Steel Thickness Welding Chart . How to choose the right welding rod size. Therefore, you have to know how thick your metal is. E6010 and e6011 size and amperage chart. Welding rod sizes sizes & material thickness chart (mild steel) contents. You will also get the required polarity, position, and other related information. The primary factor when choosing the size of a welding rod is the thickness of the base metal that’s going to be welded. The calculator below pinpoints exactly which electrode you need for the metal you are welding. 10 rows estimates the range of mild steel thicknesses you can weld with each setting on your mig welder. Find below the mig welding sheet metal settings chart which displays the recommended settings for welding different gauge thicknesses of sheet metal. Here is a chart that summarizes the mig welding amps according to the three most common types of metal and their thickness:. You set the amperage according to the thickness of the metal. A general rule of thumb is you need 1 amp of power for. Welding rod sizes and base metal thickness chart.

from app.aws.org

How to choose the right welding rod size. The primary factor when choosing the size of a welding rod is the thickness of the base metal that’s going to be welded. Welding rod sizes sizes & material thickness chart (mild steel) contents. Here is a chart that summarizes the mig welding amps according to the three most common types of metal and their thickness:. The calculator below pinpoints exactly which electrode you need for the metal you are welding. You will also get the required polarity, position, and other related information. You set the amperage according to the thickness of the metal. 10 rows estimates the range of mild steel thicknesses you can weld with each setting on your mig welder. A general rule of thumb is you need 1 amp of power for. Find below the mig welding sheet metal settings chart which displays the recommended settings for welding different gauge thicknesses of sheet metal.

