Explain The Firing Process In Kiln . Cook your piece at 1000 °c for 30 minutes. ceramic firing is an essential process in the creation of pottery and ceramic art. the firing process is the most important part of pottery making. The final aim is to heat the object to the point that the clay and glazes are mature—that is, that they have reached their optimal level of melting. Let the pieces cool down in the kiln to prevent them from breaking or cracking, and. The clay objects are placed inside the kiln and heated to a. It involves heating raw clay objects in a kiln. firing is the process of bringing clay and glazes up to a high temperature. It involves heating raw clay objects in a kiln at a high temperature. the pottery firing process is a critical step in the creation of ceramic items. The ceramist places ware in the chamber. a kiln is a chamber made from refractory (nonmelting) materials. the firing process in the kiln includes sintering, which heats the clay until the particles partially melt and flow.

from www.zkg.de

Let the pieces cool down in the kiln to prevent them from breaking or cracking, and. firing is the process of bringing clay and glazes up to a high temperature. The ceramist places ware in the chamber. a kiln is a chamber made from refractory (nonmelting) materials. the firing process is the most important part of pottery making. the pottery firing process is a critical step in the creation of ceramic items. the firing process in the kiln includes sintering, which heats the clay until the particles partially melt and flow. It involves heating raw clay objects in a kiln. The final aim is to heat the object to the point that the clay and glazes are mature—that is, that they have reached their optimal level of melting. The clay objects are placed inside the kiln and heated to a.

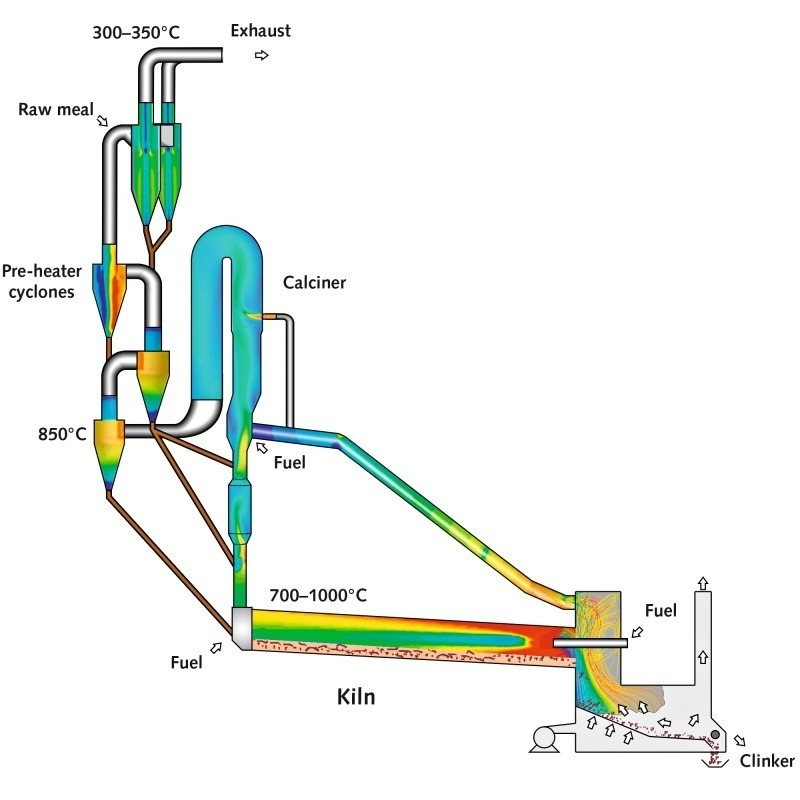

Modelbased kiln control for green cement production Cement Lime Gypsum

Explain The Firing Process In Kiln the pottery firing process is a critical step in the creation of ceramic items. the firing process is the most important part of pottery making. Let the pieces cool down in the kiln to prevent them from breaking or cracking, and. the pottery firing process is a critical step in the creation of ceramic items. a kiln is a chamber made from refractory (nonmelting) materials. The clay objects are placed inside the kiln and heated to a. It involves heating raw clay objects in a kiln at a high temperature. firing is the process of bringing clay and glazes up to a high temperature. ceramic firing is an essential process in the creation of pottery and ceramic art. The ceramist places ware in the chamber. the firing process in the kiln includes sintering, which heats the clay until the particles partially melt and flow. The final aim is to heat the object to the point that the clay and glazes are mature—that is, that they have reached their optimal level of melting. Cook your piece at 1000 °c for 30 minutes. It involves heating raw clay objects in a kiln.

From www.mdpi.com

Sensors Free FullText Advanced Process Control for Clinker Rotary Explain The Firing Process In Kiln firing is the process of bringing clay and glazes up to a high temperature. a kiln is a chamber made from refractory (nonmelting) materials. the firing process in the kiln includes sintering, which heats the clay until the particles partially melt and flow. ceramic firing is an essential process in the creation of pottery and ceramic. Explain The Firing Process In Kiln.

