Cost Compression Moulding . Fictiv’s ultimate guide to compression molding explains what part designers need to know about this parts production process for plastic, rubber, and composite materials. Compression moulding uses a heated cavity to shape the material under pressure, whereas injection moulding injects molten material into a mould. Compression molding is a manufacturing process used to create plastic and composite parts. Through a mixture of heat and high pressure, it squeezes materials—like. Fast mold and part quote; Compression molding is a common polymer manufacturing process for thermosets, thermoplastics, as well as elastomers and. Low cost, high quality, fast turnaround; Good for small production runs the lower capital cost of manufacturing a mould tool, setting up a press and beginning to run production parts means that compression moulding is the most cost effective method of making smaller runs of parts. The cost of designing and manufacturing a compression mold can be significant, making it less economical for low.

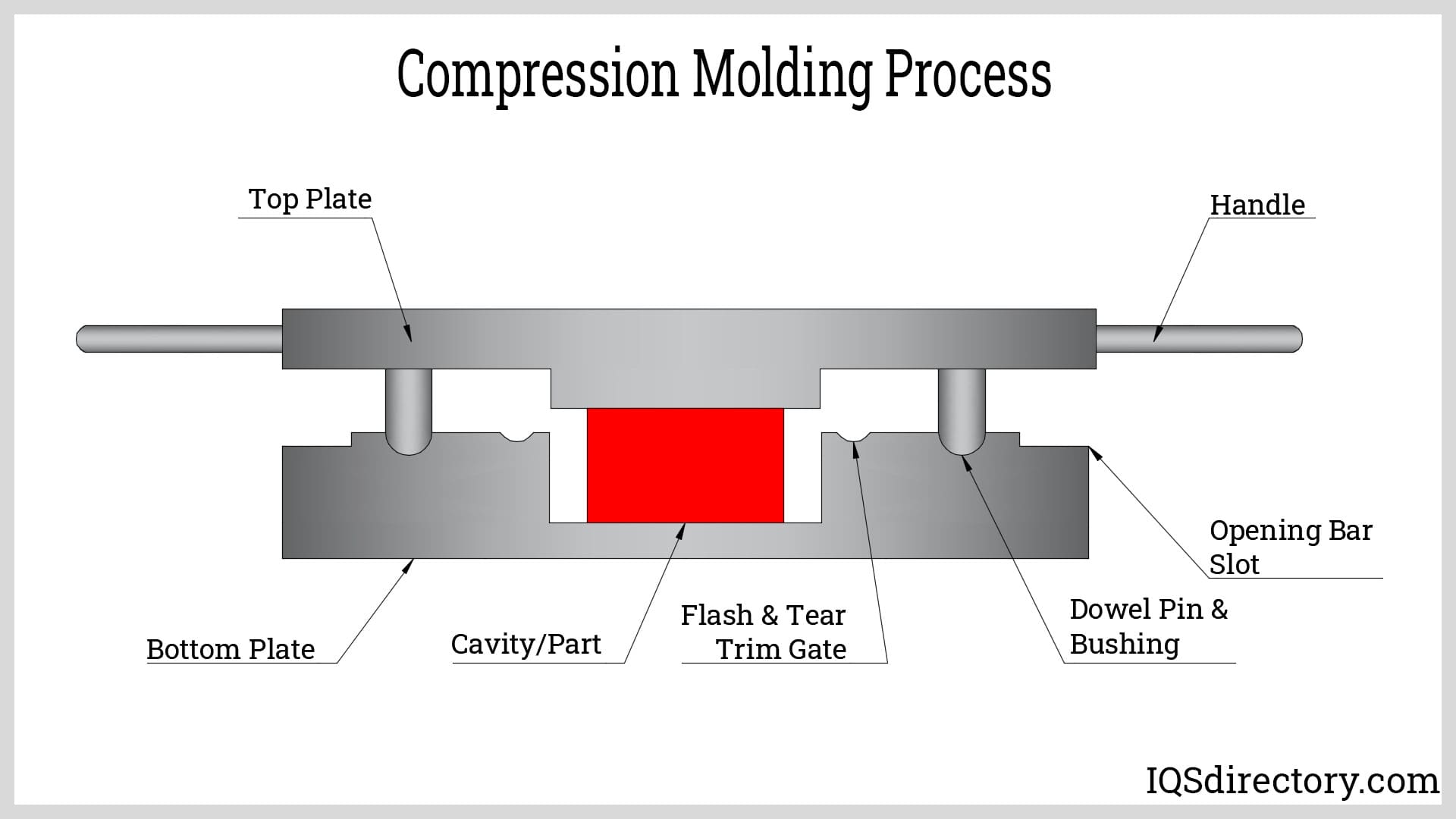

from www.iqsdirectory.com

Low cost, high quality, fast turnaround; Compression molding is a common polymer manufacturing process for thermosets, thermoplastics, as well as elastomers and. Fictiv’s ultimate guide to compression molding explains what part designers need to know about this parts production process for plastic, rubber, and composite materials. Good for small production runs the lower capital cost of manufacturing a mould tool, setting up a press and beginning to run production parts means that compression moulding is the most cost effective method of making smaller runs of parts. Through a mixture of heat and high pressure, it squeezes materials—like. Compression molding is a manufacturing process used to create plastic and composite parts. Compression moulding uses a heated cavity to shape the material under pressure, whereas injection moulding injects molten material into a mould. The cost of designing and manufacturing a compression mold can be significant, making it less economical for low. Fast mold and part quote;

Rubber Overmolding Process, Uses, Considerations & Benefits

Cost Compression Moulding Compression moulding uses a heated cavity to shape the material under pressure, whereas injection moulding injects molten material into a mould. Compression moulding uses a heated cavity to shape the material under pressure, whereas injection moulding injects molten material into a mould. Compression molding is a common polymer manufacturing process for thermosets, thermoplastics, as well as elastomers and. Fictiv’s ultimate guide to compression molding explains what part designers need to know about this parts production process for plastic, rubber, and composite materials. Good for small production runs the lower capital cost of manufacturing a mould tool, setting up a press and beginning to run production parts means that compression moulding is the most cost effective method of making smaller runs of parts. Low cost, high quality, fast turnaround; Fast mold and part quote; The cost of designing and manufacturing a compression mold can be significant, making it less economical for low. Through a mixture of heat and high pressure, it squeezes materials—like. Compression molding is a manufacturing process used to create plastic and composite parts.

