Plasma Cutting Kerf Width . The kerf widths were obtained with the “best quality” settings. to achieve the best cut quality in terms of kerf width, the lowest amperage should be selected that allows for a complete cut of any given thickness of a. When cutting parts on a cnc plasma or laser machine, you want to produce accurate cut parts, with final dimensions as close as possible to the programmed shape. This material is wasted, so you need to follow the plasma kerf chart for the cut metal and thickness. It is the result of material removal during the cutting process. cutting kerf is the width of a cut. why kerf width is important. how to measure and compensate for kerf width when cnc. So if you program a 6” by 6” square, and the plasma arc removes 0.200” of material, as it cuts, then the resulting part is going to be 5.8” by 5.8”. Almost all cutting mechanisms leave a. When plasma cutting, the arc creates a cut gap (kerf) where the material is expelled. kerf compensation protects your cut piece from becoming a part of the kerf width that’s wasted in the process.

from parts-badger.com

Almost all cutting mechanisms leave a. When plasma cutting, the arc creates a cut gap (kerf) where the material is expelled. why kerf width is important. It is the result of material removal during the cutting process. kerf compensation protects your cut piece from becoming a part of the kerf width that’s wasted in the process. how to measure and compensate for kerf width when cnc. The kerf widths were obtained with the “best quality” settings. This material is wasted, so you need to follow the plasma kerf chart for the cut metal and thickness. cutting kerf is the width of a cut. to achieve the best cut quality in terms of kerf width, the lowest amperage should be selected that allows for a complete cut of any given thickness of a.

What is Kerf? Parts Badger Your Online Machine Shop

Plasma Cutting Kerf Width kerf compensation protects your cut piece from becoming a part of the kerf width that’s wasted in the process. why kerf width is important. The kerf widths were obtained with the “best quality” settings. When plasma cutting, the arc creates a cut gap (kerf) where the material is expelled. When cutting parts on a cnc plasma or laser machine, you want to produce accurate cut parts, with final dimensions as close as possible to the programmed shape. Almost all cutting mechanisms leave a. cutting kerf is the width of a cut. kerf compensation protects your cut piece from becoming a part of the kerf width that’s wasted in the process. This material is wasted, so you need to follow the plasma kerf chart for the cut metal and thickness. So if you program a 6” by 6” square, and the plasma arc removes 0.200” of material, as it cuts, then the resulting part is going to be 5.8” by 5.8”. how to measure and compensate for kerf width when cnc. to achieve the best cut quality in terms of kerf width, the lowest amperage should be selected that allows for a complete cut of any given thickness of a. It is the result of material removal during the cutting process.

From dxoanhiyt.blob.core.windows.net

Plasma Cutting Kerf at Betty Campbell blog Plasma Cutting Kerf Width how to measure and compensate for kerf width when cnc. to achieve the best cut quality in terms of kerf width, the lowest amperage should be selected that allows for a complete cut of any given thickness of a. why kerf width is important. This material is wasted, so you need to follow the plasma kerf chart. Plasma Cutting Kerf Width.

From forum.langmuirsystems.com

Cut charts for everlast plasma 9 by hunterthehobbyist Plasma Cutters Langmuir Systems Forum Plasma Cutting Kerf Width why kerf width is important. cutting kerf is the width of a cut. how to measure and compensate for kerf width when cnc. So if you program a 6” by 6” square, and the plasma arc removes 0.200” of material, as it cuts, then the resulting part is going to be 5.8” by 5.8”. When cutting parts. Plasma Cutting Kerf Width.

From www.avidcnc.com

1. Design Plasma First Cut Instructions Plasma Cutting Kerf Width So if you program a 6” by 6” square, and the plasma arc removes 0.200” of material, as it cuts, then the resulting part is going to be 5.8” by 5.8”. It is the result of material removal during the cutting process. how to measure and compensate for kerf width when cnc. Almost all cutting mechanisms leave a. . Plasma Cutting Kerf Width.

