Gas Flow Rate In Co2 Welding . The shielding gas flow rate and the nozzle standoff distance affect markedly the occurrence of such defects as pits and blowholes. According to the selection of co 2 gas flow rate during welding (see table 8), if the average consumption of co 2 gas during welding is 10 l/min, one liquid co 2 cylinder can be. There are noticeable differences when welding with 100% co2, since at high welding temperatures, co2 changes from an inert to reactive gas. The correct gas flow rate in mig welding ranges between 15 to 25 cfh. Co2 gas shielded welding is a method that uses carbon dioxide gas as a shielding gas for arc welding. Also, take into account the. This article will show you how to set the flow rate of gas, the minimum and maximum values and the optimal gas shielding settings for the most common welding. Optimizing performance—saving time and money—requires you to be aware of some best practices that can help conserve shielding gas and promote proper coverage of the. Therefore, an appropriate gas flow rate and. But make sure to take into account the different variables while selecting the flow rate.

from rst-web.com

Co2 gas shielded welding is a method that uses carbon dioxide gas as a shielding gas for arc welding. According to the selection of co 2 gas flow rate during welding (see table 8), if the average consumption of co 2 gas during welding is 10 l/min, one liquid co 2 cylinder can be. The correct gas flow rate in mig welding ranges between 15 to 25 cfh. The shielding gas flow rate and the nozzle standoff distance affect markedly the occurrence of such defects as pits and blowholes. But make sure to take into account the different variables while selecting the flow rate. This article will show you how to set the flow rate of gas, the minimum and maximum values and the optimal gas shielding settings for the most common welding. Also, take into account the. Therefore, an appropriate gas flow rate and. There are noticeable differences when welding with 100% co2, since at high welding temperatures, co2 changes from an inert to reactive gas. Optimizing performance—saving time and money—requires you to be aware of some best practices that can help conserve shielding gas and promote proper coverage of the.

