What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit . Use contouring toolpaths for removing burrs on flat surfaces and edges. a laser cut part can have a small burr on the backside. countersink tools are used to deburr the edges of drilled holes. This blog will go over what causes burrs to form, why removing them is so critical, and what deburring methods yield the best results. Flat sanding would remove this, leaving a sharp, burr. one of the final processing steps is deburring, which removes any burrs and sharp edges that affect an affected part's safety and functionality. the 5 most common ways of removing burrs and edges are vibratory finishing, barrel tumbling, manual deburring, thermal.

from www.chegg.com

a laser cut part can have a small burr on the backside. Use contouring toolpaths for removing burrs on flat surfaces and edges. countersink tools are used to deburr the edges of drilled holes. Flat sanding would remove this, leaving a sharp, burr. the 5 most common ways of removing burrs and edges are vibratory finishing, barrel tumbling, manual deburring, thermal. This blog will go over what causes burrs to form, why removing them is so critical, and what deburring methods yield the best results. one of the final processing steps is deburring, which removes any burrs and sharp edges that affect an affected part's safety and functionality.

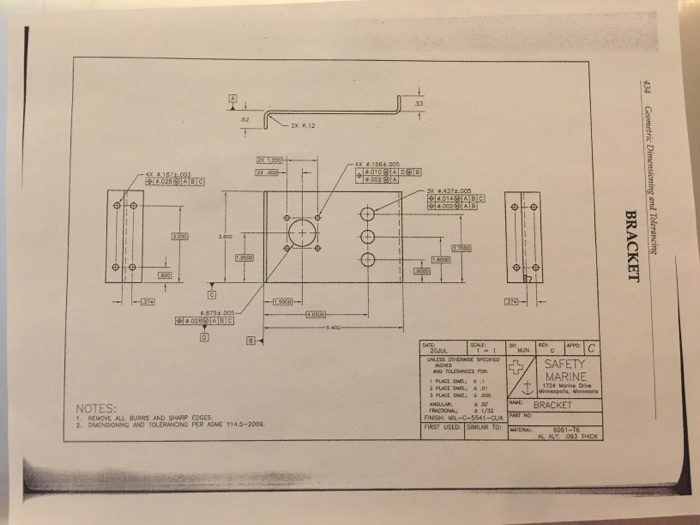

62 SAFETY MARINE NOTES BRACKET REMOVE ALL BURRS AND

What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit This blog will go over what causes burrs to form, why removing them is so critical, and what deburring methods yield the best results. This blog will go over what causes burrs to form, why removing them is so critical, and what deburring methods yield the best results. Flat sanding would remove this, leaving a sharp, burr. the 5 most common ways of removing burrs and edges are vibratory finishing, barrel tumbling, manual deburring, thermal. countersink tools are used to deburr the edges of drilled holes. a laser cut part can have a small burr on the backside. Use contouring toolpaths for removing burrs on flat surfaces and edges. one of the final processing steps is deburring, which removes any burrs and sharp edges that affect an affected part's safety and functionality.

From huanatools.com

A Comprehensive Guide on Carbide Burr Set Huana Tools What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit This blog will go over what causes burrs to form, why removing them is so critical, and what deburring methods yield the best results. Use contouring toolpaths for removing burrs on flat surfaces and edges. a laser cut part can have a small burr on the backside. one of the final processing steps is deburring, which removes any. What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit.

From latem.com

5 Ways to Remove Sharp Edges and Burrs from Metal Parts Latem Industries What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit the 5 most common ways of removing burrs and edges are vibratory finishing, barrel tumbling, manual deburring, thermal. Flat sanding would remove this, leaving a sharp, burr. a laser cut part can have a small burr on the backside. Use contouring toolpaths for removing burrs on flat surfaces and edges. This blog will go over what causes burrs. What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit.

From www.homewaremart.net

Rotary Burr 10mm Arc Sharp Pointed Nose Head Type Drill Bit Tool For Removal Of Burrs On Grinding What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit Use contouring toolpaths for removing burrs on flat surfaces and edges. one of the final processing steps is deburring, which removes any burrs and sharp edges that affect an affected part's safety and functionality. This blog will go over what causes burrs to form, why removing them is so critical, and what deburring methods yield the best results. . What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit.

