the best grade and chipbreaker for your. Turning is a common metalworking process in which a workpiece rotates while a. Unsure about which turning insert shape to use for your cnc turning operations? Don't worry, we've got you covered with these helpful tips and insights. Turning inserts are specialized cutting tools used in machining processes, specifically in turning operations. Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. Insert shape, geometry, grade, and more. There are many variables that go into choosing the correct insert for your turning operations: Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut.

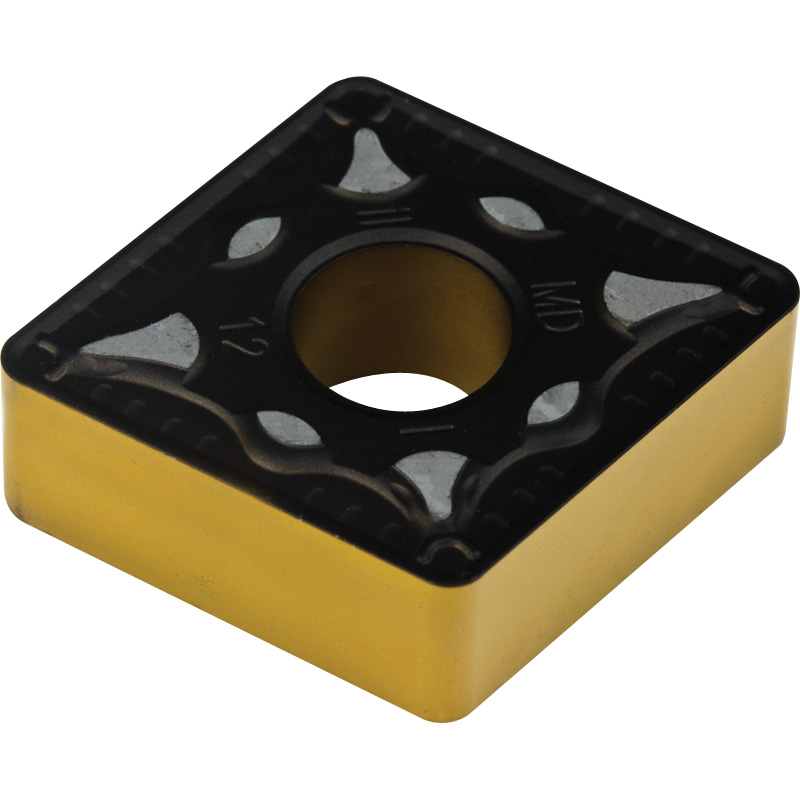

CNMG 190608 MD DP25 Carbide Inserts for Turning MTCVD Coated for Steel

Turning Machine Inserts Insert shape, geometry, grade, and more. Turning is a common metalworking process in which a workpiece rotates while a. Turning inserts are specialized cutting tools used in machining processes, specifically in turning operations. Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. Insert shape, geometry, grade, and more. Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. Select workpiece material, workpiece condition, and roughing/finishing to find the best grade and chipbreaker for your. Don't worry, we've got you covered with these helpful tips and insights. There are many variables that go into choosing the correct insert for your turning operations: Unsure about which turning insert shape to use for your cnc turning operations?

From www.indiamart.com

Carbide Taper Point CNC Machine Turning Inserts at Rs 200 in Gurugram Turning Machine Inserts Turning is a common metalworking process in which a workpiece rotates while a. Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. Unsure about which turning insert shape to use for your cnc turning operations? Turning inserts are specialized cutting tools used in machining processes, specifically in. Turning Machine Inserts.

From www.dreamstime.com

Turning Machine Inserts and End Mills Stock Photo Image of hard Turning Machine Inserts Turning inserts are specialized cutting tools used in machining processes, specifically in turning operations. Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. Insert shape, geometry, grade, and more. Unsure about which turning insert shape to use for your cnc turning operations? There are many variables that. Turning Machine Inserts.

From burraycarbide.en.made-in-china.com

Tungsten Carbide Turning Inserts for Cutting Machine China CNC Turning Machine Inserts Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. Turning is a common metalworking process in which a workpiece rotates while a. Unsure about which turning insert shape to use for your cnc turning operations? Don't worry, we've got you covered with these helpful tips and insights.. Turning Machine Inserts.