From www.indiamart.com

Compression Moulding at best price in Kolkata by D . Kapur Pvt. Ltd Cost Compression Moulding Low cost, high quality, fast turnaround; Compression molding is a common polymer manufacturing process for thermosets, thermoplastics, as well as elastomers and. Good for small production runs the lower capital cost of manufacturing a mould tool, setting up a press and beginning to run production parts means that compression moulding is the most cost effective method of making smaller runs. Cost Compression Moulding.

From www.sourceint.com

Rubber Compression Molding Source International Cost Compression Moulding Through a mixture of heat and high pressure, it squeezes materials—like. Compression moulding uses a heated cavity to shape the material under pressure, whereas injection moulding injects molten material into a mould. Fictiv’s ultimate guide to compression molding explains what part designers need to know about this parts production process for plastic, rubber, and composite materials. Fast mold and part. Cost Compression Moulding.

From dpseals.com

Rubber Moulding Process Comparisons DP Seals Cost Compression Moulding Fictiv’s ultimate guide to compression molding explains what part designers need to know about this parts production process for plastic, rubber, and composite materials. The cost of designing and manufacturing a compression mold can be significant, making it less economical for low. Good for small production runs the lower capital cost of manufacturing a mould tool, setting up a press. Cost Compression Moulding.

From www.iqsdirectory.com

Rubber Overmolding Process, Uses, Considerations & Benefits Cost Compression Moulding Compression moulding uses a heated cavity to shape the material under pressure, whereas injection moulding injects molten material into a mould. Compression molding is a common polymer manufacturing process for thermosets, thermoplastics, as well as elastomers and. Through a mixture of heat and high pressure, it squeezes materials—like. Fictiv’s ultimate guide to compression molding explains what part designers need to. Cost Compression Moulding.

From www.iqsdirectory.com

Compression Molding Process, Types of Molds, Features and Benefits Cost Compression Moulding The cost of designing and manufacturing a compression mold can be significant, making it less economical for low. Compression molding is a common polymer manufacturing process for thermosets, thermoplastics, as well as elastomers and. Compression molding is a manufacturing process used to create plastic and composite parts. Fictiv’s ultimate guide to compression molding explains what part designers need to know. Cost Compression Moulding.

