Control Valve Function Test . Discover why accuracy & reliability are crucial for optimal. Improve control valve performance with functional testing & preventive maintenance. To ensure the reliability and efficiency of process control systems, it is important to perform functional testing of control valve positioners. Engineers conduct a series of tests to assess. To identify any potential issues or defects in valves before they are put into service, and to ensure that valves continue to function properly throughout. To check the valve at the fully open position—called a span position check—adjust the source current to 20 ma using the range. In this article, we will discuss the importance of functional testing, the types of tests performed, and the steps involved in conducting the tests. Loop check can refer to entire control loop from sensor through transmitter and controller, to the valve positioner and final control element (valve). Functional testing is the cornerstone of the validation process for control valves. The purpose of valve testing is twofold:

from whatispiping.com

The purpose of valve testing is twofold: Functional testing is the cornerstone of the validation process for control valves. Improve control valve performance with functional testing & preventive maintenance. In this article, we will discuss the importance of functional testing, the types of tests performed, and the steps involved in conducting the tests. To identify any potential issues or defects in valves before they are put into service, and to ensure that valves continue to function properly throughout. Loop check can refer to entire control loop from sensor through transmitter and controller, to the valve positioner and final control element (valve). Engineers conduct a series of tests to assess. Discover why accuracy & reliability are crucial for optimal. To check the valve at the fully open position—called a span position check—adjust the source current to 20 ma using the range. To ensure the reliability and efficiency of process control systems, it is important to perform functional testing of control valve positioners.

What are Control Valves? Selection and Types of Control Valves What

Control Valve Function Test In this article, we will discuss the importance of functional testing, the types of tests performed, and the steps involved in conducting the tests. The purpose of valve testing is twofold: Improve control valve performance with functional testing & preventive maintenance. To identify any potential issues or defects in valves before they are put into service, and to ensure that valves continue to function properly throughout. In this article, we will discuss the importance of functional testing, the types of tests performed, and the steps involved in conducting the tests. Discover why accuracy & reliability are crucial for optimal. To ensure the reliability and efficiency of process control systems, it is important to perform functional testing of control valve positioners. Functional testing is the cornerstone of the validation process for control valves. Loop check can refer to entire control loop from sensor through transmitter and controller, to the valve positioner and final control element (valve). To check the valve at the fully open position—called a span position check—adjust the source current to 20 ma using the range. Engineers conduct a series of tests to assess.

From instrumentationtools.com

Self Actuated Pressure Control Valve Functional Testing Instrumentation Control Valve Function Test To identify any potential issues or defects in valves before they are put into service, and to ensure that valves continue to function properly throughout. Engineers conduct a series of tests to assess. To ensure the reliability and efficiency of process control systems, it is important to perform functional testing of control valve positioners. Improve control valve performance with functional. Control Valve Function Test.

From www.youtube.com

How Solenoid Valves Work Basics actuator control valve working Control Valve Function Test To ensure the reliability and efficiency of process control systems, it is important to perform functional testing of control valve positioners. Engineers conduct a series of tests to assess. Improve control valve performance with functional testing & preventive maintenance. To identify any potential issues or defects in valves before they are put into service, and to ensure that valves continue. Control Valve Function Test.

From www.hqts.com

Valve Testing and Inspection in Quality Control Explained HQTS Control Valve Function Test Engineers conduct a series of tests to assess. Discover why accuracy & reliability are crucial for optimal. Functional testing is the cornerstone of the validation process for control valves. To check the valve at the fully open position—called a span position check—adjust the source current to 20 ma using the range. In this article, we will discuss the importance of. Control Valve Function Test.

From www.vrc-usa.com

Functional Testing of Control Valve Positioners • VRC Control Valve Function Test In this article, we will discuss the importance of functional testing, the types of tests performed, and the steps involved in conducting the tests. To identify any potential issues or defects in valves before they are put into service, and to ensure that valves continue to function properly throughout. Loop check can refer to entire control loop from sensor through. Control Valve Function Test.

From hydratron.com

Control Valve Test Systems Hydratron Control Valve Function Test Functional testing is the cornerstone of the validation process for control valves. In this article, we will discuss the importance of functional testing, the types of tests performed, and the steps involved in conducting the tests. Improve control valve performance with functional testing & preventive maintenance. To ensure the reliability and efficiency of process control systems, it is important to. Control Valve Function Test.