From www.indiamart.com

Milling Carbide Turning Inserts, For Machinery Processing at Rs 135 Turning Machine Inserts Select workpiece material, workpiece condition, and roughing/finishing to find the best grade and chipbreaker for your. Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. There are many variables that go into choosing the correct insert for your turning operations: Understanding the material properties and machining conditions. Turning Machine Inserts.

From www.practicalmachinist.com

THINBIT® GROOVE ’N TURN® DOVETAIL GROOVING INSERTS Practical Turning Machine Inserts Don't worry, we've got you covered with these helpful tips and insights. Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. Select workpiece material, workpiece condition, and roughing/finishing to find the best grade and chipbreaker for your. Understanding the material properties and machining conditions is crucial for. Turning Machine Inserts.

From huanatools.com

How to choose the right carbide turning insert Huana Tools Turning Machine Inserts Insert shape, geometry, grade, and more. Turning is a common metalworking process in which a workpiece rotates while a. Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. There are many variables that go into choosing the correct insert for your turning operations: Turning inserts are specialized. Turning Machine Inserts.

From www.cnccarbideinserts.com

TNMG160404L Cermet Hard Turning Inserts For High Speed Machining Inserts Turning Machine Inserts Turning inserts are specialized cutting tools used in machining processes, specifically in turning operations. Don't worry, we've got you covered with these helpful tips and insights. Insert shape, geometry, grade, and more. Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. Select workpiece material, workpiece condition, and roughing/finishing to find the best grade. Turning Machine Inserts.

From www.shop-apt.co.uk

CNMG 190608 MD DP25 Carbide Inserts for Turning MTCVD Coated for Steel Turning Machine Inserts Don't worry, we've got you covered with these helpful tips and insights. Unsure about which turning insert shape to use for your cnc turning operations? Select workpiece material, workpiece condition, and roughing/finishing to find the best grade and chipbreaker for your. Turning inserts are specialized cutting tools used in machining processes, specifically in turning operations. Understanding the material properties and. Turning Machine Inserts.

From www.aliexpress.com

Buy 10pcs Golden WNMG080404 Carbide Inserts Turning Machine Inserts Insert shape, geometry, grade, and more. Turning inserts are specialized cutting tools used in machining processes, specifically in turning operations. Turning is a common metalworking process in which a workpiece rotates while a. There are many variables that go into choosing the correct insert for your turning operations: Select workpiece material, workpiece condition, and roughing/finishing to find the best grade. Turning Machine Inserts.

From www.shop-apt.co.uk

DNMG 150608 GP DP15 Carbide Inserts for Turning MTCVD Coated for Steel Turning Machine Inserts Turning is a common metalworking process in which a workpiece rotates while a. Select workpiece material, workpiece condition, and roughing/finishing to find the best grade and chipbreaker for your. There are many variables that go into choosing the correct insert for your turning operations: Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length,. Turning Machine Inserts.

From www.aliexpress.com

10Pcs Mayitr Gold CCMT060204 US735 CCMT21.51 Turning Inserts CNC Turning Machine Inserts There are many variables that go into choosing the correct insert for your turning operations: Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. Select workpiece material, workpiece condition, and roughing/finishing. Turning Machine Inserts.

From www.aliexpress.com

Buy 10pcs Inserts External Repair For Lathe Turning Turning Machine Inserts Insert shape, geometry, grade, and more. Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. Select workpiece material, workpiece condition, and roughing/finishing to find the best grade and chipbreaker for your. Turning is a common metalworking process in which a workpiece rotates while a. Understanding the material. Turning Machine Inserts.

From www.aliexpress.com

10pcs/lot VNMG160404 Carbide Inserts V shape Gold Inserts For Turning Machine Inserts Select workpiece material, workpiece condition, and roughing/finishing to find the best grade and chipbreaker for your. There are many variables that go into choosing the correct insert for your turning operations: Unsure about which turning insert shape to use for your cnc turning operations? Turning is a common metalworking process in which a workpiece rotates while a. Turning inserts are. Turning Machine Inserts.

From www.indiamart.com

Carbide Turning Inserts, For CNC Machine at best price in Gurgaon ID Turning Machine Inserts Don't worry, we've got you covered with these helpful tips and insights. Turning inserts are specialized cutting tools used in machining processes, specifically in turning operations. Select workpiece material, workpiece condition, and roughing/finishing to find the best grade and chipbreaker for your. Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius,. Turning Machine Inserts.

