Types Of Machining Finishes . Each of these parameters can be classified in terms of the geometrical shape of the surface. bead blasting adds a uniform matte or satin surface finish to a machined part, which removes the tool marks. From the coolant used to the width and depth of a cut, every process of. there are three parameters that distinguish a surface finish lay, roughness, and waviness. if you are a machinist or an engineer these charts will help you choose the best lathe settings to get the desired. machining surface finishes are greatly influenced by the manufacturing process used. Anodizing is a surface finishing process. surface finishes like sanding, polishing, electroplating, or painting help conceal sharp edges and machining. several factors influence the type of surface finish ideal for a part, including the tool used in machining,. It works by bombarding your part with. Which is created when a tooling form and/or material, such as abrasive grains, impacts the surface of a workpiece. Enhancing surface durability and appearance.

from technofaq.org

Each of these parameters can be classified in terms of the geometrical shape of the surface. Enhancing surface durability and appearance. machining surface finishes are greatly influenced by the manufacturing process used. if you are a machinist or an engineer these charts will help you choose the best lathe settings to get the desired. several factors influence the type of surface finish ideal for a part, including the tool used in machining,. Anodizing is a surface finishing process. From the coolant used to the width and depth of a cut, every process of. bead blasting adds a uniform matte or satin surface finish to a machined part, which removes the tool marks. there are three parameters that distinguish a surface finish lay, roughness, and waviness. surface finishes like sanding, polishing, electroplating, or painting help conceal sharp edges and machining.

9 Common Surface Finishes In Metal CNC Machining Techno FAQ

Types Of Machining Finishes several factors influence the type of surface finish ideal for a part, including the tool used in machining,. machining surface finishes are greatly influenced by the manufacturing process used. From the coolant used to the width and depth of a cut, every process of. Enhancing surface durability and appearance. Which is created when a tooling form and/or material, such as abrasive grains, impacts the surface of a workpiece. Anodizing is a surface finishing process. if you are a machinist or an engineer these charts will help you choose the best lathe settings to get the desired. surface finishes like sanding, polishing, electroplating, or painting help conceal sharp edges and machining. Each of these parameters can be classified in terms of the geometrical shape of the surface. It works by bombarding your part with. there are three parameters that distinguish a surface finish lay, roughness, and waviness. several factors influence the type of surface finish ideal for a part, including the tool used in machining,. bead blasting adds a uniform matte or satin surface finish to a machined part, which removes the tool marks.

From www.hubs.com

What are the types of surface finishes for CNC machining? Hubs Types Of Machining Finishes machining surface finishes are greatly influenced by the manufacturing process used. if you are a machinist or an engineer these charts will help you choose the best lathe settings to get the desired. several factors influence the type of surface finish ideal for a part, including the tool used in machining,. Enhancing surface durability and appearance. Each. Types Of Machining Finishes.

From lghfhissbh.blogspot.com

Thalia Decker Types Of Machining Finishes Anodizing is a surface finishing process. Enhancing surface durability and appearance. bead blasting adds a uniform matte or satin surface finish to a machined part, which removes the tool marks. if you are a machinist or an engineer these charts will help you choose the best lathe settings to get the desired. machining surface finishes are greatly. Types Of Machining Finishes.

From www.youtube.com

MACHINING SYMBOL AND SURFACE TEXTURE YouTube Types Of Machining Finishes there are three parameters that distinguish a surface finish lay, roughness, and waviness. several factors influence the type of surface finish ideal for a part, including the tool used in machining,. machining surface finishes are greatly influenced by the manufacturing process used. From the coolant used to the width and depth of a cut, every process of.. Types Of Machining Finishes.

From www.slideserve.com

PPT Surface Finish PowerPoint Presentation, free download ID3866407 Types Of Machining Finishes Each of these parameters can be classified in terms of the geometrical shape of the surface. surface finishes like sanding, polishing, electroplating, or painting help conceal sharp edges and machining. Which is created when a tooling form and/or material, such as abrasive grains, impacts the surface of a workpiece. Anodizing is a surface finishing process. there are three. Types Of Machining Finishes.

From www.slideserve.com

PPT Surface Finish PowerPoint Presentation, free download ID3866407 Types Of Machining Finishes bead blasting adds a uniform matte or satin surface finish to a machined part, which removes the tool marks. Which is created when a tooling form and/or material, such as abrasive grains, impacts the surface of a workpiece. there are three parameters that distinguish a surface finish lay, roughness, and waviness. It works by bombarding your part with.. Types Of Machining Finishes.