From www.rutlandplastics.co.uk

Plastics Moulding Methods Compression Rutland Plastics Cost Compression Moulding The cost of designing and manufacturing a compression mold can be significant, making it less economical for low. Fictiv’s ultimate guide to compression molding explains what part designers need to know about this parts production process for plastic, rubber, and composite materials. Compression molding is a manufacturing process used to create plastic and composite parts. Low cost, high quality, fast. Cost Compression Moulding.

From www.lsr-molding.com

What is Rubber Compression Moulding? Liquid Injection Moulding Cost Compression Moulding Compression moulding uses a heated cavity to shape the material under pressure, whereas injection moulding injects molten material into a mould. Fictiv’s ultimate guide to compression molding explains what part designers need to know about this parts production process for plastic, rubber, and composite materials. Through a mixture of heat and high pressure, it squeezes materials—like. Compression molding is a. Cost Compression Moulding.

From www.boyiprototyping.com

Compression Molding vs Injection Molding Cost and Process Differences Cost Compression Moulding The cost of designing and manufacturing a compression mold can be significant, making it less economical for low. Compression moulding uses a heated cavity to shape the material under pressure, whereas injection moulding injects molten material into a mould. Good for small production runs the lower capital cost of manufacturing a mould tool, setting up a press and beginning to. Cost Compression Moulding.

From www.indiamart.com

1000 x 1500 mm Upstroke Compression Moulding Machine, 600 Tons at best Cost Compression Moulding Compression moulding uses a heated cavity to shape the material under pressure, whereas injection moulding injects molten material into a mould. Fictiv’s ultimate guide to compression molding explains what part designers need to know about this parts production process for plastic, rubber, and composite materials. Compression molding is a common polymer manufacturing process for thermosets, thermoplastics, as well as elastomers. Cost Compression Moulding.

From www.iqsdirectory.com

Compression Molding Process, Types of Molds, Features and Benefits Cost Compression Moulding Good for small production runs the lower capital cost of manufacturing a mould tool, setting up a press and beginning to run production parts means that compression moulding is the most cost effective method of making smaller runs of parts. Compression molding is a manufacturing process used to create plastic and composite parts. Fast mold and part quote; Fictiv’s ultimate. Cost Compression Moulding.

From www.researchgate.net

The schematic of compression moulding process. Download Scientific Cost Compression Moulding The cost of designing and manufacturing a compression mold can be significant, making it less economical for low. Compression molding is a common polymer manufacturing process for thermosets, thermoplastics, as well as elastomers and. Compression molding is a manufacturing process used to create plastic and composite parts. Fast mold and part quote; Compression moulding uses a heated cavity to shape. Cost Compression Moulding.

From www.wemould.com

What is Compression Mould 2k mould, gas assisted mould, compression mould Cost Compression Moulding Compression molding is a common polymer manufacturing process for thermosets, thermoplastics, as well as elastomers and. Through a mixture of heat and high pressure, it squeezes materials—like. Fictiv’s ultimate guide to compression molding explains what part designers need to know about this parts production process for plastic, rubber, and composite materials. Fast mold and part quote; Compression molding is a. Cost Compression Moulding.

From www.researchgate.net

Process principle of compression moulding Download HighResolution Cost Compression Moulding Compression molding is a common polymer manufacturing process for thermosets, thermoplastics, as well as elastomers and. Compression molding is a manufacturing process used to create plastic and composite parts. Low cost, high quality, fast turnaround; Fast mold and part quote; Compression moulding uses a heated cavity to shape the material under pressure, whereas injection moulding injects molten material into a. Cost Compression Moulding.

From www.better-silicone.com

Silicone Rubber Compression Molding for Grommet from China manufacturer Cost Compression Moulding Low cost, high quality, fast turnaround; Compression molding is a common polymer manufacturing process for thermosets, thermoplastics, as well as elastomers and. Fictiv’s ultimate guide to compression molding explains what part designers need to know about this parts production process for plastic, rubber, and composite materials. Fast mold and part quote; The cost of designing and manufacturing a compression mold. Cost Compression Moulding.

From www.alpinemold.com

Injection Molding vs. Compression Molding Alpine mold Cost Compression Moulding Fictiv’s ultimate guide to compression molding explains what part designers need to know about this parts production process for plastic, rubber, and composite materials. Compression moulding uses a heated cavity to shape the material under pressure, whereas injection moulding injects molten material into a mould. The cost of designing and manufacturing a compression mold can be significant, making it less. Cost Compression Moulding.