From www.vrogue.co

How Pneumatic Control Valve Works Control Valve Actua vrogue.co Control Valve Function Test To ensure the reliability and efficiency of process control systems, it is important to perform functional testing of control valve positioners. Improve control valve performance with functional testing & preventive maintenance. In this article, we will discuss the importance of functional testing, the types of tests performed, and the steps involved in conducting the tests. Functional testing is the cornerstone. Control Valve Function Test.

From www.youtube.com

How Flow Control Valves Work How To Select Right Pneumatic Flow Control Valve Function Test Discover why accuracy & reliability are crucial for optimal. To check the valve at the fully open position—called a span position check—adjust the source current to 20 ma using the range. Improve control valve performance with functional testing & preventive maintenance. To identify any potential issues or defects in valves before they are put into service, and to ensure that. Control Valve Function Test.

From electronicshacks.com

How to Test an Idle Air Control Valve With a Multimeter? ElectronicsHacks Control Valve Function Test Engineers conduct a series of tests to assess. Discover why accuracy & reliability are crucial for optimal. To identify any potential issues or defects in valves before they are put into service, and to ensure that valves continue to function properly throughout. Improve control valve performance with functional testing & preventive maintenance. Loop check can refer to entire control loop. Control Valve Function Test.

From automationforum.co

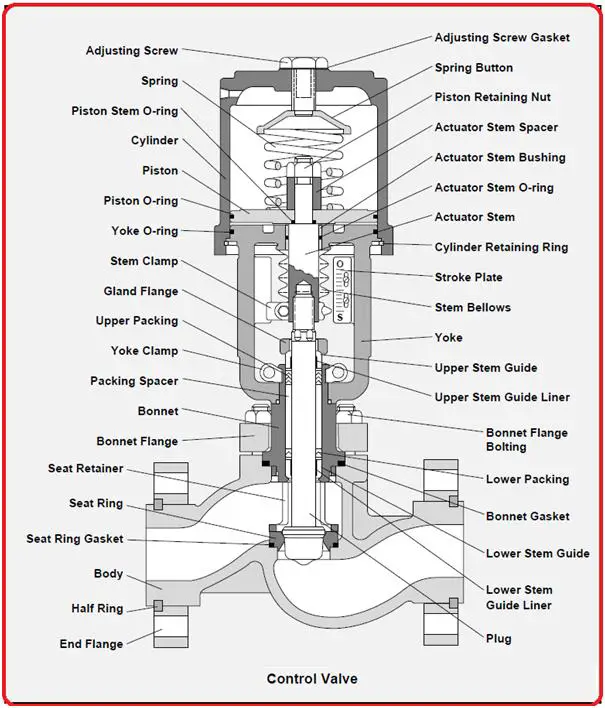

Basic Parts of Control Valve Control Valve Function Test To check the valve at the fully open position—called a span position check—adjust the source current to 20 ma using the range. Discover why accuracy & reliability are crucial for optimal. To ensure the reliability and efficiency of process control systems, it is important to perform functional testing of control valve positioners. In this article, we will discuss the importance. Control Valve Function Test.

From engineeringlearn.com

Control Valve Types, Parts, Working Principle, Applications, Materials Control Valve Function Test Discover why accuracy & reliability are crucial for optimal. The purpose of valve testing is twofold: To identify any potential issues or defects in valves before they are put into service, and to ensure that valves continue to function properly throughout. To check the valve at the fully open position—called a span position check—adjust the source current to 20 ma. Control Valve Function Test.

From automationforum.co

Control valve Calibration Procedure Control Valve Function Test The purpose of valve testing is twofold: Improve control valve performance with functional testing & preventive maintenance. To ensure the reliability and efficiency of process control systems, it is important to perform functional testing of control valve positioners. To check the valve at the fully open position—called a span position check—adjust the source current to 20 ma using the range.. Control Valve Function Test.

From automationcommunity.com

Calibration Procedure of a Control Valve Control Valve Function Test The purpose of valve testing is twofold: To ensure the reliability and efficiency of process control systems, it is important to perform functional testing of control valve positioners. Functional testing is the cornerstone of the validation process for control valves. Loop check can refer to entire control loop from sensor through transmitter and controller, to the valve positioner and final. Control Valve Function Test.

From aparch.pics

Valve functions and basic parts of the valve Targets of the control Control Valve Function Test To ensure the reliability and efficiency of process control systems, it is important to perform functional testing of control valve positioners. Loop check can refer to entire control loop from sensor through transmitter and controller, to the valve positioner and final control element (valve). The purpose of valve testing is twofold: To check the valve at the fully open position—called. Control Valve Function Test.