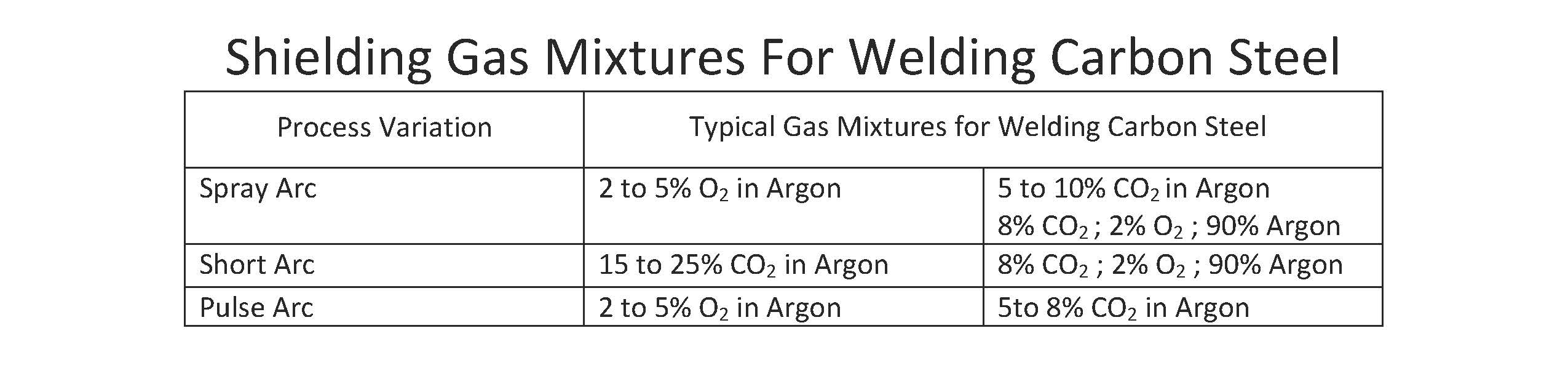

Selecting the Right Shielding Gas For Your Welding Process RonSon's

Gas Flow Rate In Co2 Welding Optimizing performance—saving time and money—requires you to be aware of some best practices that can help conserve shielding gas and promote proper coverage of the. This article will show you how to set the flow rate of gas, the minimum and maximum values and the optimal gas shielding settings for the most common welding. Also, take into account the. But make sure to take into account the different variables while selecting the flow rate. According to the selection of co 2 gas flow rate during welding (see table 8), if the average consumption of co 2 gas during welding is 10 l/min, one liquid co 2 cylinder can be. Therefore, an appropriate gas flow rate and. There are noticeable differences when welding with 100% co2, since at high welding temperatures, co2 changes from an inert to reactive gas. Optimizing performance—saving time and money—requires you to be aware of some best practices that can help conserve shielding gas and promote proper coverage of the. The correct gas flow rate in mig welding ranges between 15 to 25 cfh. Co2 gas shielded welding is a method that uses carbon dioxide gas as a shielding gas for arc welding. The shielding gas flow rate and the nozzle standoff distance affect markedly the occurrence of such defects as pits and blowholes.

From www.lazada.com.my

Manooby Argon CO2 Gas Flow Meter Flow Rate Gas Shielding Welding Tool Gas Flow Rate In Co2 Welding The shielding gas flow rate and the nozzle standoff distance affect markedly the occurrence of such defects as pits and blowholes. Therefore, an appropriate gas flow rate and. Also, take into account the. But make sure to take into account the different variables while selecting the flow rate. This article will show you how to set the flow rate of. Gas Flow Rate In Co2 Welding.

From www.wire-wizard.com

Gas Flow Monitor Wire Wizard Welding Products Gas Flow Rate In Co2 Welding According to the selection of co 2 gas flow rate during welding (see table 8), if the average consumption of co 2 gas during welding is 10 l/min, one liquid co 2 cylinder can be. There are noticeable differences when welding with 100% co2, since at high welding temperatures, co2 changes from an inert to reactive gas. This article will. Gas Flow Rate In Co2 Welding.

From makemoneywelding.com

MIG Welding Gas Pressure Settings Gas Flow Rate In Co2 Welding Therefore, an appropriate gas flow rate and. According to the selection of co 2 gas flow rate during welding (see table 8), if the average consumption of co 2 gas during welding is 10 l/min, one liquid co 2 cylinder can be. The shielding gas flow rate and the nozzle standoff distance affect markedly the occurrence of such defects as. Gas Flow Rate In Co2 Welding.

From www.mdpi.com

Applied Sciences Free FullText Effect of Local Gas Flow in Full Gas Flow Rate In Co2 Welding There are noticeable differences when welding with 100% co2, since at high welding temperatures, co2 changes from an inert to reactive gas. Co2 gas shielded welding is a method that uses carbon dioxide gas as a shielding gas for arc welding. But make sure to take into account the different variables while selecting the flow rate. Optimizing performance—saving time and. Gas Flow Rate In Co2 Welding.

From www.youtube.com

Mass and volume flow rates Ideal Gas Example YouTube Gas Flow Rate In Co2 Welding According to the selection of co 2 gas flow rate during welding (see table 8), if the average consumption of co 2 gas during welding is 10 l/min, one liquid co 2 cylinder can be. There are noticeable differences when welding with 100% co2, since at high welding temperatures, co2 changes from an inert to reactive gas. The shielding gas. Gas Flow Rate In Co2 Welding.

From alexnld.com

Argon CO2 Gas Mig Tig Flow Meter Welding Weld Regulator Gauge Welder Gas Flow Rate In Co2 Welding The correct gas flow rate in mig welding ranges between 15 to 25 cfh. The shielding gas flow rate and the nozzle standoff distance affect markedly the occurrence of such defects as pits and blowholes. This article will show you how to set the flow rate of gas, the minimum and maximum values and the optimal gas shielding settings for. Gas Flow Rate In Co2 Welding.

From www.walmart.ca

Suncoda Flowmeter, Scale Gas Meter for Argon Welding 25L/Min Gas Gas Flow Rate In Co2 Welding The correct gas flow rate in mig welding ranges between 15 to 25 cfh. Co2 gas shielded welding is a method that uses carbon dioxide gas as a shielding gas for arc welding. There are noticeable differences when welding with 100% co2, since at high welding temperatures, co2 changes from an inert to reactive gas. But make sure to take. Gas Flow Rate In Co2 Welding.

From weldempire.com

What Should Be the Gas Pressure for MIG Welding? Weld Empire Gas Flow Rate In Co2 Welding The shielding gas flow rate and the nozzle standoff distance affect markedly the occurrence of such defects as pits and blowholes. Therefore, an appropriate gas flow rate and. But make sure to take into account the different variables while selecting the flow rate. Optimizing performance—saving time and money—requires you to be aware of some best practices that can help conserve. Gas Flow Rate In Co2 Welding.

