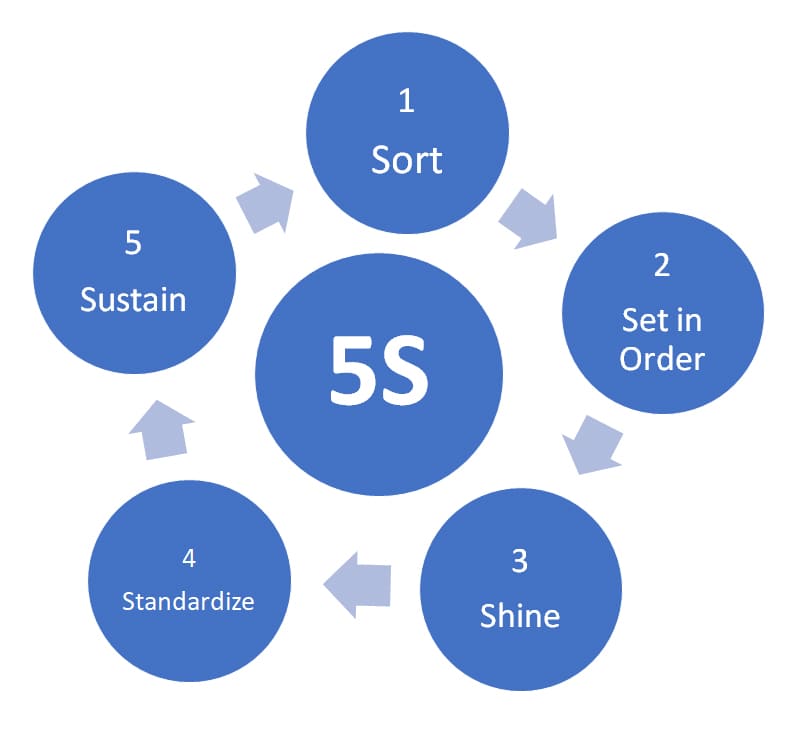

What Is 5S Principle With Example . 5s serves as a foundation for deploying more advanced lean production tools and. the 5s lean methodology, rooted in japanese manufacturing, presents a holistic approach to optimizing and enhancing workspaces across. Sort, straighten, shine, standardize, and sustain. Encourage ongoing assessment and refinement of work processes to drive continuous improvement. Look at the example below to see 5s in action. in english, the 5s’s are: foster a culture of continuous improvement: the 5s method is a standardized process that when properly implemented creates and maintains an organized, safe and efficient workplace. A simple yet powerful lean improvement approach applied in a preadmission testing center (quality.

from parsadi.com

the 5s method is a standardized process that when properly implemented creates and maintains an organized, safe and efficient workplace. foster a culture of continuous improvement: the 5s lean methodology, rooted in japanese manufacturing, presents a holistic approach to optimizing and enhancing workspaces across. in english, the 5s’s are: A simple yet powerful lean improvement approach applied in a preadmission testing center (quality. Encourage ongoing assessment and refinement of work processes to drive continuous improvement. 5s serves as a foundation for deploying more advanced lean production tools and. Look at the example below to see 5s in action. Sort, straighten, shine, standardize, and sustain.

What is 5S Methodology? Example and Implementation. Parsadi

What Is 5S Principle With Example Encourage ongoing assessment and refinement of work processes to drive continuous improvement. Sort, straighten, shine, standardize, and sustain. the 5s lean methodology, rooted in japanese manufacturing, presents a holistic approach to optimizing and enhancing workspaces across. A simple yet powerful lean improvement approach applied in a preadmission testing center (quality. foster a culture of continuous improvement: the 5s method is a standardized process that when properly implemented creates and maintains an organized, safe and efficient workplace. Look at the example below to see 5s in action. in english, the 5s’s are: 5s serves as a foundation for deploying more advanced lean production tools and. Encourage ongoing assessment and refinement of work processes to drive continuous improvement.

