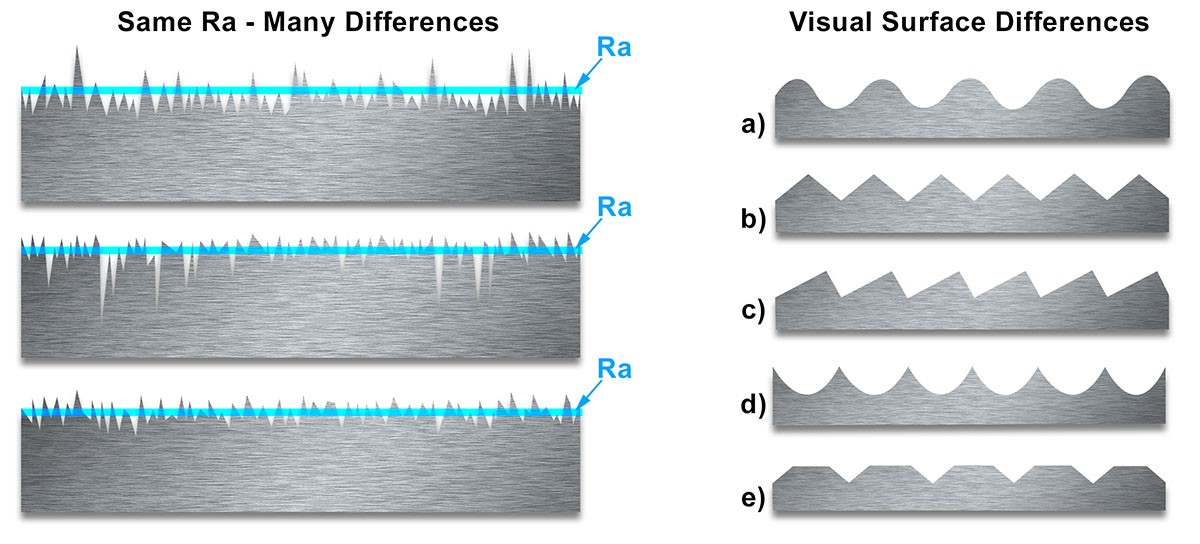

Surface Roughness Ra3.2 . As you can see in. Ra = roughness average in micrometers or microinches. If these deviations are great, the surface is rough, if they are small,. Rms = root mean square in microinches. 3.2 μm ra is the recommended maximum surface roughness for parts subject to stress, loads, and vibrations. Converting between ra and rz is not a good engineering practice. It is quantified by the vertical deviations of a real surface from its ideal form. A typical cnc machining finish, ‘as machined’, is smooth to the touch (ra3.2) but will contain visible machining lines from the cutting. It is always recommended to measure according to the method in which surface roughness is indicated on the drawing. The following charts and tables convert surface finish or roughness between selected industry standard units. It can also be used for mating moving surfaces when the load is light. Ra is the most ubiquitous metric for defining surface roughness in cnc machining and manufacturing in general and is measured in µm (micrometres). Surface roughness is a measure of the texture of a surface.

from isofinishing.com

As you can see in. Ra = roughness average in micrometers or microinches. Rms = root mean square in microinches. It is quantified by the vertical deviations of a real surface from its ideal form. It can also be used for mating moving surfaces when the load is light. The following charts and tables convert surface finish or roughness between selected industry standard units. If these deviations are great, the surface is rough, if they are small,. It is always recommended to measure according to the method in which surface roughness is indicated on the drawing. Ra is the most ubiquitous metric for defining surface roughness in cnc machining and manufacturing in general and is measured in µm (micrometres). Converting between ra and rz is not a good engineering practice.