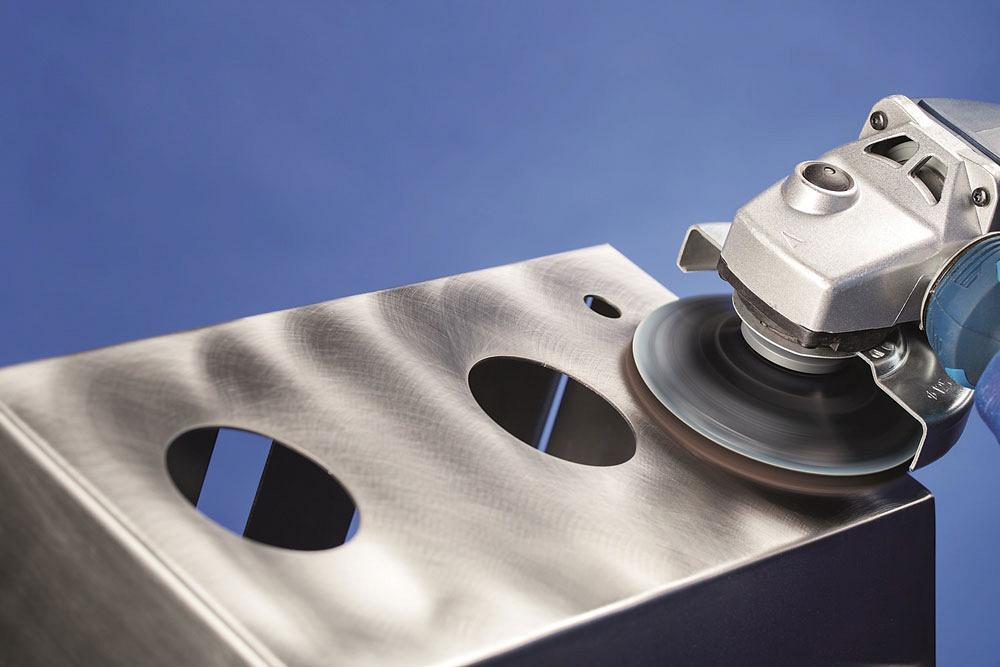

From www.thefabricator.com

The basics of metal surface finishes The Fabricator Types Of Machining Finishes Enhancing surface durability and appearance. if you are a machinist or an engineer these charts will help you choose the best lathe settings to get the desired. From the coolant used to the width and depth of a cut, every process of. several factors influence the type of surface finish ideal for a part, including the tool used. Types Of Machining Finishes.

From www.pinterest.com

Pin on Engineering Types Of Machining Finishes there are three parameters that distinguish a surface finish lay, roughness, and waviness. surface finishes like sanding, polishing, electroplating, or painting help conceal sharp edges and machining. Which is created when a tooling form and/or material, such as abrasive grains, impacts the surface of a workpiece. From the coolant used to the width and depth of a cut,. Types Of Machining Finishes.

From ermelindamccutcheon.blogspot.com

machining surface finish grades Ermelinda Mccutcheon Types Of Machining Finishes machining surface finishes are greatly influenced by the manufacturing process used. Enhancing surface durability and appearance. several factors influence the type of surface finish ideal for a part, including the tool used in machining,. Which is created when a tooling form and/or material, such as abrasive grains, impacts the surface of a workpiece. if you are a. Types Of Machining Finishes.

From moseys.com

Machining Surface Finish Chart & Specifications Moseys Production Machinists Types Of Machining Finishes Each of these parameters can be classified in terms of the geometrical shape of the surface. Enhancing surface durability and appearance. several factors influence the type of surface finish ideal for a part, including the tool used in machining,. Which is created when a tooling form and/or material, such as abrasive grains, impacts the surface of a workpiece. . Types Of Machining Finishes.

From www.scribd.com

Surface Finish Machinng Chart PDF PDF Surface Roughness Machining Types Of Machining Finishes bead blasting adds a uniform matte or satin surface finish to a machined part, which removes the tool marks. Each of these parameters can be classified in terms of the geometrical shape of the surface. From the coolant used to the width and depth of a cut, every process of. machining surface finishes are greatly influenced by the. Types Of Machining Finishes.

From www.thefabricator.com

The basics of metal surface finishes Types Of Machining Finishes machining surface finishes are greatly influenced by the manufacturing process used. Enhancing surface durability and appearance. there are three parameters that distinguish a surface finish lay, roughness, and waviness. Each of these parameters can be classified in terms of the geometrical shape of the surface. bead blasting adds a uniform matte or satin surface finish to a. Types Of Machining Finishes.

From www.thefabricator.com

Three ways to achieve a specific metal finish Types Of Machining Finishes Enhancing surface durability and appearance. there are three parameters that distinguish a surface finish lay, roughness, and waviness. surface finishes like sanding, polishing, electroplating, or painting help conceal sharp edges and machining. Anodizing is a surface finishing process. Which is created when a tooling form and/or material, such as abrasive grains, impacts the surface of a workpiece. From. Types Of Machining Finishes.