From www.cisco-eagle.com

The 5S Process 7 Visualizations That Explain It Best What Is 5S Principle With Example the 5s lean methodology, rooted in japanese manufacturing, presents a holistic approach to optimizing and enhancing workspaces across. Sort, straighten, shine, standardize, and sustain. in english, the 5s’s are: foster a culture of continuous improvement: Encourage ongoing assessment and refinement of work processes to drive continuous improvement. 5s serves as a foundation for deploying more advanced lean. What Is 5S Principle With Example.

From strategicmanagementinsight.com

5S Methodology The Ultimate Guide SM Insight What Is 5S Principle With Example foster a culture of continuous improvement: A simple yet powerful lean improvement approach applied in a preadmission testing center (quality. the 5s lean methodology, rooted in japanese manufacturing, presents a holistic approach to optimizing and enhancing workspaces across. 5s serves as a foundation for deploying more advanced lean production tools and. in english, the 5s’s are: Sort,. What Is 5S Principle With Example.

From studylib.net

Principles of 5 S What Is 5S Principle With Example Sort, straighten, shine, standardize, and sustain. the 5s method is a standardized process that when properly implemented creates and maintains an organized, safe and efficient workplace. Look at the example below to see 5s in action. A simple yet powerful lean improvement approach applied in a preadmission testing center (quality. 5s serves as a foundation for deploying more advanced. What Is 5S Principle With Example.

From www.brightlysoftware.com

Operational Best Practices You May Not Know About 5S Brightly What Is 5S Principle With Example Look at the example below to see 5s in action. A simple yet powerful lean improvement approach applied in a preadmission testing center (quality. Sort, straighten, shine, standardize, and sustain. the 5s lean methodology, rooted in japanese manufacturing, presents a holistic approach to optimizing and enhancing workspaces across. foster a culture of continuous improvement: in english, the. What Is 5S Principle With Example.

From www.5stoday.com

What is 5S? 5S System is explained including tips on getting a 5S program started. What Is 5S Principle With Example foster a culture of continuous improvement: Look at the example below to see 5s in action. 5s serves as a foundation for deploying more advanced lean production tools and. Sort, straighten, shine, standardize, and sustain. the 5s method is a standardized process that when properly implemented creates and maintains an organized, safe and efficient workplace. A simple yet. What Is 5S Principle With Example.

From www.leanstrategiesinternational.com

5S System Lean Strategies International What Is 5S Principle With Example in english, the 5s’s are: Look at the example below to see 5s in action. 5s serves as a foundation for deploying more advanced lean production tools and. the 5s lean methodology, rooted in japanese manufacturing, presents a holistic approach to optimizing and enhancing workspaces across. the 5s method is a standardized process that when properly implemented. What Is 5S Principle With Example.

From www.satistar.com

Principles of 5S What Is 5S Principle With Example in english, the 5s’s are: Look at the example below to see 5s in action. A simple yet powerful lean improvement approach applied in a preadmission testing center (quality. the 5s method is a standardized process that when properly implemented creates and maintains an organized, safe and efficient workplace. Encourage ongoing assessment and refinement of work processes to. What Is 5S Principle With Example.

From www.pinterest.ph

5S was developed in Japan. 5S Methodology is a system for organizing spaces so work can be What Is 5S Principle With Example Look at the example below to see 5s in action. 5s serves as a foundation for deploying more advanced lean production tools and. Sort, straighten, shine, standardize, and sustain. in english, the 5s’s are: the 5s lean methodology, rooted in japanese manufacturing, presents a holistic approach to optimizing and enhancing workspaces across. A simple yet powerful lean improvement. What Is 5S Principle With Example.

From leanabc.blogspot.com

Lean Manufacturing Concepts 5S System A place for everything & safe working place What Is 5S Principle With Example the 5s method is a standardized process that when properly implemented creates and maintains an organized, safe and efficient workplace. Encourage ongoing assessment and refinement of work processes to drive continuous improvement. A simple yet powerful lean improvement approach applied in a preadmission testing center (quality. Sort, straighten, shine, standardize, and sustain. foster a culture of continuous improvement:. What Is 5S Principle With Example.