Surface Roughness Chart ISO Finishing

Surface Roughness Ra3.2 As you can see in. Ra is the most ubiquitous metric for defining surface roughness in cnc machining and manufacturing in general and is measured in µm (micrometres). The following charts and tables convert surface finish or roughness between selected industry standard units. It is quantified by the vertical deviations of a real surface from its ideal form. A typical cnc machining finish, ‘as machined’, is smooth to the touch (ra3.2) but will contain visible machining lines from the cutting. It can also be used for mating moving surfaces when the load is light. Converting between ra and rz is not a good engineering practice. It is always recommended to measure according to the method in which surface roughness is indicated on the drawing. As you can see in. If these deviations are great, the surface is rough, if they are small,. 3.2 μm ra is the recommended maximum surface roughness for parts subject to stress, loads, and vibrations. Rms = root mean square in microinches. Ra = roughness average in micrometers or microinches. Surface roughness is a measure of the texture of a surface.

From radiantndtservices.com

RADIANT NDT SERVICE, CONSULTING AND TRAINING INSTITUT Surface Roughness Ra3.2 The following charts and tables convert surface finish or roughness between selected industry standard units. Converting between ra and rz is not a good engineering practice. Rms = root mean square in microinches. Ra is the most ubiquitous metric for defining surface roughness in cnc machining and manufacturing in general and is measured in µm (micrometres). Surface roughness is a. Surface Roughness Ra3.2.

From joiatmuim.blob.core.windows.net

Surface Finish Roughness Chart at Emily Trevino blog Surface Roughness Ra3.2 Ra = roughness average in micrometers or microinches. Ra is the most ubiquitous metric for defining surface roughness in cnc machining and manufacturing in general and is measured in µm (micrometres). Surface roughness is a measure of the texture of a surface. It is always recommended to measure according to the method in which surface roughness is indicated on the. Surface Roughness Ra3.2.

From envmart.com

Buy REM Surface Roughness Tester Display 4 digits at best price Surface Roughness Ra3.2 The following charts and tables convert surface finish or roughness between selected industry standard units. 3.2 μm ra is the recommended maximum surface roughness for parts subject to stress, loads, and vibrations. Ra is the most ubiquitous metric for defining surface roughness in cnc machining and manufacturing in general and is measured in µm (micrometres). As you can see in.. Surface Roughness Ra3.2.

From exoefuqtg.blob.core.windows.net

Surface Roughness Rq Ra at Steven Berrios blog Surface Roughness Ra3.2 It is always recommended to measure according to the method in which surface roughness is indicated on the drawing. It can also be used for mating moving surfaces when the load is light. As you can see in. Converting between ra and rz is not a good engineering practice. Rms = root mean square in microinches. Surface roughness is a. Surface Roughness Ra3.2.

From www.researchgate.net

Relationship between average surface roughness (Ra) and the level of Surface Roughness Ra3.2 It is always recommended to measure according to the method in which surface roughness is indicated on the drawing. It is quantified by the vertical deviations of a real surface from its ideal form. The following charts and tables convert surface finish or roughness between selected industry standard units. Surface roughness is a measure of the texture of a surface.. Surface Roughness Ra3.2.

From www.researchgate.net

A specimen for textural roughness. The peaktovalley height Rz ranges Surface Roughness Ra3.2 3.2 μm ra is the recommended maximum surface roughness for parts subject to stress, loads, and vibrations. Ra is the most ubiquitous metric for defining surface roughness in cnc machining and manufacturing in general and is measured in µm (micrometres). It is always recommended to measure according to the method in which surface roughness is indicated on the drawing. Rms. Surface Roughness Ra3.2.

From www.rapiddirect.com

Surface Roughness Chart Understanding Surface Finishes RapidDirect Surface Roughness Ra3.2 The following charts and tables convert surface finish or roughness between selected industry standard units. 3.2 μm ra is the recommended maximum surface roughness for parts subject to stress, loads, and vibrations. Converting between ra and rz is not a good engineering practice. A typical cnc machining finish, ‘as machined’, is smooth to the touch (ra3.2) but will contain visible. Surface Roughness Ra3.2.