From www.rapiddirect.com

How to Get the Best CNC Machining Surface Finish RapidDirect Blog Types Of Machining Finishes surface finishes like sanding, polishing, electroplating, or painting help conceal sharp edges and machining. From the coolant used to the width and depth of a cut, every process of. there are three parameters that distinguish a surface finish lay, roughness, and waviness. bead blasting adds a uniform matte or satin surface finish to a machined part, which. Types Of Machining Finishes.

From yasminallen.z13.web.core.windows.net

Machining Surface Finish Chart Types Of Machining Finishes there are three parameters that distinguish a surface finish lay, roughness, and waviness. machining surface finishes are greatly influenced by the manufacturing process used. Enhancing surface durability and appearance. bead blasting adds a uniform matte or satin surface finish to a machined part, which removes the tool marks. It works by bombarding your part with. Which is. Types Of Machining Finishes.

From truesourcesoftware.com

5 Different Forms of CNC Machining Finishes Types Of Machining Finishes several factors influence the type of surface finish ideal for a part, including the tool used in machining,. surface finishes like sanding, polishing, electroplating, or painting help conceal sharp edges and machining. bead blasting adds a uniform matte or satin surface finish to a machined part, which removes the tool marks. It works by bombarding your part. Types Of Machining Finishes.

From www.gdandtbasics.com

The Basics of Surface Finish GD&T Basics Types Of Machining Finishes machining surface finishes are greatly influenced by the manufacturing process used. Anodizing is a surface finishing process. bead blasting adds a uniform matte or satin surface finish to a machined part, which removes the tool marks. Each of these parameters can be classified in terms of the geometrical shape of the surface. It works by bombarding your part. Types Of Machining Finishes.

From precisionmachiningpro.com

Exploring Types of CNC Machining Surface Finishes Types Of Machining Finishes bead blasting adds a uniform matte or satin surface finish to a machined part, which removes the tool marks. Each of these parameters can be classified in terms of the geometrical shape of the surface. Enhancing surface durability and appearance. surface finishes like sanding, polishing, electroplating, or painting help conceal sharp edges and machining. machining surface finishes. Types Of Machining Finishes.

From xometry.eu

Selecting right surface roughness for CNC machining Xometry Europe Types Of Machining Finishes It works by bombarding your part with. Enhancing surface durability and appearance. Each of these parameters can be classified in terms of the geometrical shape of the surface. surface finishes like sanding, polishing, electroplating, or painting help conceal sharp edges and machining. if you are a machinist or an engineer these charts will help you choose the best. Types Of Machining Finishes.

From www.cnclathing.com

CNC Machining Surface Finishes Introductions CNC Surface Roughness, Texture Topology & Finishing Types Of Machining Finishes surface finishes like sanding, polishing, electroplating, or painting help conceal sharp edges and machining. Which is created when a tooling form and/or material, such as abrasive grains, impacts the surface of a workpiece. bead blasting adds a uniform matte or satin surface finish to a machined part, which removes the tool marks. Enhancing surface durability and appearance. Each. Types Of Machining Finishes.

From machiningtoday.com

Top 7 Types of Aluminum Finishes MachiningToday Types Of Machining Finishes several factors influence the type of surface finish ideal for a part, including the tool used in machining,. Which is created when a tooling form and/or material, such as abrasive grains, impacts the surface of a workpiece. if you are a machinist or an engineer these charts will help you choose the best lathe settings to get the. Types Of Machining Finishes.

From aronness.blogspot.com

machining surface finish symbols triangle Aron Ness Types Of Machining Finishes bead blasting adds a uniform matte or satin surface finish to a machined part, which removes the tool marks. It works by bombarding your part with. surface finishes like sanding, polishing, electroplating, or painting help conceal sharp edges and machining. Which is created when a tooling form and/or material, such as abrasive grains, impacts the surface of a. Types Of Machining Finishes.

From www.americanmicroinc.com

Surface Finishes for CNC Machining American Micro Industries Types Of Machining Finishes It works by bombarding your part with. several factors influence the type of surface finish ideal for a part, including the tool used in machining,. Enhancing surface durability and appearance. surface finishes like sanding, polishing, electroplating, or painting help conceal sharp edges and machining. Anodizing is a surface finishing process. if you are a machinist or an. Types Of Machining Finishes.

From cncnow.com

How to Do CNC Machining Surface Finish? CNCNOW Types Of Machining Finishes Enhancing surface durability and appearance. Anodizing is a surface finishing process. several factors influence the type of surface finish ideal for a part, including the tool used in machining,. machining surface finishes are greatly influenced by the manufacturing process used. bead blasting adds a uniform matte or satin surface finish to a machined part, which removes the. Types Of Machining Finishes.

