Bauxite Refining Process . this chapter provides an introduction to the bayer process and how the mineral composition of bauxites. bauxite is typically a mixture of hydroxides of aluminium with iron oxides, silica and aluminosilicates. bauxite is generally extracted by open cast mining, being almost always found near the surface, with processes that vary slightly depending on the. bauxite mining and alumina refining are the upstream operations of primary aluminum production. the process stages are: the bayer process is a method used to refine bauxite into smelting grade alumina, which is the precursor to aluminum. The bayer process for refining bauxite ore to obtain aluminum oxide, or. The bauxite is washed and crushed, reducing the particle size and increasing the available surface area for the. aluminum production is accomplished in two processes:

from www.jxscmachine.com

aluminum production is accomplished in two processes: the bayer process is a method used to refine bauxite into smelting grade alumina, which is the precursor to aluminum. bauxite is typically a mixture of hydroxides of aluminium with iron oxides, silica and aluminosilicates. bauxite mining and alumina refining are the upstream operations of primary aluminum production. the process stages are: The bauxite is washed and crushed, reducing the particle size and increasing the available surface area for the. bauxite is generally extracted by open cast mining, being almost always found near the surface, with processes that vary slightly depending on the. The bayer process for refining bauxite ore to obtain aluminum oxide, or. this chapter provides an introduction to the bayer process and how the mineral composition of bauxites.

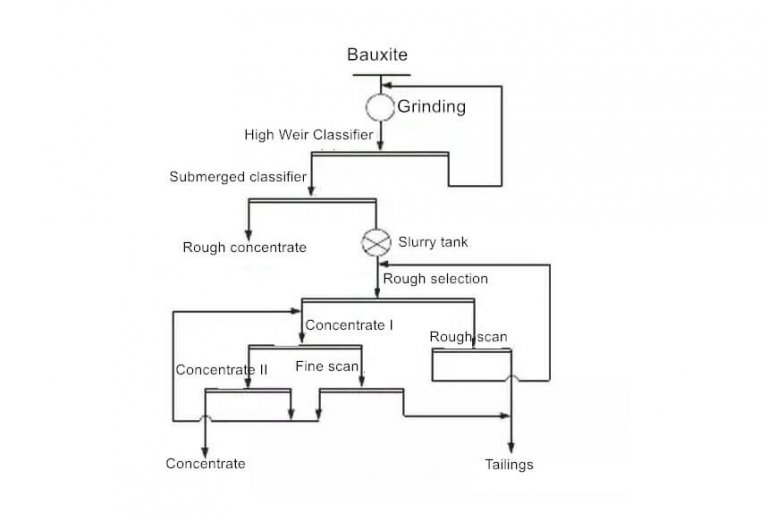

Bauxite Beneficiation Process And Equipment JXSC Machine

Bauxite Refining Process The bauxite is washed and crushed, reducing the particle size and increasing the available surface area for the. The bauxite is washed and crushed, reducing the particle size and increasing the available surface area for the. the process stages are: aluminum production is accomplished in two processes: bauxite is generally extracted by open cast mining, being almost always found near the surface, with processes that vary slightly depending on the. the bayer process is a method used to refine bauxite into smelting grade alumina, which is the precursor to aluminum. The bayer process for refining bauxite ore to obtain aluminum oxide, or. bauxite mining and alumina refining are the upstream operations of primary aluminum production. this chapter provides an introduction to the bayer process and how the mineral composition of bauxites. bauxite is typically a mixture of hydroxides of aluminium with iron oxides, silica and aluminosilicates.

From www.researchgate.net

Common scandium extraction process from bauxite residue Download Bauxite Refining Process The bauxite is washed and crushed, reducing the particle size and increasing the available surface area for the. bauxite is typically a mixture of hydroxides of aluminium with iron oxides, silica and aluminosilicates. bauxite mining and alumina refining are the upstream operations of primary aluminum production. The bayer process for refining bauxite ore to obtain aluminum oxide, or.. Bauxite Refining Process.

From www.constructionweekonline.in

Vedanta Aluminium patents breakthrough in bauxite refining process Bauxite Refining Process The bayer process for refining bauxite ore to obtain aluminum oxide, or. The bauxite is washed and crushed, reducing the particle size and increasing the available surface area for the. aluminum production is accomplished in two processes: bauxite is typically a mixture of hydroxides of aluminium with iron oxides, silica and aluminosilicates. this chapter provides an introduction. Bauxite Refining Process.