From www.hgg-group.com

How to Compensate for Plasma Beam? HGG Profiling Specialist Plasma Cutting Kerf Width This material is wasted, so you need to follow the plasma kerf chart for the cut metal and thickness. how to measure and compensate for kerf width when cnc. When plasma cutting, the arc creates a cut gap (kerf) where the material is expelled. So if you program a 6” by 6” square, and the plasma arc removes 0.200”. Plasma Cutting Kerf Width.

From cenhachb.blob.core.windows.net

Cutting Aluminum With Plasma Table at Vickie King blog Plasma Cutting Kerf Width why kerf width is important. So if you program a 6” by 6” square, and the plasma arc removes 0.200” of material, as it cuts, then the resulting part is going to be 5.8” by 5.8”. to achieve the best cut quality in terms of kerf width, the lowest amperage should be selected that allows for a complete. Plasma Cutting Kerf Width.

From www.machinery.co.uk

Kerf launches entrylevel Plasmaster 3015 plasma cutter Plasma Cutting Kerf Width Almost all cutting mechanisms leave a. When cutting parts on a cnc plasma or laser machine, you want to produce accurate cut parts, with final dimensions as close as possible to the programmed shape. kerf compensation protects your cut piece from becoming a part of the kerf width that’s wasted in the process. So if you program a 6”. Plasma Cutting Kerf Width.

From vdocuments.site

Modelling of Kerf Width in Plasma Jet Metal Cutting [PDF Document] Plasma Cutting Kerf Width The kerf widths were obtained with the “best quality” settings. Almost all cutting mechanisms leave a. how to measure and compensate for kerf width when cnc. cutting kerf is the width of a cut. kerf compensation protects your cut piece from becoming a part of the kerf width that’s wasted in the process. When cutting parts on. Plasma Cutting Kerf Width.

From www.machinery.co.uk

Kerf launches entrylevel Plasmaster 3015 plasma cutter Plasma Cutting Kerf Width Almost all cutting mechanisms leave a. So if you program a 6” by 6” square, and the plasma arc removes 0.200” of material, as it cuts, then the resulting part is going to be 5.8” by 5.8”. to achieve the best cut quality in terms of kerf width, the lowest amperage should be selected that allows for a complete. Plasma Cutting Kerf Width.

From www.machinery.co.uk

Kerf's new CombiCut combines gas and plasma cutting in one machine Plasma Cutting Kerf Width Almost all cutting mechanisms leave a. how to measure and compensate for kerf width when cnc. kerf compensation protects your cut piece from becoming a part of the kerf width that’s wasted in the process. So if you program a 6” by 6” square, and the plasma arc removes 0.200” of material, as it cuts, then the resulting. Plasma Cutting Kerf Width.

From www.finepart.com

Kerf Definition Kerf Width, Waterjet Kerf Angle Finepart Plasma Cutting Kerf Width The kerf widths were obtained with the “best quality” settings. It is the result of material removal during the cutting process. When plasma cutting, the arc creates a cut gap (kerf) where the material is expelled. So if you program a 6” by 6” square, and the plasma arc removes 0.200” of material, as it cuts, then the resulting part. Plasma Cutting Kerf Width.

From parts-badger.com

What is Kerf? Parts Badger Your Online Machine Shop Plasma Cutting Kerf Width It is the result of material removal during the cutting process. The kerf widths were obtained with the “best quality” settings. why kerf width is important. So if you program a 6” by 6” square, and the plasma arc removes 0.200” of material, as it cuts, then the resulting part is going to be 5.8” by 5.8”. how. Plasma Cutting Kerf Width.

From kerfdevelopments.com

The LincCut Profile Cutting Machine From Kerf Plasma Plasma Cutting Kerf Width kerf compensation protects your cut piece from becoming a part of the kerf width that’s wasted in the process. cutting kerf is the width of a cut. When plasma cutting, the arc creates a cut gap (kerf) where the material is expelled. why kerf width is important. to achieve the best cut quality in terms of. Plasma Cutting Kerf Width.

