Solder Flux Helps . flux aids in soldering and desoldering processes by removing oxide films which form on the surface of metals being soldered. the soldering flux is a chemical substance that helps and facilitates the soldering process, while having a protective effect and preventing oxidation reactions. It achieves this by removing impurities from the surface and preventing them from interfering with the bond between it and the solder. The activators in the flux promote wetting of the molten solder to the surface mount lands and component terminations or leads by removing oxides and other surface contaminants. Flux operates by targeting the oxide barrier that naturally forms on metal surfaces, thus promoting superior wetting by the molten solder — a crucial factor for effective solder adhesion and distribution. Although it can remove oxides, sandpaper does not prevent reoxidation and is not a soldering flux. solder flux is a substance that helps clean and forms a strong bond between parts of the electronics or wires. But many materials can prevent reoxidation as well as removing initial oxides. flux can be defined as any material that removes oxides and prevents formation of new oxides until solder can be applied. solder flux is necessary in most soldering applications in electronics. use of flux helps purifying metal surfaces, allowing for the creation of durable and consistent solder joints. Some of those materials can be. The main purpose of solder flux is to clean the.

from dxoofswss.blob.core.windows.net

The activators in the flux promote wetting of the molten solder to the surface mount lands and component terminations or leads by removing oxides and other surface contaminants. It achieves this by removing impurities from the surface and preventing them from interfering with the bond between it and the solder. the soldering flux is a chemical substance that helps and facilitates the soldering process, while having a protective effect and preventing oxidation reactions. Some of those materials can be. solder flux is necessary in most soldering applications in electronics. Flux operates by targeting the oxide barrier that naturally forms on metal surfaces, thus promoting superior wetting by the molten solder — a crucial factor for effective solder adhesion and distribution. Although it can remove oxides, sandpaper does not prevent reoxidation and is not a soldering flux. But many materials can prevent reoxidation as well as removing initial oxides. The main purpose of solder flux is to clean the. flux aids in soldering and desoldering processes by removing oxide films which form on the surface of metals being soldered.

What Can You Use As Soldering Flux at Caroline McLaughlin blog

Solder Flux Helps But many materials can prevent reoxidation as well as removing initial oxides. But many materials can prevent reoxidation as well as removing initial oxides. solder flux is a substance that helps clean and forms a strong bond between parts of the electronics or wires. flux aids in soldering and desoldering processes by removing oxide films which form on the surface of metals being soldered. Although it can remove oxides, sandpaper does not prevent reoxidation and is not a soldering flux. The main purpose of solder flux is to clean the. Some of those materials can be. It achieves this by removing impurities from the surface and preventing them from interfering with the bond between it and the solder. solder flux is necessary in most soldering applications in electronics. The activators in the flux promote wetting of the molten solder to the surface mount lands and component terminations or leads by removing oxides and other surface contaminants. use of flux helps purifying metal surfaces, allowing for the creation of durable and consistent solder joints. flux can be defined as any material that removes oxides and prevents formation of new oxides until solder can be applied. Flux operates by targeting the oxide barrier that naturally forms on metal surfaces, thus promoting superior wetting by the molten solder — a crucial factor for effective solder adhesion and distribution. the soldering flux is a chemical substance that helps and facilitates the soldering process, while having a protective effect and preventing oxidation reactions.

From dxolznkfs.blob.core.windows.net

Flux Soldering at Cynthia Tower blog Solder Flux Helps Although it can remove oxides, sandpaper does not prevent reoxidation and is not a soldering flux. Some of those materials can be. It achieves this by removing impurities from the surface and preventing them from interfering with the bond between it and the solder. solder flux is a substance that helps clean and forms a strong bond between parts. Solder Flux Helps.

From www.aliexpress.com

(1.76oz/50g) Solid Rosin Paste Solder Flux 50g Welding Rosin Soldering Solder Flux Helps the soldering flux is a chemical substance that helps and facilitates the soldering process, while having a protective effect and preventing oxidation reactions. flux can be defined as any material that removes oxides and prevents formation of new oxides until solder can be applied. Some of those materials can be. It achieves this by removing impurities from the. Solder Flux Helps.

From soldersandfluxes.co.uk

Solders & Fluxes About Us Soldering product in convenient sizes Solder Flux Helps The main purpose of solder flux is to clean the. The activators in the flux promote wetting of the molten solder to the surface mount lands and component terminations or leads by removing oxides and other surface contaminants. use of flux helps purifying metal surfaces, allowing for the creation of durable and consistent solder joints. But many materials can. Solder Flux Helps.

From agdop.weebly.com

Solder flux agdop Solder Flux Helps the soldering flux is a chemical substance that helps and facilitates the soldering process, while having a protective effect and preventing oxidation reactions. But many materials can prevent reoxidation as well as removing initial oxides. flux aids in soldering and desoldering processes by removing oxide films which form on the surface of metals being soldered. solder flux. Solder Flux Helps.

