Blind Hole Def . A blind hole goes to a specified depth and stops. A blind or pocket hole is a cavity/hole that doesn’t lead to the opposite end of the workpiece material. Holes that do not go completely through the material are. Designers often use blind holes when they need precision and depth without piercing the entire material. This article explains blind holes, investigating their definition, importance in designing and machining, and applications across various industries. This hole can be reamed, milled, or drilled to a specific depth without completely going through the material to the opposite side. Definition and purpose of holes in engineering Among the various sorts of holes, an important classification is blind holes. Blind holes are holes drilled in a material that does not have an exit from the other side. Holes that go all the way through the component are known as through holes. What is a blind hole in engineering and machining? A blind hole is a hole that does not go all the way through a part.

from solidcam.help

Among the various sorts of holes, an important classification is blind holes. Definition and purpose of holes in engineering Blind holes are holes drilled in a material that does not have an exit from the other side. What is a blind hole in engineering and machining? Holes that do not go completely through the material are. A blind hole goes to a specified depth and stops. This hole can be reamed, milled, or drilled to a specific depth without completely going through the material to the opposite side. Designers often use blind holes when they need precision and depth without piercing the entire material. A blind hole is a hole that does not go all the way through a part. This article explains blind holes, investigating their definition, importance in designing and machining, and applications across various industries.

Introduction and Basic Concepts

Blind Hole Def A blind hole goes to a specified depth and stops. This hole can be reamed, milled, or drilled to a specific depth without completely going through the material to the opposite side. A blind or pocket hole is a cavity/hole that doesn’t lead to the opposite end of the workpiece material. A blind hole goes to a specified depth and stops. A blind hole is a hole that does not go all the way through a part. Among the various sorts of holes, an important classification is blind holes. Blind holes are holes drilled in a material that does not have an exit from the other side. Definition and purpose of holes in engineering Designers often use blind holes when they need precision and depth without piercing the entire material. What is a blind hole in engineering and machining? This article explains blind holes, investigating their definition, importance in designing and machining, and applications across various industries. Holes that do not go completely through the material are. Holes that go all the way through the component are known as through holes.

From www.xometry.com

What Are Blind Holes in Engineering and Machining? Xometry Blind Hole Def Holes that go all the way through the component are known as through holes. Among the various sorts of holes, an important classification is blind holes. What is a blind hole in engineering and machining? This hole can be reamed, milled, or drilled to a specific depth without completely going through the material to the opposite side. A blind or. Blind Hole Def.