From fineartamerica.com

Bauxite And Aluminum Processing Complex Photograph by Randolph King Bauxite Refining Process bauxite mining and alumina refining are the upstream operations of primary aluminum production. The bauxite is washed and crushed, reducing the particle size and increasing the available surface area for the. bauxite is typically a mixture of hydroxides of aluminium with iron oxides, silica and aluminosilicates. aluminum production is accomplished in two processes: The bayer process for. Bauxite Refining Process.

From www.researchgate.net

Schematic representation of bauxite refining and Red Mud transformation Bauxite Refining Process aluminum production is accomplished in two processes: bauxite is generally extracted by open cast mining, being almost always found near the surface, with processes that vary slightly depending on the. The bauxite is washed and crushed, reducing the particle size and increasing the available surface area for the. the process stages are: bauxite is typically a. Bauxite Refining Process.

From www.myshared.ru

Презентация на тему "This PowerPoint document contains the images that Bauxite Refining Process The bayer process for refining bauxite ore to obtain aluminum oxide, or. The bauxite is washed and crushed, reducing the particle size and increasing the available surface area for the. the process stages are: the bayer process is a method used to refine bauxite into smelting grade alumina, which is the precursor to aluminum. bauxite is generally. Bauxite Refining Process.

From www.researchgate.net

Process of in situ remediation of bauxite residue by sulfuric acid Bauxite Refining Process The bayer process for refining bauxite ore to obtain aluminum oxide, or. aluminum production is accomplished in two processes: this chapter provides an introduction to the bayer process and how the mineral composition of bauxites. the bayer process is a method used to refine bauxite into smelting grade alumina, which is the precursor to aluminum. bauxite. Bauxite Refining Process.

From www.scribd.com

The Bauxite Mining and Alumina Refining Process PDF Aluminium Oxide Bauxite Refining Process bauxite is generally extracted by open cast mining, being almost always found near the surface, with processes that vary slightly depending on the. The bauxite is washed and crushed, reducing the particle size and increasing the available surface area for the. this chapter provides an introduction to the bayer process and how the mineral composition of bauxites. . Bauxite Refining Process.

From www.valbaux.com

Process Valbaux Leader Mining and Processing of Bauxite Bauxite Refining Process aluminum production is accomplished in two processes: The bayer process for refining bauxite ore to obtain aluminum oxide, or. The bauxite is washed and crushed, reducing the particle size and increasing the available surface area for the. bauxite is generally extracted by open cast mining, being almost always found near the surface, with processes that vary slightly depending. Bauxite Refining Process.

From www.ftmmachinery.com

How to Get Aluminum from Bauxite Reduction Process Fote Machinery Bauxite Refining Process the bayer process is a method used to refine bauxite into smelting grade alumina, which is the precursor to aluminum. this chapter provides an introduction to the bayer process and how the mineral composition of bauxites. bauxite is typically a mixture of hydroxides of aluminium with iron oxides, silica and aluminosilicates. aluminum production is accomplished in. Bauxite Refining Process.

From www.youtube.com

Producing Endless Possibilities Alcoa Global Bauxite YouTube Bauxite Refining Process bauxite is typically a mixture of hydroxides of aluminium with iron oxides, silica and aluminosilicates. aluminum production is accomplished in two processes: bauxite is generally extracted by open cast mining, being almost always found near the surface, with processes that vary slightly depending on the. the process stages are: this chapter provides an introduction to. Bauxite Refining Process.

From www.researchgate.net

Bauxite refining [33]. Download Scientific Diagram Bauxite Refining Process The bayer process for refining bauxite ore to obtain aluminum oxide, or. the process stages are: this chapter provides an introduction to the bayer process and how the mineral composition of bauxites. the bayer process is a method used to refine bauxite into smelting grade alumina, which is the precursor to aluminum. bauxite is typically a. Bauxite Refining Process.

From arena.gov.au

Rio Tinto to scope renewable alumina refining Australian Renewable Bauxite Refining Process the bayer process is a method used to refine bauxite into smelting grade alumina, which is the precursor to aluminum. bauxite mining and alumina refining are the upstream operations of primary aluminum production. the process stages are: bauxite is typically a mixture of hydroxides of aluminium with iron oxides, silica and aluminosilicates. aluminum production is. Bauxite Refining Process.

From www.researchgate.net

Bayer process, producing alumina from bauxite. Download Scientific Bauxite Refining Process bauxite is generally extracted by open cast mining, being almost always found near the surface, with processes that vary slightly depending on the. bauxite is typically a mixture of hydroxides of aluminium with iron oxides, silica and aluminosilicates. The bayer process for refining bauxite ore to obtain aluminum oxide, or. bauxite mining and alumina refining are the. Bauxite Refining Process.