From djxpyllgeco.blob.core.windows.net

Plasma Cutter Kerf Width at Gregory Hagen blog Plasma Cutting Kerf Width When cutting parts on a cnc plasma or laser machine, you want to produce accurate cut parts, with final dimensions as close as possible to the programmed shape. cutting kerf is the width of a cut. how to measure and compensate for kerf width when cnc. why kerf width is important. It is the result of material. Plasma Cutting Kerf Width.

From www.hypertherm.com

Improve cut quality with these CNC steel and metal cutting tips Plasma Cutting Kerf Width When plasma cutting, the arc creates a cut gap (kerf) where the material is expelled. kerf compensation protects your cut piece from becoming a part of the kerf width that’s wasted in the process. The kerf widths were obtained with the “best quality” settings. Almost all cutting mechanisms leave a. It is the result of material removal during the. Plasma Cutting Kerf Width.

From dxoanhiyt.blob.core.windows.net

Plasma Cutting Kerf at Betty Campbell blog Plasma Cutting Kerf Width So if you program a 6” by 6” square, and the plasma arc removes 0.200” of material, as it cuts, then the resulting part is going to be 5.8” by 5.8”. When cutting parts on a cnc plasma or laser machine, you want to produce accurate cut parts, with final dimensions as close as possible to the programmed shape. . Plasma Cutting Kerf Width.

From www.slideserve.com

PPT Quality Of A Plasma Cutter PowerPoint Presentation, free download ID10884498 Plasma Cutting Kerf Width cutting kerf is the width of a cut. kerf compensation protects your cut piece from becoming a part of the kerf width that’s wasted in the process. how to measure and compensate for kerf width when cnc. to achieve the best cut quality in terms of kerf width, the lowest amperage should be selected that allows. Plasma Cutting Kerf Width.

From www.machinery.co.uk

Kerf's new CombiCut combines gas and plasma cutting in one machine Plasma Cutting Kerf Width cutting kerf is the width of a cut. why kerf width is important. how to measure and compensate for kerf width when cnc. to achieve the best cut quality in terms of kerf width, the lowest amperage should be selected that allows for a complete cut of any given thickness of a. kerf compensation protects. Plasma Cutting Kerf Width.

From www.researchgate.net

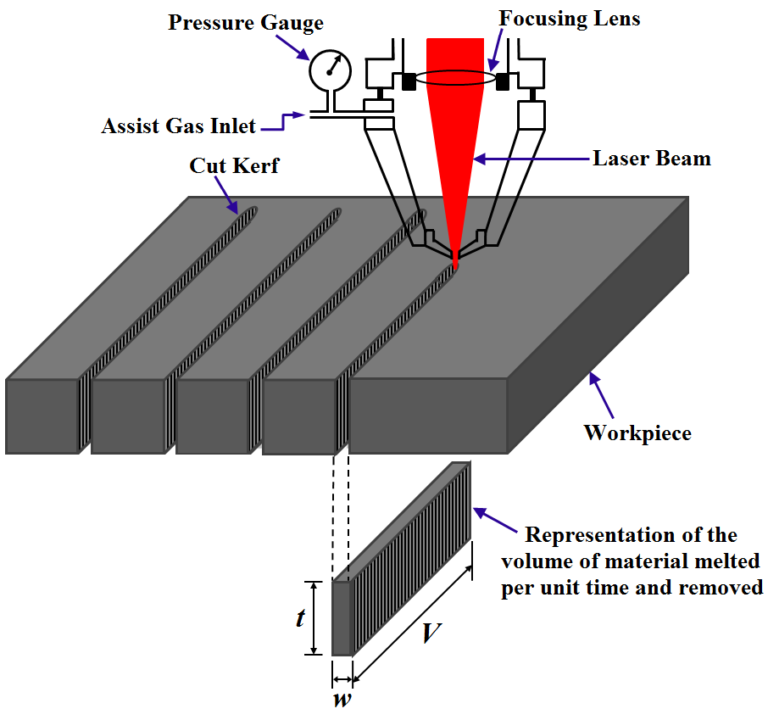

Schematic representation of kerf width and kerf taper Download Scientific Diagram Plasma Cutting Kerf Width It is the result of material removal during the cutting process. When cutting parts on a cnc plasma or laser machine, you want to produce accurate cut parts, with final dimensions as close as possible to the programmed shape. When plasma cutting, the arc creates a cut gap (kerf) where the material is expelled. This material is wasted, so you. Plasma Cutting Kerf Width.