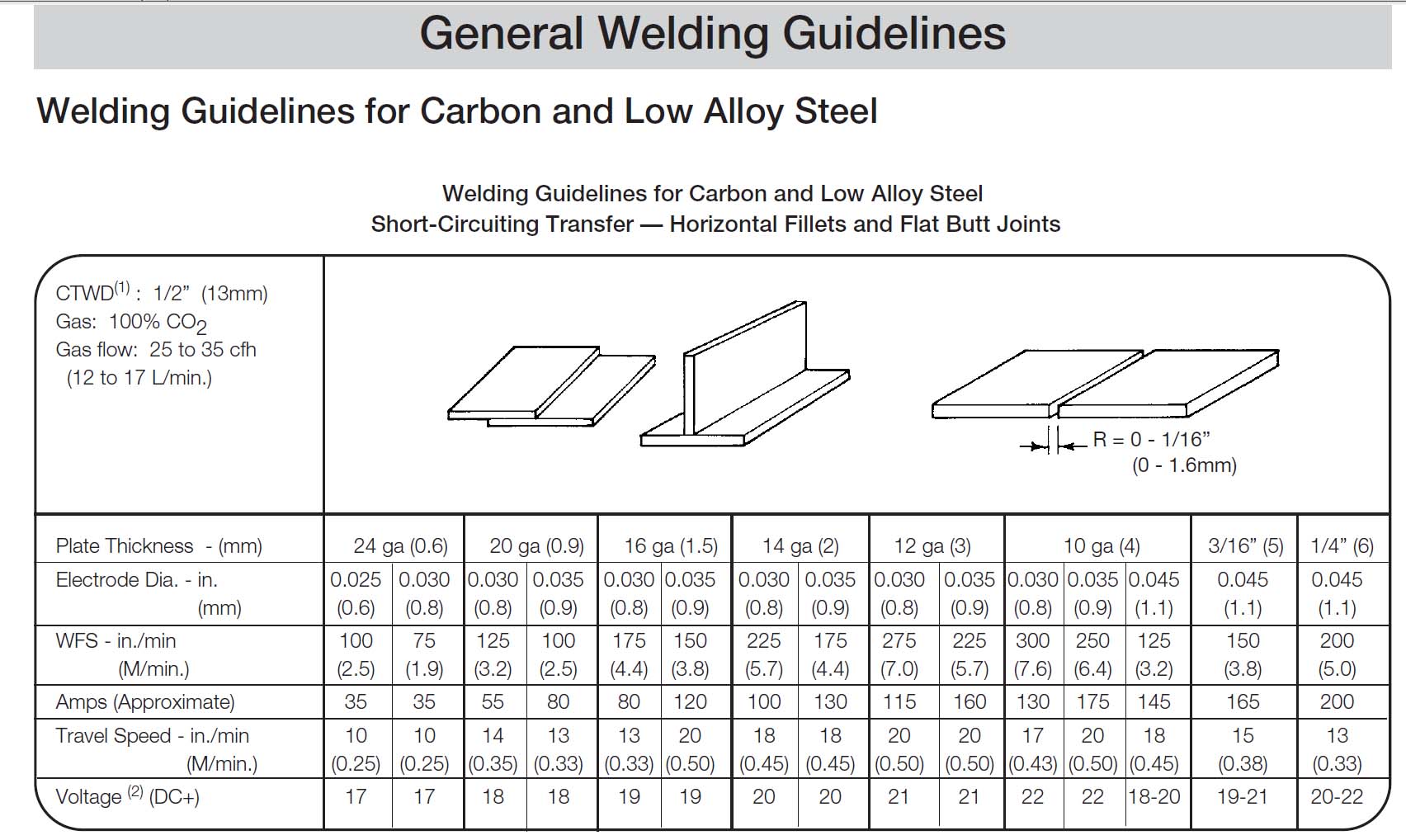

MIG settings for welding different thickness mild steel

Steel Thickness Welding Chart Therefore, you have to know how thick your metal is. 10 rows estimates the range of mild steel thicknesses you can weld with each setting on your mig welder. How to choose the right welding rod size. You set the amperage according to the thickness of the metal. Welding rod sizes sizes & material thickness chart (mild steel) contents. Find below the mig welding sheet metal settings chart which displays the recommended settings for welding different gauge thicknesses of sheet metal. Here is a chart that summarizes the mig welding amps according to the three most common types of metal and their thickness:. The calculator below pinpoints exactly which electrode you need for the metal you are welding. Therefore, you have to know how thick your metal is. The primary factor when choosing the size of a welding rod is the thickness of the base metal that’s going to be welded. E6010 and e6011 size and amperage chart. A general rule of thumb is you need 1 amp of power for. Welding rod sizes and base metal thickness chart. You will also get the required polarity, position, and other related information.

From fixitmanblog.com

Welding Rod Sizes Here's The Complete Guide Steel Thickness Welding Chart You set the amperage according to the thickness of the metal. 10 rows estimates the range of mild steel thicknesses you can weld with each setting on your mig welder. How to choose the right welding rod size. The primary factor when choosing the size of a welding rod is the thickness of the base metal that’s going to be. Steel Thickness Welding Chart.

From www.generalair.com

WeightofWeldMetalRequired General Air Steel Thickness Welding Chart Welding rod sizes sizes & material thickness chart (mild steel) contents. You set the amperage according to the thickness of the metal. Welding rod sizes and base metal thickness chart. Therefore, you have to know how thick your metal is. Find below the mig welding sheet metal settings chart which displays the recommended settings for welding different gauge thicknesses of. Steel Thickness Welding Chart.

From www.artofit.org

Types of welding Artofit Steel Thickness Welding Chart How to choose the right welding rod size. The calculator below pinpoints exactly which electrode you need for the metal you are welding. Here is a chart that summarizes the mig welding amps according to the three most common types of metal and their thickness:. You set the amperage according to the thickness of the metal. Find below the mig. Steel Thickness Welding Chart.

From www.scribd.com

WELDING CHART Stainless Steel Pipe (Fluid Conveyance) Steel Thickness Welding Chart How to choose the right welding rod size. Therefore, you have to know how thick your metal is. Welding rod sizes sizes & material thickness chart (mild steel) contents. You will also get the required polarity, position, and other related information. Here is a chart that summarizes the mig welding amps according to the three most common types of metal. Steel Thickness Welding Chart.

From weaversteelweld.com

Sheet Gauge Chart Weaver Steel Welding Steel Thickness Welding Chart You will also get the required polarity, position, and other related information. Here is a chart that summarizes the mig welding amps according to the three most common types of metal and their thickness:. How to choose the right welding rod size. Welding rod sizes sizes & material thickness chart (mild steel) contents. Find below the mig welding sheet metal. Steel Thickness Welding Chart.