From cayman.desertcart.com

Argon CO2 Regulator Welding Gas Flowmeter For TIG MIG Brass Gas Flow Rate In Co2 Welding Optimizing performance—saving time and money—requires you to be aware of some best practices that can help conserve shielding gas and promote proper coverage of the. The shielding gas flow rate and the nozzle standoff distance affect markedly the occurrence of such defects as pits and blowholes. According to the selection of co 2 gas flow rate during welding (see table. Gas Flow Rate In Co2 Welding.

From reg.globaltextileexpo.com

Argon CO2 Gas Flow Meter Flow Rate Gas Shielding Welding Tool Flowmeter Gas Flow Rate In Co2 Welding Optimizing performance—saving time and money—requires you to be aware of some best practices that can help conserve shielding gas and promote proper coverage of the. Therefore, an appropriate gas flow rate and. But make sure to take into account the different variables while selecting the flow rate. There are noticeable differences when welding with 100% co2, since at high welding. Gas Flow Rate In Co2 Welding.

From mavink.com

Mig Welding Gas Flow Rate Chart Gas Flow Rate In Co2 Welding Co2 gas shielded welding is a method that uses carbon dioxide gas as a shielding gas for arc welding. The correct gas flow rate in mig welding ranges between 15 to 25 cfh. According to the selection of co 2 gas flow rate during welding (see table 8), if the average consumption of co 2 gas during welding is 10. Gas Flow Rate In Co2 Welding.

From rst-web.com

Selecting the Right Shielding Gas For Your Welding Process RonSon's Gas Flow Rate In Co2 Welding But make sure to take into account the different variables while selecting the flow rate. This article will show you how to set the flow rate of gas, the minimum and maximum values and the optimal gas shielding settings for the most common welding. The correct gas flow rate in mig welding ranges between 15 to 25 cfh. Co2 gas. Gas Flow Rate In Co2 Welding.

From www.desertcart.in

Argon Co2 Gas Flow Meter Scale Tester Measure Flowmeter for Mig Tig Gas Flow Rate In Co2 Welding Optimizing performance—saving time and money—requires you to be aware of some best practices that can help conserve shielding gas and promote proper coverage of the. According to the selection of co 2 gas flow rate during welding (see table 8), if the average consumption of co 2 gas during welding is 10 l/min, one liquid co 2 cylinder can be.. Gas Flow Rate In Co2 Welding.

From giosascyx.blob.core.windows.net

Co2 Gas Flow Rate For Mig Welding at Mary Fillion blog Gas Flow Rate In Co2 Welding Optimizing performance—saving time and money—requires you to be aware of some best practices that can help conserve shielding gas and promote proper coverage of the. But make sure to take into account the different variables while selecting the flow rate. Co2 gas shielded welding is a method that uses carbon dioxide gas as a shielding gas for arc welding. The. Gas Flow Rate In Co2 Welding.

From makemoneywelding.com

MIG Welding Gas Pressure Settings Gas Flow Rate In Co2 Welding The correct gas flow rate in mig welding ranges between 15 to 25 cfh. There are noticeable differences when welding with 100% co2, since at high welding temperatures, co2 changes from an inert to reactive gas. The shielding gas flow rate and the nozzle standoff distance affect markedly the occurrence of such defects as pits and blowholes. Therefore, an appropriate. Gas Flow Rate In Co2 Welding.

From fyozmcpza.blob.core.windows.net

Tig Welding Gas Flow Settings at Angelita Smith blog Gas Flow Rate In Co2 Welding Also, take into account the. But make sure to take into account the different variables while selecting the flow rate. According to the selection of co 2 gas flow rate during welding (see table 8), if the average consumption of co 2 gas during welding is 10 l/min, one liquid co 2 cylinder can be. This article will show you. Gas Flow Rate In Co2 Welding.

From resources.arcmachines.com

Tig Welding Gas Flow Rate Arc Machines Gas Flow Rate In Co2 Welding Co2 gas shielded welding is a method that uses carbon dioxide gas as a shielding gas for arc welding. Optimizing performance—saving time and money—requires you to be aware of some best practices that can help conserve shielding gas and promote proper coverage of the. The shielding gas flow rate and the nozzle standoff distance affect markedly the occurrence of such. Gas Flow Rate In Co2 Welding.

