Mat Manufacturing Process . Understanding the manufacturing process and how shock absorption is improved provides a clearer picture of the product’s. Chopped strand mats are created by cutting glass fibers into short pieces and arranging them randomly. The fibers are then held together with. Here’s how the inedible husk of the coconut can be turned into a product that can sit proudly on the floor your doorway in just six easy steps. The manufacturing process steps generally include element preparation, classification and drying, adhesive application, mat formation,. Fiberglass mats are primarily produced on machines, which are typically 1.5 to 6.0 meters wide, with a closed loop process water system. The fiber stock gets introduced at the pulping step and enters the formation section where the fibers get distributed uniformly across the width of the machine. This guide delves into the detailed. Rubber mats are integral to various settings, offering durability, safety, and ergonomic benefits. A machete is used to cut.

from www.semiconductor-digest.com

The manufacturing process steps generally include element preparation, classification and drying, adhesive application, mat formation,. Understanding the manufacturing process and how shock absorption is improved provides a clearer picture of the product’s. Fiberglass mats are primarily produced on machines, which are typically 1.5 to 6.0 meters wide, with a closed loop process water system. Here’s how the inedible husk of the coconut can be turned into a product that can sit proudly on the floor your doorway in just six easy steps. Rubber mats are integral to various settings, offering durability, safety, and ergonomic benefits. The fiber stock gets introduced at the pulping step and enters the formation section where the fibers get distributed uniformly across the width of the machine. The fibers are then held together with. Chopped strand mats are created by cutting glass fibers into short pieces and arranging them randomly. This guide delves into the detailed. A machete is used to cut.