From schematiclisthelen.z6.web.core.windows.net

Stick Welding Rod Sizes Steel Thickness Welding Chart 10 rows estimates the range of mild steel thicknesses you can weld with each setting on your mig welder. Here is a chart that summarizes the mig welding amps according to the three most common types of metal and their thickness:. Welding rod sizes sizes & material thickness chart (mild steel) contents. Find below the mig welding sheet metal settings. Steel Thickness Welding Chart.

From studylibrarywulf.z19.web.core.windows.net

Welding Amps Metal Thickness Chart Steel Thickness Welding Chart Welding rod sizes and base metal thickness chart. You will also get the required polarity, position, and other related information. The primary factor when choosing the size of a welding rod is the thickness of the base metal that’s going to be welded. The calculator below pinpoints exactly which electrode you need for the metal you are welding. Welding rod. Steel Thickness Welding Chart.

From www.pinterest.com

Sheet metal gauge to mm Gauge to Thickness Chart Download Sheet Steel Thickness Welding Chart Welding rod sizes and base metal thickness chart. Welding rod sizes sizes & material thickness chart (mild steel) contents. You will also get the required polarity, position, and other related information. E6010 and e6011 size and amperage chart. You set the amperage according to the thickness of the metal. How to choose the right welding rod size. Here is a. Steel Thickness Welding Chart.

From www.welderdestiny.com

the Base Metal Thickness Essential Variable for Welding Procedures is Steel Thickness Welding Chart The calculator below pinpoints exactly which electrode you need for the metal you are welding. How to choose the right welding rod size. 10 rows estimates the range of mild steel thicknesses you can weld with each setting on your mig welder. A general rule of thumb is you need 1 amp of power for. Welding rod sizes sizes &. Steel Thickness Welding Chart.

From studycampuslemann.z19.web.core.windows.net

Welding Amps To Metal Thickness Chart Steel Thickness Welding Chart You will also get the required polarity, position, and other related information. How to choose the right welding rod size. Welding rod sizes sizes & material thickness chart (mild steel) contents. 10 rows estimates the range of mild steel thicknesses you can weld with each setting on your mig welder. Therefore, you have to know how thick your metal is.. Steel Thickness Welding Chart.

From studymagicjill.z21.web.core.windows.net

Welding Amps To Metal Thickness Chart Steel Thickness Welding Chart How to choose the right welding rod size. Welding rod sizes sizes & material thickness chart (mild steel) contents. You set the amperage according to the thickness of the metal. Welding rod sizes and base metal thickness chart. The calculator below pinpoints exactly which electrode you need for the metal you are welding. A general rule of thumb is you. Steel Thickness Welding Chart.

From www.hobartbrothers.com

TIG Welding Parameters Hobart Brothers Steel Thickness Welding Chart The primary factor when choosing the size of a welding rod is the thickness of the base metal that’s going to be welded. You set the amperage according to the thickness of the metal. The calculator below pinpoints exactly which electrode you need for the metal you are welding. 10 rows estimates the range of mild steel thicknesses you can. Steel Thickness Welding Chart.

From learningtrommler.z1.web.core.windows.net

Mig Welding Amps To Metal Thickness Chart Steel Thickness Welding Chart Welding rod sizes sizes & material thickness chart (mild steel) contents. Find below the mig welding sheet metal settings chart which displays the recommended settings for welding different gauge thicknesses of sheet metal. The calculator below pinpoints exactly which electrode you need for the metal you are welding. E6010 and e6011 size and amperage chart. The primary factor when choosing. Steel Thickness Welding Chart.

From americanprime.com.br

TIG Welding Amp Charts PDF Welding Construction, 45 OFF Steel Thickness Welding Chart The calculator below pinpoints exactly which electrode you need for the metal you are welding. The primary factor when choosing the size of a welding rod is the thickness of the base metal that’s going to be welded. Find below the mig welding sheet metal settings chart which displays the recommended settings for welding different gauge thicknesses of sheet metal.. Steel Thickness Welding Chart.

From www.vrogue.co

Metal Thickness Stick Welding Amperage Chart vrogue.co Steel Thickness Welding Chart Welding rod sizes sizes & material thickness chart (mild steel) contents. 10 rows estimates the range of mild steel thicknesses you can weld with each setting on your mig welder. You set the amperage according to the thickness of the metal. You will also get the required polarity, position, and other related information. Welding rod sizes and base metal thickness. Steel Thickness Welding Chart.