From www.aliexpress.com

ZCCCT ceramic turning inserts CNC turning inserts VCGT110304 HF YBC251 Turning Machine Inserts Turning inserts are specialized cutting tools used in machining processes, specifically in turning operations. Insert shape, geometry, grade, and more. Unsure about which turning insert shape to use for your cnc turning operations? Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. There are many variables that. Turning Machine Inserts.

From www.indiamart.com

Carbide WNMG 64352 Turning Inserts, For CNC Machine at Rs 250 in Rajkot Turning Machine Inserts Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. Don't worry, we've got you covered with these helpful tips and insights. There are many variables that go into choosing the correct insert for your turning operations: Select workpiece material, workpiece condition, and roughing/finishing to find the best grade and chipbreaker for your. Unsure. Turning Machine Inserts.

From www.indiamart.com

Widia Tc Turning Inserts, For Industries, Cutmac Marketing Private Turning Machine Inserts Turning is a common metalworking process in which a workpiece rotates while a. Select workpiece material, workpiece condition, and roughing/finishing to find the best grade and chipbreaker for your. Turning inserts are specialized cutting tools used in machining processes, specifically in turning operations. Insert shape, geometry, grade, and more. Selecting the right turning inserts involves considering multiple factors, including insert. Turning Machine Inserts.

From www.aliexpress.com

10pcs Carbide Inserts APKT1604PDFR MA3 H01 Insert with Corrosion Turning Machine Inserts Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. Select workpiece material, workpiece condition, and roughing/finishing to find the best grade and chipbreaker for your. Turning is a common metalworking process in which a workpiece rotates while a. Turning inserts are specialized cutting tools used in machining. Turning Machine Inserts.

From www.indiamart.com

Carbide multiple Turning Inserts, For CNC Machine at Rs 150 in Ahmedabad Turning Machine Inserts Unsure about which turning insert shape to use for your cnc turning operations? Select workpiece material, workpiece condition, and roughing/finishing to find the best grade and chipbreaker for your. Turning inserts are specialized cutting tools used in machining processes, specifically in turning operations. Turning is a common metalworking process in which a workpiece rotates while a. Selecting the right turning. Turning Machine Inserts.

From www.rsis.co.uk

Sumitomo Carbide Turning Insert CNMG 120408 NEG AC6030m (SPA) RSIS Turning Machine Inserts Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. Turning is a common metalworking process in which a workpiece rotates while a. Don't worry, we've got you covered with these helpful tips and insights. There are many variables that go into choosing the correct insert for your turning operations: Unsure about which turning. Turning Machine Inserts.

From www.shop-apt.co.uk

VCGT 110304 FS US05 Carbide Turning Inserts for Finishing High Turning Machine Inserts Turning is a common metalworking process in which a workpiece rotates while a. Select workpiece material, workpiece condition, and roughing/finishing to find the best grade and chipbreaker for your. Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. Insert shape, geometry, grade, and more. Unsure about which. Turning Machine Inserts.

From www.aliexpress.com

MZG S16Q MTUNR16 20mm 25mm Triangle Insert Turning Machine Toolholder Turning Machine Inserts Don't worry, we've got you covered with these helpful tips and insights. Select workpiece material, workpiece condition, and roughing/finishing to find the best grade and chipbreaker for your. Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length,. Turning Machine Inserts.

From cdbp2009.en.made-in-china.com

China Turning Inserts (DNMG150604) China Turning Inserts, Carbide Inserts Turning Machine Inserts Don't worry, we've got you covered with these helpful tips and insights. Turning is a common metalworking process in which a workpiece rotates while a. Insert shape, geometry, grade, and more. Select workpiece material, workpiece condition, and roughing/finishing to find the best grade and chipbreaker for your. Understanding the material properties and machining conditions is crucial for optimizing performance and. Turning Machine Inserts.

From www.canadianmetalworking.com

The anatomy of a turning insert Turning Machine Inserts Unsure about which turning insert shape to use for your cnc turning operations? Turning is a common metalworking process in which a workpiece rotates while a. There are many variables that go into choosing the correct insert for your turning operations: Don't worry, we've got you covered with these helpful tips and insights. Understanding the material properties and machining conditions. Turning Machine Inserts.

