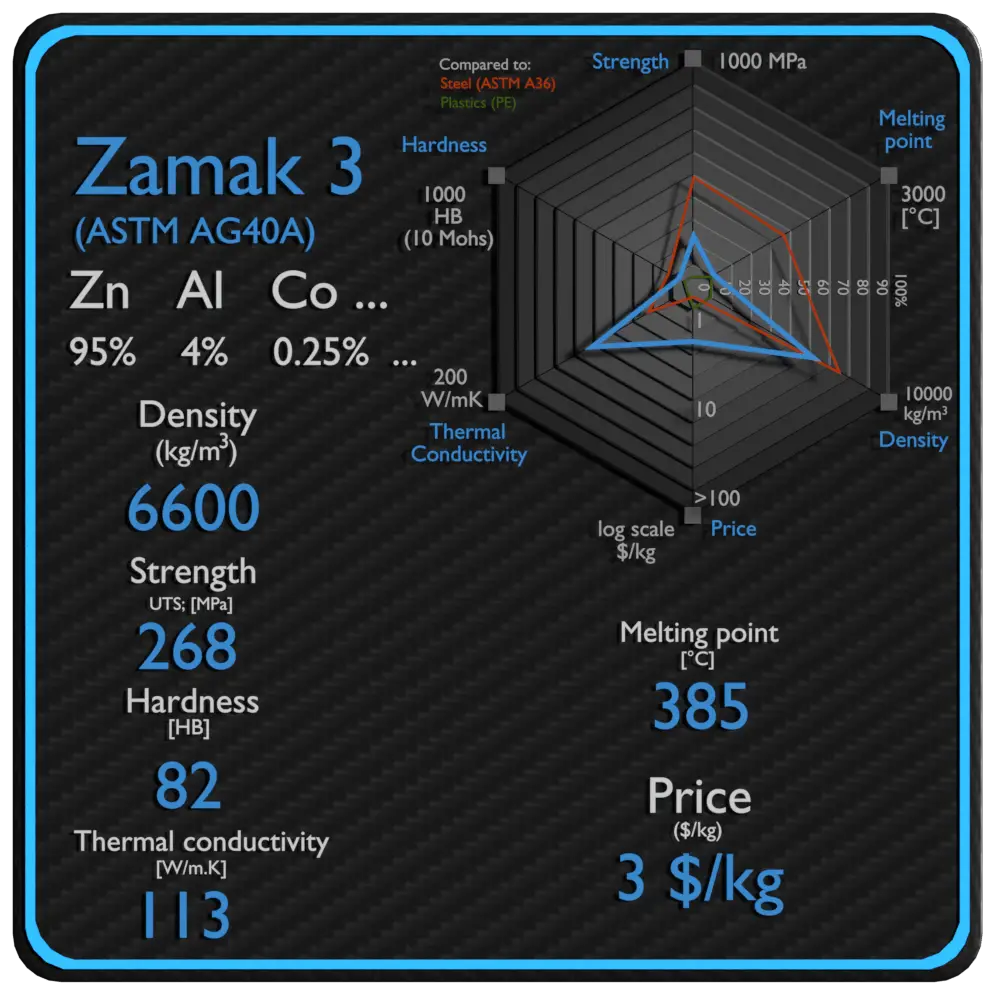

Zamak Alloy Properties . Eastern alloys manufactures the complete range of zinc die casting alloys. The main components of zamak 3 alloy have about 96% zinc and a small percent of. 210 mpa 31 x 103 psi. Zamak 3 (zinc alloy 3) is the most common zamak alloy and a popular die casting material. Ultimate (uts) 280 mpa 41 x 103 psi. Zamak alloys were first developed during the 1920's by. The mechanical or physical properties vary from one member to the other in zamak. Zamak alloy primarily consists of zinc and aluminum in addition to other metals. It has excellent physical and mechanical. But all the alloys share some steadfast features,. Zamak, also known as zamak or zamac, a family of alloys with zinc as the base metal and. Grade zamak 3 alloy is the most widely used zinc alloy in zinc die casting industry.

from material-properties.org

Eastern alloys manufactures the complete range of zinc die casting alloys. Ultimate (uts) 280 mpa 41 x 103 psi. It has excellent physical and mechanical. The mechanical or physical properties vary from one member to the other in zamak. But all the alloys share some steadfast features,. Zamak, also known as zamak or zamac, a family of alloys with zinc as the base metal and. Zamak 3 (zinc alloy 3) is the most common zamak alloy and a popular die casting material. The main components of zamak 3 alloy have about 96% zinc and a small percent of. 210 mpa 31 x 103 psi. Grade zamak 3 alloy is the most widely used zinc alloy in zinc die casting industry.