From www.amazon.in

3mm Form sheet Signboard 5s techniques (24" X 16") Amazon.in Office Products What Is 5S Principle With Example 5s serves as a foundation for deploying more advanced lean production tools and. Sort, straighten, shine, standardize, and sustain. the 5s method is a standardized process that when properly implemented creates and maintains an organized, safe and efficient workplace. in english, the 5s’s are: Encourage ongoing assessment and refinement of work processes to drive continuous improvement. the. What Is 5S Principle With Example.

From www.100pceffectivetraining.com

Getting to grips with 5S [INFOGRAPHIC] What Is 5S Principle With Example Look at the example below to see 5s in action. Sort, straighten, shine, standardize, and sustain. the 5s lean methodology, rooted in japanese manufacturing, presents a holistic approach to optimizing and enhancing workspaces across. A simple yet powerful lean improvement approach applied in a preadmission testing center (quality. foster a culture of continuous improvement: the 5s method. What Is 5S Principle With Example.

From blogs.mtu.edu

Document Management A 5S Opportunity Continuous Improvement Blog What Is 5S Principle With Example the 5s lean methodology, rooted in japanese manufacturing, presents a holistic approach to optimizing and enhancing workspaces across. in english, the 5s’s are: foster a culture of continuous improvement: A simple yet powerful lean improvement approach applied in a preadmission testing center (quality. Sort, straighten, shine, standardize, and sustain. Encourage ongoing assessment and refinement of work processes. What Is 5S Principle With Example.

From what-benefits.com

What Are The Benefits Of 5s What Is 5S Principle With Example A simple yet powerful lean improvement approach applied in a preadmission testing center (quality. Look at the example below to see 5s in action. foster a culture of continuous improvement: Encourage ongoing assessment and refinement of work processes to drive continuous improvement. Sort, straighten, shine, standardize, and sustain. the 5s method is a standardized process that when properly. What Is 5S Principle With Example.

From www.projectcubicle.com

5s methodology 5s principles infographic projectcubicle What Is 5S Principle With Example 5s serves as a foundation for deploying more advanced lean production tools and. the 5s method is a standardized process that when properly implemented creates and maintains an organized, safe and efficient workplace. foster a culture of continuous improvement: the 5s lean methodology, rooted in japanese manufacturing, presents a holistic approach to optimizing and enhancing workspaces across.. What Is 5S Principle With Example.

From parsadi.com

What is 5S Methodology? Example and Implementation. Parsadi What Is 5S Principle With Example foster a culture of continuous improvement: A simple yet powerful lean improvement approach applied in a preadmission testing center (quality. Look at the example below to see 5s in action. 5s serves as a foundation for deploying more advanced lean production tools and. Encourage ongoing assessment and refinement of work processes to drive continuous improvement. the 5s lean. What Is 5S Principle With Example.

From www.vrogue.co

5s What Is 5s Methodology Lean Manufacturing Visual M vrogue.co What Is 5S Principle With Example 5s serves as a foundation for deploying more advanced lean production tools and. the 5s lean methodology, rooted in japanese manufacturing, presents a holistic approach to optimizing and enhancing workspaces across. the 5s method is a standardized process that when properly implemented creates and maintains an organized, safe and efficient workplace. in english, the 5s’s are: Sort,. What Is 5S Principle With Example.

From www.youtube.com

What is 5S? 5S Workplace Organization Method Course Preview YouTube What Is 5S Principle With Example Look at the example below to see 5s in action. the 5s method is a standardized process that when properly implemented creates and maintains an organized, safe and efficient workplace. the 5s lean methodology, rooted in japanese manufacturing, presents a holistic approach to optimizing and enhancing workspaces across. in english, the 5s’s are: A simple yet powerful. What Is 5S Principle With Example.

From www.starbank-uk.com

Our 5S Workplace Starbank Panel Products What Is 5S Principle With Example foster a culture of continuous improvement: Sort, straighten, shine, standardize, and sustain. Look at the example below to see 5s in action. 5s serves as a foundation for deploying more advanced lean production tools and. in english, the 5s’s are: the 5s lean methodology, rooted in japanese manufacturing, presents a holistic approach to optimizing and enhancing workspaces. What Is 5S Principle With Example.