From www.desertcart.in

Buy THE ULTIMATE GUIDE TO FIRING AND KILN FOR BEGINNERS Understanding Explain The Firing Process In Kiln firing is the process of bringing clay and glazes up to a high temperature. a kiln is a chamber made from refractory (nonmelting) materials. the firing process is the most important part of pottery making. It involves heating raw clay objects in a kiln at a high temperature. The clay objects are placed inside the kiln and. Explain The Firing Process In Kiln.

From rareearthpottery.ca

Woodfiring Our kiln firing process Explain The Firing Process In Kiln It involves heating raw clay objects in a kiln at a high temperature. the firing process is the most important part of pottery making. the firing process in the kiln includes sintering, which heats the clay until the particles partially melt and flow. Cook your piece at 1000 °c for 30 minutes. ceramic firing is an essential. Explain The Firing Process In Kiln.

From hxehjkmoe.blob.core.windows.net

Temperature To Unload Kiln at Edmund Beauchamp blog Explain The Firing Process In Kiln the firing process is the most important part of pottery making. a kiln is a chamber made from refractory (nonmelting) materials. Cook your piece at 1000 °c for 30 minutes. ceramic firing is an essential process in the creation of pottery and ceramic art. The ceramist places ware in the chamber. It involves heating raw clay objects. Explain The Firing Process In Kiln.

From rareearthpottery.ca

Woodfiring Our kiln firing process Explain The Firing Process In Kiln It involves heating raw clay objects in a kiln. the firing process in the kiln includes sintering, which heats the clay until the particles partially melt and flow. The ceramist places ware in the chamber. the firing process is the most important part of pottery making. It involves heating raw clay objects in a kiln at a high. Explain The Firing Process In Kiln.

From www.researchgate.net

The industrial process diagram of the rotary kiln system. Download Explain The Firing Process In Kiln It involves heating raw clay objects in a kiln at a high temperature. the firing process in the kiln includes sintering, which heats the clay until the particles partially melt and flow. firing is the process of bringing clay and glazes up to a high temperature. The final aim is to heat the object to the point that. Explain The Firing Process In Kiln.

From matclad.co.uk

What is the 'Firing' process? » www.matclad.co.uk Explain The Firing Process In Kiln The final aim is to heat the object to the point that the clay and glazes are mature—that is, that they have reached their optimal level of melting. The ceramist places ware in the chamber. It involves heating raw clay objects in a kiln. the firing process in the kiln includes sintering, which heats the clay until the particles. Explain The Firing Process In Kiln.

From www.hkdivedi.com

CEMENT KILN FIRING SYSTEM ENGINEERING APPLICATIONS Explain The Firing Process In Kiln firing is the process of bringing clay and glazes up to a high temperature. Cook your piece at 1000 °c for 30 minutes. It involves heating raw clay objects in a kiln. a kiln is a chamber made from refractory (nonmelting) materials. The ceramist places ware in the chamber. It involves heating raw clay objects in a kiln. Explain The Firing Process In Kiln.

From susannoltpottery.com

Raku Firing Explain The Firing Process In Kiln Cook your piece at 1000 °c for 30 minutes. The ceramist places ware in the chamber. the pottery firing process is a critical step in the creation of ceramic items. the firing process is the most important part of pottery making. The final aim is to heat the object to the point that the clay and glazes are. Explain The Firing Process In Kiln.

From www.mdpi.com

Energies Free FullText Thermal Performance Combined with Cooling Explain The Firing Process In Kiln It involves heating raw clay objects in a kiln. The ceramist places ware in the chamber. It involves heating raw clay objects in a kiln at a high temperature. Cook your piece at 1000 °c for 30 minutes. a kiln is a chamber made from refractory (nonmelting) materials. The clay objects are placed inside the kiln and heated to. Explain The Firing Process In Kiln.

From exyufsyjh.blob.core.windows.net

Pottery Kiln Calgary at Beverly Neal blog Explain The Firing Process In Kiln The final aim is to heat the object to the point that the clay and glazes are mature—that is, that they have reached their optimal level of melting. The clay objects are placed inside the kiln and heated to a. It involves heating raw clay objects in a kiln at a high temperature. It involves heating raw clay objects in. Explain The Firing Process In Kiln.

From rareearthpottery.ca

Woodfiring Our kiln firing process Explain The Firing Process In Kiln It involves heating raw clay objects in a kiln. The final aim is to heat the object to the point that the clay and glazes are mature—that is, that they have reached their optimal level of melting. The clay objects are placed inside the kiln and heated to a. The ceramist places ware in the chamber. the firing process. Explain The Firing Process In Kiln.