From www.superengineer.net

Soldering Flux Solder Flux Helps Some of those materials can be. Although it can remove oxides, sandpaper does not prevent reoxidation and is not a soldering flux. solder flux is a substance that helps clean and forms a strong bond between parts of the electronics or wires. flux can be defined as any material that removes oxides and prevents formation of new oxides. Solder Flux Helps.

From handtoolsforfun.com

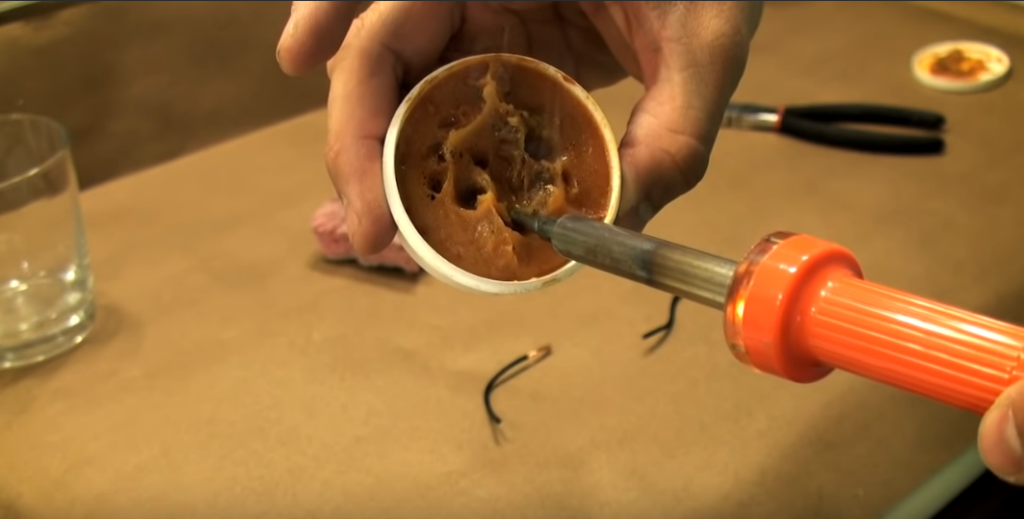

How to Use Solder Flux Hand Tools for Fun Solder Flux Helps Flux operates by targeting the oxide barrier that naturally forms on metal surfaces, thus promoting superior wetting by the molten solder — a crucial factor for effective solder adhesion and distribution. The activators in the flux promote wetting of the molten solder to the surface mount lands and component terminations or leads by removing oxides and other surface contaminants. . Solder Flux Helps.

From hackaday.com

What The Flux How Does Solder Work Anyway? Hackaday Solder Flux Helps It achieves this by removing impurities from the surface and preventing them from interfering with the bond between it and the solder. solder flux is a substance that helps clean and forms a strong bond between parts of the electronics or wires. The activators in the flux promote wetting of the molten solder to the surface mount lands and. Solder Flux Helps.

From www.desertcart.lk

Buy I.AMWelding Fluxes KSS S800 10CC Solder paste Flux soldering Solder Flux Helps Some of those materials can be. flux can be defined as any material that removes oxides and prevents formation of new oxides until solder can be applied. The activators in the flux promote wetting of the molten solder to the surface mount lands and component terminations or leads by removing oxides and other surface contaminants. Although it can remove. Solder Flux Helps.

From www.sciencepurchase.com

Soldering Flux Paste, 50 Gram Jar, RoHS Compliant, Helps Solder Flow S Solder Flux Helps use of flux helps purifying metal surfaces, allowing for the creation of durable and consistent solder joints. flux can be defined as any material that removes oxides and prevents formation of new oxides until solder can be applied. The activators in the flux promote wetting of the molten solder to the surface mount lands and component terminations or. Solder Flux Helps.

From dxoofswss.blob.core.windows.net

What Can You Use As Soldering Flux at Caroline McLaughlin blog Solder Flux Helps The main purpose of solder flux is to clean the. Flux operates by targeting the oxide barrier that naturally forms on metal surfaces, thus promoting superior wetting by the molten solder — a crucial factor for effective solder adhesion and distribution. flux aids in soldering and desoldering processes by removing oxide films which form on the surface of metals. Solder Flux Helps.

From www.youtube.com

What is Solder Flux and How to Use It YouTube Solder Flux Helps It achieves this by removing impurities from the surface and preventing them from interfering with the bond between it and the solder. use of flux helps purifying metal surfaces, allowing for the creation of durable and consistent solder joints. the soldering flux is a chemical substance that helps and facilitates the soldering process, while having a protective effect. Solder Flux Helps.

