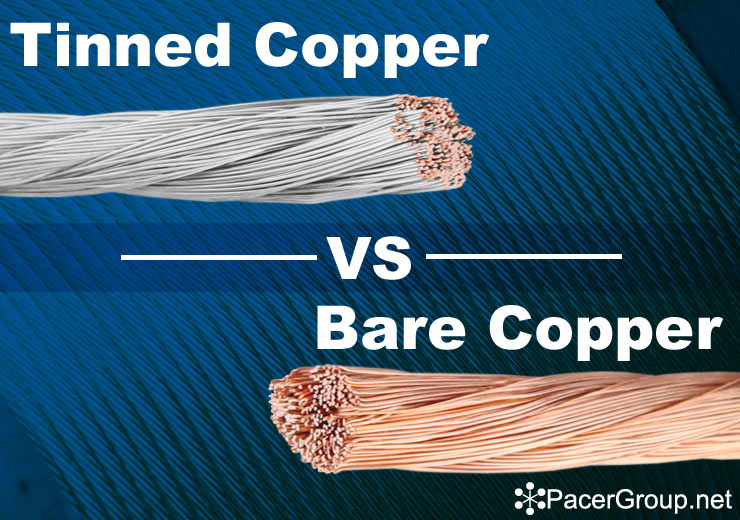

Tinned Copper Tape Vs Bare Copper Tape . the difference in electrical conductivity between bare and tinned copper is minimal. Recently manufactured, fresh bare copper conductor works very well, but bare copper wire is prone to oxidation over time much more than its tinner counterpart. Bare copper is slightly more conductive. The primary purpose of tinning copper is to shield it from oxidation and corrosion. tinned copper vs bare copper is a common topic of discussion. while bare copper exhibits decent resistance to corrosion, tinned copper conductors offer superior protection against accelerated corrosion in moist and contaminated environments. It’s versatile, with powerful electrical conductivity and corrosion resistance, but there are some situations where a layer of tin can add to its capabilities. Tinned copper conductors offer superior corrosion resistance due to the protective tin coating, which prevents the copper from coming into direct contact with corrosive elements in the marine environment, such as. pacer shows how superior tinned copper is to bare copper and why. one of the primary differences between tinned copper and bare copper marine cables is their resistance to corrosion. Generally speaking, the conductor material of the wire and cable will be bare copper, aluminum and tinned copper, etc. Learn more about the benefits and the processes behind tinned copper as well as it's uses in the marine industry. what is tinned copper wire? Tinned copper wire is an uninsulated wire that is coated by a layer of tin. There will be differences between them, and most people will have difficulty in choosing between them when buying the wire and cable.

from www.pacergroup.net

Recently manufactured, fresh bare copper conductor works very well, but bare copper wire is prone to oxidation over time much more than its tinner counterpart. Tinned copper conductors offer superior corrosion resistance due to the protective tin coating, which prevents the copper from coming into direct contact with corrosive elements in the marine environment, such as. There will be differences between them, and most people will have difficulty in choosing between them when buying the wire and cable. The primary purpose of tinning copper is to shield it from oxidation and corrosion. Generally speaking, the conductor material of the wire and cable will be bare copper, aluminum and tinned copper, etc. tinned copper vs bare copper is a common topic of discussion. what is tinned copper wire? It’s versatile, with powerful electrical conductivity and corrosion resistance, but there are some situations where a layer of tin can add to its capabilities. one of the primary differences between tinned copper and bare copper marine cables is their resistance to corrosion. the difference in electrical conductivity between bare and tinned copper is minimal.

Tinned Copper VS Bare Copper Pacer Group

Tinned Copper Tape Vs Bare Copper Tape Recently manufactured, fresh bare copper conductor works very well, but bare copper wire is prone to oxidation over time much more than its tinner counterpart. Recently manufactured, fresh bare copper conductor works very well, but bare copper wire is prone to oxidation over time much more than its tinner counterpart. The primary purpose of tinning copper is to shield it from oxidation and corrosion. tinned copper vs bare copper is a common topic of discussion. Tinned copper wire is an uninsulated wire that is coated by a layer of tin. Generally speaking, the conductor material of the wire and cable will be bare copper, aluminum and tinned copper, etc. There will be differences between them, and most people will have difficulty in choosing between them when buying the wire and cable. It’s versatile, with powerful electrical conductivity and corrosion resistance, but there are some situations where a layer of tin can add to its capabilities. Learn more about the benefits and the processes behind tinned copper as well as it's uses in the marine industry. pacer shows how superior tinned copper is to bare copper and why. Tinned copper conductors offer superior corrosion resistance due to the protective tin coating, which prevents the copper from coming into direct contact with corrosive elements in the marine environment, such as. the difference in electrical conductivity between bare and tinned copper is minimal. Bare copper is slightly more conductive. while bare copper exhibits decent resistance to corrosion, tinned copper conductors offer superior protection against accelerated corrosion in moist and contaminated environments. what is tinned copper wire? one of the primary differences between tinned copper and bare copper marine cables is their resistance to corrosion.