From dxoeequoi.blob.core.windows.net

Surface Roughness Measurement Of Metals at Troy Schneider blog Surface Roughness Ra3.2 It is always recommended to measure according to the method in which surface roughness is indicated on the drawing. It can also be used for mating moving surfaces when the load is light. If these deviations are great, the surface is rough, if they are small,. A typical cnc machining finish, ‘as machined’, is smooth to the touch (ra3.2) but. Surface Roughness Ra3.2.

From imagesee.biz

Ra Surface Roughness Comparison Chart IMAGESEE Surface Roughness Ra3.2 It is always recommended to measure according to the method in which surface roughness is indicated on the drawing. 3.2 μm ra is the recommended maximum surface roughness for parts subject to stress, loads, and vibrations. It can also be used for mating moving surfaces when the load is light. If these deviations are great, the surface is rough, if. Surface Roughness Ra3.2.

From www.amazon.com

KHZKHC Portable Surface Roughness Tester, Surface Profile Surface Roughness Ra3.2 Ra is the most ubiquitous metric for defining surface roughness in cnc machining and manufacturing in general and is measured in µm (micrometres). As you can see in. The following charts and tables convert surface finish or roughness between selected industry standard units. If these deviations are great, the surface is rough, if they are small,. Rms = root mean. Surface Roughness Ra3.2.

From www.youtube.com

Surface Roughness Parameters Ra, Ry, Rz, RMS (हिंदी में) YouTube Surface Roughness Ra3.2 As you can see in. It is always recommended to measure according to the method in which surface roughness is indicated on the drawing. The following charts and tables convert surface finish or roughness between selected industry standard units. Rms = root mean square in microinches. Surface roughness is a measure of the texture of a surface. Converting between ra. Surface Roughness Ra3.2.

From michmet.com

Average Roughness basics Michigan Metrology Surface Roughness Ra3.2 Surface roughness is a measure of the texture of a surface. 3.2 μm ra is the recommended maximum surface roughness for parts subject to stress, loads, and vibrations. Converting between ra and rz is not a good engineering practice. It can also be used for mating moving surfaces when the load is light. It is always recommended to measure according. Surface Roughness Ra3.2.

From mechutopia.com

Surface Finishing in CNC Machining with Symbols, Charts, RZ,RA Surface Roughness Ra3.2 Rms = root mean square in microinches. A typical cnc machining finish, ‘as machined’, is smooth to the touch (ra3.2) but will contain visible machining lines from the cutting. It is always recommended to measure according to the method in which surface roughness is indicated on the drawing. Ra is the most ubiquitous metric for defining surface roughness in cnc. Surface Roughness Ra3.2.

From mungfali.com

Ra Surface Roughness Chart Surface Roughness Ra3.2 3.2 μm ra is the recommended maximum surface roughness for parts subject to stress, loads, and vibrations. As you can see in. It can also be used for mating moving surfaces when the load is light. The following charts and tables convert surface finish or roughness between selected industry standard units. It is always recommended to measure according to the. Surface Roughness Ra3.2.

From www.machinemetalparts.com

Powder Coating Chrome Plated Ra3.2 CNC Aluminum Machining Parts Surface Roughness Ra3.2 Rms = root mean square in microinches. It can also be used for mating moving surfaces when the load is light. The following charts and tables convert surface finish or roughness between selected industry standard units. If these deviations are great, the surface is rough, if they are small,. 3.2 μm ra is the recommended maximum surface roughness for parts. Surface Roughness Ra3.2.

From mungfali.com

Ra Surface Roughness Chart Surface Roughness Ra3.2 Rms = root mean square in microinches. Converting between ra and rz is not a good engineering practice. If these deviations are great, the surface is rough, if they are small,. Ra = roughness average in micrometers or microinches. It can also be used for mating moving surfaces when the load is light. It is quantified by the vertical deviations. Surface Roughness Ra3.2.

From mavink.com

Surface Roughness Ra Surface Roughness Ra3.2 It is quantified by the vertical deviations of a real surface from its ideal form. If these deviations are great, the surface is rough, if they are small,. It is always recommended to measure according to the method in which surface roughness is indicated on the drawing. As you can see in. Surface roughness is a measure of the texture. Surface Roughness Ra3.2.