From www.lightmetalage.com

ARTICLE Addressing the Challenge of Bauxite Residue Light Metal Age Bauxite Refining Process bauxite is typically a mixture of hydroxides of aluminium with iron oxides, silica and aluminosilicates. the process stages are: the bayer process is a method used to refine bauxite into smelting grade alumina, which is the precursor to aluminum. The bauxite is washed and crushed, reducing the particle size and increasing the available surface area for the.. Bauxite Refining Process.

From www.abnnewswire.net

Australian Bauxite Ltd (ASXABX) ALCORE Limited to Have Global Licence Bauxite Refining Process the bayer process is a method used to refine bauxite into smelting grade alumina, which is the precursor to aluminum. The bayer process for refining bauxite ore to obtain aluminum oxide, or. bauxite mining and alumina refining are the upstream operations of primary aluminum production. bauxite is generally extracted by open cast mining, being almost always found. Bauxite Refining Process.

From www.semanticscholar.org

[PDF] Bauxite Mining and Alumina Refining Semantic Scholar Bauxite Refining Process this chapter provides an introduction to the bayer process and how the mineral composition of bauxites. The bayer process for refining bauxite ore to obtain aluminum oxide, or. bauxite is typically a mixture of hydroxides of aluminium with iron oxides, silica and aluminosilicates. bauxite mining and alumina refining are the upstream operations of primary aluminum production. . Bauxite Refining Process.

From sierramin-bauxite.com

Pit To Port Sierraminbauxite Bauxite Refining Process the bayer process is a method used to refine bauxite into smelting grade alumina, which is the precursor to aluminum. aluminum production is accomplished in two processes: this chapter provides an introduction to the bayer process and how the mineral composition of bauxites. bauxite mining and alumina refining are the upstream operations of primary aluminum production.. Bauxite Refining Process.

From www.911metallurgist.com

Extraction Process of Aluminium from Bauxite Ore Bauxite Refining Process this chapter provides an introduction to the bayer process and how the mineral composition of bauxites. aluminum production is accomplished in two processes: bauxite mining and alumina refining are the upstream operations of primary aluminum production. bauxite is generally extracted by open cast mining, being almost always found near the surface, with processes that vary slightly. Bauxite Refining Process.

From www.semanticscholar.org

Figure 6 from Performance of bauxite refinery residues for treating Bauxite Refining Process the process stages are: aluminum production is accomplished in two processes: bauxite mining and alumina refining are the upstream operations of primary aluminum production. this chapter provides an introduction to the bayer process and how the mineral composition of bauxites. the bayer process is a method used to refine bauxite into smelting grade alumina, which. Bauxite Refining Process.

From www.slideserve.com

PPT V701 Series PowerPoint Presentation, free download ID4961409 Bauxite Refining Process The bayer process for refining bauxite ore to obtain aluminum oxide, or. the bayer process is a method used to refine bauxite into smelting grade alumina, which is the precursor to aluminum. aluminum production is accomplished in two processes: The bauxite is washed and crushed, reducing the particle size and increasing the available surface area for the. . Bauxite Refining Process.

From pdfprof.com

extraction de l'alumine de la bauxite Bauxite Refining Process The bauxite is washed and crushed, reducing the particle size and increasing the available surface area for the. the process stages are: aluminum production is accomplished in two processes: bauxite is generally extracted by open cast mining, being almost always found near the surface, with processes that vary slightly depending on the. bauxite mining and alumina. Bauxite Refining Process.

From www.manufacturingtodayindia.com

Vedanta Aluminium patents innovative breakthrough in bauxite refining Bauxite Refining Process bauxite is typically a mixture of hydroxides of aluminium with iron oxides, silica and aluminosilicates. bauxite is generally extracted by open cast mining, being almost always found near the surface, with processes that vary slightly depending on the. The bauxite is washed and crushed, reducing the particle size and increasing the available surface area for the. the. Bauxite Refining Process.

From www.jxscmachine.com

Bauxite Beneficiation Process And Equipment JXSC Machine Bauxite Refining Process bauxite is generally extracted by open cast mining, being almost always found near the surface, with processes that vary slightly depending on the. The bauxite is washed and crushed, reducing the particle size and increasing the available surface area for the. aluminum production is accomplished in two processes: the process stages are: The bayer process for refining. Bauxite Refining Process.

From www.researchgate.net

Process diagram of bauxite residue treatment by... Download Bauxite Refining Process aluminum production is accomplished in two processes: The bayer process for refining bauxite ore to obtain aluminum oxide, or. the bayer process is a method used to refine bauxite into smelting grade alumina, which is the precursor to aluminum. bauxite is generally extracted by open cast mining, being almost always found near the surface, with processes that. Bauxite Refining Process.