From www.lsr-molding.com

What is Rubber Compression Moulding? Liquid Injection Moulding Cost Compression Moulding Compression molding is a manufacturing process used to create plastic and composite parts. The cost of designing and manufacturing a compression mold can be significant, making it less economical for low. Good for small production runs the lower capital cost of manufacturing a mould tool, setting up a press and beginning to run production parts means that compression moulding is. Cost Compression Moulding.

From www.stockwell.com

Rubber Compression Molding, Silicone Rubber Compression Molding Cost Compression Moulding Compression moulding uses a heated cavity to shape the material under pressure, whereas injection moulding injects molten material into a mould. The cost of designing and manufacturing a compression mold can be significant, making it less economical for low. Low cost, high quality, fast turnaround; Compression molding is a manufacturing process used to create plastic and composite parts. Good for. Cost Compression Moulding.

From www.iqsdirectory.com

Compression Molding Process, Types of Molds, Features and Benefits Cost Compression Moulding Compression molding is a common polymer manufacturing process for thermosets, thermoplastics, as well as elastomers and. Fast mold and part quote; Low cost, high quality, fast turnaround; Compression moulding uses a heated cavity to shape the material under pressure, whereas injection moulding injects molten material into a mould. The cost of designing and manufacturing a compression mold can be significant,. Cost Compression Moulding.

From www.cecence.com

How hot compression moulding saves production costs Cecence Cost Compression Moulding Through a mixture of heat and high pressure, it squeezes materials—like. Compression molding is a common polymer manufacturing process for thermosets, thermoplastics, as well as elastomers and. Low cost, high quality, fast turnaround; Compression moulding uses a heated cavity to shape the material under pressure, whereas injection moulding injects molten material into a mould. Fast mold and part quote; The. Cost Compression Moulding.

From polymerspk.com

Compression moulding Polymers Cost Compression Moulding Compression moulding uses a heated cavity to shape the material under pressure, whereas injection moulding injects molten material into a mould. Fast mold and part quote; Good for small production runs the lower capital cost of manufacturing a mould tool, setting up a press and beginning to run production parts means that compression moulding is the most cost effective method. Cost Compression Moulding.

From plasticoid.com

Compression Molding Plasticoid Company Cost Compression Moulding Compression molding is a common polymer manufacturing process for thermosets, thermoplastics, as well as elastomers and. Good for small production runs the lower capital cost of manufacturing a mould tool, setting up a press and beginning to run production parts means that compression moulding is the most cost effective method of making smaller runs of parts. Compression molding is a. Cost Compression Moulding.

From www.lsr-molding.com

What is Compression Molding & Rubber Injection Moulding? Better Cost Compression Moulding Through a mixture of heat and high pressure, it squeezes materials—like. Compression molding is a manufacturing process used to create plastic and composite parts. Good for small production runs the lower capital cost of manufacturing a mould tool, setting up a press and beginning to run production parts means that compression moulding is the most cost effective method of making. Cost Compression Moulding.

From www.tradeindia.com

Ptfe Compression Moulding at Best Price in Changzhou, Jiangsu Cost Compression Moulding Fictiv’s ultimate guide to compression molding explains what part designers need to know about this parts production process for plastic, rubber, and composite materials. Through a mixture of heat and high pressure, it squeezes materials—like. Compression molding is a common polymer manufacturing process for thermosets, thermoplastics, as well as elastomers and. Low cost, high quality, fast turnaround; The cost of. Cost Compression Moulding.

From www.hardwareinterviews.fyi

Basics of Compression Molding Consumer Hardware Guide Hardware FYI Cost Compression Moulding The cost of designing and manufacturing a compression mold can be significant, making it less economical for low. Compression molding is a manufacturing process used to create plastic and composite parts. Compression moulding uses a heated cavity to shape the material under pressure, whereas injection moulding injects molten material into a mould. Low cost, high quality, fast turnaround; Through a. Cost Compression Moulding.

From www.rcoeng.com

Compression Molding Services RCO Engineering Cost Compression Moulding Fictiv’s ultimate guide to compression molding explains what part designers need to know about this parts production process for plastic, rubber, and composite materials. Compression moulding uses a heated cavity to shape the material under pressure, whereas injection moulding injects molten material into a mould. Fast mold and part quote; Low cost, high quality, fast turnaround; Good for small production. Cost Compression Moulding.