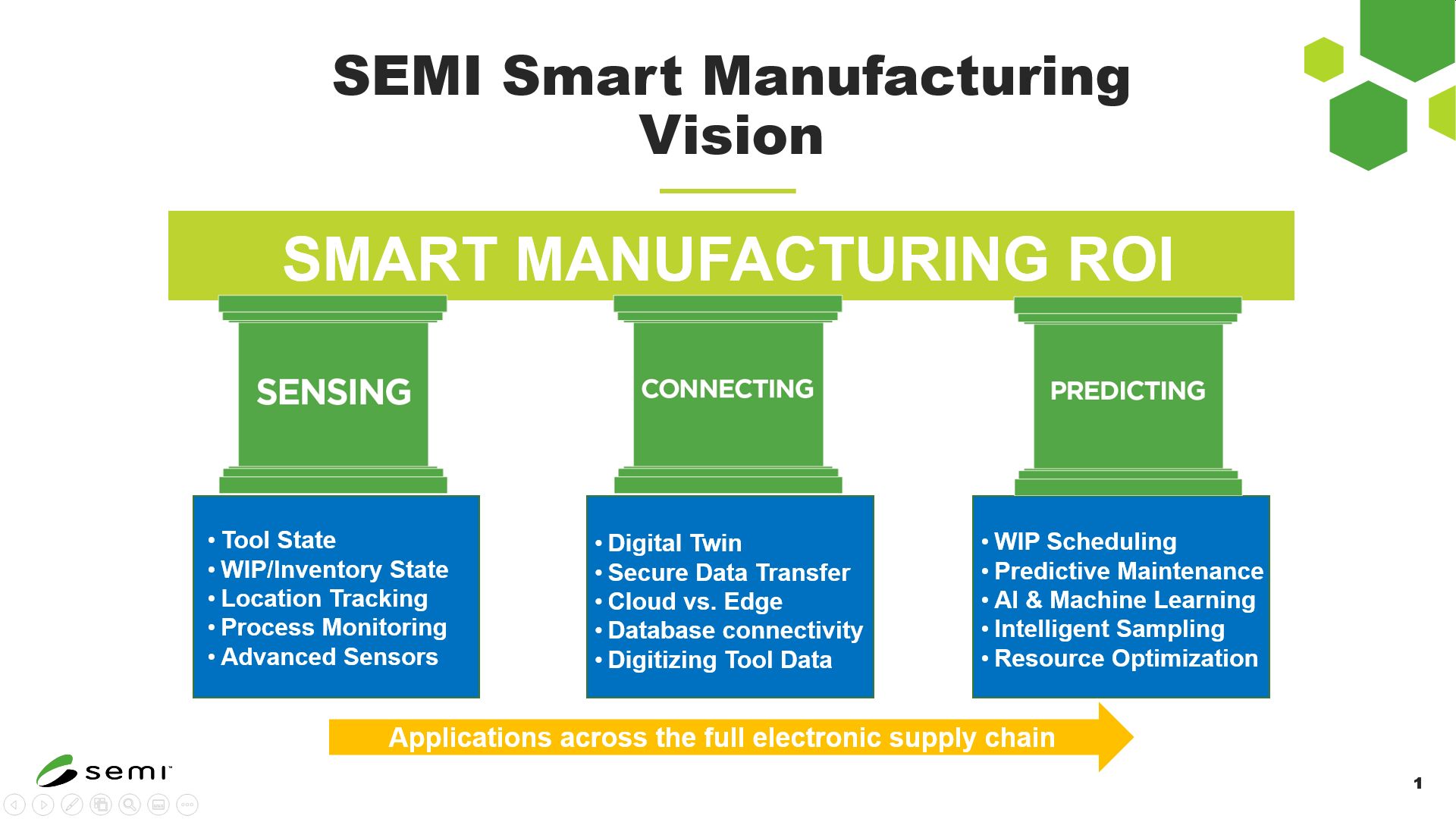

Be Smart About Smart Manufacturing Semiconductor Digest

Mat Manufacturing Process Fiberglass mats are primarily produced on machines, which are typically 1.5 to 6.0 meters wide, with a closed loop process water system. Rubber mats are integral to various settings, offering durability, safety, and ergonomic benefits. The fibers are then held together with. The fiber stock gets introduced at the pulping step and enters the formation section where the fibers get distributed uniformly across the width of the machine. This guide delves into the detailed. A machete is used to cut. Understanding the manufacturing process and how shock absorption is improved provides a clearer picture of the product’s. Here’s how the inedible husk of the coconut can be turned into a product that can sit proudly on the floor your doorway in just six easy steps. Chopped strand mats are created by cutting glass fibers into short pieces and arranging them randomly. Fiberglass mats are primarily produced on machines, which are typically 1.5 to 6.0 meters wide, with a closed loop process water system. The manufacturing process steps generally include element preparation, classification and drying, adhesive application, mat formation,.

From smartmanufacturingcluster.org

Implementing DataDriven Manufacturing in Northeast Ohio Smart Mat Manufacturing Process Here’s how the inedible husk of the coconut can be turned into a product that can sit proudly on the floor your doorway in just six easy steps. Chopped strand mats are created by cutting glass fibers into short pieces and arranging them randomly. Understanding the manufacturing process and how shock absorption is improved provides a clearer picture of the. Mat Manufacturing Process.

From www.collidu.com

Smart Manufacturing PowerPoint Presentation Slides PPT Template Mat Manufacturing Process The fiber stock gets introduced at the pulping step and enters the formation section where the fibers get distributed uniformly across the width of the machine. Fiberglass mats are primarily produced on machines, which are typically 1.5 to 6.0 meters wide, with a closed loop process water system. Chopped strand mats are created by cutting glass fibers into short pieces. Mat Manufacturing Process.

From aiswix.com

Learn About The Chopped Strand Mat Manufacturing Process Aiswix Mat Manufacturing Process Chopped strand mats are created by cutting glass fibers into short pieces and arranging them randomly. Fiberglass mats are primarily produced on machines, which are typically 1.5 to 6.0 meters wide, with a closed loop process water system. Here’s how the inedible husk of the coconut can be turned into a product that can sit proudly on the floor your. Mat Manufacturing Process.

From www.br-automation.com

Smart manufacturing for ultimate production effectiveness B&R Mat Manufacturing Process The fibers are then held together with. The manufacturing process steps generally include element preparation, classification and drying, adhesive application, mat formation,. Chopped strand mats are created by cutting glass fibers into short pieces and arranging them randomly. Understanding the manufacturing process and how shock absorption is improved provides a clearer picture of the product’s. Here’s how the inedible husk. Mat Manufacturing Process.

From blog.rheincs.com

Improve Manufacturing Efficiency using Smart ERP System RheinBrücke Mat Manufacturing Process A machete is used to cut. Rubber mats are integral to various settings, offering durability, safety, and ergonomic benefits. Understanding the manufacturing process and how shock absorption is improved provides a clearer picture of the product’s. The fibers are then held together with. Fiberglass mats are primarily produced on machines, which are typically 1.5 to 6.0 meters wide, with a. Mat Manufacturing Process.