From www.mdpi.com

Applied Sciences Free FullText Experimental Investigation of Industrial Laser Cutting The Plasma Cutting Kerf Width cutting kerf is the width of a cut. When plasma cutting, the arc creates a cut gap (kerf) where the material is expelled. The kerf widths were obtained with the “best quality” settings. This material is wasted, so you need to follow the plasma kerf chart for the cut metal and thickness. It is the result of material removal. Plasma Cutting Kerf Width.

From ceagwxyu.blob.core.windows.net

Plasma Cutter Kerf Width at Kevin Black blog Plasma Cutting Kerf Width When cutting parts on a cnc plasma or laser machine, you want to produce accurate cut parts, with final dimensions as close as possible to the programmed shape. The kerf widths were obtained with the “best quality” settings. It is the result of material removal during the cutting process. Almost all cutting mechanisms leave a. to achieve the best. Plasma Cutting Kerf Width.

From djxpyllgeco.blob.core.windows.net

Plasma Cutter Kerf Width at Gregory Hagen blog Plasma Cutting Kerf Width When plasma cutting, the arc creates a cut gap (kerf) where the material is expelled. It is the result of material removal during the cutting process. When cutting parts on a cnc plasma or laser machine, you want to produce accurate cut parts, with final dimensions as close as possible to the programmed shape. kerf compensation protects your cut. Plasma Cutting Kerf Width.

From www.researchgate.net

Schematic representation of laser cut kerf top kerf width,... Download Scientific Diagram Plasma Cutting Kerf Width It is the result of material removal during the cutting process. how to measure and compensate for kerf width when cnc. Almost all cutting mechanisms leave a. When plasma cutting, the arc creates a cut gap (kerf) where the material is expelled. to achieve the best cut quality in terms of kerf width, the lowest amperage should be. Plasma Cutting Kerf Width.

From kerfdevelopments.com

What Is HighDefinition Plasma Cutting? Kerf Developments Plasma Cutting Kerf Width When cutting parts on a cnc plasma or laser machine, you want to produce accurate cut parts, with final dimensions as close as possible to the programmed shape. to achieve the best cut quality in terms of kerf width, the lowest amperage should be selected that allows for a complete cut of any given thickness of a. cutting. Plasma Cutting Kerf Width.

From dxoanhiyt.blob.core.windows.net

Plasma Cutting Kerf at Betty Campbell blog Plasma Cutting Kerf Width kerf compensation protects your cut piece from becoming a part of the kerf width that’s wasted in the process. why kerf width is important. When cutting parts on a cnc plasma or laser machine, you want to produce accurate cut parts, with final dimensions as close as possible to the programmed shape. The kerf widths were obtained with. Plasma Cutting Kerf Width.

From forums.autodesk.com

Solved Plasma Cutter Kerf Width Has No Effect Autodesk Community Plasma Cutting Kerf Width why kerf width is important. The kerf widths were obtained with the “best quality” settings. to achieve the best cut quality in terms of kerf width, the lowest amperage should be selected that allows for a complete cut of any given thickness of a. So if you program a 6” by 6” square, and the plasma arc removes. Plasma Cutting Kerf Width.

From wiki.makeict.org

CNCPlasmaCutter MakeICT Wiki Plasma Cutting Kerf Width The kerf widths were obtained with the “best quality” settings. kerf compensation protects your cut piece from becoming a part of the kerf width that’s wasted in the process. This material is wasted, so you need to follow the plasma kerf chart for the cut metal and thickness. to achieve the best cut quality in terms of kerf. Plasma Cutting Kerf Width.