From rareearthpottery.ca

Woodfiring Our kiln firing process Explain The Firing Process In Kiln It involves heating raw clay objects in a kiln at a high temperature. firing is the process of bringing clay and glazes up to a high temperature. Cook your piece at 1000 °c for 30 minutes. The clay objects are placed inside the kiln and heated to a. The ceramist places ware in the chamber. the firing process. Explain The Firing Process In Kiln.

From facts.net

11 Mindblowing Facts About Kiln Firing Explain The Firing Process In Kiln Let the pieces cool down in the kiln to prevent them from breaking or cracking, and. the firing process is the most important part of pottery making. It involves heating raw clay objects in a kiln. ceramic firing is an essential process in the creation of pottery and ceramic art. The clay objects are placed inside the kiln. Explain The Firing Process In Kiln.

From aiagreekkiln.arizona.edu

The kiln firing during the night Ancient Greek Kiln Project Explain The Firing Process In Kiln a kiln is a chamber made from refractory (nonmelting) materials. It involves heating raw clay objects in a kiln at a high temperature. the firing process is the most important part of pottery making. The clay objects are placed inside the kiln and heated to a. firing is the process of bringing clay and glazes up to. Explain The Firing Process In Kiln.

From potterycrafted.com

What Is The Alternative To Kiln Firing? Pottery Crafted Explain The Firing Process In Kiln a kiln is a chamber made from refractory (nonmelting) materials. the pottery firing process is a critical step in the creation of ceramic items. the firing process is the most important part of pottery making. The ceramist places ware in the chamber. Cook your piece at 1000 °c for 30 minutes. The final aim is to heat. Explain The Firing Process In Kiln.

From www.youtube.com

Reduction Firing in a Gas Kiln YouTube Explain The Firing Process In Kiln The clay objects are placed inside the kiln and heated to a. firing is the process of bringing clay and glazes up to a high temperature. the firing process is the most important part of pottery making. a kiln is a chamber made from refractory (nonmelting) materials. The ceramist places ware in the chamber. It involves heating. Explain The Firing Process In Kiln.

From www.thesprucecrafts.com

The Firing Process for Making Ceramics Explain The Firing Process In Kiln the pottery firing process is a critical step in the creation of ceramic items. The clay objects are placed inside the kiln and heated to a. the firing process in the kiln includes sintering, which heats the clay until the particles partially melt and flow. a kiln is a chamber made from refractory (nonmelting) materials. ceramic. Explain The Firing Process In Kiln.

From thepotterywheel.com

What is Raku Pottery? A Beginners Guide on How To Make Raku Explain The Firing Process In Kiln Cook your piece at 1000 °c for 30 minutes. the firing process in the kiln includes sintering, which heats the clay until the particles partially melt and flow. ceramic firing is an essential process in the creation of pottery and ceramic art. the pottery firing process is a critical step in the creation of ceramic items. The. Explain The Firing Process In Kiln.

From www.cementequipment.org

DRY PROCESS KILN PREHEATER/PRECALCINER SYSTEM INFINITY FOR CEMENT Explain The Firing Process In Kiln the firing process is the most important part of pottery making. the pottery firing process is a critical step in the creation of ceramic items. Let the pieces cool down in the kiln to prevent them from breaking or cracking, and. The clay objects are placed inside the kiln and heated to a. It involves heating raw clay. Explain The Firing Process In Kiln.

From depositphotos.com

Roasted ceramic products without glaze in the potters hands close up Explain The Firing Process In Kiln It involves heating raw clay objects in a kiln at a high temperature. ceramic firing is an essential process in the creation of pottery and ceramic art. firing is the process of bringing clay and glazes up to a high temperature. The ceramist places ware in the chamber. a kiln is a chamber made from refractory (nonmelting). Explain The Firing Process In Kiln.

From rareearthpottery.ca

Woodfiring Our kiln firing process Explain The Firing Process In Kiln the firing process is the most important part of pottery making. It involves heating raw clay objects in a kiln at a high temperature. the firing process in the kiln includes sintering, which heats the clay until the particles partially melt and flow. ceramic firing is an essential process in the creation of pottery and ceramic art.. Explain The Firing Process In Kiln.

From www.katherinefortnumceramics.com

Kiln Firing Method Wood Firing Explain The Firing Process In Kiln the firing process is the most important part of pottery making. the pottery firing process is a critical step in the creation of ceramic items. the firing process in the kiln includes sintering, which heats the clay until the particles partially melt and flow. Let the pieces cool down in the kiln to prevent them from breaking. Explain The Firing Process In Kiln.

From www.shutterstock.com

Firing Wood Fire Kiln Part Process Stock Photo 2165386407 Shutterstock Explain The Firing Process In Kiln the pottery firing process is a critical step in the creation of ceramic items. Let the pieces cool down in the kiln to prevent them from breaking or cracking, and. the firing process in the kiln includes sintering, which heats the clay until the particles partially melt and flow. ceramic firing is an essential process in the. Explain The Firing Process In Kiln.

