Cylinder Sleeve Measurement . precisely decide the measure of obstruction, you require two measurements: measure your piston at the skirt to properly bore the sleeved cylinder to the correct bore size. Studs, bolts, manifolds, power valves, etc. To accurately determine the amount of interference, you need two dimensions: generally, the most popular wall thickness sleeve is 3/32. The cylinder must be stripped of all removable parts: To ensure safe operation, the gauge point must be at least 0.250˝ or more above the bottom of the sleeve so it will completely capture the piston and prevent rocking. installing a sleeve can save a block that would otherwise be unrebuildable. The normal outside breadth (od) of the sleeves, and the normal inside width (id) of the bores in the square. you must calculate half the stroke length, rod and gauge point to see if it will accommodate your needs. This size allows oversize bores, while maintaining the strength of. The average outside diameter (od) of. But sleeves can also be used to.

from automotiveenginemechanics.tpub.com

The normal outside breadth (od) of the sleeves, and the normal inside width (id) of the bores in the square. The average outside diameter (od) of. you must calculate half the stroke length, rod and gauge point to see if it will accommodate your needs. precisely decide the measure of obstruction, you require two measurements: This size allows oversize bores, while maintaining the strength of. But sleeves can also be used to. installing a sleeve can save a block that would otherwise be unrebuildable. Studs, bolts, manifolds, power valves, etc. The cylinder must be stripped of all removable parts: To accurately determine the amount of interference, you need two dimensions:

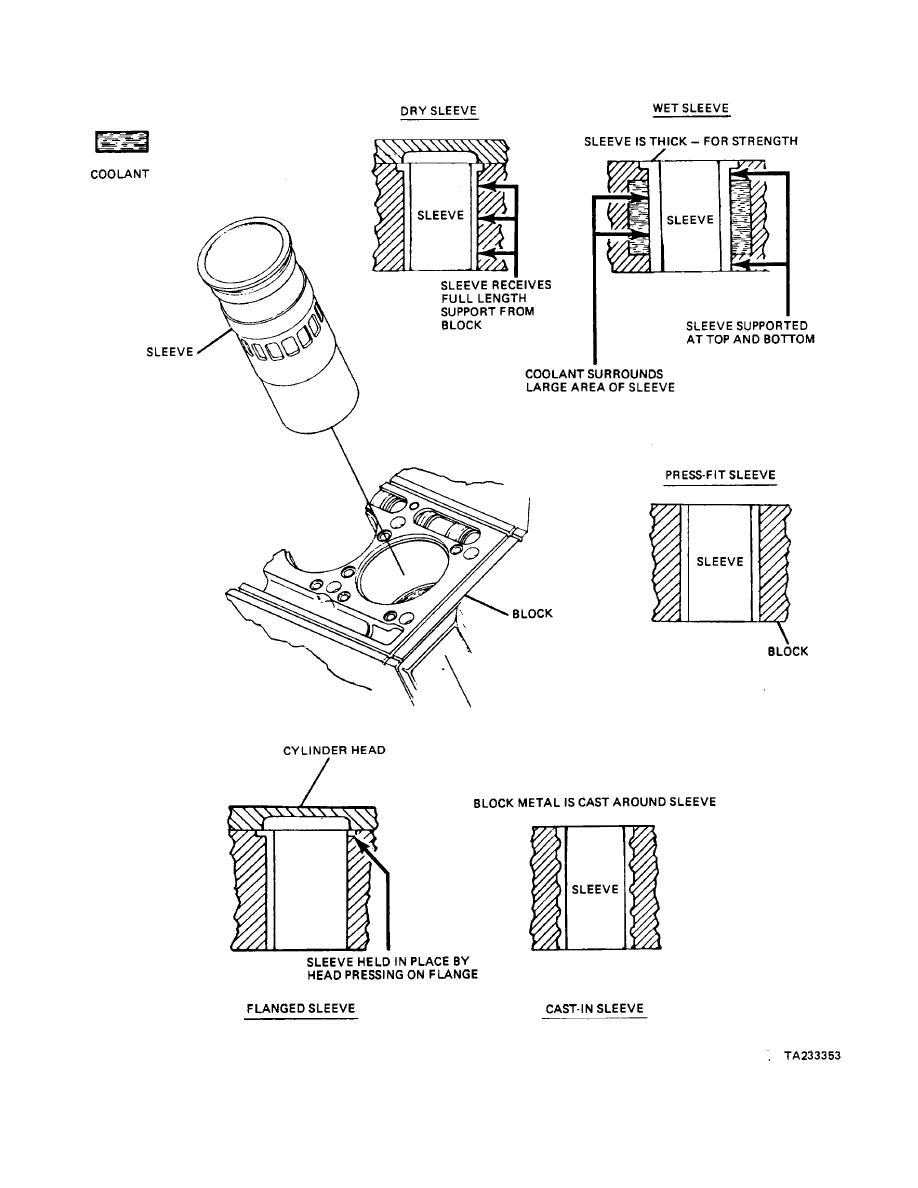

Figure 33. Cylinder Sleeves.

Cylinder Sleeve Measurement Studs, bolts, manifolds, power valves, etc. installing a sleeve can save a block that would otherwise be unrebuildable. But sleeves can also be used to. precisely decide the measure of obstruction, you require two measurements: The average outside diameter (od) of. To accurately determine the amount of interference, you need two dimensions: The cylinder must be stripped of all removable parts: you must calculate half the stroke length, rod and gauge point to see if it will accommodate your needs. To ensure safe operation, the gauge point must be at least 0.250˝ or more above the bottom of the sleeve so it will completely capture the piston and prevent rocking. Studs, bolts, manifolds, power valves, etc. The normal outside breadth (od) of the sleeves, and the normal inside width (id) of the bores in the square. measure your piston at the skirt to properly bore the sleeved cylinder to the correct bore size. generally, the most popular wall thickness sleeve is 3/32. This size allows oversize bores, while maintaining the strength of.

From www.slideserve.com

PPT Cylinder Sleeves Manufacturing, Fit and Finish PowerPoint Cylinder Sleeve Measurement But sleeves can also be used to. To accurately determine the amount of interference, you need two dimensions: generally, the most popular wall thickness sleeve is 3/32. measure your piston at the skirt to properly bore the sleeved cylinder to the correct bore size. This size allows oversize bores, while maintaining the strength of. precisely decide the. Cylinder Sleeve Measurement.

From www.powersportsid.com

L.A. Sleeve® Cylinder Sleeve Cylinder Sleeve Measurement This size allows oversize bores, while maintaining the strength of. But sleeves can also be used to. you must calculate half the stroke length, rod and gauge point to see if it will accommodate your needs. The cylinder must be stripped of all removable parts: To accurately determine the amount of interference, you need two dimensions: The average outside. Cylinder Sleeve Measurement.

From www.enginelabs.com

Melling Introduces Updated Cylinder Sleeve Catalog Cylinder Sleeve Measurement measure your piston at the skirt to properly bore the sleeved cylinder to the correct bore size. To accurately determine the amount of interference, you need two dimensions: The cylinder must be stripped of all removable parts: generally, the most popular wall thickness sleeve is 3/32. precisely decide the measure of obstruction, you require two measurements: . Cylinder Sleeve Measurement.

From capitalremanexchange.com

Mack E7 Cylinder Liner Protrusion Installation Tips Capital Reman Cylinder Sleeve Measurement But sleeves can also be used to. generally, the most popular wall thickness sleeve is 3/32. The cylinder must be stripped of all removable parts: The normal outside breadth (od) of the sleeves, and the normal inside width (id) of the bores in the square. you must calculate half the stroke length, rod and gauge point to see. Cylinder Sleeve Measurement.

From www.comingsooncars.com

Basic Guidelines You need Know About Cylinder Sleeves Coming Soon Cars Cylinder Sleeve Measurement To ensure safe operation, the gauge point must be at least 0.250˝ or more above the bottom of the sleeve so it will completely capture the piston and prevent rocking. installing a sleeve can save a block that would otherwise be unrebuildable. The cylinder must be stripped of all removable parts: generally, the most popular wall thickness sleeve. Cylinder Sleeve Measurement.

From www.slideshare.net

Best Installation Tips for Cylinder Sleeves Cylinder Sleeve Measurement you must calculate half the stroke length, rod and gauge point to see if it will accommodate your needs. The cylinder must be stripped of all removable parts: measure your piston at the skirt to properly bore the sleeved cylinder to the correct bore size. To ensure safe operation, the gauge point must be at least 0.250˝ or. Cylinder Sleeve Measurement.