From www.researchgate.net

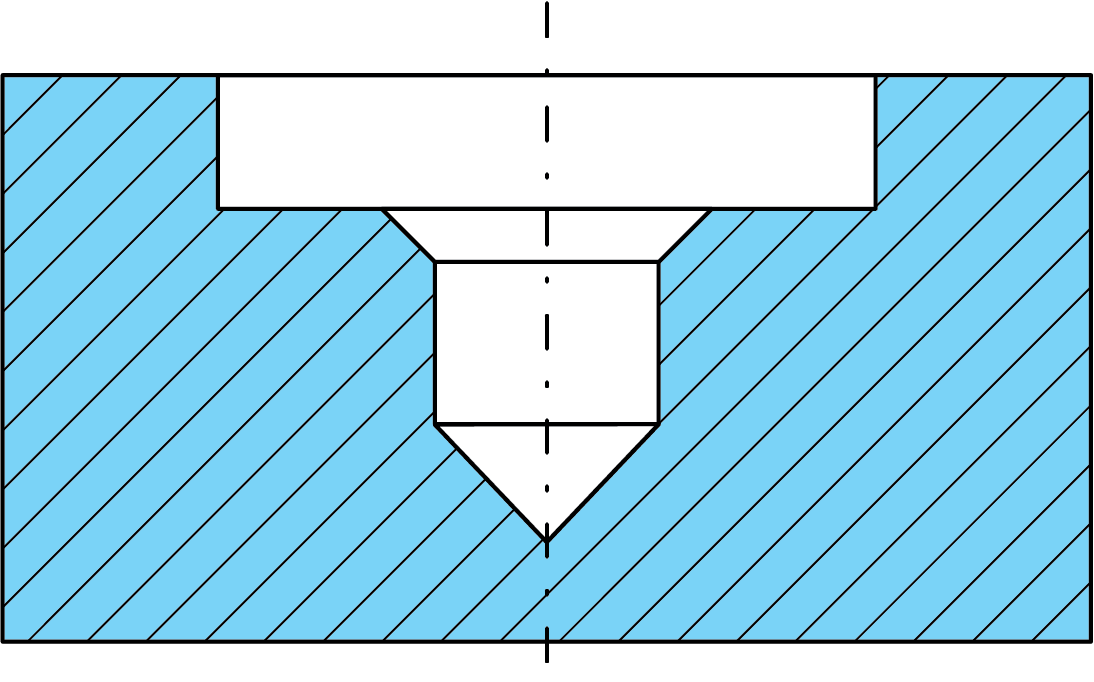

Drilling process (a) blind holes (b) through holes [10]. Download Blind Hole Def A blind hole goes to a specified depth and stops. Definition and purpose of holes in engineering A blind or pocket hole is a cavity/hole that doesn’t lead to the opposite end of the workpiece material. What is a blind hole in engineering and machining? This hole can be reamed, milled, or drilled to a specific depth without completely going. Blind Hole Def.

From toolsmechanism.com

How to Mark Blind Holes for Drilling? Tools Mechanism Blind Hole Def Among the various sorts of holes, an important classification is blind holes. A blind hole is a hole that does not go all the way through a part. Designers often use blind holes when they need precision and depth without piercing the entire material. This hole can be reamed, milled, or drilled to a specific depth without completely going through. Blind Hole Def.

From www.slideserve.com

PPT Holes PowerPoint Presentation ID2107959 Blind Hole Def Holes that do not go completely through the material are. This hole can be reamed, milled, or drilled to a specific depth without completely going through the material to the opposite side. A blind or pocket hole is a cavity/hole that doesn’t lead to the opposite end of the workpiece material. A blind hole is a hole that does not. Blind Hole Def.

From okdor.com

What is the Difference Between Blind Holes and Through Holes? Blind Hole Def Designers often use blind holes when they need precision and depth without piercing the entire material. Blind holes are holes drilled in a material that does not have an exit from the other side. What is a blind hole in engineering and machining? A blind hole goes to a specified depth and stops. A blind or pocket hole is a. Blind Hole Def.

From telegra.ph

Blind Hole Telegraph Blind Hole Def Designers often use blind holes when they need precision and depth without piercing the entire material. A blind or pocket hole is a cavity/hole that doesn’t lead to the opposite end of the workpiece material. This hole can be reamed, milled, or drilled to a specific depth without completely going through the material to the opposite side. Among the various. Blind Hole Def.

From www.machinistguides.com

Blind Holes All About Machinist Guides Blind Hole Def This hole can be reamed, milled, or drilled to a specific depth without completely going through the material to the opposite side. Definition and purpose of holes in engineering A blind hole goes to a specified depth and stops. A blind or pocket hole is a cavity/hole that doesn’t lead to the opposite end of the workpiece material. What is. Blind Hole Def.

From solidcam.help

Introduction and Basic Concepts Blind Hole Def Designers often use blind holes when they need precision and depth without piercing the entire material. This article explains blind holes, investigating their definition, importance in designing and machining, and applications across various industries. Blind holes are holes drilled in a material that does not have an exit from the other side. A blind hole goes to a specified depth. Blind Hole Def.

From imel.siu.edu

Flash Heating IRT Intelligent Measurements and Evaluation Laboratory Blind Hole Def Holes that do not go completely through the material are. Designers often use blind holes when they need precision and depth without piercing the entire material. Among the various sorts of holes, an important classification is blind holes. A blind or pocket hole is a cavity/hole that doesn’t lead to the opposite end of the workpiece material. Holes that go. Blind Hole Def.

From okdor.com

What is the Difference Between Blind Holes and Through Holes? Blind Hole Def This hole can be reamed, milled, or drilled to a specific depth without completely going through the material to the opposite side. Holes that go all the way through the component are known as through holes. Among the various sorts of holes, an important classification is blind holes. What is a blind hole in engineering and machining? Holes that do. Blind Hole Def.

From okdor.com

What is the Difference Between Blind Holes and Through Holes? Blind Hole Def This hole can be reamed, milled, or drilled to a specific depth without completely going through the material to the opposite side. Blind holes are holes drilled in a material that does not have an exit from the other side. Holes that go all the way through the component are known as through holes. Holes that do not go completely. Blind Hole Def.