From siliconemakers.com

A Comprehensive Guide to Silicone Compression Molding Cost Compression Moulding Low cost, high quality, fast turnaround; Through a mixture of heat and high pressure, it squeezes materials—like. Fast mold and part quote; Good for small production runs the lower capital cost of manufacturing a mould tool, setting up a press and beginning to run production parts means that compression moulding is the most cost effective method of making smaller runs. Cost Compression Moulding.

From www.iqsdirectory.com

Compression Molding Process, Types of Molds, Features and Benefits Cost Compression Moulding Through a mixture of heat and high pressure, it squeezes materials—like. Good for small production runs the lower capital cost of manufacturing a mould tool, setting up a press and beginning to run production parts means that compression moulding is the most cost effective method of making smaller runs of parts. Low cost, high quality, fast turnaround; Fast mold and. Cost Compression Moulding.

From www.better-silicone.com

Slicone Compression Molding Rubber Compression Molding Process Cost Compression Moulding Through a mixture of heat and high pressure, it squeezes materials—like. Fast mold and part quote; Fictiv’s ultimate guide to compression molding explains what part designers need to know about this parts production process for plastic, rubber, and composite materials. Good for small production runs the lower capital cost of manufacturing a mould tool, setting up a press and beginning. Cost Compression Moulding.

From learnmech.com

Compression molding Process Advantages and Disadvantages Cost Compression Moulding Good for small production runs the lower capital cost of manufacturing a mould tool, setting up a press and beginning to run production parts means that compression moulding is the most cost effective method of making smaller runs of parts. Low cost, high quality, fast turnaround; Compression molding is a manufacturing process used to create plastic and composite parts. Compression. Cost Compression Moulding.

From www.tradeindia.com

Hydraulic Compression Moulding Machine Application Industrial at Cost Compression Moulding The cost of designing and manufacturing a compression mold can be significant, making it less economical for low. Compression moulding uses a heated cavity to shape the material under pressure, whereas injection moulding injects molten material into a mould. Compression molding is a common polymer manufacturing process for thermosets, thermoplastics, as well as elastomers and. Low cost, high quality, fast. Cost Compression Moulding.

From www.flickriver.com

Compression moulding a photo on Flickriver Cost Compression Moulding Compression molding is a common polymer manufacturing process for thermosets, thermoplastics, as well as elastomers and. Compression molding is a manufacturing process used to create plastic and composite parts. The cost of designing and manufacturing a compression mold can be significant, making it less economical for low. Compression moulding uses a heated cavity to shape the material under pressure, whereas. Cost Compression Moulding.

From www.iqsdirectory.com

Compression Molding Process, Types of Molds, Features and Benefits Cost Compression Moulding Compression moulding uses a heated cavity to shape the material under pressure, whereas injection moulding injects molten material into a mould. Fictiv’s ultimate guide to compression molding explains what part designers need to know about this parts production process for plastic, rubber, and composite materials. Good for small production runs the lower capital cost of manufacturing a mould tool, setting. Cost Compression Moulding.

From avmr.com

Rubber Injection Moulding & Compression Moulding AVMR Cost Compression Moulding Fictiv’s ultimate guide to compression molding explains what part designers need to know about this parts production process for plastic, rubber, and composite materials. Compression moulding uses a heated cavity to shape the material under pressure, whereas injection moulding injects molten material into a mould. Fast mold and part quote; Compression molding is a common polymer manufacturing process for thermosets,. Cost Compression Moulding.

From lakeerierubber.com

Custom Rubber Compression Molding Manufacturer in PA Cost Compression Moulding Compression moulding uses a heated cavity to shape the material under pressure, whereas injection moulding injects molten material into a mould. Fast mold and part quote; Low cost, high quality, fast turnaround; Compression molding is a manufacturing process used to create plastic and composite parts. Good for small production runs the lower capital cost of manufacturing a mould tool, setting. Cost Compression Moulding.

From www.iqsdirectory.com

Compression Molding Process, Types of Molds, Features and Benefits Cost Compression Moulding Compression molding is a manufacturing process used to create plastic and composite parts. Fictiv’s ultimate guide to compression molding explains what part designers need to know about this parts production process for plastic, rubber, and composite materials. Compression molding is a common polymer manufacturing process for thermosets, thermoplastics, as well as elastomers and. Through a mixture of heat and high. Cost Compression Moulding.