From medium.com

StepbyStep Guide On How Cylinder Sleeves Are Installed by Cylinder Sleeve Measurement This size allows oversize bores, while maintaining the strength of. you must calculate half the stroke length, rod and gauge point to see if it will accommodate your needs. The cylinder must be stripped of all removable parts: generally, the most popular wall thickness sleeve is 3/32. measure your piston at the skirt to properly bore the. Cylinder Sleeve Measurement.

From spareto.com

021 WN 05 00 Cylinder Sleeve Spareto Cylinder Sleeve Measurement precisely decide the measure of obstruction, you require two measurements: you must calculate half the stroke length, rod and gauge point to see if it will accommodate your needs. measure your piston at the skirt to properly bore the sleeved cylinder to the correct bore size. The cylinder must be stripped of all removable parts: The normal. Cylinder Sleeve Measurement.

From maritime-engineering.blogspot.com

How to Measure Cylinder Liner Bore Wear on ship? Around the World Cylinder Sleeve Measurement you must calculate half the stroke length, rod and gauge point to see if it will accommodate your needs. generally, the most popular wall thickness sleeve is 3/32. The normal outside breadth (od) of the sleeves, and the normal inside width (id) of the bores in the square. The cylinder must be stripped of all removable parts: The. Cylinder Sleeve Measurement.

From www.powersportsid.com

L.A. Sleeve® Cylinder Sleeve Cylinder Sleeve Measurement The average outside diameter (od) of. The normal outside breadth (od) of the sleeves, and the normal inside width (id) of the bores in the square. But sleeves can also be used to. installing a sleeve can save a block that would otherwise be unrebuildable. you must calculate half the stroke length, rod and gauge point to see. Cylinder Sleeve Measurement.

From carsnauto.com

Different Types Of High Performance Cylinder Sleeves, And How To Take Cylinder Sleeve Measurement The cylinder must be stripped of all removable parts: precisely decide the measure of obstruction, you require two measurements: The average outside diameter (od) of. generally, the most popular wall thickness sleeve is 3/32. To ensure safe operation, the gauge point must be at least 0.250˝ or more above the bottom of the sleeve so it will completely. Cylinder Sleeve Measurement.

From www.youtube.com

Engine Block Cylinder sleeve/How To Install Engine Cylinder Sleeve Cylinder Sleeve Measurement Studs, bolts, manifolds, power valves, etc. precisely decide the measure of obstruction, you require two measurements: This size allows oversize bores, while maintaining the strength of. you must calculate half the stroke length, rod and gauge point to see if it will accommodate your needs. measure your piston at the skirt to properly bore the sleeved cylinder. Cylinder Sleeve Measurement.

From dieselgenerators.tpub.com

Figure 103. Measuring outof8quare relationship of cylinder sleeve Cylinder Sleeve Measurement But sleeves can also be used to. To accurately determine the amount of interference, you need two dimensions: The average outside diameter (od) of. This size allows oversize bores, while maintaining the strength of. Studs, bolts, manifolds, power valves, etc. To ensure safe operation, the gauge point must be at least 0.250˝ or more above the bottom of the sleeve. Cylinder Sleeve Measurement.

From www.powersportsid.com

L.A. Sleeve® Cylinder Sleeve Cylinder Sleeve Measurement To ensure safe operation, the gauge point must be at least 0.250˝ or more above the bottom of the sleeve so it will completely capture the piston and prevent rocking. The average outside diameter (od) of. Studs, bolts, manifolds, power valves, etc. To accurately determine the amount of interference, you need two dimensions: precisely decide the measure of obstruction,. Cylinder Sleeve Measurement.

From www.slideserve.com

PPT Cylinder Sleeves Manufacturers – A Complete Guide of Production Cylinder Sleeve Measurement To accurately determine the amount of interference, you need two dimensions: generally, the most popular wall thickness sleeve is 3/32. The normal outside breadth (od) of the sleeves, and the normal inside width (id) of the bores in the square. This size allows oversize bores, while maintaining the strength of. you must calculate half the stroke length, rod. Cylinder Sleeve Measurement.

From constructionmanuals.tpub.com

Figure 34.Cylinder sleeves. Cylinder Sleeve Measurement The normal outside breadth (od) of the sleeves, and the normal inside width (id) of the bores in the square. Studs, bolts, manifolds, power valves, etc. To accurately determine the amount of interference, you need two dimensions: installing a sleeve can save a block that would otherwise be unrebuildable. precisely decide the measure of obstruction, you require two. Cylinder Sleeve Measurement.