From www.nassit.org.sl

Surface Roughness Explained Ra Roughness Chart, 45 OFF Surface Roughness Ra3.2 Converting between ra and rz is not a good engineering practice. It is quantified by the vertical deviations of a real surface from its ideal form. A typical cnc machining finish, ‘as machined’, is smooth to the touch (ra3.2) but will contain visible machining lines from the cutting. It is always recommended to measure according to the method in which. Surface Roughness Ra3.2.

From michmet.com

Average Roughness basics Michigan Metrology Surface Roughness Ra3.2 Ra is the most ubiquitous metric for defining surface roughness in cnc machining and manufacturing in general and is measured in µm (micrometres). It is always recommended to measure according to the method in which surface roughness is indicated on the drawing. Surface roughness is a measure of the texture of a surface. If these deviations are great, the surface. Surface Roughness Ra3.2.

From mungfali.com

RMS Surface Finish Chart Surface Roughness Ra3.2 It is always recommended to measure according to the method in which surface roughness is indicated on the drawing. A typical cnc machining finish, ‘as machined’, is smooth to the touch (ra3.2) but will contain visible machining lines from the cutting. Rms = root mean square in microinches. It is quantified by the vertical deviations of a real surface from. Surface Roughness Ra3.2.

From brunofuga.adv.br

Surface Roughness Symbol In Autocad, 51 OFF Surface Roughness Ra3.2 It is always recommended to measure according to the method in which surface roughness is indicated on the drawing. Ra = roughness average in micrometers or microinches. It can also be used for mating moving surfaces when the load is light. 3.2 μm ra is the recommended maximum surface roughness for parts subject to stress, loads, and vibrations. A typical. Surface Roughness Ra3.2.

From isofinishing.com

Surface Roughness Chart ISO Finishing Surface Roughness Ra3.2 It can also be used for mating moving surfaces when the load is light. As you can see in. The following charts and tables convert surface finish or roughness between selected industry standard units. It is quantified by the vertical deviations of a real surface from its ideal form. It is always recommended to measure according to the method in. Surface Roughness Ra3.2.

From blenderartists.org

Index of Roughness? Materials and Textures Blender Artists Community Surface Roughness Ra3.2 If these deviations are great, the surface is rough, if they are small,. Rms = root mean square in microinches. 3.2 μm ra is the recommended maximum surface roughness for parts subject to stress, loads, and vibrations. Surface roughness is a measure of the texture of a surface. As you can see in. It can also be used for mating. Surface Roughness Ra3.2.

From mungfali.com

Ra Surface Roughness Chart Surface Roughness Ra3.2 The following charts and tables convert surface finish or roughness between selected industry standard units. Rms = root mean square in microinches. Converting between ra and rz is not a good engineering practice. It can also be used for mating moving surfaces when the load is light. It is always recommended to measure according to the method in which surface. Surface Roughness Ra3.2.

From mungfali.com

RZ Surface Roughness Chart Surface Roughness Ra3.2 A typical cnc machining finish, ‘as machined’, is smooth to the touch (ra3.2) but will contain visible machining lines from the cutting. 3.2 μm ra is the recommended maximum surface roughness for parts subject to stress, loads, and vibrations. As you can see in. It can also be used for mating moving surfaces when the load is light. Surface roughness. Surface Roughness Ra3.2.

From mungfali.com

Ra Surface Roughness Chart Surface Roughness Ra3.2 Converting between ra and rz is not a good engineering practice. Ra is the most ubiquitous metric for defining surface roughness in cnc machining and manufacturing in general and is measured in µm (micrometres). The following charts and tables convert surface finish or roughness between selected industry standard units. As you can see in. Rms = root mean square in. Surface Roughness Ra3.2.

