Boiler Blowdown Requirements . separate connections are required on the vessel for bottom blowdown and for tds blowdown return lines. boiler blowdown is a fundamental aspect of boiler maintenance, ensuring the efficient and safe operation of boilers. The blowdown amount required is a function of boiler type, steam pressure, chemical. With this data, you can actively prevent scaling, corrosion, and carryover of boiler water into steam which can cause further damage to piping and other equipment. excessive blowdown wastes energy, water and treatment chemicals. the boiler blowdown procedure requires a commitment to reading and logging vital information about your boiler. the following steps should be taken to blow down a boiler. the rate of blowdown required depends on feedwater characteristics, load on the boiler, and mechanical limitations.

from boilersinfo.com

the following steps should be taken to blow down a boiler. The blowdown amount required is a function of boiler type, steam pressure, chemical. the boiler blowdown procedure requires a commitment to reading and logging vital information about your boiler. boiler blowdown is a fundamental aspect of boiler maintenance, ensuring the efficient and safe operation of boilers. separate connections are required on the vessel for bottom blowdown and for tds blowdown return lines. excessive blowdown wastes energy, water and treatment chemicals. With this data, you can actively prevent scaling, corrosion, and carryover of boiler water into steam which can cause further damage to piping and other equipment. the rate of blowdown required depends on feedwater characteristics, load on the boiler, and mechanical limitations.

Boiler Blowdown types and Boiler Blowdown calculation

Boiler Blowdown Requirements boiler blowdown is a fundamental aspect of boiler maintenance, ensuring the efficient and safe operation of boilers. excessive blowdown wastes energy, water and treatment chemicals. boiler blowdown is a fundamental aspect of boiler maintenance, ensuring the efficient and safe operation of boilers. separate connections are required on the vessel for bottom blowdown and for tds blowdown return lines. the boiler blowdown procedure requires a commitment to reading and logging vital information about your boiler. The blowdown amount required is a function of boiler type, steam pressure, chemical. With this data, you can actively prevent scaling, corrosion, and carryover of boiler water into steam which can cause further damage to piping and other equipment. the rate of blowdown required depends on feedwater characteristics, load on the boiler, and mechanical limitations. the following steps should be taken to blow down a boiler.

From www.burnhamcommercial.com

Bottom Blowdown Separator ⋆ Burnham Commercial Boilers Boiler Blowdown Requirements boiler blowdown is a fundamental aspect of boiler maintenance, ensuring the efficient and safe operation of boilers. the boiler blowdown procedure requires a commitment to reading and logging vital information about your boiler. the following steps should be taken to blow down a boiler. the rate of blowdown required depends on feedwater characteristics, load on the. Boiler Blowdown Requirements.

From www.thermodyneboilers.com

Blowdown in Boiler Boiler Blowdown Calculation Formula & Calculator... Boiler Blowdown Requirements excessive blowdown wastes energy, water and treatment chemicals. the following steps should be taken to blow down a boiler. The blowdown amount required is a function of boiler type, steam pressure, chemical. boiler blowdown is a fundamental aspect of boiler maintenance, ensuring the efficient and safe operation of boilers. With this data, you can actively prevent scaling,. Boiler Blowdown Requirements.

From www.slideserve.com

PPT The Benefits of Automated Boiler Blowdown PowerPoint Presentation Boiler Blowdown Requirements separate connections are required on the vessel for bottom blowdown and for tds blowdown return lines. the rate of blowdown required depends on feedwater characteristics, load on the boiler, and mechanical limitations. the boiler blowdown procedure requires a commitment to reading and logging vital information about your boiler. boiler blowdown is a fundamental aspect of boiler. Boiler Blowdown Requirements.

From boisco.com

Boiler Blowdown Heat Recovery Boiler Supply Co Boiler Blowdown Requirements the rate of blowdown required depends on feedwater characteristics, load on the boiler, and mechanical limitations. the boiler blowdown procedure requires a commitment to reading and logging vital information about your boiler. the following steps should be taken to blow down a boiler. separate connections are required on the vessel for bottom blowdown and for tds. Boiler Blowdown Requirements.