From www.youtube.com

Burrs Removal YouTube What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit countersink tools are used to deburr the edges of drilled holes. the 5 most common ways of removing burrs and edges are vibratory finishing, barrel tumbling, manual deburring, thermal. Use contouring toolpaths for removing burrs on flat surfaces and edges. a laser cut part can have a small burr on the backside. This blog will go over. What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit.

From slideplayer.com

3 Chapter Basic Hand Tools. 3 Chapter Basic Hand Tools. ppt download What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit countersink tools are used to deburr the edges of drilled holes. one of the final processing steps is deburring, which removes any burrs and sharp edges that affect an affected part's safety and functionality. a laser cut part can have a small burr on the backside. Flat sanding would remove this, leaving a sharp, burr. the. What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit.

From industryinsider.eu

How To Remove Burrs and Sharp Edge On Precision Machining Parts Industry Insider The World What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit Use contouring toolpaths for removing burrs on flat surfaces and edges. a laser cut part can have a small burr on the backside. This blog will go over what causes burrs to form, why removing them is so critical, and what deburring methods yield the best results. the 5 most common ways of removing burrs and edges are. What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit.

From www.youtube.com

Quick burr removal tool YouTube What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit a laser cut part can have a small burr on the backside. the 5 most common ways of removing burrs and edges are vibratory finishing, barrel tumbling, manual deburring, thermal. one of the final processing steps is deburring, which removes any burrs and sharp edges that affect an affected part's safety and functionality. Use contouring toolpaths for. What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit.

From www.machinemfg.com

13 Methods to Remove Metal Burrs (Deburring) MachineMfg What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit the 5 most common ways of removing burrs and edges are vibratory finishing, barrel tumbling, manual deburring, thermal. one of the final processing steps is deburring, which removes any burrs and sharp edges that affect an affected part's safety and functionality. a laser cut part can have a small burr on the backside. Use contouring toolpaths for. What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit.

From www.gdandtbasics.com

Break Edges Note GD&T Basics What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit countersink tools are used to deburr the edges of drilled holes. the 5 most common ways of removing burrs and edges are vibratory finishing, barrel tumbling, manual deburring, thermal. one of the final processing steps is deburring, which removes any burrs and sharp edges that affect an affected part's safety and functionality. This blog will go over. What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit.

From issuu.com

Best deburring tool remove burrs and sharp edges easily copy by ericsparker17 Issuu What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit countersink tools are used to deburr the edges of drilled holes. the 5 most common ways of removing burrs and edges are vibratory finishing, barrel tumbling, manual deburring, thermal. Use contouring toolpaths for removing burrs on flat surfaces and edges. This blog will go over what causes burrs to form, why removing them is so critical, and what. What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit.

From www.homewaremart.net

Rotary Burr 10mm Arc Sharp Pointed Nose Head Type Drill Bit Tool For Removal Of Burrs On Grinding What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit one of the final processing steps is deburring, which removes any burrs and sharp edges that affect an affected part's safety and functionality. a laser cut part can have a small burr on the backside. Use contouring toolpaths for removing burrs on flat surfaces and edges. the 5 most common ways of removing burrs and edges are. What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit.

From www.chegg.com

62 SAFETY MARINE NOTES BRACKET REMOVE ALL BURRS AND What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit countersink tools are used to deburr the edges of drilled holes. Use contouring toolpaths for removing burrs on flat surfaces and edges. one of the final processing steps is deburring, which removes any burrs and sharp edges that affect an affected part's safety and functionality. the 5 most common ways of removing burrs and edges are vibratory. What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit.

From dengarden.com

A Complete Guide to Using Plumbing Fittings for Joining PEX Pipe, PVC and Copper Dengarden What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit countersink tools are used to deburr the edges of drilled holes. Use contouring toolpaths for removing burrs on flat surfaces and edges. a laser cut part can have a small burr on the backside. one of the final processing steps is deburring, which removes any burrs and sharp edges that affect an affected part's safety and functionality.. What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit.

From www.homewaremart.net

Rotary Burr 10mm Arc Sharp Pointed Nose Head Type Drill Bit Tool For Removal Of Burrs On Grinding What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit one of the final processing steps is deburring, which removes any burrs and sharp edges that affect an affected part's safety and functionality. Use contouring toolpaths for removing burrs on flat surfaces and edges. Flat sanding would remove this, leaving a sharp, burr. a laser cut part can have a small burr on the backside. countersink tools. What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit.