From www.youtube.com

How to Measure and Compensate for Kerf Width When CNC Plasma Cutting Eastwood YouTube Plasma Cutting Kerf Width kerf compensation protects your cut piece from becoming a part of the kerf width that’s wasted in the process. So if you program a 6” by 6” square, and the plasma arc removes 0.200” of material, as it cuts, then the resulting part is going to be 5.8” by 5.8”. Almost all cutting mechanisms leave a. why kerf. Plasma Cutting Kerf Width.

From www.thefabricator.com

A check list for a plasma cutting table retrofit The Fabricator Plasma Cutting Kerf Width kerf compensation protects your cut piece from becoming a part of the kerf width that’s wasted in the process. how to measure and compensate for kerf width when cnc. The kerf widths were obtained with the “best quality” settings. This material is wasted, so you need to follow the plasma kerf chart for the cut metal and thickness.. Plasma Cutting Kerf Width.

From www.machinery.co.uk

Kerf Developments Burny & Kaliburn plasma profiling machines Plasma Cutting Kerf Width So if you program a 6” by 6” square, and the plasma arc removes 0.200” of material, as it cuts, then the resulting part is going to be 5.8” by 5.8”. When plasma cutting, the arc creates a cut gap (kerf) where the material is expelled. how to measure and compensate for kerf width when cnc. kerf compensation. Plasma Cutting Kerf Width.

From www.researchgate.net

(PDF) Modelling of Kerf Width in Plasma Jet Metal Cutting Process using ANN Approach Plasma Cutting Kerf Width This material is wasted, so you need to follow the plasma kerf chart for the cut metal and thickness. When cutting parts on a cnc plasma or laser machine, you want to produce accurate cut parts, with final dimensions as close as possible to the programmed shape. why kerf width is important. kerf compensation protects your cut piece. Plasma Cutting Kerf Width.

From kerfdevelopments.com

Plasma Cutting Machines Kerf Developments Plasma Cutting Kerf Width why kerf width is important. When plasma cutting, the arc creates a cut gap (kerf) where the material is expelled. So if you program a 6” by 6” square, and the plasma arc removes 0.200” of material, as it cuts, then the resulting part is going to be 5.8” by 5.8”. When cutting parts on a cnc plasma or. Plasma Cutting Kerf Width.

From parts-badger.com

What is Kerf? Parts Badger Your Online Machine Shop Plasma Cutting Kerf Width So if you program a 6” by 6” square, and the plasma arc removes 0.200” of material, as it cuts, then the resulting part is going to be 5.8” by 5.8”. When plasma cutting, the arc creates a cut gap (kerf) where the material is expelled. Almost all cutting mechanisms leave a. It is the result of material removal during. Plasma Cutting Kerf Width.

From www.machinery.co.uk

Kerf launches entrylevel Plasmaster 3015 plasma cutter Plasma Cutting Kerf Width why kerf width is important. When cutting parts on a cnc plasma or laser machine, you want to produce accurate cut parts, with final dimensions as close as possible to the programmed shape. This material is wasted, so you need to follow the plasma kerf chart for the cut metal and thickness. cutting kerf is the width of. Plasma Cutting Kerf Width.

From djxpyllgeco.blob.core.windows.net

Plasma Cutter Kerf Width at Gregory Hagen blog Plasma Cutting Kerf Width So if you program a 6” by 6” square, and the plasma arc removes 0.200” of material, as it cuts, then the resulting part is going to be 5.8” by 5.8”. When cutting parts on a cnc plasma or laser machine, you want to produce accurate cut parts, with final dimensions as close as possible to the programmed shape. . Plasma Cutting Kerf Width.

From www.youtube.com

Kerf RUR 2500 Plasma profile cutting machine. NEW 2011 YouTube Plasma Cutting Kerf Width This material is wasted, so you need to follow the plasma kerf chart for the cut metal and thickness. It is the result of material removal during the cutting process. how to measure and compensate for kerf width when cnc. kerf compensation protects your cut piece from becoming a part of the kerf width that’s wasted in the. Plasma Cutting Kerf Width.