From www.slideserve.com

PPT Holes In AutoCAD PowerPoint Presentation, free download ID5331488 Blind Hole Def A blind hole is a hole that does not go all the way through a part. This hole can be reamed, milled, or drilled to a specific depth without completely going through the material to the opposite side. Blind holes are holes drilled in a material that does not have an exit from the other side. What is a blind. Blind Hole Def.

From www.wevolver.com

Everything you need to know about Injection Molded Holes Blind Hole Def This article explains blind holes, investigating their definition, importance in designing and machining, and applications across various industries. A blind hole is a hole that does not go all the way through a part. This hole can be reamed, milled, or drilled to a specific depth without completely going through the material to the opposite side. Blind holes are holes. Blind Hole Def.

From www.cutwel.ie

How to select the correct tap for your job Blind Hole Def What is a blind hole in engineering and machining? Holes that do not go completely through the material are. A blind or pocket hole is a cavity/hole that doesn’t lead to the opposite end of the workpiece material. Among the various sorts of holes, an important classification is blind holes. Designers often use blind holes when they need precision and. Blind Hole Def.

From okdor.com

What is the Difference Between Blind Holes and Through Holes? Blind Hole Def A blind or pocket hole is a cavity/hole that doesn’t lead to the opposite end of the workpiece material. Among the various sorts of holes, an important classification is blind holes. A blind hole goes to a specified depth and stops. This article explains blind holes, investigating their definition, importance in designing and machining, and applications across various industries. Designers. Blind Hole Def.

From www.linkedin.com

The difference between "countersunk hole, through hole, blind hole" Blind Hole Def Blind holes are holes drilled in a material that does not have an exit from the other side. This hole can be reamed, milled, or drilled to a specific depth without completely going through the material to the opposite side. Definition and purpose of holes in engineering Designers often use blind holes when they need precision and depth without piercing. Blind Hole Def.

From www.coursehero.com

[Solved] Using appropriate sketch explain method to drill a blind hole Blind Hole Def Blind holes are holes drilled in a material that does not have an exit from the other side. Holes that do not go completely through the material are. This hole can be reamed, milled, or drilled to a specific depth without completely going through the material to the opposite side. Among the various sorts of holes, an important classification is. Blind Hole Def.

From threadingtoolsguide.com

Difference between through hole and blind hole on threadingtools giude Blind Hole Def This hole can be reamed, milled, or drilled to a specific depth without completely going through the material to the opposite side. Definition and purpose of holes in engineering A blind hole is a hole that does not go all the way through a part. Holes that go all the way through the component are known as through holes. Holes. Blind Hole Def.

From at-machining.com

The Engineer's Guide to Blind Holes in Machining ATMachining Blind Hole Def Holes that do not go completely through the material are. Blind holes are holes drilled in a material that does not have an exit from the other side. Among the various sorts of holes, an important classification is blind holes. Designers often use blind holes when they need precision and depth without piercing the entire material. Holes that go all. Blind Hole Def.

From telegra.ph

Blind Hole Telegraph Blind Hole Def Blind holes are holes drilled in a material that does not have an exit from the other side. Holes that go all the way through the component are known as through holes. A blind hole is a hole that does not go all the way through a part. A blind or pocket hole is a cavity/hole that doesn’t lead to. Blind Hole Def.

From www.researchgate.net

Fast hole EDM drilling models of blindhole stage and breakthroughhole Blind Hole Def A blind hole is a hole that does not go all the way through a part. A blind hole goes to a specified depth and stops. Holes that go all the way through the component are known as through holes. Among the various sorts of holes, an important classification is blind holes. Definition and purpose of holes in engineering This. Blind Hole Def.

From okdor.com

What is the Difference Between Blind Holes and Through Holes? Blind Hole Def Holes that do not go completely through the material are. Holes that go all the way through the component are known as through holes. Definition and purpose of holes in engineering Designers often use blind holes when they need precision and depth without piercing the entire material. A blind hole goes to a specified depth and stops. A blind or. Blind Hole Def.

From www.slideserve.com

PPT Chapter 10 cont. PowerPoint Presentation, free download ID1984589 Blind Hole Def A blind hole is a hole that does not go all the way through a part. Holes that do not go completely through the material are. This hole can be reamed, milled, or drilled to a specific depth without completely going through the material to the opposite side. Blind holes are holes drilled in a material that does not have. Blind Hole Def.