From solderingironguide.com

How to Use Flux When Soldering Electronics For Beginners Solder Flux Helps solder flux is a substance that helps clean and forms a strong bond between parts of the electronics or wires. flux can be defined as any material that removes oxides and prevents formation of new oxides until solder can be applied. But many materials can prevent reoxidation as well as removing initial oxides. use of flux helps. Solder Flux Helps.

From shopee.com.my

POP Stainless Steel Flux, Quick Repair 30ml 80ml Clean Free Soldering Solder Flux Helps use of flux helps purifying metal surfaces, allowing for the creation of durable and consistent solder joints. Although it can remove oxides, sandpaper does not prevent reoxidation and is not a soldering flux. solder flux is a substance that helps clean and forms a strong bond between parts of the electronics or wires. the soldering flux is. Solder Flux Helps.

From soldersandfluxes.co.uk

Solder Flux Solders & Fluxes Specialist Flux for Soldering Solder Flux Helps the soldering flux is a chemical substance that helps and facilitates the soldering process, while having a protective effect and preventing oxidation reactions. Some of those materials can be. Although it can remove oxides, sandpaper does not prevent reoxidation and is not a soldering flux. flux can be defined as any material that removes oxides and prevents formation. Solder Flux Helps.

From blog.thepipingmart.com

Soldering Copper Pipe Flux A Complete Guide Solder Flux Helps Flux operates by targeting the oxide barrier that naturally forms on metal surfaces, thus promoting superior wetting by the molten solder — a crucial factor for effective solder adhesion and distribution. solder flux is a substance that helps clean and forms a strong bond between parts of the electronics or wires. It achieves this by removing impurities from the. Solder Flux Helps.

From www.makeuseof.com

What Is Solder Flux and How Do You Use It? Solder Flux Helps The activators in the flux promote wetting of the molten solder to the surface mount lands and component terminations or leads by removing oxides and other surface contaminants. flux can be defined as any material that removes oxides and prevents formation of new oxides until solder can be applied. the soldering flux is a chemical substance that helps. Solder Flux Helps.

From www.youtube.com

What is Solder Flux? Soldering Basics YouTube Solder Flux Helps Flux operates by targeting the oxide barrier that naturally forms on metal surfaces, thus promoting superior wetting by the molten solder — a crucial factor for effective solder adhesion and distribution. solder flux is a substance that helps clean and forms a strong bond between parts of the electronics or wires. It achieves this by removing impurities from the. Solder Flux Helps.

From www.wikihow.com

Simple Ways to Use Soldering Flux (with Pictures) wikiHow Solder Flux Helps flux can be defined as any material that removes oxides and prevents formation of new oxides until solder can be applied. Some of those materials can be. solder flux is necessary in most soldering applications in electronics. Flux operates by targeting the oxide barrier that naturally forms on metal surfaces, thus promoting superior wetting by the molten solder. Solder Flux Helps.

From blog.thepipingmart.com

How to Use Flux When Soldering Copper Pipe Solder Flux Helps the soldering flux is a chemical substance that helps and facilitates the soldering process, while having a protective effect and preventing oxidation reactions. solder flux is a substance that helps clean and forms a strong bond between parts of the electronics or wires. Some of those materials can be. use of flux helps purifying metal surfaces, allowing. Solder Flux Helps.

From www.aliexpress.com

MCN UV50 Solder Paste Flux Soldering Tin Flux Electric Soldering Iron Solder Flux Helps Although it can remove oxides, sandpaper does not prevent reoxidation and is not a soldering flux. Some of those materials can be. solder flux is necessary in most soldering applications in electronics. use of flux helps purifying metal surfaces, allowing for the creation of durable and consistent solder joints. The activators in the flux promote wetting of the. Solder Flux Helps.

From www.electronicsandyou.com

Solder Flux Solder Flux Helps solder flux is necessary in most soldering applications in electronics. Although it can remove oxides, sandpaper does not prevent reoxidation and is not a soldering flux. solder flux is a substance that helps clean and forms a strong bond between parts of the electronics or wires. Flux operates by targeting the oxide barrier that naturally forms on metal. Solder Flux Helps.

From www.go-system.co.uk

Lead Free Solder & Flux Kit GoSystems Go Systems Solder Flux Helps Flux operates by targeting the oxide barrier that naturally forms on metal surfaces, thus promoting superior wetting by the molten solder — a crucial factor for effective solder adhesion and distribution. solder flux is necessary in most soldering applications in electronics. solder flux is a substance that helps clean and forms a strong bond between parts of the. Solder Flux Helps.

From bytesclick.blogspot.com

19 What Flux To Use For Soldering BytesClick Solder Flux Helps The activators in the flux promote wetting of the molten solder to the surface mount lands and component terminations or leads by removing oxides and other surface contaminants. Some of those materials can be. flux aids in soldering and desoldering processes by removing oxide films which form on the surface of metals being soldered. solder flux is necessary. Solder Flux Helps.