From cayman.desertcart.com

Argon CO2 Regulator Welding Gas Flowmeter For TIG MIG Brass Gas Flow Rate In Co2 Welding Optimizing performance—saving time and money—requires you to be aware of some best practices that can help conserve shielding gas and promote proper coverage of the. According to the selection of co 2 gas flow rate during welding (see table 8), if the average consumption of co 2 gas during welding is 10 l/min, one liquid co 2 cylinder can be.. Gas Flow Rate In Co2 Welding.

From www.pinterest.com

Ensuring the proper gas flow rate is essential to the quality of the Gas Flow Rate In Co2 Welding Co2 gas shielded welding is a method that uses carbon dioxide gas as a shielding gas for arc welding. The correct gas flow rate in mig welding ranges between 15 to 25 cfh. Optimizing performance—saving time and money—requires you to be aware of some best practices that can help conserve shielding gas and promote proper coverage of the. There are. Gas Flow Rate In Co2 Welding.

From www.pricepulse.app

Argon CO2 Regulator Welding Gas Flowmeter For TIG MIG Brass Gas Flow Rate In Co2 Welding There are noticeable differences when welding with 100% co2, since at high welding temperatures, co2 changes from an inert to reactive gas. Therefore, an appropriate gas flow rate and. The shielding gas flow rate and the nozzle standoff distance affect markedly the occurrence of such defects as pits and blowholes. The correct gas flow rate in mig welding ranges between. Gas Flow Rate In Co2 Welding.

From weldguru.com

MIG Welding Gas Pressure Settings (with Charts) Gas Flow Rate In Co2 Welding But make sure to take into account the different variables while selecting the flow rate. According to the selection of co 2 gas flow rate during welding (see table 8), if the average consumption of co 2 gas during welding is 10 l/min, one liquid co 2 cylinder can be. Co2 gas shielded welding is a method that uses carbon. Gas Flow Rate In Co2 Welding.

From www.perfectwelders.com

How To Optimize MIG Welding Shielding Gas Pressure PERFECT POWER Gas Flow Rate In Co2 Welding Also, take into account the. According to the selection of co 2 gas flow rate during welding (see table 8), if the average consumption of co 2 gas during welding is 10 l/min, one liquid co 2 cylinder can be. There are noticeable differences when welding with 100% co2, since at high welding temperatures, co2 changes from an inert to. Gas Flow Rate In Co2 Welding.

From fado.vn

Mua Welding Gas Flow Meter Argon CO2 Flowmeter with Flow Rate Gauge Gas Flow Rate In Co2 Welding This article will show you how to set the flow rate of gas, the minimum and maximum values and the optimal gas shielding settings for the most common welding. According to the selection of co 2 gas flow rate during welding (see table 8), if the average consumption of co 2 gas during welding is 10 l/min, one liquid co. Gas Flow Rate In Co2 Welding.

From weldguru.com

MIG Welding Gas Pressure Settings (with Charts) Gas Flow Rate In Co2 Welding The correct gas flow rate in mig welding ranges between 15 to 25 cfh. Co2 gas shielded welding is a method that uses carbon dioxide gas as a shielding gas for arc welding. Also, take into account the. Optimizing performance—saving time and money—requires you to be aware of some best practices that can help conserve shielding gas and promote proper. Gas Flow Rate In Co2 Welding.

From gnv4all.org

Argon CO2 Mig Tig Welding Flow Meter Regulator Weld Gauge Gas Pressure Gas Flow Rate In Co2 Welding But make sure to take into account the different variables while selecting the flow rate. There are noticeable differences when welding with 100% co2, since at high welding temperatures, co2 changes from an inert to reactive gas. The shielding gas flow rate and the nozzle standoff distance affect markedly the occurrence of such defects as pits and blowholes. Co2 gas. Gas Flow Rate In Co2 Welding.

From protigwelders.com

Can You Use Argon CO2 Mix For Tig Welding? 2024 ProTigWelders Gas Flow Rate In Co2 Welding According to the selection of co 2 gas flow rate during welding (see table 8), if the average consumption of co 2 gas during welding is 10 l/min, one liquid co 2 cylinder can be. The shielding gas flow rate and the nozzle standoff distance affect markedly the occurrence of such defects as pits and blowholes. The correct gas flow. Gas Flow Rate In Co2 Welding.