What is Zamak Zinc Alloy Properties Definition Material Properties

Zamak Alloy Properties Ultimate (uts) 280 mpa 41 x 103 psi. Zamak alloy primarily consists of zinc and aluminum in addition to other metals. But all the alloys share some steadfast features,. The main components of zamak 3 alloy have about 96% zinc and a small percent of. Grade zamak 3 alloy is the most widely used zinc alloy in zinc die casting industry. Ultimate (uts) 280 mpa 41 x 103 psi. Zamak alloys were first developed during the 1920's by. The mechanical or physical properties vary from one member to the other in zamak. It has excellent physical and mechanical. Zamak 3 (zinc alloy 3) is the most common zamak alloy and a popular die casting material. Zamak, also known as zamak or zamac, a family of alloys with zinc as the base metal and. 210 mpa 31 x 103 psi. Eastern alloys manufactures the complete range of zinc die casting alloys.

From belgcast.be

Zamak alloy Belgcast Zamak Alloy Properties Zamak alloy primarily consists of zinc and aluminum in addition to other metals. Eastern alloys manufactures the complete range of zinc die casting alloys. The mechanical or physical properties vary from one member to the other in zamak. Zamak 3 (zinc alloy 3) is the most common zamak alloy and a popular die casting material. 210 mpa 31 x 103. Zamak Alloy Properties.

From www.belmontmetals.com

What Manufacturers Need To Know About Zamak Alloys Belmont Metals Zamak Alloy Properties It has excellent physical and mechanical. Zamak alloy primarily consists of zinc and aluminum in addition to other metals. But all the alloys share some steadfast features,. 210 mpa 31 x 103 psi. Eastern alloys manufactures the complete range of zinc die casting alloys. Zamak alloys were first developed during the 1920's by. Grade zamak 3 alloy is the most. Zamak Alloy Properties.

From patents.google.com

WO2015053820A1 Ballistic zinc alloys, firearm projectiles, and Zamak Alloy Properties Ultimate (uts) 280 mpa 41 x 103 psi. Zamak, also known as zamak or zamac, a family of alloys with zinc as the base metal and. Eastern alloys manufactures the complete range of zinc die casting alloys. Zamak 3 (zinc alloy 3) is the most common zamak alloy and a popular die casting material. It has excellent physical and mechanical.. Zamak Alloy Properties.

From www.beyontech.co.in

Beyon Tech About Us Zamak Alloy Properties Eastern alloys manufactures the complete range of zinc die casting alloys. Zamak alloy primarily consists of zinc and aluminum in addition to other metals. The mechanical or physical properties vary from one member to the other in zamak. But all the alloys share some steadfast features,. Grade zamak 3 alloy is the most widely used zinc alloy in zinc die. Zamak Alloy Properties.

From autocastinc.com

Autocast Inc. Alloy Types Zinc Zamak 3 Aluminum A380 Zamak Alloy Properties Grade zamak 3 alloy is the most widely used zinc alloy in zinc die casting industry. The mechanical or physical properties vary from one member to the other in zamak. Zamak alloy primarily consists of zinc and aluminum in addition to other metals. It has excellent physical and mechanical. Zamak alloys were first developed during the 1920's by. The main. Zamak Alloy Properties.

From www.newayprecision.com

Zamak 5 Zamak Alloy Properties The main components of zamak 3 alloy have about 96% zinc and a small percent of. It has excellent physical and mechanical. The mechanical or physical properties vary from one member to the other in zamak. But all the alloys share some steadfast features,. Zamak alloy primarily consists of zinc and aluminum in addition to other metals. Zamak, also known. Zamak Alloy Properties.

From www.youtube.com

HCM SA new casting line of ZAMAK Alloys YouTube Zamak Alloy Properties Ultimate (uts) 280 mpa 41 x 103 psi. Zamak alloys were first developed during the 1920's by. But all the alloys share some steadfast features,. It has excellent physical and mechanical. 210 mpa 31 x 103 psi. The main components of zamak 3 alloy have about 96% zinc and a small percent of. Grade zamak 3 alloy is the most. Zamak Alloy Properties.