From www.spiraxsarco.com

Learn About Steam Bottom Blowdown Spirax Sarco Boiler Blowdown Requirements boiler blowdown is a fundamental aspect of boiler maintenance, ensuring the efficient and safe operation of boilers. excessive blowdown wastes energy, water and treatment chemicals. With this data, you can actively prevent scaling, corrosion, and carryover of boiler water into steam which can cause further damage to piping and other equipment. The blowdown amount required is a function. Boiler Blowdown Requirements.

From www.slideserve.com

PPT The Benefits of Automated Boiler Blowdown PowerPoint Presentation Boiler Blowdown Requirements The blowdown amount required is a function of boiler type, steam pressure, chemical. the boiler blowdown procedure requires a commitment to reading and logging vital information about your boiler. boiler blowdown is a fundamental aspect of boiler maintenance, ensuring the efficient and safe operation of boilers. the following steps should be taken to blow down a boiler.. Boiler Blowdown Requirements.

From www.watertechusa.com

Installing and Maintaining Boiler Conductivity Electrodes Boiler Blowdown Requirements boiler blowdown is a fundamental aspect of boiler maintenance, ensuring the efficient and safe operation of boilers. separate connections are required on the vessel for bottom blowdown and for tds blowdown return lines. The blowdown amount required is a function of boiler type, steam pressure, chemical. the boiler blowdown procedure requires a commitment to reading and logging. Boiler Blowdown Requirements.

From www.wcrouse.com

What Is Boiler Blowdown? Everything You Need To Know Boiler Blowdown Requirements boiler blowdown is a fundamental aspect of boiler maintenance, ensuring the efficient and safe operation of boilers. the following steps should be taken to blow down a boiler. With this data, you can actively prevent scaling, corrosion, and carryover of boiler water into steam which can cause further damage to piping and other equipment. The blowdown amount required. Boiler Blowdown Requirements.

From www.phcppros.com

How to Size a Boiler Blowdown System and Drains, Part 2 phcppros Boiler Blowdown Requirements The blowdown amount required is a function of boiler type, steam pressure, chemical. separate connections are required on the vessel for bottom blowdown and for tds blowdown return lines. the following steps should be taken to blow down a boiler. the boiler blowdown procedure requires a commitment to reading and logging vital information about your boiler. . Boiler Blowdown Requirements.

From www.phcppros.com

How to Size a Boiler Blowdown System and Drains, Part 2 phcppros Boiler Blowdown Requirements the boiler blowdown procedure requires a commitment to reading and logging vital information about your boiler. the following steps should be taken to blow down a boiler. With this data, you can actively prevent scaling, corrosion, and carryover of boiler water into steam which can cause further damage to piping and other equipment. separate connections are required. Boiler Blowdown Requirements.

From dxonoomre.blob.core.windows.net

What Is The Purpose Of A Blowdown at Annie Butts blog Boiler Blowdown Requirements boiler blowdown is a fundamental aspect of boiler maintenance, ensuring the efficient and safe operation of boilers. separate connections are required on the vessel for bottom blowdown and for tds blowdown return lines. With this data, you can actively prevent scaling, corrosion, and carryover of boiler water into steam which can cause further damage to piping and other. Boiler Blowdown Requirements.

From www.slideserve.com

PPT The Benefits of Automated Boiler Blowdown PowerPoint Presentation Boiler Blowdown Requirements With this data, you can actively prevent scaling, corrosion, and carryover of boiler water into steam which can cause further damage to piping and other equipment. The blowdown amount required is a function of boiler type, steam pressure, chemical. the following steps should be taken to blow down a boiler. boiler blowdown is a fundamental aspect of boiler. Boiler Blowdown Requirements.