From weldguru.com

What Gas Should You Use for TIG Welding? (with Chart) Gas Flow Rate In Co2 Welding But make sure to take into account the different variables while selecting the flow rate. Co2 gas shielded welding is a method that uses carbon dioxide gas as a shielding gas for arc welding. Optimizing performance—saving time and money—requires you to be aware of some best practices that can help conserve shielding gas and promote proper coverage of the. There. Gas Flow Rate In Co2 Welding.

From www.researchgate.net

Effect of reactant gas flow rates on CH4 concentration, CO2 conversion Gas Flow Rate In Co2 Welding Co2 gas shielded welding is a method that uses carbon dioxide gas as a shielding gas for arc welding. According to the selection of co 2 gas flow rate during welding (see table 8), if the average consumption of co 2 gas during welding is 10 l/min, one liquid co 2 cylinder can be. Therefore, an appropriate gas flow rate. Gas Flow Rate In Co2 Welding.

From www.researchgate.net

11 The effect of the gas flow rate in the static reaction unit Gas Flow Rate In Co2 Welding This article will show you how to set the flow rate of gas, the minimum and maximum values and the optimal gas shielding settings for the most common welding. Co2 gas shielded welding is a method that uses carbon dioxide gas as a shielding gas for arc welding. Optimizing performance—saving time and money—requires you to be aware of some best. Gas Flow Rate In Co2 Welding.

From www.youtube.com

Gas Flow Settings for MIG & TIG Welding YouTube Gas Flow Rate In Co2 Welding The shielding gas flow rate and the nozzle standoff distance affect markedly the occurrence of such defects as pits and blowholes. There are noticeable differences when welding with 100% co2, since at high welding temperatures, co2 changes from an inert to reactive gas. Also, take into account the. Co2 gas shielded welding is a method that uses carbon dioxide gas. Gas Flow Rate In Co2 Welding.

From weldguru.com

Best Gas for MIG Welding What to Use (with Chart) Gas Flow Rate In Co2 Welding Therefore, an appropriate gas flow rate and. But make sure to take into account the different variables while selecting the flow rate. According to the selection of co 2 gas flow rate during welding (see table 8), if the average consumption of co 2 gas during welding is 10 l/min, one liquid co 2 cylinder can be. There are noticeable. Gas Flow Rate In Co2 Welding.

From rst-web.com

Selecting the Right Shielding Gas For Your Welding Process RonSon's Gas Flow Rate In Co2 Welding The shielding gas flow rate and the nozzle standoff distance affect markedly the occurrence of such defects as pits and blowholes. Optimizing performance—saving time and money—requires you to be aware of some best practices that can help conserve shielding gas and promote proper coverage of the. But make sure to take into account the different variables while selecting the flow. Gas Flow Rate In Co2 Welding.

From www.weldfabworld.com

Shielding Gases For Arc Welding Welding Fabrication World Gas Flow Rate In Co2 Welding Also, take into account the. But make sure to take into account the different variables while selecting the flow rate. The shielding gas flow rate and the nozzle standoff distance affect markedly the occurrence of such defects as pits and blowholes. The correct gas flow rate in mig welding ranges between 15 to 25 cfh. Optimizing performance—saving time and money—requires. Gas Flow Rate In Co2 Welding.

From www.semanticscholar.org

[PDF] Validated methods for flue gas flow rate calculation with Gas Flow Rate In Co2 Welding Optimizing performance—saving time and money—requires you to be aware of some best practices that can help conserve shielding gas and promote proper coverage of the. There are noticeable differences when welding with 100% co2, since at high welding temperatures, co2 changes from an inert to reactive gas. But make sure to take into account the different variables while selecting the. Gas Flow Rate In Co2 Welding.

From www.farmacologiaactual.com

Discount special sell store Top Selling Products timelimited Specials Gas Flow Rate In Co2 Welding Optimizing performance—saving time and money—requires you to be aware of some best practices that can help conserve shielding gas and promote proper coverage of the. The correct gas flow rate in mig welding ranges between 15 to 25 cfh. But make sure to take into account the different variables while selecting the flow rate. Therefore, an appropriate gas flow rate. Gas Flow Rate In Co2 Welding.