Extend Cutting Tool Life . The three main machining parameters when turning are speed, feed, and depth of cut. One may think that it is marked by the duration between when it comes into use and when it breaks. However, it is, in fact, the period marked by the actual cutting time, following which the tool experiences wear and tear and eventually goes out of use. here are our top 5 strategies for extending the life of your endmills: by understanding the factors that affect tool life and implementing an effective tool life program, you can extend tool longevity,. regular machine inspections, maintenance, and alignment checks are vital for optimizing machine conditions and extending tool life. tool life corresponds to the usefulness of a machine tool. how to improve tool life in turning. The chosen tool path affects tool life due to factors like cutting forces, chip formation, chip evacuation,.

from www.chegg.com

One may think that it is marked by the duration between when it comes into use and when it breaks. The three main machining parameters when turning are speed, feed, and depth of cut. The chosen tool path affects tool life due to factors like cutting forces, chip formation, chip evacuation,. However, it is, in fact, the period marked by the actual cutting time, following which the tool experiences wear and tear and eventually goes out of use. regular machine inspections, maintenance, and alignment checks are vital for optimizing machine conditions and extending tool life. how to improve tool life in turning. tool life corresponds to the usefulness of a machine tool. here are our top 5 strategies for extending the life of your endmills: by understanding the factors that affect tool life and implementing an effective tool life program, you can extend tool longevity,.

Solved A tool life of 48 mins for a cutting speed of 80

Extend Cutting Tool Life by understanding the factors that affect tool life and implementing an effective tool life program, you can extend tool longevity,. tool life corresponds to the usefulness of a machine tool. regular machine inspections, maintenance, and alignment checks are vital for optimizing machine conditions and extending tool life. by understanding the factors that affect tool life and implementing an effective tool life program, you can extend tool longevity,. The three main machining parameters when turning are speed, feed, and depth of cut. here are our top 5 strategies for extending the life of your endmills: One may think that it is marked by the duration between when it comes into use and when it breaks. However, it is, in fact, the period marked by the actual cutting time, following which the tool experiences wear and tear and eventually goes out of use. how to improve tool life in turning. The chosen tool path affects tool life due to factors like cutting forces, chip formation, chip evacuation,.

From www.sumipol.com

11 Tips เพิ่ม Tool Life ลด Tool Wear ในงาน Machining Sumipol Extend Cutting Tool Life how to improve tool life in turning. The three main machining parameters when turning are speed, feed, and depth of cut. However, it is, in fact, the period marked by the actual cutting time, following which the tool experiences wear and tear and eventually goes out of use. tool life corresponds to the usefulness of a machine tool.. Extend Cutting Tool Life.

From www.sumipol.com

11 Tips เพิ่ม Tool Life ลด Tool Wear ในงาน Machining Sumipol Extend Cutting Tool Life how to improve tool life in turning. regular machine inspections, maintenance, and alignment checks are vital for optimizing machine conditions and extending tool life. by understanding the factors that affect tool life and implementing an effective tool life program, you can extend tool longevity,. The chosen tool path affects tool life due to factors like cutting forces,. Extend Cutting Tool Life.

From www.youtube.com

Techniks Certified End Mill Holders Extend Cutting Tool Life YouTube Extend Cutting Tool Life The three main machining parameters when turning are speed, feed, and depth of cut. by understanding the factors that affect tool life and implementing an effective tool life program, you can extend tool longevity,. here are our top 5 strategies for extending the life of your endmills: However, it is, in fact, the period marked by the actual. Extend Cutting Tool Life.