From www.pinterest.com.au

Stick Amps Vs Rod size Vs metal thickness Welding rod chart, Welding Steel Thickness Welding Chart The primary factor when choosing the size of a welding rod is the thickness of the base metal that’s going to be welded. 10 rows estimates the range of mild steel thicknesses you can weld with each setting on your mig welder. Welding rod sizes and base metal thickness chart. Find below the mig welding sheet metal settings chart which. Steel Thickness Welding Chart.

From weldingmastermind.com

A MIG Welding Amps to Metal Thickness Chart Welding Mastermind Steel Thickness Welding Chart E6010 and e6011 size and amperage chart. A general rule of thumb is you need 1 amp of power for. You set the amperage according to the thickness of the metal. Welding rod sizes sizes & material thickness chart (mild steel) contents. Welding rod sizes and base metal thickness chart. Find below the mig welding sheet metal settings chart which. Steel Thickness Welding Chart.

From weldguru.com

MIG Welder Settings Explained (with Chart) Weld Guru Steel Thickness Welding Chart You set the amperage according to the thickness of the metal. A general rule of thumb is you need 1 amp of power for. Here is a chart that summarizes the mig welding amps according to the three most common types of metal and their thickness:. The calculator below pinpoints exactly which electrode you need for the metal you are. Steel Thickness Welding Chart.

From www.eng-tips.com

Maximum weld thickness Welding, Bonding & Fastener engineering EngTips Steel Thickness Welding Chart How to choose the right welding rod size. Welding rod sizes and base metal thickness chart. Here is a chart that summarizes the mig welding amps according to the three most common types of metal and their thickness:. Therefore, you have to know how thick your metal is. Find below the mig welding sheet metal settings chart which displays the. Steel Thickness Welding Chart.

From www.kingsofwelding.com

Welding Rod Sizes, Amperage & Metal Thickness Chart Kings of Welding Steel Thickness Welding Chart The primary factor when choosing the size of a welding rod is the thickness of the base metal that’s going to be welded. Welding rod sizes and base metal thickness chart. A general rule of thumb is you need 1 amp of power for. You set the amperage according to the thickness of the metal. Here is a chart that. Steel Thickness Welding Chart.

From weldingmastermind.com

A MIG Welding Amps to Metal Thickness Chart Welding Mastermind Steel Thickness Welding Chart How to choose the right welding rod size. Here is a chart that summarizes the mig welding amps according to the three most common types of metal and their thickness:. The calculator below pinpoints exactly which electrode you need for the metal you are welding. 10 rows estimates the range of mild steel thicknesses you can weld with each setting. Steel Thickness Welding Chart.

From haydenowen.z21.web.core.windows.net

Welding Amps To Metal Thickness Chart Steel Thickness Welding Chart You set the amperage according to the thickness of the metal. A general rule of thumb is you need 1 amp of power for. Find below the mig welding sheet metal settings chart which displays the recommended settings for welding different gauge thicknesses of sheet metal. Here is a chart that summarizes the mig welding amps according to the three. Steel Thickness Welding Chart.

From classschoolziegler.z19.web.core.windows.net

Thickness Welding Rod Sizes Chart Steel Thickness Welding Chart Find below the mig welding sheet metal settings chart which displays the recommended settings for welding different gauge thicknesses of sheet metal. Welding rod sizes sizes & material thickness chart (mild steel) contents. Therefore, you have to know how thick your metal is. You set the amperage according to the thickness of the metal. E6010 and e6011 size and amperage. Steel Thickness Welding Chart.

From www.metafab.com

Sheet Metal Material Thickness Guide Meta Fab, Inc. Steel Thickness Welding Chart Welding rod sizes and base metal thickness chart. You will also get the required polarity, position, and other related information. Welding rod sizes sizes & material thickness chart (mild steel) contents. How to choose the right welding rod size. The calculator below pinpoints exactly which electrode you need for the metal you are welding. 10 rows estimates the range of. Steel Thickness Welding Chart.

From lucaswoods.z21.web.core.windows.net

Welding Amps Metal Thickness Chart Steel Thickness Welding Chart The primary factor when choosing the size of a welding rod is the thickness of the base metal that’s going to be welded. The calculator below pinpoints exactly which electrode you need for the metal you are welding. E6010 and e6011 size and amperage chart. Therefore, you have to know how thick your metal is. How to choose the right. Steel Thickness Welding Chart.