From www.artofit.org

How to do cylinder sleeves installation Artofit Cylinder Sleeve Measurement measure your piston at the skirt to properly bore the sleeved cylinder to the correct bore size. This size allows oversize bores, while maintaining the strength of. To accurately determine the amount of interference, you need two dimensions: To ensure safe operation, the gauge point must be at least 0.250˝ or more above the bottom of the sleeve so. Cylinder Sleeve Measurement.

From www.slideshare.net

How to install cylinder sleeves Cylinder Sleeve Measurement The normal outside breadth (od) of the sleeves, and the normal inside width (id) of the bores in the square. measure your piston at the skirt to properly bore the sleeved cylinder to the correct bore size. generally, the most popular wall thickness sleeve is 3/32. To accurately determine the amount of interference, you need two dimensions: Studs,. Cylinder Sleeve Measurement.

From www.slideserve.com

PPT Process and Preparation of Cylinder Sleeves Manufacturing Cylinder Sleeve Measurement installing a sleeve can save a block that would otherwise be unrebuildable. To ensure safe operation, the gauge point must be at least 0.250˝ or more above the bottom of the sleeve so it will completely capture the piston and prevent rocking. The normal outside breadth (od) of the sleeves, and the normal inside width (id) of the bores. Cylinder Sleeve Measurement.

From kiwiindian.com

Cylinder Sleeve Standard Kiwi Indian Cylinder Sleeve Measurement The normal outside breadth (od) of the sleeves, and the normal inside width (id) of the bores in the square. To accurately determine the amount of interference, you need two dimensions: The cylinder must be stripped of all removable parts: To ensure safe operation, the gauge point must be at least 0.250˝ or more above the bottom of the sleeve. Cylinder Sleeve Measurement.

From dannysengineportal.com

Cylinder Sleeve How To Install A Cylinder Sleeve To Save A Block Cylinder Sleeve Measurement The cylinder must be stripped of all removable parts: installing a sleeve can save a block that would otherwise be unrebuildable. This size allows oversize bores, while maintaining the strength of. precisely decide the measure of obstruction, you require two measurements: The average outside diameter (od) of. measure your piston at the skirt to properly bore the. Cylinder Sleeve Measurement.

From www.pinterest.com

How Cylinder Sleeves are Used in Other Industrial Components Cylinder Sleeve Measurement But sleeves can also be used to. To ensure safe operation, the gauge point must be at least 0.250˝ or more above the bottom of the sleeve so it will completely capture the piston and prevent rocking. installing a sleeve can save a block that would otherwise be unrebuildable. The average outside diameter (od) of. The cylinder must be. Cylinder Sleeve Measurement.

From issuu.com

Why Are Cylinder Sleeves Used and Why to Sleeve Cylinders? by Jai Shah Cylinder Sleeve Measurement The normal outside breadth (od) of the sleeves, and the normal inside width (id) of the bores in the square. The cylinder must be stripped of all removable parts: measure your piston at the skirt to properly bore the sleeved cylinder to the correct bore size. This size allows oversize bores, while maintaining the strength of. To accurately determine. Cylinder Sleeve Measurement.

From www.thlmachine.com

cylinder Liner/Sleeve_Guide/Seat/Sleeve_Engine Rebuilding Tools Cylinder Sleeve Measurement To ensure safe operation, the gauge point must be at least 0.250˝ or more above the bottom of the sleeve so it will completely capture the piston and prevent rocking. installing a sleeve can save a block that would otherwise be unrebuildable. The cylinder must be stripped of all removable parts: To accurately determine the amount of interference, you. Cylinder Sleeve Measurement.

From www.youtube.com

Measuring piston protrusion With a dial gauge and measurement bridge Cylinder Sleeve Measurement measure your piston at the skirt to properly bore the sleeved cylinder to the correct bore size. The average outside diameter (od) of. installing a sleeve can save a block that would otherwise be unrebuildable. The normal outside breadth (od) of the sleeves, and the normal inside width (id) of the bores in the square. This size allows. Cylinder Sleeve Measurement.

