Stainless Steel Welding Settings . when it comes to setting your welder’s amps for welding stainless steel, consider using lower amp settings to reduce heat input. Preparation, choosing the correct welding method, setting up your equipment, and performing the welding. Stainless steel mig welding settings chart. If you have a project that involves metals you might have to use mig welding. this process can be divided into four main stages: You can produce a product that will meet even the most demanding standards if you master these steps. We will go into great detail on this subject. navigating the nuances of tig welding stainless steel involves managing unique challenges, such as heat distortion, while also focusing on precision and proper preparation. common welding methods for stainless steel include tig, mig, smaw, fcaw, resistance, and friction welding, each with specific advantages and applications.

from aviationandaccessories.tpub.com

Preparation, choosing the correct welding method, setting up your equipment, and performing the welding. If you have a project that involves metals you might have to use mig welding. Stainless steel mig welding settings chart. We will go into great detail on this subject. navigating the nuances of tig welding stainless steel involves managing unique challenges, such as heat distortion, while also focusing on precision and proper preparation. You can produce a product that will meet even the most demanding standards if you master these steps. when it comes to setting your welder’s amps for welding stainless steel, consider using lower amp settings to reduce heat input. common welding methods for stainless steel include tig, mig, smaw, fcaw, resistance, and friction welding, each with specific advantages and applications. this process can be divided into four main stages:

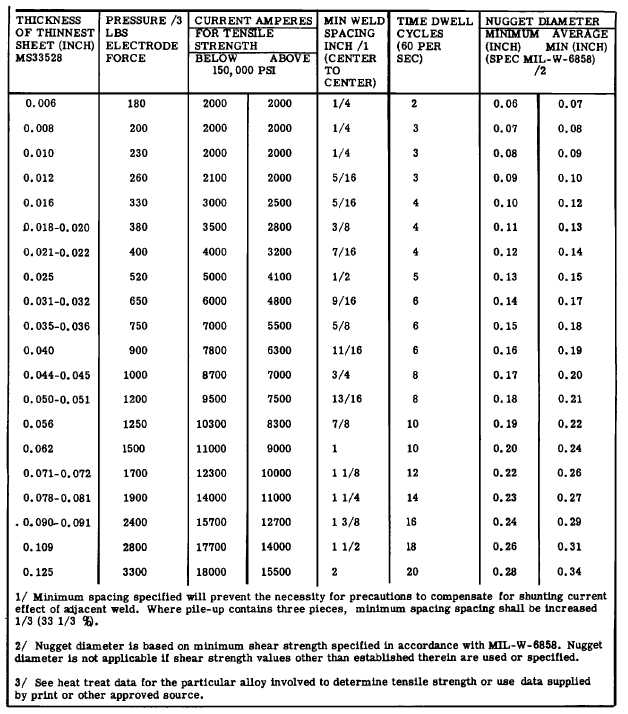

TABLE 221. TYPICAL MACHINE SETTINGS, MINIMUM SPACING AND NUGGET DIAMETER FOR SPOT WELDING

Stainless Steel Welding Settings this process can be divided into four main stages: common welding methods for stainless steel include tig, mig, smaw, fcaw, resistance, and friction welding, each with specific advantages and applications. If you have a project that involves metals you might have to use mig welding. You can produce a product that will meet even the most demanding standards if you master these steps. Preparation, choosing the correct welding method, setting up your equipment, and performing the welding. this process can be divided into four main stages: when it comes to setting your welder’s amps for welding stainless steel, consider using lower amp settings to reduce heat input. navigating the nuances of tig welding stainless steel involves managing unique challenges, such as heat distortion, while also focusing on precision and proper preparation. We will go into great detail on this subject. Stainless steel mig welding settings chart.

From spotweldinc.com

SetUp Guides Spot Weld, Inc. Stainless Steel Welding Settings If you have a project that involves metals you might have to use mig welding. We will go into great detail on this subject. Stainless steel mig welding settings chart. You can produce a product that will meet even the most demanding standards if you master these steps. navigating the nuances of tig welding stainless steel involves managing unique. Stainless Steel Welding Settings.

From blog.thepipingmart.com

How to Spot Weld Stainless Steel A Complete Guide Stainless Steel Welding Settings You can produce a product that will meet even the most demanding standards if you master these steps. navigating the nuances of tig welding stainless steel involves managing unique challenges, such as heat distortion, while also focusing on precision and proper preparation. If you have a project that involves metals you might have to use mig welding. common. Stainless Steel Welding Settings.