From www.familyhandyman.com

Mastering the Art of Electrical Conduit Family Handyman What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit countersink tools are used to deburr the edges of drilled holes. Flat sanding would remove this, leaving a sharp, burr. This blog will go over what causes burrs to form, why removing them is so critical, and what deburring methods yield the best results. a laser cut part can have a small burr on the backside. one. What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit.

From www.walmart.com

HES EDC Deburring Tool Effortlessly Remove Burrs Steep Sharp Cutting Blade Compact What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit Use contouring toolpaths for removing burrs on flat surfaces and edges. the 5 most common ways of removing burrs and edges are vibratory finishing, barrel tumbling, manual deburring, thermal. This blog will go over what causes burrs to form, why removing them is so critical, and what deburring methods yield the best results. countersink tools are used to. What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit.

From makerpipe.com

Which Pipe Cutting Tool Is Right For You? Maker Pipe What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit one of the final processing steps is deburring, which removes any burrs and sharp edges that affect an affected part's safety and functionality. Flat sanding would remove this, leaving a sharp, burr. Use contouring toolpaths for removing burrs on flat surfaces and edges. the 5 most common ways of removing burrs and edges are vibratory finishing, barrel tumbling,. What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit.

From www.jotunpolishing.com

5 Effective Ways to Remove Sharp Edges and Burrs from Sheet Metal Parts jotunpolishing What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit one of the final processing steps is deburring, which removes any burrs and sharp edges that affect an affected part's safety and functionality. countersink tools are used to deburr the edges of drilled holes. Use contouring toolpaths for removing burrs on flat surfaces and edges. Flat sanding would remove this, leaving a sharp, burr. the 5 most. What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit.

From transquip.com.au

8020S2, Saber 3 Piece Burr Set Professional Series. What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit Use contouring toolpaths for removing burrs on flat surfaces and edges. one of the final processing steps is deburring, which removes any burrs and sharp edges that affect an affected part's safety and functionality. countersink tools are used to deburr the edges of drilled holes. a laser cut part can have a small burr on the backside.. What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit.

From www.youtube.com

Edge Pro Apex Burr Removal Sharp At Any Grit YouTube What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit a laser cut part can have a small burr on the backside. Flat sanding would remove this, leaving a sharp, burr. one of the final processing steps is deburring, which removes any burrs and sharp edges that affect an affected part's safety and functionality. Use contouring toolpaths for removing burrs on flat surfaces and edges. countersink tools. What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit.

From www.homewaremart.net

Rotary Burr 10mm Arc Sharp Pointed Nose Head Type Drill Bit Tool For Removal Of Burrs On Grinding What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit the 5 most common ways of removing burrs and edges are vibratory finishing, barrel tumbling, manual deburring, thermal. Flat sanding would remove this, leaving a sharp, burr. countersink tools are used to deburr the edges of drilled holes. This blog will go over what causes burrs to form, why removing them is so critical, and what deburring methods. What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit.

From prochain-cnc.com

How to remove metal burrs? 5 ways for you to choose PROCHAIN PRECISION What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit a laser cut part can have a small burr on the backside. This blog will go over what causes burrs to form, why removing them is so critical, and what deburring methods yield the best results. countersink tools are used to deburr the edges of drilled holes. one of the final processing steps is deburring, which removes. What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit.

From www.youtube.com

How To Remove Burrs & Sharp Edges From EMT Conduit Maker Pipe YouTube What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit countersink tools are used to deburr the edges of drilled holes. Flat sanding would remove this, leaving a sharp, burr. Use contouring toolpaths for removing burrs on flat surfaces and edges. one of the final processing steps is deburring, which removes any burrs and sharp edges that affect an affected part's safety and functionality. This blog will go. What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit.

From www.homewaremart.net

Rotary Burr 10mm Arc Sharp Pointed Nose Head Type Drill Bit Tool For Removal Of Burrs On Grinding What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit Flat sanding would remove this, leaving a sharp, burr. This blog will go over what causes burrs to form, why removing them is so critical, and what deburring methods yield the best results. a laser cut part can have a small burr on the backside. countersink tools are used to deburr the edges of drilled holes. Use contouring. What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit.

From www.xavier-parts.com

Ways To Remove Sharp Edges And Burrs From Metal Parts Xavier What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit Flat sanding would remove this, leaving a sharp, burr. Use contouring toolpaths for removing burrs on flat surfaces and edges. the 5 most common ways of removing burrs and edges are vibratory finishing, barrel tumbling, manual deburring, thermal. This blog will go over what causes burrs to form, why removing them is so critical, and what deburring methods yield. What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit.