From www.indiamart.com

Bare Copper Tape at Rs 800/kg copper strip wire in Ahmedabad ID Tinned Copper Tape Vs Bare Copper Tape The primary purpose of tinning copper is to shield it from oxidation and corrosion. pacer shows how superior tinned copper is to bare copper and why. Generally speaking, the conductor material of the wire and cable will be bare copper, aluminum and tinned copper, etc. Learn more about the benefits and the processes behind tinned copper as well as. Tinned Copper Tape Vs Bare Copper Tape.

From blog.thepipingmart.com

The Difference Between Tinned Copper and Bare Copper Wire Tinned Copper Tape Vs Bare Copper Tape Recently manufactured, fresh bare copper conductor works very well, but bare copper wire is prone to oxidation over time much more than its tinner counterpart. Learn more about the benefits and the processes behind tinned copper as well as it's uses in the marine industry. Bare copper is slightly more conductive. The primary purpose of tinning copper is to shield. Tinned Copper Tape Vs Bare Copper Tape.

From www.cef.co.uk

Kingsmill Industries 25mm x 3mm Bare Copper Tape (25m Coil) (CTBA2530 Tinned Copper Tape Vs Bare Copper Tape while bare copper exhibits decent resistance to corrosion, tinned copper conductors offer superior protection against accelerated corrosion in moist and contaminated environments. Generally speaking, the conductor material of the wire and cable will be bare copper, aluminum and tinned copper, etc. tinned copper vs bare copper is a common topic of discussion. Learn more about the benefits and. Tinned Copper Tape Vs Bare Copper Tape.

From www.alcomet.net

Tinned Copper Tape Earthing Conductor Tinned Copper Tape Vs Bare Copper Tape what is tinned copper wire? Recently manufactured, fresh bare copper conductor works very well, but bare copper wire is prone to oxidation over time much more than its tinner counterpart. Tinned copper conductors offer superior corrosion resistance due to the protective tin coating, which prevents the copper from coming into direct contact with corrosive elements in the marine environment,. Tinned Copper Tape Vs Bare Copper Tape.

From internationalwire.com

Tinned Copper vs. Bare Copper Wire International Wire Tinned Copper Tape Vs Bare Copper Tape the difference in electrical conductivity between bare and tinned copper is minimal. Generally speaking, the conductor material of the wire and cable will be bare copper, aluminum and tinned copper, etc. Recently manufactured, fresh bare copper conductor works very well, but bare copper wire is prone to oxidation over time much more than its tinner counterpart. Bare copper is. Tinned Copper Tape Vs Bare Copper Tape.

From citizenmetalloys.com

Tinned Copper Tapes Citizen Metalloys Tinned Copper Tape Vs Bare Copper Tape There will be differences between them, and most people will have difficulty in choosing between them when buying the wire and cable. It’s versatile, with powerful electrical conductivity and corrosion resistance, but there are some situations where a layer of tin can add to its capabilities. what is tinned copper wire? pacer shows how superior tinned copper is. Tinned Copper Tape Vs Bare Copper Tape.

From blog.thepipingmart.com

Differences Between Annealed Copper and Tinned Copper Tinned Copper Tape Vs Bare Copper Tape Recently manufactured, fresh bare copper conductor works very well, but bare copper wire is prone to oxidation over time much more than its tinner counterpart. It’s versatile, with powerful electrical conductivity and corrosion resistance, but there are some situations where a layer of tin can add to its capabilities. Bare copper is slightly more conductive. Tinned copper wire is an. Tinned Copper Tape Vs Bare Copper Tape.

From wesbellwireandcable.com

Bare vs. Tinned Copper Wires WesBell Electronics Tinned Copper Tape Vs Bare Copper Tape There will be differences between them, and most people will have difficulty in choosing between them when buying the wire and cable. while bare copper exhibits decent resistance to corrosion, tinned copper conductors offer superior protection against accelerated corrosion in moist and contaminated environments. Learn more about the benefits and the processes behind tinned copper as well as it's. Tinned Copper Tape Vs Bare Copper Tape.