From www.weldingtipsandtricks.com

Stainless Steel TIG Welding Videos and Tips Stainless Steel Welding Settings We will go into great detail on this subject. Preparation, choosing the correct welding method, setting up your equipment, and performing the welding. navigating the nuances of tig welding stainless steel involves managing unique challenges, such as heat distortion, while also focusing on precision and proper preparation. when it comes to setting your welder’s amps for welding stainless. Stainless Steel Welding Settings.

From weldingpros.net

Welding Stainless Steel How To Weld Different Alloys Of Stainless Stainless Steel Welding Settings Stainless steel mig welding settings chart. common welding methods for stainless steel include tig, mig, smaw, fcaw, resistance, and friction welding, each with specific advantages and applications. navigating the nuances of tig welding stainless steel involves managing unique challenges, such as heat distortion, while also focusing on precision and proper preparation. Preparation, choosing the correct welding method, setting. Stainless Steel Welding Settings.

From exoklzlsc.blob.core.windows.net

How To Weld Stainless With A Mig Welder at Lois Ray blog Stainless Steel Welding Settings If you have a project that involves metals you might have to use mig welding. when it comes to setting your welder’s amps for welding stainless steel, consider using lower amp settings to reduce heat input. common welding methods for stainless steel include tig, mig, smaw, fcaw, resistance, and friction welding, each with specific advantages and applications. We. Stainless Steel Welding Settings.

From mesinpotongkertass.blogspot.com

Inspirasi 36+ Stainless Steel TIG Welding Settings Stainless Steel Welding Settings navigating the nuances of tig welding stainless steel involves managing unique challenges, such as heat distortion, while also focusing on precision and proper preparation. Preparation, choosing the correct welding method, setting up your equipment, and performing the welding. If you have a project that involves metals you might have to use mig welding. You can produce a product that. Stainless Steel Welding Settings.

From joshuawest.z13.web.core.windows.net

Mig Welder Chart Settings Stainless Steel Welding Settings common welding methods for stainless steel include tig, mig, smaw, fcaw, resistance, and friction welding, each with specific advantages and applications. If you have a project that involves metals you might have to use mig welding. this process can be divided into four main stages: Stainless steel mig welding settings chart. when it comes to setting your. Stainless Steel Welding Settings.

From weldguru.com

How To MIG Weld Aluminum Beginners Guide (with Chart) Stainless Steel Welding Settings If you have a project that involves metals you might have to use mig welding. this process can be divided into four main stages: You can produce a product that will meet even the most demanding standards if you master these steps. Preparation, choosing the correct welding method, setting up your equipment, and performing the welding. We will go. Stainless Steel Welding Settings.

From www.hobartbrothers.com

TIG Welding Parameters Hobart Brothers Stainless Steel Welding Settings common welding methods for stainless steel include tig, mig, smaw, fcaw, resistance, and friction welding, each with specific advantages and applications. We will go into great detail on this subject. when it comes to setting your welder’s amps for welding stainless steel, consider using lower amp settings to reduce heat input. Stainless steel mig welding settings chart. If. Stainless Steel Welding Settings.

From dxojffzqw.blob.core.windows.net

Welder Settings Guide at Stephen Soltis blog Stainless Steel Welding Settings We will go into great detail on this subject. If you have a project that involves metals you might have to use mig welding. navigating the nuances of tig welding stainless steel involves managing unique challenges, such as heat distortion, while also focusing on precision and proper preparation. You can produce a product that will meet even the most. Stainless Steel Welding Settings.

From weldguru.com

TIG Welding Stainless Steel A Beginners Guide Weld Guru Stainless Steel Welding Settings Preparation, choosing the correct welding method, setting up your equipment, and performing the welding. You can produce a product that will meet even the most demanding standards if you master these steps. We will go into great detail on this subject. this process can be divided into four main stages: navigating the nuances of tig welding stainless steel. Stainless Steel Welding Settings.

From rickyswelding.com

How to weld stainless steel Complete step by step guide Stainless Steel Welding Settings common welding methods for stainless steel include tig, mig, smaw, fcaw, resistance, and friction welding, each with specific advantages and applications. Stainless steel mig welding settings chart. Preparation, choosing the correct welding method, setting up your equipment, and performing the welding. We will go into great detail on this subject. this process can be divided into four main. Stainless Steel Welding Settings.

From millenniumalloys.ca

Common Methods Of Welding Stainless Steel Millennium Alloys Stainless Steel Welding Settings You can produce a product that will meet even the most demanding standards if you master these steps. We will go into great detail on this subject. when it comes to setting your welder’s amps for welding stainless steel, consider using lower amp settings to reduce heat input. Stainless steel mig welding settings chart. navigating the nuances of. Stainless Steel Welding Settings.