From www.handymanmagazine.co.nz

How to clean your tools New Zealand Handyman Magazine What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit countersink tools are used to deburr the edges of drilled holes. a laser cut part can have a small burr on the backside. Use contouring toolpaths for removing burrs on flat surfaces and edges. the 5 most common ways of removing burrs and edges are vibratory finishing, barrel tumbling, manual deburring, thermal. This blog will go over. What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit.

From www.youbeli.com

Rotary Burr 10mm Arc Sharp Pointed Nose Head Type Drill Bit Tool For Removal Of Burrs On Grinding What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit countersink tools are used to deburr the edges of drilled holes. a laser cut part can have a small burr on the backside. one of the final processing steps is deburring, which removes any burrs and sharp edges that affect an affected part's safety and functionality. Flat sanding would remove this, leaving a sharp, burr. the. What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit.

From bangshift.com

Quick Tech How To Use Steel Braided Hose As A Tool To Remove Burrs From Cut Pipe What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit Flat sanding would remove this, leaving a sharp, burr. one of the final processing steps is deburring, which removes any burrs and sharp edges that affect an affected part's safety and functionality. This blog will go over what causes burrs to form, why removing them is so critical, and what deburring methods yield the best results. the 5. What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit.

From www.walmart.com

High Abrasion Resistance Removal Of Edges Burr Removal Of Burrs Rotarys Burr Bit For Carving What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit one of the final processing steps is deburring, which removes any burrs and sharp edges that affect an affected part's safety and functionality. a laser cut part can have a small burr on the backside. Flat sanding would remove this, leaving a sharp, burr. This blog will go over what causes burrs to form, why removing them is. What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit.

From www.cooksongold.com

How to Use Different Types of Burrs The Bench What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit Use contouring toolpaths for removing burrs on flat surfaces and edges. one of the final processing steps is deburring, which removes any burrs and sharp edges that affect an affected part's safety and functionality. the 5 most common ways of removing burrs and edges are vibratory finishing, barrel tumbling, manual deburring, thermal. a laser cut part can. What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit.

From www.homewaremart.net

Rotary Burr 10mm Arc Sharp Pointed Nose Head Type Drill Bit Tool For Removal Of Burrs On Grinding What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit a laser cut part can have a small burr on the backside. Flat sanding would remove this, leaving a sharp, burr. Use contouring toolpaths for removing burrs on flat surfaces and edges. the 5 most common ways of removing burrs and edges are vibratory finishing, barrel tumbling, manual deburring, thermal. one of the final processing steps is. What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit.

From suginocorp.com

Types of Burrs by Machining Process What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit the 5 most common ways of removing burrs and edges are vibratory finishing, barrel tumbling, manual deburring, thermal. a laser cut part can have a small burr on the backside. This blog will go over what causes burrs to form, why removing them is so critical, and what deburring methods yield the best results. Flat sanding would remove. What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit.

From www.youtube.com

Cutting Copper Pipes & Remove Burrs The 1st Step To Soldering YouTube What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit This blog will go over what causes burrs to form, why removing them is so critical, and what deburring methods yield the best results. Use contouring toolpaths for removing burrs on flat surfaces and edges. a laser cut part can have a small burr on the backside. one of the final processing steps is deburring, which removes any. What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit.

From bangshift.com

Quick Tech How To Use Steel Braided Hose As A Tool To Remove Burrs From Cut Pipe What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit This blog will go over what causes burrs to form, why removing them is so critical, and what deburring methods yield the best results. a laser cut part can have a small burr on the backside. Use contouring toolpaths for removing burrs on flat surfaces and edges. the 5 most common ways of removing burrs and edges are. What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit.

From www.homewaremart.net

Rotary Burr 10mm Arc Sharp Pointed Nose Head Type Drill Bit Tool For Removal Of Burrs On Grinding What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit Use contouring toolpaths for removing burrs on flat surfaces and edges. countersink tools are used to deburr the edges of drilled holes. the 5 most common ways of removing burrs and edges are vibratory finishing, barrel tumbling, manual deburring, thermal. Flat sanding would remove this, leaving a sharp, burr. one of the final processing steps is deburring,. What Kind Of Tool You Will Use To Remove The Burrs And Sharp Edges Of The Cut Conduit.