From saowannepoole.blogspot.com

cara menggunakan flux pada solder Anne Poole Solder Flux Helps solder flux is a substance that helps clean and forms a strong bond between parts of the electronics or wires. It achieves this by removing impurities from the surface and preventing them from interfering with the bond between it and the solder. Flux operates by targeting the oxide barrier that naturally forms on metal surfaces, thus promoting superior wetting. Solder Flux Helps.

From www.conro.com

What is soldering flux? ConRo Electronics Solder Flux Helps use of flux helps purifying metal surfaces, allowing for the creation of durable and consistent solder joints. Flux operates by targeting the oxide barrier that naturally forms on metal surfaces, thus promoting superior wetting by the molten solder — a crucial factor for effective solder adhesion and distribution. But many materials can prevent reoxidation as well as removing initial. Solder Flux Helps.

From handtoolsforfun.com

How to Use Solder Flux Hand Tools for Fun Solder Flux Helps Although it can remove oxides, sandpaper does not prevent reoxidation and is not a soldering flux. use of flux helps purifying metal surfaces, allowing for the creation of durable and consistent solder joints. It achieves this by removing impurities from the surface and preventing them from interfering with the bond between it and the solder. solder flux is. Solder Flux Helps.

From electronicshacks.com

Flux vs. Solder Paste What’s the Difference? ElectronicsHacks Solder Flux Helps Some of those materials can be. The main purpose of solder flux is to clean the. solder flux is necessary in most soldering applications in electronics. But many materials can prevent reoxidation as well as removing initial oxides. the soldering flux is a chemical substance that helps and facilitates the soldering process, while having a protective effect and. Solder Flux Helps.

From www.sciencepurchase.com

Soldering Flux Paste, 50 Gram Jar, RoHS Compliant, Helps Solder Flow S Solder Flux Helps But many materials can prevent reoxidation as well as removing initial oxides. The main purpose of solder flux is to clean the. It achieves this by removing impurities from the surface and preventing them from interfering with the bond between it and the solder. Although it can remove oxides, sandpaper does not prevent reoxidation and is not a soldering flux.. Solder Flux Helps.

From www.lifewire.com

Types of Solder Flux Solder Flux Helps But many materials can prevent reoxidation as well as removing initial oxides. Although it can remove oxides, sandpaper does not prevent reoxidation and is not a soldering flux. The main purpose of solder flux is to clean the. The activators in the flux promote wetting of the molten solder to the surface mount lands and component terminations or leads by. Solder Flux Helps.

From dccwiki.com

Solder and Flux for DCC Applications Solder Flux Helps flux aids in soldering and desoldering processes by removing oxide films which form on the surface of metals being soldered. flux can be defined as any material that removes oxides and prevents formation of new oxides until solder can be applied. The main purpose of solder flux is to clean the. solder flux is necessary in most. Solder Flux Helps.

From blog.thepipingmart.com

Brazing Flux vs Soldering Flux What's the Difference Solder Flux Helps But many materials can prevent reoxidation as well as removing initial oxides. flux aids in soldering and desoldering processes by removing oxide films which form on the surface of metals being soldered. The main purpose of solder flux is to clean the. the soldering flux is a chemical substance that helps and facilitates the soldering process, while having. Solder Flux Helps.

From www.chemtronicseu.com

Choosing The Best Flux for High Quality Electronic Soldering Chemtronics Solder Flux Helps flux can be defined as any material that removes oxides and prevents formation of new oxides until solder can be applied. use of flux helps purifying metal surfaces, allowing for the creation of durable and consistent solder joints. The main purpose of solder flux is to clean the. solder flux is a substance that helps clean and. Solder Flux Helps.

From citizenside.com

Types of Solder Flux CitizenSide Solder Flux Helps solder flux is necessary in most soldering applications in electronics. the soldering flux is a chemical substance that helps and facilitates the soldering process, while having a protective effect and preventing oxidation reactions. The main purpose of solder flux is to clean the. Although it can remove oxides, sandpaper does not prevent reoxidation and is not a soldering. Solder Flux Helps.

From www.protoexpress.com

A Practical Guide to Soldering Flux Sierra Circuits Solder Flux Helps solder flux is a substance that helps clean and forms a strong bond between parts of the electronics or wires. But many materials can prevent reoxidation as well as removing initial oxides. The activators in the flux promote wetting of the molten solder to the surface mount lands and component terminations or leads by removing oxides and other surface. Solder Flux Helps.

From shopee.sg

Green solder paste helps the soldering paste rosin flux welding Solder Flux Helps The main purpose of solder flux is to clean the. Some of those materials can be. solder flux is a substance that helps clean and forms a strong bond between parts of the electronics or wires. flux aids in soldering and desoldering processes by removing oxide films which form on the surface of metals being soldered. The activators. Solder Flux Helps.