From askfilo.com

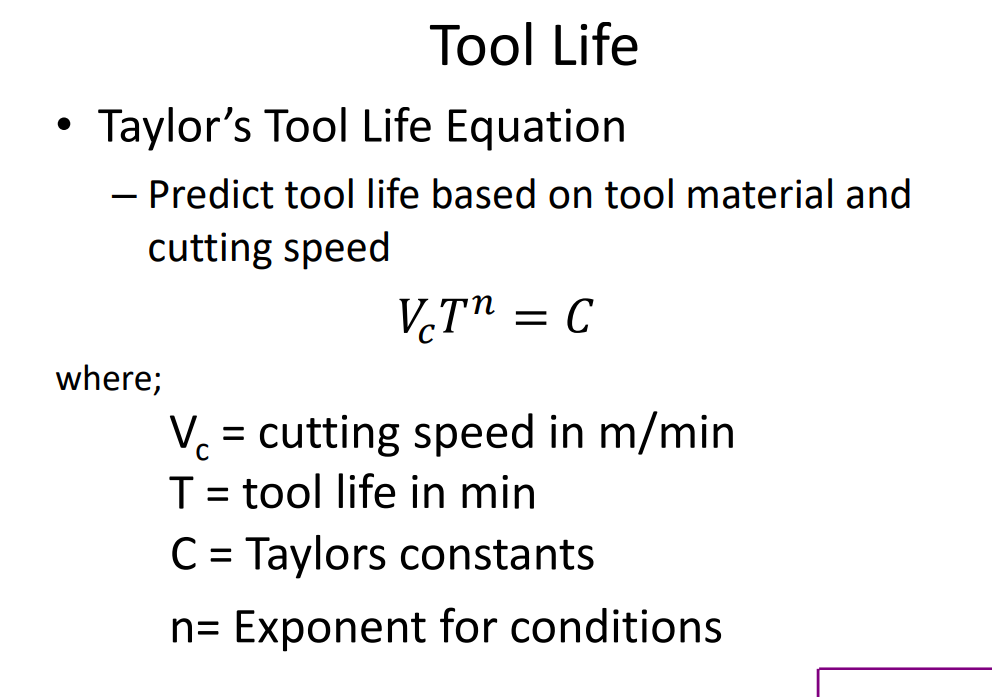

1. If Taylor's tool life constants are given as n=0.5 and C=400, what is Extend Cutting Tool Life tool life corresponds to the usefulness of a machine tool. here are our top 5 strategies for extending the life of your endmills: However, it is, in fact, the period marked by the actual cutting time, following which the tool experiences wear and tear and eventually goes out of use. by understanding the factors that affect tool. Extend Cutting Tool Life.

From www.chegg.com

Solved A tool life of 48 mins for a cutting speed of 80 Extend Cutting Tool Life However, it is, in fact, the period marked by the actual cutting time, following which the tool experiences wear and tear and eventually goes out of use. by understanding the factors that affect tool life and implementing an effective tool life program, you can extend tool longevity,. The three main machining parameters when turning are speed, feed, and depth. Extend Cutting Tool Life.

From www.slideshare.net

5 easy tips to extend the metal cutting tool life Extend Cutting Tool Life how to improve tool life in turning. by understanding the factors that affect tool life and implementing an effective tool life program, you can extend tool longevity,. The chosen tool path affects tool life due to factors like cutting forces, chip formation, chip evacuation,. here are our top 5 strategies for extending the life of your endmills:. Extend Cutting Tool Life.

From slidetodoc.com

CUTTING TOOL TECHNOLOGY 1 Tool Life 2 Tool Extend Cutting Tool Life here are our top 5 strategies for extending the life of your endmills: One may think that it is marked by the duration between when it comes into use and when it breaks. However, it is, in fact, the period marked by the actual cutting time, following which the tool experiences wear and tear and eventually goes out of. Extend Cutting Tool Life.

From rakeangle.com

How to Improve Cutting Tool Life? Rake Angle Extend Cutting Tool Life how to improve tool life in turning. here are our top 5 strategies for extending the life of your endmills: The chosen tool path affects tool life due to factors like cutting forces, chip formation, chip evacuation,. tool life corresponds to the usefulness of a machine tool. One may think that it is marked by the duration. Extend Cutting Tool Life.

From www.walmart.com

Barber Lights for Cutting Hair Photo Remover Haircut Comb Hair Cutting Extend Cutting Tool Life here are our top 5 strategies for extending the life of your endmills: The chosen tool path affects tool life due to factors like cutting forces, chip formation, chip evacuation,. by understanding the factors that affect tool life and implementing an effective tool life program, you can extend tool longevity,. regular machine inspections, maintenance, and alignment checks. Extend Cutting Tool Life.

From www.alamy.com

machining cutting tool regrinding equipment ; to extend tool life Extend Cutting Tool Life here are our top 5 strategies for extending the life of your endmills: how to improve tool life in turning. by understanding the factors that affect tool life and implementing an effective tool life program, you can extend tool longevity,. One may think that it is marked by the duration between when it comes into use and. Extend Cutting Tool Life.

From shopmetaltech.com

5 Ways to extend cutting tool life Shop Metalworking Technology Extend Cutting Tool Life tool life corresponds to the usefulness of a machine tool. The three main machining parameters when turning are speed, feed, and depth of cut. However, it is, in fact, the period marked by the actual cutting time, following which the tool experiences wear and tear and eventually goes out of use. The chosen tool path affects tool life due. Extend Cutting Tool Life.

From www.slideserve.com

PPT Chapter 23 CUTTING TOOL TECHNOLOGY PowerPoint Presentation, free Extend Cutting Tool Life tool life corresponds to the usefulness of a machine tool. However, it is, in fact, the period marked by the actual cutting time, following which the tool experiences wear and tear and eventually goes out of use. The three main machining parameters when turning are speed, feed, and depth of cut. regular machine inspections, maintenance, and alignment checks. Extend Cutting Tool Life.