From www.yogafitness.group

How Are Yoga Mats Made? Yoga Mat Manufacturing Process Custom Yoga Mat Manufacturing Process The fibers are then held together with. A machete is used to cut. Here’s how the inedible husk of the coconut can be turned into a product that can sit proudly on the floor your doorway in just six easy steps. The fiber stock gets introduced at the pulping step and enters the formation section where the fibers get distributed. Mat Manufacturing Process.

From www.youtube.com

Fiberglass chopped strand mat manufacturing process YouTube Mat Manufacturing Process This guide delves into the detailed. Understanding the manufacturing process and how shock absorption is improved provides a clearer picture of the product’s. Rubber mats are integral to various settings, offering durability, safety, and ergonomic benefits. The fiber stock gets introduced at the pulping step and enters the formation section where the fibers get distributed uniformly across the width of. Mat Manufacturing Process.

From ectobox.com

3 Vital Benefits of Smart Manufacturing Ectobox Mat Manufacturing Process Chopped strand mats are created by cutting glass fibers into short pieces and arranging them randomly. The manufacturing process steps generally include element preparation, classification and drying, adhesive application, mat formation,. The fibers are then held together with. Understanding the manufacturing process and how shock absorption is improved provides a clearer picture of the product’s. A machete is used to. Mat Manufacturing Process.

From www.chinabarmat.com

Natural rubber bar mat making process Ever Star Mat Manufacturing Process The fiber stock gets introduced at the pulping step and enters the formation section where the fibers get distributed uniformly across the width of the machine. Chopped strand mats are created by cutting glass fibers into short pieces and arranging them randomly. Here’s how the inedible husk of the coconut can be turned into a product that can sit proudly. Mat Manufacturing Process.

From www.researchgate.net

3 Schematic diagram of needle punched flax fiber mat manufacturing Mat Manufacturing Process The manufacturing process steps generally include element preparation, classification and drying, adhesive application, mat formation,. Fiberglass mats are primarily produced on machines, which are typically 1.5 to 6.0 meters wide, with a closed loop process water system. Here’s how the inedible husk of the coconut can be turned into a product that can sit proudly on the floor your doorway. Mat Manufacturing Process.

From www.youtube.com

Coir mat manufacturing process Mat making machine door mat making Mat Manufacturing Process Chopped strand mats are created by cutting glass fibers into short pieces and arranging them randomly. The fibers are then held together with. Here’s how the inedible husk of the coconut can be turned into a product that can sit proudly on the floor your doorway in just six easy steps. Understanding the manufacturing process and how shock absorption is. Mat Manufacturing Process.

From www.slideteam.net

8 Methods To Boost Smart Manufacturing Process Mat Manufacturing Process Fiberglass mats are primarily produced on machines, which are typically 1.5 to 6.0 meters wide, with a closed loop process water system. Understanding the manufacturing process and how shock absorption is improved provides a clearer picture of the product’s. Rubber mats are integral to various settings, offering durability, safety, and ergonomic benefits. Chopped strand mats are created by cutting glass. Mat Manufacturing Process.

From www.youtube.com

Texturing Process Yoga Mat Manufacturing Process YouTube Mat Manufacturing Process Fiberglass mats are primarily produced on machines, which are typically 1.5 to 6.0 meters wide, with a closed loop process water system. The manufacturing process steps generally include element preparation, classification and drying, adhesive application, mat formation,. This guide delves into the detailed. A machete is used to cut. Rubber mats are integral to various settings, offering durability, safety, and. Mat Manufacturing Process.

From www.rockwellautomation.com

Smart Manufacturing Starts Here Rockwell Automation Australia Mat Manufacturing Process Here’s how the inedible husk of the coconut can be turned into a product that can sit proudly on the floor your doorway in just six easy steps. Fiberglass mats are primarily produced on machines, which are typically 1.5 to 6.0 meters wide, with a closed loop process water system. The manufacturing process steps generally include element preparation, classification and. Mat Manufacturing Process.

From www.semiconductor-digest.com

Be Smart About Smart Manufacturing Semiconductor Digest Mat Manufacturing Process The fibers are then held together with. Chopped strand mats are created by cutting glass fibers into short pieces and arranging them randomly. Fiberglass mats are primarily produced on machines, which are typically 1.5 to 6.0 meters wide, with a closed loop process water system. Understanding the manufacturing process and how shock absorption is improved provides a clearer picture of. Mat Manufacturing Process.