From www.quality-assurance-solutions.com

5s Implementation in the Office What Is 5S Principle With Example Look at the example below to see 5s in action. the 5s lean methodology, rooted in japanese manufacturing, presents a holistic approach to optimizing and enhancing workspaces across. foster a culture of continuous improvement: A simple yet powerful lean improvement approach applied in a preadmission testing center (quality. the 5s method is a standardized process that when. What Is 5S Principle With Example.

From trdsf.com

5s Lean Tools & Techniques TRADESAFE What Is 5S Principle With Example in english, the 5s’s are: Encourage ongoing assessment and refinement of work processes to drive continuous improvement. A simple yet powerful lean improvement approach applied in a preadmission testing center (quality. foster a culture of continuous improvement: the 5s method is a standardized process that when properly implemented creates and maintains an organized, safe and efficient workplace.. What Is 5S Principle With Example.

From smathanshse.blogspot.com

HSE Insider The 5S System What Is 5S Principle With Example 5s serves as a foundation for deploying more advanced lean production tools and. foster a culture of continuous improvement: Sort, straighten, shine, standardize, and sustain. in english, the 5s’s are: Look at the example below to see 5s in action. the 5s method is a standardized process that when properly implemented creates and maintains an organized, safe. What Is 5S Principle With Example.

From leansmarts.com

What is Lean 5S Methodology Training & Overview Lean Smarts What Is 5S Principle With Example the 5s lean methodology, rooted in japanese manufacturing, presents a holistic approach to optimizing and enhancing workspaces across. A simple yet powerful lean improvement approach applied in a preadmission testing center (quality. Look at the example below to see 5s in action. 5s serves as a foundation for deploying more advanced lean production tools and. the 5s method. What Is 5S Principle With Example.

From www.6sigma.us

Explained 5S Framework Beginner's Guide 5s methodology What Is 5S Principle With Example Sort, straighten, shine, standardize, and sustain. 5s serves as a foundation for deploying more advanced lean production tools and. in english, the 5s’s are: foster a culture of continuous improvement: Look at the example below to see 5s in action. the 5s lean methodology, rooted in japanese manufacturing, presents a holistic approach to optimizing and enhancing workspaces. What Is 5S Principle With Example.

From www.safetyscience.be

Lean 5S Six Sigma Safety Science What Is 5S Principle With Example A simple yet powerful lean improvement approach applied in a preadmission testing center (quality. Look at the example below to see 5s in action. the 5s lean methodology, rooted in japanese manufacturing, presents a holistic approach to optimizing and enhancing workspaces across. foster a culture of continuous improvement: Sort, straighten, shine, standardize, and sustain. the 5s method. What Is 5S Principle With Example.

From www.iqsdirectory.com

Contract Manufacturing What Is It? How Does It Work? Types What Is 5S Principle With Example foster a culture of continuous improvement: the 5s method is a standardized process that when properly implemented creates and maintains an organized, safe and efficient workplace. in english, the 5s’s are: 5s serves as a foundation for deploying more advanced lean production tools and. Encourage ongoing assessment and refinement of work processes to drive continuous improvement. A. What Is 5S Principle With Example.

From www.youtube.com

Electronic 5S Digital File Clean Up and Organization Course Lean Six Sigma Methods Portland What Is 5S Principle With Example 5s serves as a foundation for deploying more advanced lean production tools and. the 5s method is a standardized process that when properly implemented creates and maintains an organized, safe and efficient workplace. A simple yet powerful lean improvement approach applied in a preadmission testing center (quality. the 5s lean methodology, rooted in japanese manufacturing, presents a holistic. What Is 5S Principle With Example.