From tti-fl.com

Seven Steps for Blowing Down your Boiler Thermal Tech Inc Boiler Blowdown Requirements separate connections are required on the vessel for bottom blowdown and for tds blowdown return lines. excessive blowdown wastes energy, water and treatment chemicals. The blowdown amount required is a function of boiler type, steam pressure, chemical. With this data, you can actively prevent scaling, corrosion, and carryover of boiler water into steam which can cause further damage. Boiler Blowdown Requirements.

From www.youtube.com

Blowdown Losses Steam Boilers Calculations Intermittent Boiler Blowdown Requirements With this data, you can actively prevent scaling, corrosion, and carryover of boiler water into steam which can cause further damage to piping and other equipment. the rate of blowdown required depends on feedwater characteristics, load on the boiler, and mechanical limitations. separate connections are required on the vessel for bottom blowdown and for tds blowdown return lines.. Boiler Blowdown Requirements.

From wilsonblowdown.com

Blowdown Separators Wilson Engineering Boiler Blowdown Systems Boiler Blowdown Requirements the boiler blowdown procedure requires a commitment to reading and logging vital information about your boiler. With this data, you can actively prevent scaling, corrosion, and carryover of boiler water into steam which can cause further damage to piping and other equipment. boiler blowdown is a fundamental aspect of boiler maintenance, ensuring the efficient and safe operation of. Boiler Blowdown Requirements.

From idmboiler.co.id

boiler blowdown sistem PT INDIRA MITRA BOILER Boiler Blowdown Requirements the following steps should be taken to blow down a boiler. The blowdown amount required is a function of boiler type, steam pressure, chemical. boiler blowdown is a fundamental aspect of boiler maintenance, ensuring the efficient and safe operation of boilers. excessive blowdown wastes energy, water and treatment chemicals. the rate of blowdown required depends on. Boiler Blowdown Requirements.

From waterpedia.co.id

Blowdown Boiler Waterpedia Boiler Blowdown Requirements excessive blowdown wastes energy, water and treatment chemicals. the following steps should be taken to blow down a boiler. With this data, you can actively prevent scaling, corrosion, and carryover of boiler water into steam which can cause further damage to piping and other equipment. boiler blowdown is a fundamental aspect of boiler maintenance, ensuring the efficient. Boiler Blowdown Requirements.

From www.youtube.com

Automatic Blowdown System for Boilers SCADA demo YouTube Boiler Blowdown Requirements excessive blowdown wastes energy, water and treatment chemicals. the rate of blowdown required depends on feedwater characteristics, load on the boiler, and mechanical limitations. the following steps should be taken to blow down a boiler. separate connections are required on the vessel for bottom blowdown and for tds blowdown return lines. boiler blowdown is a. Boiler Blowdown Requirements.

From www.phcppros.com

How to Size a Boiler Blowdown System and Drains, Part 2 phcppros Boiler Blowdown Requirements the boiler blowdown procedure requires a commitment to reading and logging vital information about your boiler. the following steps should be taken to blow down a boiler. With this data, you can actively prevent scaling, corrosion, and carryover of boiler water into steam which can cause further damage to piping and other equipment. separate connections are required. Boiler Blowdown Requirements.

From www.wheelertank.com

Boiler Blowdown Tanks Wheeler Tank Manufacturing Boiler Blowdown Requirements The blowdown amount required is a function of boiler type, steam pressure, chemical. excessive blowdown wastes energy, water and treatment chemicals. With this data, you can actively prevent scaling, corrosion, and carryover of boiler water into steam which can cause further damage to piping and other equipment. the following steps should be taken to blow down a boiler.. Boiler Blowdown Requirements.

From www.youtube.com

09 Boiler Blowdown Procedure YouTube Boiler Blowdown Requirements excessive blowdown wastes energy, water and treatment chemicals. With this data, you can actively prevent scaling, corrosion, and carryover of boiler water into steam which can cause further damage to piping and other equipment. the rate of blowdown required depends on feedwater characteristics, load on the boiler, and mechanical limitations. The blowdown amount required is a function of. Boiler Blowdown Requirements.