From weldguru.com

How to Weld Stainless Steel A Complete Guide Steel Thickness Welding Chart How to choose the right welding rod size. You set the amperage according to the thickness of the metal. 10 rows estimates the range of mild steel thicknesses you can weld with each setting on your mig welder. Welding rod sizes and base metal thickness chart. Welding rod sizes sizes & material thickness chart (mild steel) contents. E6010 and e6011. Steel Thickness Welding Chart.

From mavink.com

Welding Thickness Chart Steel Thickness Welding Chart E6010 and e6011 size and amperage chart. The primary factor when choosing the size of a welding rod is the thickness of the base metal that’s going to be welded. Here is a chart that summarizes the mig welding amps according to the three most common types of metal and their thickness:. You set the amperage according to the thickness. Steel Thickness Welding Chart.

From weaversteelweld.com

Pipe Size Chart Weaver Steel Welding Steel Thickness Welding Chart 10 rows estimates the range of mild steel thicknesses you can weld with each setting on your mig welder. Here is a chart that summarizes the mig welding amps according to the three most common types of metal and their thickness:. How to choose the right welding rod size. Welding rod sizes sizes & material thickness chart (mild steel) contents.. Steel Thickness Welding Chart.

From app.aws.org

MIG settings for welding different thickness mild steel Steel Thickness Welding Chart E6010 and e6011 size and amperage chart. You will also get the required polarity, position, and other related information. Find below the mig welding sheet metal settings chart which displays the recommended settings for welding different gauge thicknesses of sheet metal. 10 rows estimates the range of mild steel thicknesses you can weld with each setting on your mig welder.. Steel Thickness Welding Chart.

From weldguru.com

Best Gas for MIG Welding What to Use (with Chart) Steel Thickness Welding Chart You will also get the required polarity, position, and other related information. Welding rod sizes and base metal thickness chart. E6010 and e6011 size and amperage chart. A general rule of thumb is you need 1 amp of power for. Here is a chart that summarizes the mig welding amps according to the three most common types of metal and. Steel Thickness Welding Chart.

From maker-hub.georgefox.edu

MIG Welder makerhub Steel Thickness Welding Chart You will also get the required polarity, position, and other related information. How to choose the right welding rod size. A general rule of thumb is you need 1 amp of power for. Welding rod sizes and base metal thickness chart. The calculator below pinpoints exactly which electrode you need for the metal you are welding. Therefore, you have to. Steel Thickness Welding Chart.

From revivalportal.goodwood.com

Tig Welding Amps To Metal Thickness Chart Steel Thickness Welding Chart The primary factor when choosing the size of a welding rod is the thickness of the base metal that’s going to be welded. E6010 and e6011 size and amperage chart. How to choose the right welding rod size. You set the amperage according to the thickness of the metal. The calculator below pinpoints exactly which electrode you need for the. Steel Thickness Welding Chart.

From lessonzoneoster.z19.web.core.windows.net

Mig Welding Chart Settings And Guides Steel Thickness Welding Chart Therefore, you have to know how thick your metal is. E6010 and e6011 size and amperage chart. Welding rod sizes sizes & material thickness chart (mild steel) contents. Here is a chart that summarizes the mig welding amps according to the three most common types of metal and their thickness:. The primary factor when choosing the size of a welding. Steel Thickness Welding Chart.

From mollypickering.z19.web.core.windows.net

Metal Thickness Stick Welding Amperage Chart Steel Thickness Welding Chart You set the amperage according to the thickness of the metal. Here is a chart that summarizes the mig welding amps according to the three most common types of metal and their thickness:. The calculator below pinpoints exactly which electrode you need for the metal you are welding. E6010 and e6011 size and amperage chart. Welding rod sizes and base. Steel Thickness Welding Chart.

From shop.aionzones.com

Steel Thickness Chart Sheet Metal Tools, Welding Classes,, 58 OFF Steel Thickness Welding Chart Welding rod sizes sizes & material thickness chart (mild steel) contents. Find below the mig welding sheet metal settings chart which displays the recommended settings for welding different gauge thicknesses of sheet metal. Therefore, you have to know how thick your metal is. Here is a chart that summarizes the mig welding amps according to the three most common types. Steel Thickness Welding Chart.