From www.fordmuscle.com

MIGWelding Basics To Help You Correctly Melt Metal Stainless Steel Welding Settings You can produce a product that will meet even the most demanding standards if you master these steps. common welding methods for stainless steel include tig, mig, smaw, fcaw, resistance, and friction welding, each with specific advantages and applications. Preparation, choosing the correct welding method, setting up your equipment, and performing the welding. navigating the nuances of tig. Stainless Steel Welding Settings.

From aviationandaccessories.tpub.com

TABLE 221. TYPICAL MACHINE SETTINGS, MINIMUM SPACING AND NUGGET DIAMETER FOR SPOT WELDING Stainless Steel Welding Settings when it comes to setting your welder’s amps for welding stainless steel, consider using lower amp settings to reduce heat input. navigating the nuances of tig welding stainless steel involves managing unique challenges, such as heat distortion, while also focusing on precision and proper preparation. We will go into great detail on this subject. this process can. Stainless Steel Welding Settings.

From exobtflbe.blob.core.windows.net

How To Set Up A Miller Tig Welder For Stainless Steel at Ned Marcello blog Stainless Steel Welding Settings common welding methods for stainless steel include tig, mig, smaw, fcaw, resistance, and friction welding, each with specific advantages and applications. navigating the nuances of tig welding stainless steel involves managing unique challenges, such as heat distortion, while also focusing on precision and proper preparation. this process can be divided into four main stages: Preparation, choosing the. Stainless Steel Welding Settings.

From www.weldingtipsandtricks.com

Tig Welding Stainless Steel Corner in 16 ga Stainless Steel Welding Settings You can produce a product that will meet even the most demanding standards if you master these steps. If you have a project that involves metals you might have to use mig welding. navigating the nuances of tig welding stainless steel involves managing unique challenges, such as heat distortion, while also focusing on precision and proper preparation. Stainless steel. Stainless Steel Welding Settings.

From demiwalton.z13.web.core.windows.net

Mig Welder Settings Chart Stainless Steel Welding Settings If you have a project that involves metals you might have to use mig welding. when it comes to setting your welder’s amps for welding stainless steel, consider using lower amp settings to reduce heat input. Preparation, choosing the correct welding method, setting up your equipment, and performing the welding. You can produce a product that will meet even. Stainless Steel Welding Settings.

From www.leoscoralloys.com

Welding Techniques for 321 Stainless Steel Plates Tips and Tricks Blog Stainless Steel Welding Settings If you have a project that involves metals you might have to use mig welding. this process can be divided into four main stages: Stainless steel mig welding settings chart. navigating the nuances of tig welding stainless steel involves managing unique challenges, such as heat distortion, while also focusing on precision and proper preparation. when it comes. Stainless Steel Welding Settings.

From www.youtube.com

Stainless steel tig welding YouTube Stainless Steel Welding Settings We will go into great detail on this subject. You can produce a product that will meet even the most demanding standards if you master these steps. Stainless steel mig welding settings chart. Preparation, choosing the correct welding method, setting up your equipment, and performing the welding. If you have a project that involves metals you might have to use. Stainless Steel Welding Settings.

From brandonkss.github.io

Mig Welding Settings Chart Stainless Steel Welding Settings common welding methods for stainless steel include tig, mig, smaw, fcaw, resistance, and friction welding, each with specific advantages and applications. You can produce a product that will meet even the most demanding standards if you master these steps. when it comes to setting your welder’s amps for welding stainless steel, consider using lower amp settings to reduce. Stainless Steel Welding Settings.

From www.youtube.com

Tips for Tig Welding Stainless Steel using Pulse Settings YouTube Stainless Steel Welding Settings You can produce a product that will meet even the most demanding standards if you master these steps. navigating the nuances of tig welding stainless steel involves managing unique challenges, such as heat distortion, while also focusing on precision and proper preparation. this process can be divided into four main stages: Preparation, choosing the correct welding method, setting. Stainless Steel Welding Settings.

From livinmetal.com

Stainless Steel Pipe Welding Welding Shop in San Diego Livin Metal Stainless Steel Welding Settings We will go into great detail on this subject. Preparation, choosing the correct welding method, setting up your equipment, and performing the welding. common welding methods for stainless steel include tig, mig, smaw, fcaw, resistance, and friction welding, each with specific advantages and applications. this process can be divided into four main stages: If you have a project. Stainless Steel Welding Settings.

From gowelding.org

MIG Welding Electrodes Wire Selection, Charts Settings and Classification Stainless Steel Welding Settings this process can be divided into four main stages: You can produce a product that will meet even the most demanding standards if you master these steps. Preparation, choosing the correct welding method, setting up your equipment, and performing the welding. We will go into great detail on this subject. common welding methods for stainless steel include tig,. Stainless Steel Welding Settings.