From www.indiamart.com

Zinc Alloy Ingot Zamak 3 at best price in New Delhi by Alzinc India Pvt Zamak Alloy Properties Zamak 3 (zinc alloy 3) is the most common zamak alloy and a popular die casting material. But all the alloys share some steadfast features,. Grade zamak 3 alloy is the most widely used zinc alloy in zinc die casting industry. The mechanical or physical properties vary from one member to the other in zamak. Zamak, also known as zamak. Zamak Alloy Properties.

From www.beyontech.co.in

Beyon Tech About Us Zamak Alloy Properties The mechanical or physical properties vary from one member to the other in zamak. Zamak alloy primarily consists of zinc and aluminum in addition to other metals. Zamak, also known as zamak or zamac, a family of alloys with zinc as the base metal and. 210 mpa 31 x 103 psi. It has excellent physical and mechanical. Ultimate (uts) 280. Zamak Alloy Properties.

From www.researchgate.net

Hypoeutectic Zamak 5 microstructure (a) and SEMEDS analysis (b Zamak Alloy Properties Zamak alloy primarily consists of zinc and aluminum in addition to other metals. Zamak, also known as zamak or zamac, a family of alloys with zinc as the base metal and. Grade zamak 3 alloy is the most widely used zinc alloy in zinc die casting industry. Ultimate (uts) 280 mpa 41 x 103 psi. 210 mpa 31 x 103. Zamak Alloy Properties.

From dokumen.tips

(PDF) Zinc Die Casting Alloy Guide EAZALL · PDF fileZINC DIE CASTING Zamak Alloy Properties Zamak alloys were first developed during the 1920's by. Grade zamak 3 alloy is the most widely used zinc alloy in zinc die casting industry. The main components of zamak 3 alloy have about 96% zinc and a small percent of. Ultimate (uts) 280 mpa 41 x 103 psi. Zamak alloy primarily consists of zinc and aluminum in addition to. Zamak Alloy Properties.

From www.subcontracting-vietnam.com

Zamak Die Casting Manufacturing of stamping, sheet metal fabrication Zamak Alloy Properties But all the alloys share some steadfast features,. Zamak alloys were first developed during the 1920's by. Zamak alloy primarily consists of zinc and aluminum in addition to other metals. The main components of zamak 3 alloy have about 96% zinc and a small percent of. It has excellent physical and mechanical. The mechanical or physical properties vary from one. Zamak Alloy Properties.

From en.evtektika.com

Coatingrefining flux for ZAMAC alloys Evtektika EN Zamak Alloy Properties 210 mpa 31 x 103 psi. The mechanical or physical properties vary from one member to the other in zamak. Grade zamak 3 alloy is the most widely used zinc alloy in zinc die casting industry. Zamak 3 (zinc alloy 3) is the most common zamak alloy and a popular die casting material. It has excellent physical and mechanical. Ultimate. Zamak Alloy Properties.

From sizermetal.com

Zamak 3 Sizer Metal India Zamak Alloy Properties The main components of zamak 3 alloy have about 96% zinc and a small percent of. Eastern alloys manufactures the complete range of zinc die casting alloys. Zamak alloy primarily consists of zinc and aluminum in addition to other metals. Grade zamak 3 alloy is the most widely used zinc alloy in zinc die casting industry. Zamak, also known as. Zamak Alloy Properties.

From www.indiamart.com

Zamak2 Zinc Alloy at best price in Kolkata by Atma Metchem Pvt. Ltd Zamak Alloy Properties Zamak 3 (zinc alloy 3) is the most common zamak alloy and a popular die casting material. It has excellent physical and mechanical. Zamak alloys were first developed during the 1920's by. 210 mpa 31 x 103 psi. The main components of zamak 3 alloy have about 96% zinc and a small percent of. But all the alloys share some. Zamak Alloy Properties.

From www.indiamart.com

Zamak 5 Zinc Alloy at Rs 205/kilogram Neemrana ID 8928382730 Zamak Alloy Properties 210 mpa 31 x 103 psi. Eastern alloys manufactures the complete range of zinc die casting alloys. The main components of zamak 3 alloy have about 96% zinc and a small percent of. Zamak alloy primarily consists of zinc and aluminum in addition to other metals. Ultimate (uts) 280 mpa 41 x 103 psi. The mechanical or physical properties vary. Zamak Alloy Properties.

