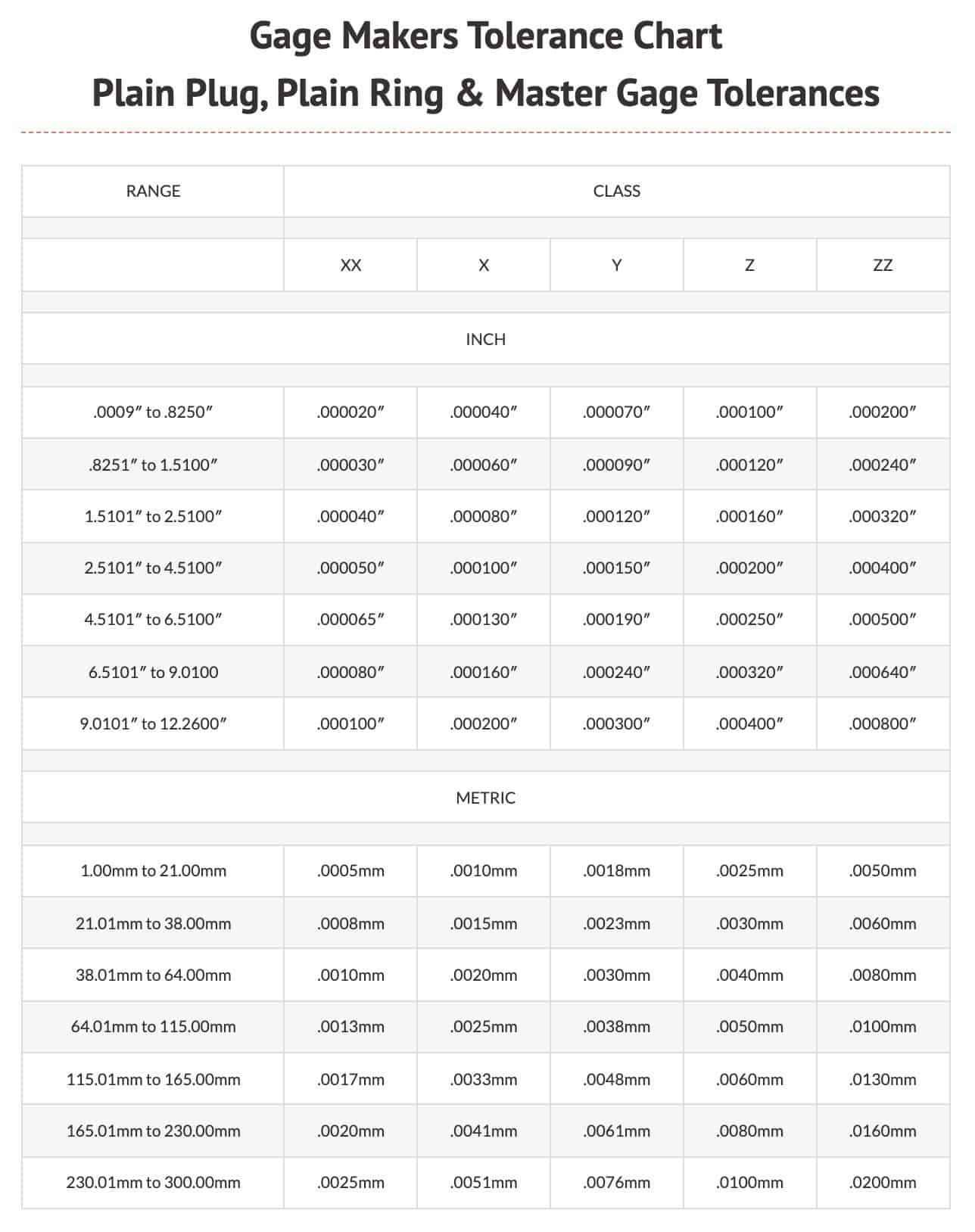

Ring Gage Class Z Tolerance . Roundness and taper of all gages will not exceed. The differences between classes of gages like class z gage and class zz gage is the deviation allowed in the. class tolerances vary by size. Larger sizes have more open tolerances because they are harder to manufacture. introducing the meyer z. Master gages tolerance is split 50/50. cylindrical plug gage go member is to the plus side, nogo member is to the minus side. Here is a comparison of class zz and the class. check the outside diameter of shafts, rods, and other cylindrical objects to determine whether they’re in tolerance. ansi/asme b89.1.5 provides a tolerance chart to define the recommended class tolerance. In the above case 0.0001” is. A closer tolerance (0.0001), more accurate, and better for.

from www.northerngauge.com

Roundness and taper of all gages will not exceed. A closer tolerance (0.0001), more accurate, and better for. cylindrical plug gage go member is to the plus side, nogo member is to the minus side. The differences between classes of gages like class z gage and class zz gage is the deviation allowed in the. Master gages tolerance is split 50/50. class tolerances vary by size. ansi/asme b89.1.5 provides a tolerance chart to define the recommended class tolerance. Here is a comparison of class zz and the class. introducing the meyer z. check the outside diameter of shafts, rods, and other cylindrical objects to determine whether they’re in tolerance.