From www.youtube.com

korai mat making process korai pai manufacturing, sleeping mat making Mat Manufacturing Process Chopped strand mats are created by cutting glass fibers into short pieces and arranging them randomly. This guide delves into the detailed. A machete is used to cut. The fiber stock gets introduced at the pulping step and enters the formation section where the fibers get distributed uniformly across the width of the machine. Fiberglass mats are primarily produced on. Mat Manufacturing Process.

From www.youtube.com

Coir mat manufacturing process in Kerala/ full process video YouTube Mat Manufacturing Process This guide delves into the detailed. Fiberglass mats are primarily produced on machines, which are typically 1.5 to 6.0 meters wide, with a closed loop process water system. The manufacturing process steps generally include element preparation, classification and drying, adhesive application, mat formation,. Understanding the manufacturing process and how shock absorption is improved provides a clearer picture of the product’s.. Mat Manufacturing Process.

From www.renishaw.se

Demonstrating the latest smart manufacturing and process control Mat Manufacturing Process Rubber mats are integral to various settings, offering durability, safety, and ergonomic benefits. Here’s how the inedible husk of the coconut can be turned into a product that can sit proudly on the floor your doorway in just six easy steps. A machete is used to cut. Chopped strand mats are created by cutting glass fibers into short pieces and. Mat Manufacturing Process.

From www.prnewswire.com

Sanofi opens its first digitallyenabled, continuous manufacturing Mat Manufacturing Process Chopped strand mats are created by cutting glass fibers into short pieces and arranging them randomly. Fiberglass mats are primarily produced on machines, which are typically 1.5 to 6.0 meters wide, with a closed loop process water system. Rubber mats are integral to various settings, offering durability, safety, and ergonomic benefits. The manufacturing process steps generally include element preparation, classification. Mat Manufacturing Process.

From www.l2l.com

Smart Manufacturing Concept, Technologies, and Examples Mat Manufacturing Process Understanding the manufacturing process and how shock absorption is improved provides a clearer picture of the product’s. A machete is used to cut. The fibers are then held together with. This guide delves into the detailed. Here’s how the inedible husk of the coconut can be turned into a product that can sit proudly on the floor your doorway in. Mat Manufacturing Process.

From smartamerica.org

Smart Manufacturing » Smart America Mat Manufacturing Process This guide delves into the detailed. Here’s how the inedible husk of the coconut can be turned into a product that can sit proudly on the floor your doorway in just six easy steps. The fiber stock gets introduced at the pulping step and enters the formation section where the fibers get distributed uniformly across the width of the machine.. Mat Manufacturing Process.

From blog.mesa.org

'Where Manufacturing Meets IT' Blog How to Achieve Smart Manufacturing Mat Manufacturing Process This guide delves into the detailed. The manufacturing process steps generally include element preparation, classification and drying, adhesive application, mat formation,. Rubber mats are integral to various settings, offering durability, safety, and ergonomic benefits. The fibers are then held together with. Fiberglass mats are primarily produced on machines, which are typically 1.5 to 6.0 meters wide, with a closed loop. Mat Manufacturing Process.

From www.dreamstime.com

Smart Manufacturing Process at Production Industry. Engineer Works with Mat Manufacturing Process The manufacturing process steps generally include element preparation, classification and drying, adhesive application, mat formation,. Rubber mats are integral to various settings, offering durability, safety, and ergonomic benefits. A machete is used to cut. This guide delves into the detailed. Understanding the manufacturing process and how shock absorption is improved provides a clearer picture of the product’s. Here’s how the. Mat Manufacturing Process.

From slcontrols.com

Smart Factory Solutions Mat Manufacturing Process The fiber stock gets introduced at the pulping step and enters the formation section where the fibers get distributed uniformly across the width of the machine. Understanding the manufacturing process and how shock absorption is improved provides a clearer picture of the product’s. A machete is used to cut. This guide delves into the detailed. Rubber mats are integral to. Mat Manufacturing Process.

From www.youtube.com

Allumium Entrance Mat Manufacturing Process YouTube Mat Manufacturing Process A machete is used to cut. Chopped strand mats are created by cutting glass fibers into short pieces and arranging them randomly. The fibers are then held together with. Fiberglass mats are primarily produced on machines, which are typically 1.5 to 6.0 meters wide, with a closed loop process water system. Rubber mats are integral to various settings, offering durability,. Mat Manufacturing Process.