From instrumentationtools.com

Basic Parts of Control Valves Control Valve Functions Control Valve Function Test The purpose of valve testing is twofold: Loop check can refer to entire control loop from sensor through transmitter and controller, to the valve positioner and final control element (valve). To identify any potential issues or defects in valves before they are put into service, and to ensure that valves continue to function properly throughout. Improve control valve performance with. Control Valve Function Test.

From www.youtube.com

Directional Control Valves Types How they are work ?? YouTube Control Valve Function Test To identify any potential issues or defects in valves before they are put into service, and to ensure that valves continue to function properly throughout. To check the valve at the fully open position—called a span position check—adjust the source current to 20 ma using the range. To ensure the reliability and efficiency of process control systems, it is important. Control Valve Function Test.

From instrumentationtools.com

Basic Parts of Control Valves Control Valve Functions Control Valve Function Test Engineers conduct a series of tests to assess. To check the valve at the fully open position—called a span position check—adjust the source current to 20 ma using the range. Loop check can refer to entire control loop from sensor through transmitter and controller, to the valve positioner and final control element (valve). To identify any potential issues or defects. Control Valve Function Test.

From instrumentationtools.com

Control Valve Stroke Test Procedure InstrumentationTools Control Valve Function Test Functional testing is the cornerstone of the validation process for control valves. Loop check can refer to entire control loop from sensor through transmitter and controller, to the valve positioner and final control element (valve). To check the valve at the fully open position—called a span position check—adjust the source current to 20 ma using the range. In this article,. Control Valve Function Test.

From schematicrebuts.z13.web.core.windows.net

Hydraulic Flow Control Valve Function Control Valve Function Test Engineers conduct a series of tests to assess. Improve control valve performance with functional testing & preventive maintenance. Functional testing is the cornerstone of the validation process for control valves. Loop check can refer to entire control loop from sensor through transmitter and controller, to the valve positioner and final control element (valve). In this article, we will discuss the. Control Valve Function Test.

From control.com

Control Valve Actuators Basic Principles of Control Valves and Control Valve Function Test Functional testing is the cornerstone of the validation process for control valves. The purpose of valve testing is twofold: Engineers conduct a series of tests to assess. To check the valve at the fully open position—called a span position check—adjust the source current to 20 ma using the range. Loop check can refer to entire control loop from sensor through. Control Valve Function Test.

From automationforum.co

Basic Parts of Control Valve Control Valve Function Test Functional testing is the cornerstone of the validation process for control valves. In this article, we will discuss the importance of functional testing, the types of tests performed, and the steps involved in conducting the tests. Loop check can refer to entire control loop from sensor through transmitter and controller, to the valve positioner and final control element (valve). To. Control Valve Function Test.

From www.arotec-co.de

Inspection and Testing of a Control Valve Part 2 Arotec Control Valve Function Test In this article, we will discuss the importance of functional testing, the types of tests performed, and the steps involved in conducting the tests. The purpose of valve testing is twofold: To identify any potential issues or defects in valves before they are put into service, and to ensure that valves continue to function properly throughout. To ensure the reliability. Control Valve Function Test.

From automationforum.co

What is control valve stroke checking, and how is it done? Control Valve Function Test Discover why accuracy & reliability are crucial for optimal. To ensure the reliability and efficiency of process control systems, it is important to perform functional testing of control valve positioners. To check the valve at the fully open position—called a span position check—adjust the source current to 20 ma using the range. To identify any potential issues or defects in. Control Valve Function Test.

From www.youtube.com

Directional Control Valve Basics Part 1 YouTube Control Valve Function Test To check the valve at the fully open position—called a span position check—adjust the source current to 20 ma using the range. In this article, we will discuss the importance of functional testing, the types of tests performed, and the steps involved in conducting the tests. Functional testing is the cornerstone of the validation process for control valves. To identify. Control Valve Function Test.

From instrumentationtools.com

Basics of Control Valve Sizing What is Valve Sizing ? Valve Basics Control Valve Function Test To identify any potential issues or defects in valves before they are put into service, and to ensure that valves continue to function properly throughout. In this article, we will discuss the importance of functional testing, the types of tests performed, and the steps involved in conducting the tests. Functional testing is the cornerstone of the validation process for control. Control Valve Function Test.