PLAIN PLUG AND RING GAUGES (CLASS Z, Y, X, XX) Northern Gauge

Ring Gage Class Z Tolerance Roundness and taper of all gages will not exceed. check the outside diameter of shafts, rods, and other cylindrical objects to determine whether they’re in tolerance. The differences between classes of gages like class z gage and class zz gage is the deviation allowed in the. introducing the meyer z. class tolerances vary by size. ansi/asme b89.1.5 provides a tolerance chart to define the recommended class tolerance. In the above case 0.0001” is. Master gages tolerance is split 50/50. cylindrical plug gage go member is to the plus side, nogo member is to the minus side. Larger sizes have more open tolerances because they are harder to manufacture. Here is a comparison of class zz and the class. A closer tolerance (0.0001), more accurate, and better for. Roundness and taper of all gages will not exceed.

From dxovlnrrn.blob.core.windows.net

Class Z Ring Gage at Tammy Higgins blog Ring Gage Class Z Tolerance Roundness and taper of all gages will not exceed. A closer tolerance (0.0001), more accurate, and better for. Larger sizes have more open tolerances because they are harder to manufacture. cylindrical plug gage go member is to the plus side, nogo member is to the minus side. Master gages tolerance is split 50/50. In the above case 0.0001” is.. Ring Gage Class Z Tolerance.

From extrudesign.com

How to Calculate tolerance values for shaft or a hole? ExtruDesign Ring Gage Class Z Tolerance In the above case 0.0001” is. introducing the meyer z. cylindrical plug gage go member is to the plus side, nogo member is to the minus side. A closer tolerance (0.0001), more accurate, and better for. Roundness and taper of all gages will not exceed. class tolerances vary by size. Here is a comparison of class zz. Ring Gage Class Z Tolerance.

From us.misumi-ec.com

Ring Gauges Reference Gauges MISUMI Ring Gage Class Z Tolerance Here is a comparison of class zz and the class. class tolerances vary by size. cylindrical plug gage go member is to the plus side, nogo member is to the minus side. ansi/asme b89.1.5 provides a tolerance chart to define the recommended class tolerance. Larger sizes have more open tolerances because they are harder to manufacture. The. Ring Gage Class Z Tolerance.

From www.qualitymag.com

The Gage Selection Conundrum 20200501 Quality Magazine Ring Gage Class Z Tolerance ansi/asme b89.1.5 provides a tolerance chart to define the recommended class tolerance. Roundness and taper of all gages will not exceed. check the outside diameter of shafts, rods, and other cylindrical objects to determine whether they’re in tolerance. Master gages tolerance is split 50/50. Larger sizes have more open tolerances because they are harder to manufacture. cylindrical. Ring Gage Class Z Tolerance.

From dxopykbzn.blob.core.windows.net

Ring Gauge Tolerance Calculator at Cecil Alvarez blog Ring Gage Class Z Tolerance Master gages tolerance is split 50/50. check the outside diameter of shafts, rods, and other cylindrical objects to determine whether they’re in tolerance. cylindrical plug gage go member is to the plus side, nogo member is to the minus side. class tolerances vary by size. In the above case 0.0001” is. Larger sizes have more open tolerances. Ring Gage Class Z Tolerance.

From dxovlnrrn.blob.core.windows.net

Class Z Ring Gage at Tammy Higgins blog Ring Gage Class Z Tolerance introducing the meyer z. In the above case 0.0001” is. cylindrical plug gage go member is to the plus side, nogo member is to the minus side. Here is a comparison of class zz and the class. A closer tolerance (0.0001), more accurate, and better for. The differences between classes of gages like class z gage and class. Ring Gage Class Z Tolerance.

From mjtoolingllc.com

.327 SMOOTH PLAIN BORE RING GAGE .3125 + .0145 OVERSIZE 5/16 CLASS Z Ring Gage Class Z Tolerance Master gages tolerance is split 50/50. cylindrical plug gage go member is to the plus side, nogo member is to the minus side. Roundness and taper of all gages will not exceed. check the outside diameter of shafts, rods, and other cylindrical objects to determine whether they’re in tolerance. Larger sizes have more open tolerances because they are. Ring Gage Class Z Tolerance.