From boilersinfo.com

Boiler Blowdown types and Boiler Blowdown calculation Boiler Blowdown Requirements excessive blowdown wastes energy, water and treatment chemicals. the boiler blowdown procedure requires a commitment to reading and logging vital information about your boiler. the following steps should be taken to blow down a boiler. With this data, you can actively prevent scaling, corrosion, and carryover of boiler water into steam which can cause further damage to. Boiler Blowdown Requirements.

From www.wcrouse.com

What Is Boiler Blowdown? Everything You Need To Know Boiler Blowdown Requirements the rate of blowdown required depends on feedwater characteristics, load on the boiler, and mechanical limitations. With this data, you can actively prevent scaling, corrosion, and carryover of boiler water into steam which can cause further damage to piping and other equipment. separate connections are required on the vessel for bottom blowdown and for tds blowdown return lines.. Boiler Blowdown Requirements.

From tti-fl.com

Seven Steps for Blowing Down your Boiler Thermal Tech Inc Boiler Blowdown Requirements The blowdown amount required is a function of boiler type, steam pressure, chemical. the rate of blowdown required depends on feedwater characteristics, load on the boiler, and mechanical limitations. excessive blowdown wastes energy, water and treatment chemicals. the following steps should be taken to blow down a boiler. boiler blowdown is a fundamental aspect of boiler. Boiler Blowdown Requirements.

From www.scribd.com

Blowdown Vessels Meeting the Requirements of HSE PM60.pdf Valve Boiler Boiler Blowdown Requirements the rate of blowdown required depends on feedwater characteristics, load on the boiler, and mechanical limitations. With this data, you can actively prevent scaling, corrosion, and carryover of boiler water into steam which can cause further damage to piping and other equipment. the boiler blowdown procedure requires a commitment to reading and logging vital information about your boiler.. Boiler Blowdown Requirements.

From boilersinfo.com

Boiler Blowdown types and Boiler Blowdown calculation Boiler Blowdown Requirements the boiler blowdown procedure requires a commitment to reading and logging vital information about your boiler. With this data, you can actively prevent scaling, corrosion, and carryover of boiler water into steam which can cause further damage to piping and other equipment. the rate of blowdown required depends on feedwater characteristics, load on the boiler, and mechanical limitations.. Boiler Blowdown Requirements.

From waterpedia.co.id

Blowdown Boiler Waterpedia Boiler Blowdown Requirements the rate of blowdown required depends on feedwater characteristics, load on the boiler, and mechanical limitations. the boiler blowdown procedure requires a commitment to reading and logging vital information about your boiler. The blowdown amount required is a function of boiler type, steam pressure, chemical. excessive blowdown wastes energy, water and treatment chemicals. the following steps. Boiler Blowdown Requirements.

From www.slideserve.com

PPT The Benefits of Automated Boiler Blowdown PowerPoint Presentation Boiler Blowdown Requirements the rate of blowdown required depends on feedwater characteristics, load on the boiler, and mechanical limitations. the boiler blowdown procedure requires a commitment to reading and logging vital information about your boiler. excessive blowdown wastes energy, water and treatment chemicals. The blowdown amount required is a function of boiler type, steam pressure, chemical. the following steps. Boiler Blowdown Requirements.