From www.aliexpress.com

CCGT09T308 1PCS Turning Inserts Metal Ceramic Turning Insert For Turning Machine Inserts Don't worry, we've got you covered with these helpful tips and insights. Select workpiece material, workpiece condition, and roughing/finishing to find the best grade and chipbreaker for your. Turning inserts are specialized cutting tools used in machining processes, specifically in turning operations. There are many variables that go into choosing the correct insert for your turning operations: Turning is a. Turning Machine Inserts.

From www.amazon.com

Indexable Lathe Turning Tool,1/2'' Shank 7 Pieces Carbide Turning Machine Inserts Don't worry, we've got you covered with these helpful tips and insights. Insert shape, geometry, grade, and more. Turning is a common metalworking process in which a workpiece rotates while a. Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. Unsure about which turning insert shape to. Turning Machine Inserts.

From www.mmc-carbide.com

Turning Inserts Products MITSUBISHI MATERIALS CORPORATION Turning Machine Inserts Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. Select workpiece material, workpiece condition, and roughing/finishing to find the best grade and chipbreaker for your. Unsure about which turning insert shape to use for your cnc turning operations? Insert shape, geometry, grade, and more. Don't worry, we've got you covered with these helpful. Turning Machine Inserts.

From www.indiamart.com

DCMT 11T304 TURNING INSERTS, For CNC Machine, Material Grade For SS Turning Machine Inserts Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. Turning is a common metalworking process in which a workpiece rotates while a. Don't worry, we've got you covered with these helpful tips and insights. Turning inserts are specialized cutting tools used in machining processes, specifically in turning. Turning Machine Inserts.

From www.estoolcarbide.com

Common Turning Inserts,Tungsten Carbide Turning Inserts,CNC Cutting Tool Turning Machine Inserts There are many variables that go into choosing the correct insert for your turning operations: Turning inserts are specialized cutting tools used in machining processes, specifically in turning operations. Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge. Turning Machine Inserts.

From www.aliexpress.com

Free shipping CNC turning inserts CNMG120404 for lathe machine suitable Turning Machine Inserts Insert shape, geometry, grade, and more. Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. Unsure about which turning insert shape to use for your cnc turning operations? Turning is a common metalworking process in which a workpiece rotates while a. Understanding the material properties and machining. Turning Machine Inserts.

From www.teruicnc.com

Factory Promotional Vertical Turning Lathe Machine Tool SANDVIK metal Turning Machine Inserts Turning inserts are specialized cutting tools used in machining processes, specifically in turning operations. Unsure about which turning insert shape to use for your cnc turning operations? Turning is a common metalworking process in which a workpiece rotates while a. Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. Don't worry, we've got. Turning Machine Inserts.

From brmeccanicaitaly.com

Cutting tools and carbide Inserts Milling Inserts,Grooving Inserts Turning Machine Inserts Select workpiece material, workpiece condition, and roughing/finishing to find the best grade and chipbreaker for your. Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. There are many variables that go into choosing the correct insert for your turning operations: Turning is a common metalworking process in. Turning Machine Inserts.

From www.indiamart.com

Tooling Carbide ISO Turning inserts, For CNC Machine at Rs 250 Turning Machine Inserts There are many variables that go into choosing the correct insert for your turning operations: Select workpiece material, workpiece condition, and roughing/finishing to find the best grade and chipbreaker for your. Unsure about which turning insert shape to use for your cnc turning operations? Insert shape, geometry, grade, and more. Understanding the material properties and machining conditions is crucial for. Turning Machine Inserts.

From xmhcnctool.en.made-in-china.com

High Quality Turning Tools Carbide CNC Machine Turning Inserts for Turning Machine Inserts Insert shape, geometry, grade, and more. Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. There are many variables that go into choosing the correct insert for your turning operations: Turning is a common metalworking process in which a workpiece rotates while a. Selecting the right turning inserts involves considering multiple factors, including. Turning Machine Inserts.

From tamachinery.com

General Turning Inserts TA MACHINERY Turning Machine Inserts Select workpiece material, workpiece condition, and roughing/finishing to find the best grade and chipbreaker for your. Unsure about which turning insert shape to use for your cnc turning operations? Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. Turning is a common metalworking process in which a. Turning Machine Inserts.