From chinainsulation.en.made-in-china.com

Grounding Earthing Flexible Braided Copper Tape China Bare Copper Tinned Copper Tape Vs Bare Copper Tape the difference in electrical conductivity between bare and tinned copper is minimal. while bare copper exhibits decent resistance to corrosion, tinned copper conductors offer superior protection against accelerated corrosion in moist and contaminated environments. It’s versatile, with powerful electrical conductivity and corrosion resistance, but there are some situations where a layer of tin can add to its capabilities.. Tinned Copper Tape Vs Bare Copper Tape.

From dir.indiamart.com

Copper Tape Tinned Copper Tape Latest Price, Manufacturers & Suppliers Tinned Copper Tape Vs Bare Copper Tape Learn more about the benefits and the processes behind tinned copper as well as it's uses in the marine industry. Tinned copper wire is an uninsulated wire that is coated by a layer of tin. Tinned copper conductors offer superior corrosion resistance due to the protective tin coating, which prevents the copper from coming into direct contact with corrosive elements. Tinned Copper Tape Vs Bare Copper Tape.

From www.hubbell.com

Tinned Copper Tape 000038807401 Hubbell Tinned Copper Tape Vs Bare Copper Tape pacer shows how superior tinned copper is to bare copper and why. Tinned copper conductors offer superior corrosion resistance due to the protective tin coating, which prevents the copper from coming into direct contact with corrosive elements in the marine environment, such as. Tinned copper wire is an uninsulated wire that is coated by a layer of tin. Generally. Tinned Copper Tape Vs Bare Copper Tape.

From kingsmillindustries.com

Tinned Copper Tape Kingsmill Industries Tinned Copper Tape Vs Bare Copper Tape It’s versatile, with powerful electrical conductivity and corrosion resistance, but there are some situations where a layer of tin can add to its capabilities. Recently manufactured, fresh bare copper conductor works very well, but bare copper wire is prone to oxidation over time much more than its tinner counterpart. Tinned copper wire is an uninsulated wire that is coated by. Tinned Copper Tape Vs Bare Copper Tape.

From nassaunationalcable.com

Tinned Copper Wire vs. Bare Copper Wire When Is It Best to Use Each O Tinned Copper Tape Vs Bare Copper Tape pacer shows how superior tinned copper is to bare copper and why. Recently manufactured, fresh bare copper conductor works very well, but bare copper wire is prone to oxidation over time much more than its tinner counterpart. The primary purpose of tinning copper is to shield it from oxidation and corrosion. Learn more about the benefits and the processes. Tinned Copper Tape Vs Bare Copper Tape.

From www.raychemrpg.com

Bare Copper Tape Lightning Protection Systems Raychem RPG Tinned Copper Tape Vs Bare Copper Tape Tinned copper wire is an uninsulated wire that is coated by a layer of tin. the difference in electrical conductivity between bare and tinned copper is minimal. tinned copper vs bare copper is a common topic of discussion. Tinned copper conductors offer superior corrosion resistance due to the protective tin coating, which prevents the copper from coming into. Tinned Copper Tape Vs Bare Copper Tape.

From manavenergy.com

Bare Copper Tape Manav Energy Tinned Copper Tape Vs Bare Copper Tape Tinned copper conductors offer superior corrosion resistance due to the protective tin coating, which prevents the copper from coming into direct contact with corrosive elements in the marine environment, such as. one of the primary differences between tinned copper and bare copper marine cables is their resistance to corrosion. The primary purpose of tinning copper is to shield it. Tinned Copper Tape Vs Bare Copper Tape.

From chinainsulation.en.made-in-china.com

Flat Tinned Copper Braid China Bare Copper Strand Wire Flexible Round Tinned Copper Tape Vs Bare Copper Tape It’s versatile, with powerful electrical conductivity and corrosion resistance, but there are some situations where a layer of tin can add to its capabilities. Recently manufactured, fresh bare copper conductor works very well, but bare copper wire is prone to oxidation over time much more than its tinner counterpart. tinned copper vs bare copper is a common topic of. Tinned Copper Tape Vs Bare Copper Tape.

From internationalwire.com

Tinned Copper vs. Bare Copper Wire International Wire Tinned Copper Tape Vs Bare Copper Tape Learn more about the benefits and the processes behind tinned copper as well as it's uses in the marine industry. what is tinned copper wire? There will be differences between them, and most people will have difficulty in choosing between them when buying the wire and cable. one of the primary differences between tinned copper and bare copper. Tinned Copper Tape Vs Bare Copper Tape.