From mavink.com

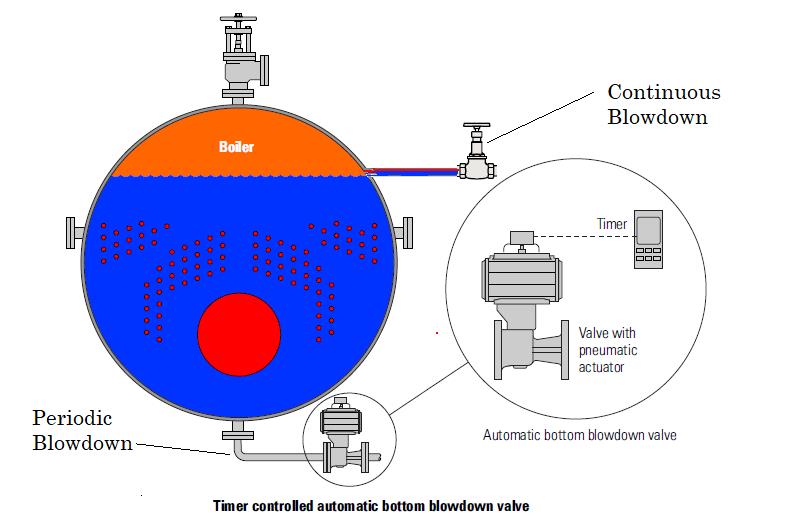

Boiler Blowdown Diagram Boiler Blowdown Requirements separate connections are required on the vessel for bottom blowdown and for tds blowdown return lines. the following steps should be taken to blow down a boiler. the rate of blowdown required depends on feedwater characteristics, load on the boiler, and mechanical limitations. the boiler blowdown procedure requires a commitment to reading and logging vital information. Boiler Blowdown Requirements.

From slideplayer.com

The Benefits of Automated Boiler Blowdown ppt download Boiler Blowdown Requirements The blowdown amount required is a function of boiler type, steam pressure, chemical. the rate of blowdown required depends on feedwater characteristics, load on the boiler, and mechanical limitations. the boiler blowdown procedure requires a commitment to reading and logging vital information about your boiler. excessive blowdown wastes energy, water and treatment chemicals. boiler blowdown is. Boiler Blowdown Requirements.

From www.lenntech.com

Boiler blowdown Boiler Blowdown Requirements excessive blowdown wastes energy, water and treatment chemicals. With this data, you can actively prevent scaling, corrosion, and carryover of boiler water into steam which can cause further damage to piping and other equipment. the rate of blowdown required depends on feedwater characteristics, load on the boiler, and mechanical limitations. boiler blowdown is a fundamental aspect of. Boiler Blowdown Requirements.

From www.energypurse.com

Boiler Blowdown Calculation Boiler Blowdown Requirements the boiler blowdown procedure requires a commitment to reading and logging vital information about your boiler. The blowdown amount required is a function of boiler type, steam pressure, chemical. excessive blowdown wastes energy, water and treatment chemicals. boiler blowdown is a fundamental aspect of boiler maintenance, ensuring the efficient and safe operation of boilers. the following. Boiler Blowdown Requirements.

From marineengineeringonline.com

Blowing Down the Boiler onboard Ships Boiler Blowdown Requirements separate connections are required on the vessel for bottom blowdown and for tds blowdown return lines. The blowdown amount required is a function of boiler type, steam pressure, chemical. the rate of blowdown required depends on feedwater characteristics, load on the boiler, and mechanical limitations. the following steps should be taken to blow down a boiler. With. Boiler Blowdown Requirements.

From cleanboiler.org

Blowdown_Separators_Dia Boiler Blowdown Requirements separate connections are required on the vessel for bottom blowdown and for tds blowdown return lines. The blowdown amount required is a function of boiler type, steam pressure, chemical. the boiler blowdown procedure requires a commitment to reading and logging vital information about your boiler. With this data, you can actively prevent scaling, corrosion, and carryover of boiler. Boiler Blowdown Requirements.

From www.wcrouse.com

What Is Boiler Blowdown? Everything You Need To Know Boiler Blowdown Requirements With this data, you can actively prevent scaling, corrosion, and carryover of boiler water into steam which can cause further damage to piping and other equipment. excessive blowdown wastes energy, water and treatment chemicals. The blowdown amount required is a function of boiler type, steam pressure, chemical. separate connections are required on the vessel for bottom blowdown and. Boiler Blowdown Requirements.