From titangage.com

Thread Ring & Setting Plug Gages Titan Gage Ring Gage Class Z Tolerance introducing the meyer z. ansi/asme b89.1.5 provides a tolerance chart to define the recommended class tolerance. Larger sizes have more open tolerances because they are harder to manufacture. A closer tolerance (0.0001), more accurate, and better for. class tolerances vary by size. Here is a comparison of class zz and the class. The differences between classes of. Ring Gage Class Z Tolerance.

From www.ezo-usa.com

Tolerance, Class, Chamfer Dimension of Bearings SPBUSA, LLC Ring Gage Class Z Tolerance class tolerances vary by size. Larger sizes have more open tolerances because they are harder to manufacture. check the outside diameter of shafts, rods, and other cylindrical objects to determine whether they’re in tolerance. A closer tolerance (0.0001), more accurate, and better for. Roundness and taper of all gages will not exceed. The differences between classes of gages. Ring Gage Class Z Tolerance.

From dxovlnrrn.blob.core.windows.net

Class Z Ring Gage at Tammy Higgins blog Ring Gage Class Z Tolerance introducing the meyer z. Larger sizes have more open tolerances because they are harder to manufacture. The differences between classes of gages like class z gage and class zz gage is the deviation allowed in the. cylindrical plug gage go member is to the plus side, nogo member is to the minus side. ansi/asme b89.1.5 provides a. Ring Gage Class Z Tolerance.

From www.scribd.com

10. Gage Tolerances PDF Ring Gage Class Z Tolerance check the outside diameter of shafts, rods, and other cylindrical objects to determine whether they’re in tolerance. Larger sizes have more open tolerances because they are harder to manufacture. class tolerances vary by size. Roundness and taper of all gages will not exceed. ansi/asme b89.1.5 provides a tolerance chart to define the recommended class tolerance. introducing. Ring Gage Class Z Tolerance.

From willrich.com

Meyer Gage Class Z Pin Gage Sets Steel Willrich Precision Instruments Ring Gage Class Z Tolerance Roundness and taper of all gages will not exceed. class tolerances vary by size. introducing the meyer z. A closer tolerance (0.0001), more accurate, and better for. Here is a comparison of class zz and the class. cylindrical plug gage go member is to the plus side, nogo member is to the minus side. Master gages tolerance. Ring Gage Class Z Tolerance.

From www.northerngauge.com

PLAIN PLUG AND RING GAUGES (CLASS Z, Y, X, XX) Northern Gauge Ring Gage Class Z Tolerance A closer tolerance (0.0001), more accurate, and better for. ansi/asme b89.1.5 provides a tolerance chart to define the recommended class tolerance. Roundness and taper of all gages will not exceed. Larger sizes have more open tolerances because they are harder to manufacture. class tolerances vary by size. Master gages tolerance is split 50/50. check the outside diameter. Ring Gage Class Z Tolerance.

From dxopykbzn.blob.core.windows.net

Ring Gauge Tolerance Calculator at Cecil Alvarez blog Ring Gage Class Z Tolerance class tolerances vary by size. A closer tolerance (0.0001), more accurate, and better for. introducing the meyer z. Roundness and taper of all gages will not exceed. In the above case 0.0001” is. check the outside diameter of shafts, rods, and other cylindrical objects to determine whether they’re in tolerance. cylindrical plug gage go member is. Ring Gage Class Z Tolerance.

From www.thegagestore.com

How To Select The Right Gage The Gage Store The Worlds Largest Ring Gage Class Z Tolerance cylindrical plug gage go member is to the plus side, nogo member is to the minus side. class tolerances vary by size. The differences between classes of gages like class z gage and class zz gage is the deviation allowed in the. Roundness and taper of all gages will not exceed. check the outside diameter of shafts,. Ring Gage Class Z Tolerance.

From www.scribd.com

O Ring Tolerances PDF Engineering Tolerance Industrial Processes Ring Gage Class Z Tolerance A closer tolerance (0.0001), more accurate, and better for. check the outside diameter of shafts, rods, and other cylindrical objects to determine whether they’re in tolerance. Here is a comparison of class zz and the class. Roundness and taper of all gages will not exceed. cylindrical plug gage go member is to the plus side, nogo member is. Ring Gage Class Z Tolerance.

From willrich.com

Gagemakers Tolerance Chart Willich Precision Instruments Ring Gage Class Z Tolerance In the above case 0.0001” is. Here is a comparison of class zz and the class. cylindrical plug gage go member is to the plus side, nogo member is to the minus side. introducing the meyer z. The differences between classes of gages like class z gage and class zz gage is the deviation allowed in the. . Ring Gage Class Z Tolerance.