From www.indiamart.com

Zamak 7 Zinc Alloy at Rs 200/kilogram ज़िंक अलॉय्ज in Neemrana ID Zamak Alloy Properties 210 mpa 31 x 103 psi. Ultimate (uts) 280 mpa 41 x 103 psi. It has excellent physical and mechanical. Grade zamak 3 alloy is the most widely used zinc alloy in zinc die casting industry. Zamak alloy primarily consists of zinc and aluminum in addition to other metals. Eastern alloys manufactures the complete range of zinc die casting alloys.. Zamak Alloy Properties.

From www.indiamart.com

Zamak 2 Zinc Alloy at Rs 210/kg Zinc Alloy Ingot in Neemrana ID Zamak Alloy Properties 210 mpa 31 x 103 psi. Zamak alloys were first developed during the 1920's by. It has excellent physical and mechanical. Zamak 3 (zinc alloy 3) is the most common zamak alloy and a popular die casting material. Eastern alloys manufactures the complete range of zinc die casting alloys. Zamak, also known as zamak or zamac, a family of alloys. Zamak Alloy Properties.

From www.pittella.com.au

ZAMAK Zamak Alloy Properties It has excellent physical and mechanical. The mechanical or physical properties vary from one member to the other in zamak. Ultimate (uts) 280 mpa 41 x 103 psi. 210 mpa 31 x 103 psi. Zamak, also known as zamak or zamac, a family of alloys with zinc as the base metal and. Eastern alloys manufactures the complete range of zinc. Zamak Alloy Properties.

From www.researchgate.net

(PDF) Microstructure and Mechanical Properties of Zamak 3 Alloy Zamak Alloy Properties The mechanical or physical properties vary from one member to the other in zamak. Eastern alloys manufactures the complete range of zinc die casting alloys. Zamak, also known as zamak or zamac, a family of alloys with zinc as the base metal and. But all the alloys share some steadfast features,. Grade zamak 3 alloy is the most widely used. Zamak Alloy Properties.

From www.sunrise-metal.com

Zamak 5 Alloy Properties Zinc Alloy Die Casting Manufacturing Zamak Alloy Properties It has excellent physical and mechanical. Zamak alloy primarily consists of zinc and aluminum in addition to other metals. Ultimate (uts) 280 mpa 41 x 103 psi. The mechanical or physical properties vary from one member to the other in zamak. Eastern alloys manufactures the complete range of zinc die casting alloys. The main components of zamak 3 alloy have. Zamak Alloy Properties.

From www.inoxcast.com

Zamak Alloys Inox Cast Zamak Alloy Properties But all the alloys share some steadfast features,. Zamak alloys were first developed during the 1920's by. Grade zamak 3 alloy is the most widely used zinc alloy in zinc die casting industry. Zamak, also known as zamak or zamac, a family of alloys with zinc as the base metal and. 210 mpa 31 x 103 psi. The mechanical or. Zamak Alloy Properties.

From hobes.sk

Zincalloy ZAMAK Diecasting HOBES Slovakia Zamak Alloy Properties Eastern alloys manufactures the complete range of zinc die casting alloys. The main components of zamak 3 alloy have about 96% zinc and a small percent of. Zamak 3 (zinc alloy 3) is the most common zamak alloy and a popular die casting material. The mechanical or physical properties vary from one member to the other in zamak. 210 mpa. Zamak Alloy Properties.

From www.indiamart.com

Zamak 2 Zinc Alloys Ingot at Rs 250.10/kg जिंक एलॉय इंगोट्स in Mumbai Zamak Alloy Properties Grade zamak 3 alloy is the most widely used zinc alloy in zinc die casting industry. Zamak alloy primarily consists of zinc and aluminum in addition to other metals. The mechanical or physical properties vary from one member to the other in zamak. Zamak 3 (zinc alloy 3) is the most common zamak alloy and a popular die casting material.. Zamak Alloy Properties.

From www.tradekey.com

ZAMAK3 Foundry Alloy By namrata exports, India Zamak Alloy Properties Zamak, also known as zamak or zamac, a family of alloys with zinc as the base metal and. Ultimate (uts) 280 mpa 41 x 103 psi. It has excellent physical and mechanical. 210 mpa 31 x 103 psi. Zamak 3 (zinc alloy 3) is the most common zamak alloy and a popular die casting material. But all the alloys share. Zamak Alloy Properties.