From sheetstainlesssteel.com

Master Your Craft Stainless Steel Welding Settings Guide Stainless Steel Welding Settings Stainless steel mig welding settings chart. when it comes to setting your welder’s amps for welding stainless steel, consider using lower amp settings to reduce heat input. We will go into great detail on this subject. Preparation, choosing the correct welding method, setting up your equipment, and performing the welding. navigating the nuances of tig welding stainless steel. Stainless Steel Welding Settings.

From www.thefabricator.com

TIG welding stainless steel? Investing in three areas may help Stainless Steel Welding Settings when it comes to setting your welder’s amps for welding stainless steel, consider using lower amp settings to reduce heat input. If you have a project that involves metals you might have to use mig welding. Preparation, choosing the correct welding method, setting up your equipment, and performing the welding. common welding methods for stainless steel include tig,. Stainless Steel Welding Settings.

From www.youtube.com

Tig welding pulse setting and how to pulse weld stainless steel outside corner joint YouTube Stainless Steel Welding Settings navigating the nuances of tig welding stainless steel involves managing unique challenges, such as heat distortion, while also focusing on precision and proper preparation. You can produce a product that will meet even the most demanding standards if you master these steps. We will go into great detail on this subject. common welding methods for stainless steel include. Stainless Steel Welding Settings.

From www.westermans.com

Guide to welding Stainless Steel Westermans Blog Stainless Steel Welding Settings Stainless steel mig welding settings chart. when it comes to setting your welder’s amps for welding stainless steel, consider using lower amp settings to reduce heat input. Preparation, choosing the correct welding method, setting up your equipment, and performing the welding. We will go into great detail on this subject. common welding methods for stainless steel include tig,. Stainless Steel Welding Settings.

From weldguru.com

How To Stick Weld (SMAW) Stainless Steel A Beginners’ Guide Stainless Steel Welding Settings If you have a project that involves metals you might have to use mig welding. when it comes to setting your welder’s amps for welding stainless steel, consider using lower amp settings to reduce heat input. Stainless steel mig welding settings chart. this process can be divided into four main stages: navigating the nuances of tig welding. Stainless Steel Welding Settings.

From drillly.com

TIG Welding Settings Stainless Steel & Aluminum (StepbyStep) Stainless Steel Welding Settings navigating the nuances of tig welding stainless steel involves managing unique challenges, such as heat distortion, while also focusing on precision and proper preparation. this process can be divided into four main stages: Preparation, choosing the correct welding method, setting up your equipment, and performing the welding. common welding methods for stainless steel include tig, mig, smaw,. Stainless Steel Welding Settings.

From exobtflbe.blob.core.windows.net

How To Set Up A Miller Tig Welder For Stainless Steel at Ned Marcello blog Stainless Steel Welding Settings We will go into great detail on this subject. You can produce a product that will meet even the most demanding standards if you master these steps. when it comes to setting your welder’s amps for welding stainless steel, consider using lower amp settings to reduce heat input. common welding methods for stainless steel include tig, mig, smaw,. Stainless Steel Welding Settings.

From whatispiping.com

Methods for Welding Stainless Steel What Is Piping Stainless Steel Welding Settings this process can be divided into four main stages: when it comes to setting your welder’s amps for welding stainless steel, consider using lower amp settings to reduce heat input. common welding methods for stainless steel include tig, mig, smaw, fcaw, resistance, and friction welding, each with specific advantages and applications. We will go into great detail. Stainless Steel Welding Settings.

From weldguru.com

How to Weld Stainless Steel A Complete Guide Stainless Steel Welding Settings Preparation, choosing the correct welding method, setting up your equipment, and performing the welding. We will go into great detail on this subject. this process can be divided into four main stages: navigating the nuances of tig welding stainless steel involves managing unique challenges, such as heat distortion, while also focusing on precision and proper preparation. Stainless steel. Stainless Steel Welding Settings.

From mesinpotongkertass.blogspot.com

Inspirasi 36+ Stainless Steel TIG Welding Settings Stainless Steel Welding Settings You can produce a product that will meet even the most demanding standards if you master these steps. navigating the nuances of tig welding stainless steel involves managing unique challenges, such as heat distortion, while also focusing on precision and proper preparation. Preparation, choosing the correct welding method, setting up your equipment, and performing the welding. If you have. Stainless Steel Welding Settings.

From weldguru.com

TIG Welding Stainless Steel A Beginners Guide Weld Guru Stainless Steel Welding Settings common welding methods for stainless steel include tig, mig, smaw, fcaw, resistance, and friction welding, each with specific advantages and applications. If you have a project that involves metals you might have to use mig welding. Preparation, choosing the correct welding method, setting up your equipment, and performing the welding. navigating the nuances of tig welding stainless steel. Stainless Steel Welding Settings.