From www.sterling-group.in

Bare Copper Tape Sterling Group Tinned Copper Tape Vs Bare Copper Tape tinned copper vs bare copper is a common topic of discussion. Recently manufactured, fresh bare copper conductor works very well, but bare copper wire is prone to oxidation over time much more than its tinner counterpart. The primary purpose of tinning copper is to shield it from oxidation and corrosion. pacer shows how superior tinned copper is to. Tinned Copper Tape Vs Bare Copper Tape.

From chinainsulation.en.made-in-china.com

Industry Bare Copper Strand Wire Flexible Round Braided Copper China Tinned Copper Tape Vs Bare Copper Tape Generally speaking, the conductor material of the wire and cable will be bare copper, aluminum and tinned copper, etc. tinned copper vs bare copper is a common topic of discussion. one of the primary differences between tinned copper and bare copper marine cables is their resistance to corrosion. Tinned copper wire is an uninsulated wire that is coated. Tinned Copper Tape Vs Bare Copper Tape.

From wesbellwireandcable.com

Bare vs. Tinned Copper Wires WesBell Electronics Tinned Copper Tape Vs Bare Copper Tape what is tinned copper wire? Bare copper is slightly more conductive. Generally speaking, the conductor material of the wire and cable will be bare copper, aluminum and tinned copper, etc. Recently manufactured, fresh bare copper conductor works very well, but bare copper wire is prone to oxidation over time much more than its tinner counterpart. The primary purpose of. Tinned Copper Tape Vs Bare Copper Tape.

From www.indiamart.com

Baretinned Plated Copper Tape at best price in Ahmedabad by Citizen Tinned Copper Tape Vs Bare Copper Tape It’s versatile, with powerful electrical conductivity and corrosion resistance, but there are some situations where a layer of tin can add to its capabilities. Tinned copper conductors offer superior corrosion resistance due to the protective tin coating, which prevents the copper from coming into direct contact with corrosive elements in the marine environment, such as. while bare copper exhibits. Tinned Copper Tape Vs Bare Copper Tape.

From chinainsulation.en.made-in-china.com

Dia 0.05mm Bare Copper Flat Braided Wire Grounding Tape China Bare Tinned Copper Tape Vs Bare Copper Tape the difference in electrical conductivity between bare and tinned copper is minimal. Recently manufactured, fresh bare copper conductor works very well, but bare copper wire is prone to oxidation over time much more than its tinner counterpart. The primary purpose of tinning copper is to shield it from oxidation and corrosion. Tinned copper wire is an uninsulated wire that. Tinned Copper Tape Vs Bare Copper Tape.

From www.slideserve.com

PPT Tinned Copper Wire vs Bare Capper wire PowerPoint Presentation Tinned Copper Tape Vs Bare Copper Tape tinned copper vs bare copper is a common topic of discussion. the difference in electrical conductivity between bare and tinned copper is minimal. Recently manufactured, fresh bare copper conductor works very well, but bare copper wire is prone to oxidation over time much more than its tinner counterpart. Generally speaking, the conductor material of the wire and cable. Tinned Copper Tape Vs Bare Copper Tape.

From issuu.com

Tinned copper wire vs bare copper wires by Ganpati Wires Issuu Tinned Copper Tape Vs Bare Copper Tape There will be differences between them, and most people will have difficulty in choosing between them when buying the wire and cable. the difference in electrical conductivity between bare and tinned copper is minimal. tinned copper vs bare copper is a common topic of discussion. It’s versatile, with powerful electrical conductivity and corrosion resistance, but there are some. Tinned Copper Tape Vs Bare Copper Tape.

From chinainsulation.en.made-in-china.com

Bare or Tinned Copper Braided Tape China Bare Copper Strand Wire Tinned Copper Tape Vs Bare Copper Tape the difference in electrical conductivity between bare and tinned copper is minimal. Tinned copper conductors offer superior corrosion resistance due to the protective tin coating, which prevents the copper from coming into direct contact with corrosive elements in the marine environment, such as. Bare copper is slightly more conductive. The primary purpose of tinning copper is to shield it. Tinned Copper Tape Vs Bare Copper Tape.

From electrical.mu

Tape Copper (Bare) 25x3mm (roll of 25m or 50m) Tinned Copper Tape Vs Bare Copper Tape while bare copper exhibits decent resistance to corrosion, tinned copper conductors offer superior protection against accelerated corrosion in moist and contaminated environments. one of the primary differences between tinned copper and bare copper marine cables is their resistance to corrosion. The primary purpose of tinning copper is to shield it from oxidation and corrosion. Tinned copper conductors offer. Tinned Copper Tape Vs Bare Copper Tape.