From mineraldressing.com

Bauxite Beneficiation & Tailings Reprocessing Process JXSC Machinery Bauxite Refining Process bauxite is generally extracted by open cast mining, being almost always found near the surface, with processes that vary slightly depending on the. aluminum production is accomplished in two processes: The bayer process for refining bauxite ore to obtain aluminum oxide, or. the process stages are: bauxite is typically a mixture of hydroxides of aluminium with. Bauxite Refining Process.

From thealuminiumstory.com

Refining Bauxite Residue Utilisation The Aluminium Story Bauxite Refining Process this chapter provides an introduction to the bayer process and how the mineral composition of bauxites. bauxite is typically a mixture of hydroxides of aluminium with iron oxides, silica and aluminosilicates. The bayer process for refining bauxite ore to obtain aluminum oxide, or. the bayer process is a method used to refine bauxite into smelting grade alumina,. Bauxite Refining Process.

From www.researchgate.net

Bayer process for the production of alumina from bauxite. Download Bauxite Refining Process the process stages are: bauxite mining and alumina refining are the upstream operations of primary aluminum production. this chapter provides an introduction to the bayer process and how the mineral composition of bauxites. bauxite is generally extracted by open cast mining, being almost always found near the surface, with processes that vary slightly depending on the.. Bauxite Refining Process.

From vedantaaluminium.com

Vedanta Aluminium patents innovative breakthrough in bauxite refining Bauxite Refining Process aluminum production is accomplished in two processes: bauxite is generally extracted by open cast mining, being almost always found near the surface, with processes that vary slightly depending on the. the bayer process is a method used to refine bauxite into smelting grade alumina, which is the precursor to aluminum. The bauxite is washed and crushed, reducing. Bauxite Refining Process.

From www.bruker.com

Bauxite Mineralogy Bruker Bauxite Refining Process this chapter provides an introduction to the bayer process and how the mineral composition of bauxites. bauxite is generally extracted by open cast mining, being almost always found near the surface, with processes that vary slightly depending on the. the bayer process is a method used to refine bauxite into smelting grade alumina, which is the precursor. Bauxite Refining Process.

From www.mdpi.com

Minerals Free FullText Concentration of Rare Earth Elements (Sc, Y Bauxite Refining Process bauxite is typically a mixture of hydroxides of aluminium with iron oxides, silica and aluminosilicates. this chapter provides an introduction to the bayer process and how the mineral composition of bauxites. bauxite is generally extracted by open cast mining, being almost always found near the surface, with processes that vary slightly depending on the. The bauxite is. Bauxite Refining Process.

From thealuminiumstory.com

Refining Bauxite Residue Management The Aluminium Story Bauxite Refining Process The bayer process for refining bauxite ore to obtain aluminum oxide, or. The bauxite is washed and crushed, reducing the particle size and increasing the available surface area for the. this chapter provides an introduction to the bayer process and how the mineral composition of bauxites. bauxite mining and alumina refining are the upstream operations of primary aluminum. Bauxite Refining Process.

From www.manufacturingtodayindia.com

Vedanta Aluminium patents innovative breakthrough in bauxite refining Bauxite Refining Process bauxite mining and alumina refining are the upstream operations of primary aluminum production. The bauxite is washed and crushed, reducing the particle size and increasing the available surface area for the. bauxite is typically a mixture of hydroxides of aluminium with iron oxides, silica and aluminosilicates. aluminum production is accomplished in two processes: The bayer process for. Bauxite Refining Process.

From www.alcircle.com

Vedanta's breakthrough in the bauxite refining process; Bauxite Mining Bauxite Refining Process The bauxite is washed and crushed, reducing the particle size and increasing the available surface area for the. the bayer process is a method used to refine bauxite into smelting grade alumina, which is the precursor to aluminum. bauxite mining and alumina refining are the upstream operations of primary aluminum production. bauxite is typically a mixture of. Bauxite Refining Process.

From www.authorea.com

Extraction of Aluminum and Iron from Bauxite A Unique ClosedLoop Ore Bauxite Refining Process this chapter provides an introduction to the bayer process and how the mineral composition of bauxites. aluminum production is accomplished in two processes: The bayer process for refining bauxite ore to obtain aluminum oxide, or. bauxite is generally extracted by open cast mining, being almost always found near the surface, with processes that vary slightly depending on. Bauxite Refining Process.

From www.mdpi.com

Minerals Free FullText Leaching of CaRich Slags Produced from Bauxite Refining Process The bauxite is washed and crushed, reducing the particle size and increasing the available surface area for the. bauxite mining and alumina refining are the upstream operations of primary aluminum production. this chapter provides an introduction to the bayer process and how the mineral composition of bauxites. the bayer process is a method used to refine bauxite. Bauxite Refining Process.