From shopmetaltech.com

5 Ways to extend cutting tool life Shop Metalworking Technology Extend Cutting Tool Life However, it is, in fact, the period marked by the actual cutting time, following which the tool experiences wear and tear and eventually goes out of use. here are our top 5 strategies for extending the life of your endmills: The chosen tool path affects tool life due to factors like cutting forces, chip formation, chip evacuation,. One may. Extend Cutting Tool Life.

From www.fintek.co.uk

Fintek Help Boost UK Productivity by Improving Cutting Tool Life and Extend Cutting Tool Life The chosen tool path affects tool life due to factors like cutting forces, chip formation, chip evacuation,. The three main machining parameters when turning are speed, feed, and depth of cut. One may think that it is marked by the duration between when it comes into use and when it breaks. However, it is, in fact, the period marked by. Extend Cutting Tool Life.

From www.harveyperformance.com

3 Ways Tool Coatings Increase Tool Life In The Loupe Extend Cutting Tool Life here are our top 5 strategies for extending the life of your endmills: The chosen tool path affects tool life due to factors like cutting forces, chip formation, chip evacuation,. One may think that it is marked by the duration between when it comes into use and when it breaks. by understanding the factors that affect tool life. Extend Cutting Tool Life.

From www.alamy.com

machining cutting tool regrinding equipment ; to extend tool life Extend Cutting Tool Life One may think that it is marked by the duration between when it comes into use and when it breaks. by understanding the factors that affect tool life and implementing an effective tool life program, you can extend tool longevity,. The chosen tool path affects tool life due to factors like cutting forces, chip formation, chip evacuation,. However, it. Extend Cutting Tool Life.

From www.slideserve.com

PPT Decoding_the_Top_Ways_to_Extend_Cutting_Tool_Life_bh1bST Extend Cutting Tool Life by understanding the factors that affect tool life and implementing an effective tool life program, you can extend tool longevity,. tool life corresponds to the usefulness of a machine tool. how to improve tool life in turning. regular machine inspections, maintenance, and alignment checks are vital for optimizing machine conditions and extending tool life. However, it. Extend Cutting Tool Life.

From tru-edge.com

Tool Life Management TruEdge Extend Cutting Tool Life regular machine inspections, maintenance, and alignment checks are vital for optimizing machine conditions and extending tool life. how to improve tool life in turning. here are our top 5 strategies for extending the life of your endmills: tool life corresponds to the usefulness of a machine tool. The chosen tool path affects tool life due to. Extend Cutting Tool Life.

From www.researchgate.net

Tool life at different machining conditions Download Table Extend Cutting Tool Life One may think that it is marked by the duration between when it comes into use and when it breaks. The three main machining parameters when turning are speed, feed, and depth of cut. However, it is, in fact, the period marked by the actual cutting time, following which the tool experiences wear and tear and eventually goes out of. Extend Cutting Tool Life.

From www.alamy.com

machining cutting tool regrinding equipment ; to extend tool life Extend Cutting Tool Life tool life corresponds to the usefulness of a machine tool. how to improve tool life in turning. regular machine inspections, maintenance, and alignment checks are vital for optimizing machine conditions and extending tool life. here are our top 5 strategies for extending the life of your endmills: However, it is, in fact, the period marked by. Extend Cutting Tool Life.

From www.researchgate.net

Cutting tool wearout monitoring setup. Download Scientific Diagram Extend Cutting Tool Life The three main machining parameters when turning are speed, feed, and depth of cut. here are our top 5 strategies for extending the life of your endmills: regular machine inspections, maintenance, and alignment checks are vital for optimizing machine conditions and extending tool life. by understanding the factors that affect tool life and implementing an effective tool. Extend Cutting Tool Life.

From www.researchgate.net

Tool life of the cutters Download Table Extend Cutting Tool Life However, it is, in fact, the period marked by the actual cutting time, following which the tool experiences wear and tear and eventually goes out of use. how to improve tool life in turning. The chosen tool path affects tool life due to factors like cutting forces, chip formation, chip evacuation,. here are our top 5 strategies for. Extend Cutting Tool Life.

From inbound.cammmetals.com

7 Ways to Extend Cutting Tool Life Extend Cutting Tool Life One may think that it is marked by the duration between when it comes into use and when it breaks. regular machine inspections, maintenance, and alignment checks are vital for optimizing machine conditions and extending tool life. The three main machining parameters when turning are speed, feed, and depth of cut. by understanding the factors that affect tool. Extend Cutting Tool Life.