From www.researchgate.net

(PDF) Zamak 2 Alloy Produced by Mechanical Alloying and Consolidated by Zamak Alloy Properties 210 mpa 31 x 103 psi. Zamak 3 (zinc alloy 3) is the most common zamak alloy and a popular die casting material. The mechanical or physical properties vary from one member to the other in zamak. But all the alloys share some steadfast features,. Zamak alloy primarily consists of zinc and aluminum in addition to other metals. The main. Zamak Alloy Properties.

From sizermetal.com

Zamak 5 Sizer Metal Singapore Zamak Alloy Properties But all the alloys share some steadfast features,. Zamak alloys were first developed during the 1920's by. Zamak, also known as zamak or zamac, a family of alloys with zinc as the base metal and. Eastern alloys manufactures the complete range of zinc die casting alloys. Zamak alloy primarily consists of zinc and aluminum in addition to other metals. Ultimate. Zamak Alloy Properties.

From material-properties.org

What is Zamak Zinc Alloy Properties Definition Material Properties Zamak Alloy Properties Ultimate (uts) 280 mpa 41 x 103 psi. The mechanical or physical properties vary from one member to the other in zamak. Zamak alloys were first developed during the 1920's by. But all the alloys share some steadfast features,. Zamak, also known as zamak or zamac, a family of alloys with zinc as the base metal and. The main components. Zamak Alloy Properties.

From patents.google.com

WO2015053820A1 Ballistic zinc alloys, firearm projectiles, and Zamak Alloy Properties Zamak alloys were first developed during the 1920's by. Zamak 3 (zinc alloy 3) is the most common zamak alloy and a popular die casting material. Zamak alloy primarily consists of zinc and aluminum in addition to other metals. Grade zamak 3 alloy is the most widely used zinc alloy in zinc die casting industry. Eastern alloys manufactures the complete. Zamak Alloy Properties.

From www.iqsdirectory.com

Zinc Die Casting What Is It? How Is it Made? Advantages Zamak Alloy Properties Zamak, also known as zamak or zamac, a family of alloys with zinc as the base metal and. Zamak alloys were first developed during the 1920's by. It has excellent physical and mechanical. Eastern alloys manufactures the complete range of zinc die casting alloys. The mechanical or physical properties vary from one member to the other in zamak. The main. Zamak Alloy Properties.

From juliansherman.net

Zamak Alloys Information, Guideline and Where to buy Zamak Alloys and Zamak Alloy Properties Zamak alloy primarily consists of zinc and aluminum in addition to other metals. The mechanical or physical properties vary from one member to the other in zamak. Zamak 3 (zinc alloy 3) is the most common zamak alloy and a popular die casting material. Grade zamak 3 alloy is the most widely used zinc alloy in zinc die casting industry.. Zamak Alloy Properties.

From blog.thepipingmart.com

Advantages and Disadvantages of Zamak Metal Zamak Alloy Properties The mechanical or physical properties vary from one member to the other in zamak. Zamak alloys were first developed during the 1920's by. It has excellent physical and mechanical. Zamak 3 (zinc alloy 3) is the most common zamak alloy and a popular die casting material. The main components of zamak 3 alloy have about 96% zinc and a small. Zamak Alloy Properties.

From www.italleghe.eu

Zamak Types and use ITAL LEGHE S.R.L. Zamak Alloy Properties The mechanical or physical properties vary from one member to the other in zamak. Zamak alloy primarily consists of zinc and aluminum in addition to other metals. Ultimate (uts) 280 mpa 41 x 103 psi. But all the alloys share some steadfast features,. It has excellent physical and mechanical. Zamak 3 (zinc alloy 3) is the most common zamak alloy. Zamak Alloy Properties.

From www.mdpi.com

Metals Free FullText Review of Microstructures and Properties of Zamak Alloy Properties The main components of zamak 3 alloy have about 96% zinc and a small percent of. The mechanical or physical properties vary from one member to the other in zamak. 210 mpa 31 x 103 psi. Eastern alloys manufactures the complete range of zinc die casting alloys. Zamak alloys were first developed during the 1920's by. Grade zamak 3 alloy. Zamak Alloy Properties.

From www.beyontech.co.in

Beyon Tech About Us Zamak Alloy Properties The main components of zamak 3 alloy have about 96% zinc and a small percent of. Zamak, also known as zamak or zamac, a family of alloys with zinc as the base metal and. The mechanical or physical properties vary from one member to the other in zamak. Zamak alloy primarily consists of zinc and aluminum in addition to other. Zamak Alloy Properties.