From chinainsulation.en.made-in-china.com

Bare Copper Strand Wire Flexible Round Braided Copper China Bare Tinned Copper Tape Vs Bare Copper Tape Recently manufactured, fresh bare copper conductor works very well, but bare copper wire is prone to oxidation over time much more than its tinner counterpart. pacer shows how superior tinned copper is to bare copper and why. Tinned copper wire is an uninsulated wire that is coated by a layer of tin. There will be differences between them, and. Tinned Copper Tape Vs Bare Copper Tape.

From www.delightfire.com

Waarom vertind koperdraad gebruiken?? DelightFire Tinned Copper Tape Vs Bare Copper Tape while bare copper exhibits decent resistance to corrosion, tinned copper conductors offer superior protection against accelerated corrosion in moist and contaminated environments. The primary purpose of tinning copper is to shield it from oxidation and corrosion. Learn more about the benefits and the processes behind tinned copper as well as it's uses in the marine industry. Bare copper is. Tinned Copper Tape Vs Bare Copper Tape.

From wesbellwireandcable.com

Bare vs. Tinned Copper Wires WesBell Electronics Tinned Copper Tape Vs Bare Copper Tape tinned copper vs bare copper is a common topic of discussion. Tinned copper conductors offer superior corrosion resistance due to the protective tin coating, which prevents the copper from coming into direct contact with corrosive elements in the marine environment, such as. the difference in electrical conductivity between bare and tinned copper is minimal. It’s versatile, with powerful. Tinned Copper Tape Vs Bare Copper Tape.

From electrical.mu

Tape Copper (Bare Tinned) 25x3mm Roll 25m Tinned Copper Tape Vs Bare Copper Tape pacer shows how superior tinned copper is to bare copper and why. Recently manufactured, fresh bare copper conductor works very well, but bare copper wire is prone to oxidation over time much more than its tinner counterpart. It’s versatile, with powerful electrical conductivity and corrosion resistance, but there are some situations where a layer of tin can add to. Tinned Copper Tape Vs Bare Copper Tape.

From www.pacergroup.net

Tinned Copper VS Bare Copper Pacer Group Tinned Copper Tape Vs Bare Copper Tape There will be differences between them, and most people will have difficulty in choosing between them when buying the wire and cable. Bare copper is slightly more conductive. pacer shows how superior tinned copper is to bare copper and why. It’s versatile, with powerful electrical conductivity and corrosion resistance, but there are some situations where a layer of tin. Tinned Copper Tape Vs Bare Copper Tape.

From www.centralwires.com

Tinned Copper vs Bare Copper Which One is Better? Tinned Copper Tape Vs Bare Copper Tape one of the primary differences between tinned copper and bare copper marine cables is their resistance to corrosion. pacer shows how superior tinned copper is to bare copper and why. the difference in electrical conductivity between bare and tinned copper is minimal. Recently manufactured, fresh bare copper conductor works very well, but bare copper wire is prone. Tinned Copper Tape Vs Bare Copper Tape.

From www.etscablecomponents.com

Tinned Copper Earth Tape ETS Cable Components Tinned Copper Tape Vs Bare Copper Tape tinned copper vs bare copper is a common topic of discussion. Recently manufactured, fresh bare copper conductor works very well, but bare copper wire is prone to oxidation over time much more than its tinner counterpart. It’s versatile, with powerful electrical conductivity and corrosion resistance, but there are some situations where a layer of tin can add to its. Tinned Copper Tape Vs Bare Copper Tape.

From wesbellwireandcable.com

Bare vs. Tinned Copper Wires WesBell Electronics Tinned Copper Tape Vs Bare Copper Tape one of the primary differences between tinned copper and bare copper marine cables is their resistance to corrosion. tinned copper vs bare copper is a common topic of discussion. The primary purpose of tinning copper is to shield it from oxidation and corrosion. Recently manufactured, fresh bare copper conductor works very well, but bare copper wire is prone. Tinned Copper Tape Vs Bare Copper Tape.

From www.indiamart.com

Tinned Copper Tape at best price in Daman by Leebo Metals Private Tinned Copper Tape Vs Bare Copper Tape Recently manufactured, fresh bare copper conductor works very well, but bare copper wire is prone to oxidation over time much more than its tinner counterpart. Tinned copper wire is an uninsulated wire that is coated by a layer of tin. while bare copper exhibits decent resistance to corrosion, tinned copper conductors offer superior protection against accelerated corrosion in moist. Tinned Copper Tape Vs Bare Copper Tape.