From www.machinemetrics.com

What is Tool Life? How to Optimize Tooling with Machine Data Extend Cutting Tool Life regular machine inspections, maintenance, and alignment checks are vital for optimizing machine conditions and extending tool life. how to improve tool life in turning. The three main machining parameters when turning are speed, feed, and depth of cut. tool life corresponds to the usefulness of a machine tool. The chosen tool path affects tool life due to. Extend Cutting Tool Life.

From www.youtube.com

Taylor's tool life equation In Metal cutting Example Problem YouTube Extend Cutting Tool Life The three main machining parameters when turning are speed, feed, and depth of cut. However, it is, in fact, the period marked by the actual cutting time, following which the tool experiences wear and tear and eventually goes out of use. The chosen tool path affects tool life due to factors like cutting forces, chip formation, chip evacuation,. One may. Extend Cutting Tool Life.

From www.gyrovia.fr

Indexable Insert Holders Cutting Tools Lathe Turning Tool Indexable Extend Cutting Tool Life One may think that it is marked by the duration between when it comes into use and when it breaks. However, it is, in fact, the period marked by the actual cutting time, following which the tool experiences wear and tear and eventually goes out of use. how to improve tool life in turning. tool life corresponds to. Extend Cutting Tool Life.

From www.slideserve.com

PPT Metal Machining PowerPoint Presentation, free download ID2292716 Extend Cutting Tool Life The three main machining parameters when turning are speed, feed, and depth of cut. However, it is, in fact, the period marked by the actual cutting time, following which the tool experiences wear and tear and eventually goes out of use. how to improve tool life in turning. One may think that it is marked by the duration between. Extend Cutting Tool Life.

From www.mecholic.com

drill tip Extend Cutting Tool Life The three main machining parameters when turning are speed, feed, and depth of cut. One may think that it is marked by the duration between when it comes into use and when it breaks. how to improve tool life in turning. regular machine inspections, maintenance, and alignment checks are vital for optimizing machine conditions and extending tool life.. Extend Cutting Tool Life.

From www.amazon.ca

Paint Contractor Life MultiAngle Paint Brush Extender Paint Edger Extend Cutting Tool Life tool life corresponds to the usefulness of a machine tool. One may think that it is marked by the duration between when it comes into use and when it breaks. regular machine inspections, maintenance, and alignment checks are vital for optimizing machine conditions and extending tool life. by understanding the factors that affect tool life and implementing. Extend Cutting Tool Life.

From blog.3keego.com

What is Drilling Machine? 3keego Cutting Tools Hole Extend Cutting Tool Life here are our top 5 strategies for extending the life of your endmills: The chosen tool path affects tool life due to factors like cutting forces, chip formation, chip evacuation,. The three main machining parameters when turning are speed, feed, and depth of cut. One may think that it is marked by the duration between when it comes into. Extend Cutting Tool Life.

From www.slideshare.net

Expert tips to increase the life of metal cutting tools Extend Cutting Tool Life The three main machining parameters when turning are speed, feed, and depth of cut. here are our top 5 strategies for extending the life of your endmills: how to improve tool life in turning. The chosen tool path affects tool life due to factors like cutting forces, chip formation, chip evacuation,. However, it is, in fact, the period. Extend Cutting Tool Life.

From www.researchgate.net

(PDF) Study on Cutting Tool Life Extend Cutting Tool Life tool life corresponds to the usefulness of a machine tool. how to improve tool life in turning. One may think that it is marked by the duration between when it comes into use and when it breaks. here are our top 5 strategies for extending the life of your endmills: regular machine inspections, maintenance, and alignment. Extend Cutting Tool Life.

From ifconnect.ifsuldeminas.edu.br

?Types Of High Precision Cutting Tools?? Tech Technology??, 58 OFF Extend Cutting Tool Life The chosen tool path affects tool life due to factors like cutting forces, chip formation, chip evacuation,. how to improve tool life in turning. The three main machining parameters when turning are speed, feed, and depth of cut. here are our top 5 strategies for extending the life of your endmills: However, it is, in fact, the period. Extend Cutting Tool Life.

From www.metalworkingworldmagazine.com

Specialty coatings extend service life of cutting tools used for non Extend Cutting Tool Life here are our top 5 strategies for extending the life of your endmills: The three main machining parameters when turning are speed, feed, and depth of cut. regular machine inspections, maintenance, and alignment checks are vital for optimizing machine conditions and extending tool life. One may think that it is marked by the duration between when it comes. Extend Cutting Tool Life.

From www.linkedin.com

How to extend the service life of wire cutting machine tools Extend Cutting Tool Life regular machine inspections, maintenance, and alignment checks are vital for optimizing machine conditions and extending tool life. by understanding the factors that affect tool life and implementing an effective tool life program, you can extend tool longevity,. tool life corresponds to the usefulness of a machine tool. how to improve tool life in turning. The three. Extend Cutting Tool Life.