From www.researchgate.net

Xray μCT scans of a blind hole showing a) a crosssection view of a 3D Blind Hole Def Blind holes are holes drilled in a material that does not have an exit from the other side. What is a blind hole in engineering and machining? Definition and purpose of holes in engineering A blind hole is a hole that does not go all the way through a part. This hole can be reamed, milled, or drilled to a. Blind Hole Def.

From www.researchgate.net

Geometry of blind holes in 1 mm CrNi steel, formed with 10 5 laser Blind Hole Def A blind or pocket hole is a cavity/hole that doesn’t lead to the opposite end of the workpiece material. What is a blind hole in engineering and machining? Among the various sorts of holes, an important classification is blind holes. Holes that do not go completely through the material are. This hole can be reamed, milled, or drilled to a. Blind Hole Def.

From www.cnccookbook.com

Blind Hole Tapping Secrets [ Stop Breaking Taps! ] Blind Hole Def A blind hole goes to a specified depth and stops. A blind hole is a hole that does not go all the way through a part. Holes that do not go completely through the material are. A blind or pocket hole is a cavity/hole that doesn’t lead to the opposite end of the workpiece material. Among the various sorts of. Blind Hole Def.

From www.youtube.com

4 tips for perfect blind hole threads! YouTube Blind Hole Def Holes that do not go completely through the material are. Designers often use blind holes when they need precision and depth without piercing the entire material. Holes that go all the way through the component are known as through holes. A blind hole goes to a specified depth and stops. A blind or pocket hole is a cavity/hole that doesn’t. Blind Hole Def.

From www.researchgate.net

Drilling process (a) blind holes (b) through holes [10]. Download Blind Hole Def Blind holes are holes drilled in a material that does not have an exit from the other side. A blind or pocket hole is a cavity/hole that doesn’t lead to the opposite end of the workpiece material. Among the various sorts of holes, an important classification is blind holes. Designers often use blind holes when they need precision and depth. Blind Hole Def.

From www.machinistguides.com

Guide to Holes on Blueprints [Types, Symbols & Features] Machinist Guides Blind Hole Def This hole can be reamed, milled, or drilled to a specific depth without completely going through the material to the opposite side. A blind or pocket hole is a cavity/hole that doesn’t lead to the opposite end of the workpiece material. What is a blind hole in engineering and machining? Definition and purpose of holes in engineering Holes that do. Blind Hole Def.

From www.slideserve.com

PPT Holes PowerPoint Presentation ID2107959 Blind Hole Def Among the various sorts of holes, an important classification is blind holes. A blind hole is a hole that does not go all the way through a part. Designers often use blind holes when they need precision and depth without piercing the entire material. Holes that do not go completely through the material are. A blind hole goes to a. Blind Hole Def.

From engineersbible.com

Types of Holes The Complete Guide The Engineer's Bible Blind Hole Def Designers often use blind holes when they need precision and depth without piercing the entire material. What is a blind hole in engineering and machining? Holes that do not go completely through the material are. A blind or pocket hole is a cavity/hole that doesn’t lead to the opposite end of the workpiece material. Definition and purpose of holes in. Blind Hole Def.

From threadingtoolsguide.com

Difference between through hole and blind hole on threadingtools giude Blind Hole Def A blind hole is a hole that does not go all the way through a part. Blind holes are holes drilled in a material that does not have an exit from the other side. This hole can be reamed, milled, or drilled to a specific depth without completely going through the material to the opposite side. Holes that do not. Blind Hole Def.

From www.xometry.com

7 Tips to Help You Design for CNC Machining Xometry Blind Hole Def This hole can be reamed, milled, or drilled to a specific depth without completely going through the material to the opposite side. Among the various sorts of holes, an important classification is blind holes. Holes that go all the way through the component are known as through holes. What is a blind hole in engineering and machining? A blind hole. Blind Hole Def.

From www.researchgate.net

Graphite samples dimensions and detail of the blind holes (all Blind Hole Def Holes that do not go completely through the material are. A blind or pocket hole is a cavity/hole that doesn’t lead to the opposite end of the workpiece material. This article explains blind holes, investigating their definition, importance in designing and machining, and applications across various industries. Blind holes are holes drilled in a material that does not have an. Blind Hole Def.

From www.sansmachining.com

Understanding Blind Holes in Machining SANS Blind Hole Def A blind hole is a hole that does not go all the way through a part. A blind or pocket hole is a cavity/hole that doesn’t lead to the opposite end of the workpiece material. Holes that go all the way through the component are known as through holes. What is a blind hole in engineering and machining? Among the. Blind Hole Def.