From mavink.com

Machining Surface Finish Symbols Chart Types Of Machining Finishes bead blasting adds a uniform matte or satin surface finish to a machined part, which removes the tool marks. Anodizing is a surface finishing process. machining surface finishes are greatly influenced by the manufacturing process used. From the coolant used to the width and depth of a cut, every process of. several factors influence the type of. Types Of Machining Finishes.

From www.rapiddirect.com

Types of Machining Process Classifications and Differences Types Of Machining Finishes It works by bombarding your part with. Which is created when a tooling form and/or material, such as abrasive grains, impacts the surface of a workpiece. surface finishes like sanding, polishing, electroplating, or painting help conceal sharp edges and machining. bead blasting adds a uniform matte or satin surface finish to a machined part, which removes the tool. Types Of Machining Finishes.

From www.mechanicalfunda.com

5 Types of Surface Finishes in CNC Machining Types Of Machining Finishes It works by bombarding your part with. Enhancing surface durability and appearance. Anodizing is a surface finishing process. From the coolant used to the width and depth of a cut, every process of. surface finishes like sanding, polishing, electroplating, or painting help conceal sharp edges and machining. Each of these parameters can be classified in terms of the geometrical. Types Of Machining Finishes.

From www.rymachining.com

What are the types of surface finishes for CNC machining? And What are the benefits of the Types Of Machining Finishes Each of these parameters can be classified in terms of the geometrical shape of the surface. surface finishes like sanding, polishing, electroplating, or painting help conceal sharp edges and machining. Enhancing surface durability and appearance. if you are a machinist or an engineer these charts will help you choose the best lathe settings to get the desired. Anodizing. Types Of Machining Finishes.

From www.rapiddirect.com

Types of Machining Process Classifications and Differences Types Of Machining Finishes surface finishes like sanding, polishing, electroplating, or painting help conceal sharp edges and machining. if you are a machinist or an engineer these charts will help you choose the best lathe settings to get the desired. From the coolant used to the width and depth of a cut, every process of. It works by bombarding your part with.. Types Of Machining Finishes.

From www.iron-foundry.com

Machining surface finish chart, conversion, comparator, method, degree, Ra, Rz, RMS Types Of Machining Finishes Each of these parameters can be classified in terms of the geometrical shape of the surface. From the coolant used to the width and depth of a cut, every process of. Enhancing surface durability and appearance. there are three parameters that distinguish a surface finish lay, roughness, and waviness. machining surface finishes are greatly influenced by the manufacturing. Types Of Machining Finishes.

From ermelindamccutcheon.blogspot.com

machining surface finish grades Ermelinda Mccutcheon Types Of Machining Finishes Anodizing is a surface finishing process. if you are a machinist or an engineer these charts will help you choose the best lathe settings to get the desired. several factors influence the type of surface finish ideal for a part, including the tool used in machining,. surface finishes like sanding, polishing, electroplating, or painting help conceal sharp. Types Of Machining Finishes.

From www.vrogue.co

Machining Surface Finish Chart Comparator Method Degr vrogue.co Types Of Machining Finishes machining surface finishes are greatly influenced by the manufacturing process used. Enhancing surface durability and appearance. Anodizing is a surface finishing process. Which is created when a tooling form and/or material, such as abrasive grains, impacts the surface of a workpiece. bead blasting adds a uniform matte or satin surface finish to a machined part, which removes the. Types Of Machining Finishes.

From technofaq.org

9 Common Surface Finishes In Metal CNC Machining Techno FAQ Types Of Machining Finishes several factors influence the type of surface finish ideal for a part, including the tool used in machining,. if you are a machinist or an engineer these charts will help you choose the best lathe settings to get the desired. From the coolant used to the width and depth of a cut, every process of. Anodizing is a. Types Of Machining Finishes.

From edmontonrealestateinvestmentblog.com

Surface Roughness Chart Understanding Surface Finishes RapidDirect (2023) Types Of Machining Finishes Each of these parameters can be classified in terms of the geometrical shape of the surface. From the coolant used to the width and depth of a cut, every process of. if you are a machinist or an engineer these charts will help you choose the best lathe settings to get the desired. Enhancing surface durability and appearance. It. Types Of Machining Finishes.

From www.violintec.com

Rough Machining And Finish Machining Know The Difference Types Of Machining Finishes Enhancing surface durability and appearance. bead blasting adds a uniform matte or satin surface finish to a machined part, which removes the tool marks. there are three parameters that distinguish a surface finish lay, roughness, and waviness. several factors influence the type of surface finish ideal for a part, including the tool used in machining,. Which is. Types Of Machining Finishes.

From www.slideserve.com

PPT Metal Machining PowerPoint Presentation, free download ID2292716 Types Of Machining Finishes if you are a machinist or an engineer these charts will help you choose the best lathe settings to get the desired. bead blasting adds a uniform matte or satin surface finish to a machined part, which removes the tool marks. From the coolant used to the width and depth of a cut, every process of. Which is. Types Of Machining Finishes.