From www.youtube.com

CYLINDER SLEEVE INSTALLATION PROCEDURE YouTube Cylinder Sleeve Measurement The cylinder must be stripped of all removable parts: To ensure safe operation, the gauge point must be at least 0.250˝ or more above the bottom of the sleeve so it will completely capture the piston and prevent rocking. generally, the most popular wall thickness sleeve is 3/32. This size allows oversize bores, while maintaining the strength of. . Cylinder Sleeve Measurement.

From www.mellingcylindersleeves.com

Cylinder Sleeves Melling Cylinder Sleeve Measurement you must calculate half the stroke length, rod and gauge point to see if it will accommodate your needs. This size allows oversize bores, while maintaining the strength of. measure your piston at the skirt to properly bore the sleeved cylinder to the correct bore size. But sleeves can also be used to. To ensure safe operation, the. Cylinder Sleeve Measurement.

From www.slideserve.com

PPT Importance of Cylinder Sleeves in Manufacturing Process Cylinder Sleeve Measurement To ensure safe operation, the gauge point must be at least 0.250˝ or more above the bottom of the sleeve so it will completely capture the piston and prevent rocking. The normal outside breadth (od) of the sleeves, and the normal inside width (id) of the bores in the square. To accurately determine the amount of interference, you need two. Cylinder Sleeve Measurement.

From themechanicalengineering.com

Cylinder Liner Definition, Function, Types, Material [Notes & PDF] Cylinder Sleeve Measurement This size allows oversize bores, while maintaining the strength of. To ensure safe operation, the gauge point must be at least 0.250˝ or more above the bottom of the sleeve so it will completely capture the piston and prevent rocking. precisely decide the measure of obstruction, you require two measurements: installing a sleeve can save a block that. Cylinder Sleeve Measurement.

From www.youtube.com

How to Cylinder Liner/Sleeve Installation with No Budget YouTube Cylinder Sleeve Measurement The average outside diameter (od) of. But sleeves can also be used to. measure your piston at the skirt to properly bore the sleeved cylinder to the correct bore size. you must calculate half the stroke length, rod and gauge point to see if it will accommodate your needs. The normal outside breadth (od) of the sleeves, and. Cylinder Sleeve Measurement.

From automotiveenginemechanics.tpub.com

Figure 33. Cylinder Sleeves. Cylinder Sleeve Measurement The normal outside breadth (od) of the sleeves, and the normal inside width (id) of the bores in the square. The average outside diameter (od) of. To accurately determine the amount of interference, you need two dimensions: generally, the most popular wall thickness sleeve is 3/32. measure your piston at the skirt to properly bore the sleeved cylinder. Cylinder Sleeve Measurement.

From www.mtceng.com

Cylinder Sleeves MTC Engineering Cylinder Sleeve Measurement To accurately determine the amount of interference, you need two dimensions: precisely decide the measure of obstruction, you require two measurements: The average outside diameter (od) of. installing a sleeve can save a block that would otherwise be unrebuildable. measure your piston at the skirt to properly bore the sleeved cylinder to the correct bore size. The. Cylinder Sleeve Measurement.

From www.pinterest.com

How To Do Cylinder Sleeves Installation? Cylinder, Cylinder liner Cylinder Sleeve Measurement installing a sleeve can save a block that would otherwise be unrebuildable. This size allows oversize bores, while maintaining the strength of. To ensure safe operation, the gauge point must be at least 0.250˝ or more above the bottom of the sleeve so it will completely capture the piston and prevent rocking. generally, the most popular wall thickness. Cylinder Sleeve Measurement.

From www.viralsolos.com

Installation Tips for Cylinder Sleeves Viral Solos Cylinder Sleeve Measurement To accurately determine the amount of interference, you need two dimensions: To ensure safe operation, the gauge point must be at least 0.250˝ or more above the bottom of the sleeve so it will completely capture the piston and prevent rocking. precisely decide the measure of obstruction, you require two measurements: generally, the most popular wall thickness sleeve. Cylinder Sleeve Measurement.

From www.youtube.com

What is cylinder liner/sleeve in an engine How does affect engine Cylinder Sleeve Measurement But sleeves can also be used to. Studs, bolts, manifolds, power valves, etc. The normal outside breadth (od) of the sleeves, and the normal inside width (id) of the bores in the square. To ensure safe operation, the gauge point must be at least 0.250˝ or more above the bottom of the sleeve so it will completely capture the piston. Cylinder Sleeve Measurement.