From rareearthpottery.ca

Woodfiring Our kiln firing process Explain The Firing Process In Kiln The clay objects are placed inside the kiln and heated to a. the pottery firing process is a critical step in the creation of ceramic items. The final aim is to heat the object to the point that the clay and glazes are mature—that is, that they have reached their optimal level of melting. Cook your piece at 1000. Explain The Firing Process In Kiln.

From www.alibaba.com

Tunnel Kiln For Brick Firing Process New Technology Brick Making Explain The Firing Process In Kiln Let the pieces cool down in the kiln to prevent them from breaking or cracking, and. a kiln is a chamber made from refractory (nonmelting) materials. the firing process is the most important part of pottery making. The ceramist places ware in the chamber. firing is the process of bringing clay and glazes up to a high. Explain The Firing Process In Kiln.

From rareearthpottery.ca

Woodfiring Our kiln firing process Explain The Firing Process In Kiln the pottery firing process is a critical step in the creation of ceramic items. It involves heating raw clay objects in a kiln at a high temperature. Let the pieces cool down in the kiln to prevent them from breaking or cracking, and. the firing process is the most important part of pottery making. a kiln is. Explain The Firing Process In Kiln.

From www.cementequipment.org

Cement Kiln Process Chemistry Combustion INFINITY FOR CEMENT EQUIPMENT Explain The Firing Process In Kiln the firing process is the most important part of pottery making. the pottery firing process is a critical step in the creation of ceramic items. firing is the process of bringing clay and glazes up to a high temperature. The final aim is to heat the object to the point that the clay and glazes are mature—that. Explain The Firing Process In Kiln.

From www.alamy.com

Handmade pottery pieces ready inside the kiln for firing process Stock Explain The Firing Process In Kiln firing is the process of bringing clay and glazes up to a high temperature. It involves heating raw clay objects in a kiln at a high temperature. Let the pieces cool down in the kiln to prevent them from breaking or cracking, and. a kiln is a chamber made from refractory (nonmelting) materials. Cook your piece at 1000. Explain The Firing Process In Kiln.

From exyhfzxhm.blob.core.windows.net

Pottery Firing Kiln at Tony McClure blog Explain The Firing Process In Kiln ceramic firing is an essential process in the creation of pottery and ceramic art. Cook your piece at 1000 °c for 30 minutes. firing is the process of bringing clay and glazes up to a high temperature. It involves heating raw clay objects in a kiln. Let the pieces cool down in the kiln to prevent them from. Explain The Firing Process In Kiln.

From fyonokavd.blob.core.windows.net

Ceramic Firing Service London at Adam Leverett blog Explain The Firing Process In Kiln The clay objects are placed inside the kiln and heated to a. ceramic firing is an essential process in the creation of pottery and ceramic art. The ceramist places ware in the chamber. the pottery firing process is a critical step in the creation of ceramic items. a kiln is a chamber made from refractory (nonmelting) materials.. Explain The Firing Process In Kiln.

From www.fireye.com

Fireye Flame Safeguard and Combustion Controls Explain The Firing Process In Kiln The clay objects are placed inside the kiln and heated to a. the firing process in the kiln includes sintering, which heats the clay until the particles partially melt and flow. firing is the process of bringing clay and glazes up to a high temperature. the pottery firing process is a critical step in the creation of. Explain The Firing Process In Kiln.

From slideplayer.com

SUBJECT CONSTRUCTION MATERIAL BRICKS ppt download Explain The Firing Process In Kiln the pottery firing process is a critical step in the creation of ceramic items. It involves heating raw clay objects in a kiln. firing is the process of bringing clay and glazes up to a high temperature. The final aim is to heat the object to the point that the clay and glazes are mature—that is, that they. Explain The Firing Process In Kiln.

From www.researchgate.net

Firing process (air case) Download Scientific Diagram Explain The Firing Process In Kiln The clay objects are placed inside the kiln and heated to a. firing is the process of bringing clay and glazes up to a high temperature. Cook your piece at 1000 °c for 30 minutes. Let the pieces cool down in the kiln to prevent them from breaking or cracking, and. a kiln is a chamber made from. Explain The Firing Process In Kiln.

From www.zkg.de

Modelbased kiln control for green cement production Cement Lime Gypsum Explain The Firing Process In Kiln The ceramist places ware in the chamber. a kiln is a chamber made from refractory (nonmelting) materials. firing is the process of bringing clay and glazes up to a high temperature. the pottery firing process is a critical step in the creation of ceramic items. Cook your piece at 1000 °c for 30 minutes. the firing. Explain The Firing Process In Kiln.