From blog.stratus.com

Smart Manufacturing is Picking Up Steam Stratus Blog Mat Manufacturing Process Rubber mats are integral to various settings, offering durability, safety, and ergonomic benefits. A machete is used to cut. Fiberglass mats are primarily produced on machines, which are typically 1.5 to 6.0 meters wide, with a closed loop process water system. Here’s how the inedible husk of the coconut can be turned into a product that can sit proudly on. Mat Manufacturing Process.

From www.datenwissen.com

Smart Manufacturing in Chemical Industry How to Integrate? [2022 Mat Manufacturing Process A machete is used to cut. The fiber stock gets introduced at the pulping step and enters the formation section where the fibers get distributed uniformly across the width of the machine. Rubber mats are integral to various settings, offering durability, safety, and ergonomic benefits. Fiberglass mats are primarily produced on machines, which are typically 1.5 to 6.0 meters wide,. Mat Manufacturing Process.

From www.youtube.com

NAMRATA GLOBAL MANUFACTURING PROCESS OF POLYPROPYLENE MATS TEASER Mat Manufacturing Process Here’s how the inedible husk of the coconut can be turned into a product that can sit proudly on the floor your doorway in just six easy steps. The fiber stock gets introduced at the pulping step and enters the formation section where the fibers get distributed uniformly across the width of the machine. Understanding the manufacturing process and how. Mat Manufacturing Process.

From iotconsultants.com.au

Smart Manufacturing IoT Consultants Mat Manufacturing Process Chopped strand mats are created by cutting glass fibers into short pieces and arranging them randomly. The manufacturing process steps generally include element preparation, classification and drying, adhesive application, mat formation,. The fibers are then held together with. A machete is used to cut. Here’s how the inedible husk of the coconut can be turned into a product that can. Mat Manufacturing Process.

From www.tuvsud.cn

Smart Manufacturing Unlocking the potential of Industrie 4.0 TÜV南德 Mat Manufacturing Process The fiber stock gets introduced at the pulping step and enters the formation section where the fibers get distributed uniformly across the width of the machine. The fibers are then held together with. The manufacturing process steps generally include element preparation, classification and drying, adhesive application, mat formation,. Understanding the manufacturing process and how shock absorption is improved provides a. Mat Manufacturing Process.

From stratmg.com

Benefits of Smart Manufacturing for Customers StratMg Mat Manufacturing Process Chopped strand mats are created by cutting glass fibers into short pieces and arranging them randomly. The fiber stock gets introduced at the pulping step and enters the formation section where the fibers get distributed uniformly across the width of the machine. Here’s how the inedible husk of the coconut can be turned into a product that can sit proudly. Mat Manufacturing Process.

From www.3ds.com

Smart Manufacturing Mat Manufacturing Process This guide delves into the detailed. The manufacturing process steps generally include element preparation, classification and drying, adhesive application, mat formation,. The fibers are then held together with. A machete is used to cut. Rubber mats are integral to various settings, offering durability, safety, and ergonomic benefits. Understanding the manufacturing process and how shock absorption is improved provides a clearer. Mat Manufacturing Process.

From www.youtube.com

Automatic production of mats from recycled rubber YouTube Mat Manufacturing Process Here’s how the inedible husk of the coconut can be turned into a product that can sit proudly on the floor your doorway in just six easy steps. The manufacturing process steps generally include element preparation, classification and drying, adhesive application, mat formation,. Understanding the manufacturing process and how shock absorption is improved provides a clearer picture of the product’s.. Mat Manufacturing Process.

From ppmatlooms.com

Samrat Industries Manufacturer of premium quality mat weaving machines Mat Manufacturing Process Understanding the manufacturing process and how shock absorption is improved provides a clearer picture of the product’s. A machete is used to cut. Here’s how the inedible husk of the coconut can be turned into a product that can sit proudly on the floor your doorway in just six easy steps. Fiberglass mats are primarily produced on machines, which are. Mat Manufacturing Process.

From iiot-world.com

Four critical steps for a successful digital transformation in Mat Manufacturing Process Understanding the manufacturing process and how shock absorption is improved provides a clearer picture of the product’s. The fibers are then held together with. Rubber mats are integral to various settings, offering durability, safety, and ergonomic benefits. A machete is used to cut. This guide delves into the detailed. Here’s how the inedible husk of the coconut can be turned. Mat Manufacturing Process.