From www.dreamstime.com

5S Methodology Management Chart Diagram With Sort. Set In Order. Shine. Standardize And Sustain What Is 5S Principle With Example A simple yet powerful lean improvement approach applied in a preadmission testing center (quality. foster a culture of continuous improvement: the 5s lean methodology, rooted in japanese manufacturing, presents a holistic approach to optimizing and enhancing workspaces across. Sort, straighten, shine, standardize, and sustain. 5s serves as a foundation for deploying more advanced lean production tools and. Look. What Is 5S Principle With Example.

From uttana.com

What is 5S and Why is it Important? What Is 5S Principle With Example Sort, straighten, shine, standardize, and sustain. in english, the 5s’s are: Encourage ongoing assessment and refinement of work processes to drive continuous improvement. Look at the example below to see 5s in action. 5s serves as a foundation for deploying more advanced lean production tools and. the 5s method is a standardized process that when properly implemented creates. What Is 5S Principle With Example.

From www.milliken.com

How Does 5S Apply to Maintenance? Milliken What Is 5S Principle With Example A simple yet powerful lean improvement approach applied in a preadmission testing center (quality. Sort, straighten, shine, standardize, and sustain. Encourage ongoing assessment and refinement of work processes to drive continuous improvement. Look at the example below to see 5s in action. the 5s method is a standardized process that when properly implemented creates and maintains an organized, safe. What Is 5S Principle With Example.

From commons.wikimedia.org

File5S methodology.png What Is 5S Principle With Example Encourage ongoing assessment and refinement of work processes to drive continuous improvement. the 5s lean methodology, rooted in japanese manufacturing, presents a holistic approach to optimizing and enhancing workspaces across. the 5s method is a standardized process that when properly implemented creates and maintains an organized, safe and efficient workplace. Look at the example below to see 5s. What Is 5S Principle With Example.

From www.6sigma.us

Article Understanding the 5S's of Kaizen 6 Sigma What Is 5S Principle With Example A simple yet powerful lean improvement approach applied in a preadmission testing center (quality. the 5s lean methodology, rooted in japanese manufacturing, presents a holistic approach to optimizing and enhancing workspaces across. Encourage ongoing assessment and refinement of work processes to drive continuous improvement. the 5s method is a standardized process that when properly implemented creates and maintains. What Is 5S Principle With Example.

From topositive.com

Applying 5S Principle For A Better Life toPositive What Is 5S Principle With Example Encourage ongoing assessment and refinement of work processes to drive continuous improvement. 5s serves as a foundation for deploying more advanced lean production tools and. Sort, straighten, shine, standardize, and sustain. the 5s method is a standardized process that when properly implemented creates and maintains an organized, safe and efficient workplace. the 5s lean methodology, rooted in japanese. What Is 5S Principle With Example.

From educationleaves.com

What is 5S methodology? History, benefits,PDF EDUCATIONLEAVES What Is 5S Principle With Example the 5s lean methodology, rooted in japanese manufacturing, presents a holistic approach to optimizing and enhancing workspaces across. Look at the example below to see 5s in action. Encourage ongoing assessment and refinement of work processes to drive continuous improvement. the 5s method is a standardized process that when properly implemented creates and maintains an organized, safe and. What Is 5S Principle With Example.

From clientsfirst-tx.com

What is 5S? Lean Manufacturing Simplified Clients First Acumatica and Dynamics ERP Partner What Is 5S Principle With Example the 5s method is a standardized process that when properly implemented creates and maintains an organized, safe and efficient workplace. A simple yet powerful lean improvement approach applied in a preadmission testing center (quality. Encourage ongoing assessment and refinement of work processes to drive continuous improvement. Sort, straighten, shine, standardize, and sustain. 5s serves as a foundation for deploying. What Is 5S Principle With Example.

From www.kent.edu

5S Methodology Kent State University What Is 5S Principle With Example the 5s method is a standardized process that when properly implemented creates and maintains an organized, safe and efficient workplace. Encourage ongoing assessment and refinement of work processes to drive continuous improvement. 5s serves as a foundation for deploying more advanced lean production tools and. Sort, straighten, shine, standardize, and sustain. A simple yet powerful lean improvement approach applied. What Is 5S Principle With Example.