From xometry.eu

Choisir le niveau de surface adapté à l’usinage CNC Xometry Europe Surface Roughness Ra3.2 Surface roughness is a measure of the texture of a surface. Converting between ra and rz is not a good engineering practice. It can also be used for mating moving surfaces when the load is light. A typical cnc machining finish, ‘as machined’, is smooth to the touch (ra3.2) but will contain visible machining lines from the cutting. Rms =. Surface Roughness Ra3.2.

From japanese.metal-cncpart.com

アルミ加工 CNC自動化部品 RA3.2 表面粗さ Surface Roughness Ra3.2 The following charts and tables convert surface finish or roughness between selected industry standard units. It is always recommended to measure according to the method in which surface roughness is indicated on the drawing. As you can see in. Rms = root mean square in microinches. 3.2 μm ra is the recommended maximum surface roughness for parts subject to stress,. Surface Roughness Ra3.2.

From mungfali.com

Ra Surface Roughness Chart Surface Roughness Ra3.2 3.2 μm ra is the recommended maximum surface roughness for parts subject to stress, loads, and vibrations. As you can see in. Ra = roughness average in micrometers or microinches. Converting between ra and rz is not a good engineering practice. It is always recommended to measure according to the method in which surface roughness is indicated on the drawing.. Surface Roughness Ra3.2.

From www.myxxgirl.com

Spi Surface Finish Conversion Chart My XXX Hot Girl Surface Roughness Ra3.2 3.2 μm ra is the recommended maximum surface roughness for parts subject to stress, loads, and vibrations. It is quantified by the vertical deviations of a real surface from its ideal form. It can also be used for mating moving surfaces when the load is light. A typical cnc machining finish, ‘as machined’, is smooth to the touch (ra3.2) but. Surface Roughness Ra3.2.

From www.nextgentooling.com

Understanding Surface Finish RMS vs Ra NEXT GENERATION TOOLING Surface Roughness Ra3.2 Rms = root mean square in microinches. A typical cnc machining finish, ‘as machined’, is smooth to the touch (ra3.2) but will contain visible machining lines from the cutting. Ra is the most ubiquitous metric for defining surface roughness in cnc machining and manufacturing in general and is measured in µm (micrometres). The following charts and tables convert surface finish. Surface Roughness Ra3.2.

From edmontonrealestateinvestmentblog.com

Surface Roughness Explained Get It Made (2022) Surface Roughness Ra3.2 It is quantified by the vertical deviations of a real surface from its ideal form. Surface roughness is a measure of the texture of a surface. Rms = root mean square in microinches. As you can see in. A typical cnc machining finish, ‘as machined’, is smooth to the touch (ra3.2) but will contain visible machining lines from the cutting.. Surface Roughness Ra3.2.

From content.phtool.com

The Importance of Surface Finish when Making NDT Reference Standards Surface Roughness Ra3.2 Ra = roughness average in micrometers or microinches. The following charts and tables convert surface finish or roughness between selected industry standard units. It is quantified by the vertical deviations of a real surface from its ideal form. 3.2 μm ra is the recommended maximum surface roughness for parts subject to stress, loads, and vibrations. It is always recommended to. Surface Roughness Ra3.2.

From www.precisioncnc-parts.com

Custom Smoking Pipe Precision CNC Turning Parts Ra0.2Ra3.2 Surface Surface Roughness Ra3.2 It is quantified by the vertical deviations of a real surface from its ideal form. The following charts and tables convert surface finish or roughness between selected industry standard units. Ra is the most ubiquitous metric for defining surface roughness in cnc machining and manufacturing in general and is measured in µm (micrometres). A typical cnc machining finish, ‘as machined’,. Surface Roughness Ra3.2.

From journal.gpps.global

An Analytical Approach to Estimate the Effect of Surface Roughness on Surface Roughness Ra3.2 A typical cnc machining finish, ‘as machined’, is smooth to the touch (ra3.2) but will contain visible machining lines from the cutting. It is quantified by the vertical deviations of a real surface from its ideal form. Rms = root mean square in microinches. It can also be used for mating moving surfaces when the load is light. It is. Surface Roughness Ra3.2.