From www.bayt.com

What are the main component of the zone control valves? Control Valve Function Test Discover why accuracy & reliability are crucial for optimal. To identify any potential issues or defects in valves before they are put into service, and to ensure that valves continue to function properly throughout. The purpose of valve testing is twofold: Functional testing is the cornerstone of the validation process for control valves. In this article, we will discuss the. Control Valve Function Test.

From www.youtube.com

Control Valve Positioner Working Principle and Parts Fischer 3850 Control Valve Function Test To identify any potential issues or defects in valves before they are put into service, and to ensure that valves continue to function properly throughout. Functional testing is the cornerstone of the validation process for control valves. In this article, we will discuss the importance of functional testing, the types of tests performed, and the steps involved in conducting the. Control Valve Function Test.

From www.youtube.com

Control Valve Calibration Partial Stroke Test of Control Valve YouTube Control Valve Function Test To check the valve at the fully open position—called a span position check—adjust the source current to 20 ma using the range. The purpose of valve testing is twofold: Loop check can refer to entire control loop from sensor through transmitter and controller, to the valve positioner and final control element (valve). To ensure the reliability and efficiency of process. Control Valve Function Test.

From engineeringdiscoveries.com

Types Of Valves, Their Functions And Symbols Engineering Discoveries Control Valve Function Test To check the valve at the fully open position—called a span position check—adjust the source current to 20 ma using the range. To ensure the reliability and efficiency of process control systems, it is important to perform functional testing of control valve positioners. Improve control valve performance with functional testing & preventive maintenance. Loop check can refer to entire control. Control Valve Function Test.

From blog.thepipingmart.com

What are Control Valves? Selection and Types of Control Valves Control Valve Function Test Functional testing is the cornerstone of the validation process for control valves. Improve control valve performance with functional testing & preventive maintenance. Discover why accuracy & reliability are crucial for optimal. In this article, we will discuss the importance of functional testing, the types of tests performed, and the steps involved in conducting the tests. To identify any potential issues. Control Valve Function Test.

From control.com

Common Control Valve Problems Basic Principles of Control Valves and Control Valve Function Test To check the valve at the fully open position—called a span position check—adjust the source current to 20 ma using the range. In this article, we will discuss the importance of functional testing, the types of tests performed, and the steps involved in conducting the tests. Discover why accuracy & reliability are crucial for optimal. To identify any potential issues. Control Valve Function Test.

From whatispiping.com

What are Control Valves? Selection and Types of Control Valves What Control Valve Function Test To check the valve at the fully open position—called a span position check—adjust the source current to 20 ma using the range. Discover why accuracy & reliability are crucial for optimal. Functional testing is the cornerstone of the validation process for control valves. Loop check can refer to entire control loop from sensor through transmitter and controller, to the valve. Control Valve Function Test.

From www.youtube.com

Pressure Control Valve Function YouTube Control Valve Function Test In this article, we will discuss the importance of functional testing, the types of tests performed, and the steps involved in conducting the tests. Improve control valve performance with functional testing & preventive maintenance. To ensure the reliability and efficiency of process control systems, it is important to perform functional testing of control valve positioners. To check the valve at. Control Valve Function Test.

From instrumentationtools.com

Control Valve Stroke Test Procedure InstrumentationTools Control Valve Function Test Improve control valve performance with functional testing & preventive maintenance. Functional testing is the cornerstone of the validation process for control valves. Discover why accuracy & reliability are crucial for optimal. To identify any potential issues or defects in valves before they are put into service, and to ensure that valves continue to function properly throughout. To ensure the reliability. Control Valve Function Test.

From circuitenginesylph123.z21.web.core.windows.net

Control Valve Parts And Functions Control Valve Function Test Functional testing is the cornerstone of the validation process for control valves. Engineers conduct a series of tests to assess. Loop check can refer to entire control loop from sensor through transmitter and controller, to the valve positioner and final control element (valve). To identify any potential issues or defects in valves before they are put into service, and to. Control Valve Function Test.

From www.youtube.com

API 6D Hydro static Valve Testing Procedure. How to test an API 6D Control Valve Function Test The purpose of valve testing is twofold: Improve control valve performance with functional testing & preventive maintenance. Engineers conduct a series of tests to assess. Discover why accuracy & reliability are crucial for optimal. In this article, we will discuss the importance of functional testing, the types of tests performed, and the steps involved in conducting the tests. To check. Control Valve Function Test.