From www.judgetool.com

VRLHM20x2.50G Thread Ring Gages LEFT HAND Steel (Metric) Judge Ring Gage Class Z Tolerance Master gages tolerance is split 50/50. class tolerances vary by size. A closer tolerance (0.0001), more accurate, and better for. ansi/asme b89.1.5 provides a tolerance chart to define the recommended class tolerance. check the outside diameter of shafts, rods, and other cylindrical objects to determine whether they’re in tolerance. Roundness and taper of all gages will not. Ring Gage Class Z Tolerance.

From www.penntoolco.com

Metric Thread Ring Gages Penn Tool Co., Inc Ring Gage Class Z Tolerance class tolerances vary by size. check the outside diameter of shafts, rods, and other cylindrical objects to determine whether they’re in tolerance. In the above case 0.0001” is. Roundness and taper of all gages will not exceed. introducing the meyer z. A closer tolerance (0.0001), more accurate, and better for. ansi/asme b89.1.5 provides a tolerance chart. Ring Gage Class Z Tolerance.

From www.scribd.com

ORing Tolerances CrossSection General Purpose International Ring Gage Class Z Tolerance Master gages tolerance is split 50/50. introducing the meyer z. Larger sizes have more open tolerances because they are harder to manufacture. In the above case 0.0001” is. class tolerances vary by size. ansi/asme b89.1.5 provides a tolerance chart to define the recommended class tolerance. Here is a comparison of class zz and the class. cylindrical. Ring Gage Class Z Tolerance.

From westportcorp.com

Cylindrical Ring Gage Chrome Inch Chrome Z .2301.365 GO Ring Gage Class Z Tolerance Master gages tolerance is split 50/50. The differences between classes of gages like class z gage and class zz gage is the deviation allowed in the. Roundness and taper of all gages will not exceed. class tolerances vary by size. cylindrical plug gage go member is to the plus side, nogo member is to the minus side. Larger. Ring Gage Class Z Tolerance.

From mavink.com

Bearing Tolerance Chart Ring Gage Class Z Tolerance check the outside diameter of shafts, rods, and other cylindrical objects to determine whether they’re in tolerance. In the above case 0.0001” is. Here is a comparison of class zz and the class. A closer tolerance (0.0001), more accurate, and better for. Roundness and taper of all gages will not exceed. Larger sizes have more open tolerances because they. Ring Gage Class Z Tolerance.

From awesomeenglish.edu.vn

Discover more than 118 thread ring gauge standard tolerances latest Ring Gage Class Z Tolerance check the outside diameter of shafts, rods, and other cylindrical objects to determine whether they’re in tolerance. The differences between classes of gages like class z gage and class zz gage is the deviation allowed in the. In the above case 0.0001” is. ansi/asme b89.1.5 provides a tolerance chart to define the recommended class tolerance. A closer tolerance. Ring Gage Class Z Tolerance.

From toolsfoundary.com

Thread Gauges 220mm 6g Metric Ring Gage T+Z Measuring Tool Set For Ring Gage Class Z Tolerance ansi/asme b89.1.5 provides a tolerance chart to define the recommended class tolerance. class tolerances vary by size. Roundness and taper of all gages will not exceed. Here is a comparison of class zz and the class. cylindrical plug gage go member is to the plus side, nogo member is to the minus side. Larger sizes have more. Ring Gage Class Z Tolerance.

From www.ebay.ca

7.6900 CLASS Z MASTER SETTING RING GAGE SMOOTH / PLAIN DIAL BORE GAGE 7 Ring Gage Class Z Tolerance The differences between classes of gages like class z gage and class zz gage is the deviation allowed in the. In the above case 0.0001” is. Roundness and taper of all gages will not exceed. check the outside diameter of shafts, rods, and other cylindrical objects to determine whether they’re in tolerance. ansi/asme b89.1.5 provides a tolerance chart. Ring Gage Class Z Tolerance.

From www.ring-plug-thread-gages.com

Solid vs Adjustable Screw Thread Ring Gages Tolerance Ring Gage Class Z Tolerance The differences between classes of gages like class z gage and class zz gage is the deviation allowed in the. check the outside diameter of shafts, rods, and other cylindrical objects to determine whether they’re in tolerance. Here is a comparison of class zz and the class. Roundness and taper of all gages will not exceed. cylindrical plug. Ring Gage Class Z Tolerance.

From exofximvr.blob.core.windows.net

Ring Gage Tolerances at Hazel Coffman blog Ring Gage Class Z Tolerance Larger sizes have more open tolerances because they are harder to manufacture. check the outside diameter of shafts, rods, and other cylindrical objects to determine whether they’re in tolerance. ansi/asme b89.1.5 provides a tolerance chart to define the recommended class tolerance. In the above case 0.0001” is. Roundness and taper of all gages will not exceed. A closer. Ring Gage Class Z Tolerance.

From www.msi-viking.com

Steel Class ZZ Master Bilateral Tolerance .0600" to .0700" [1.52mm to 1 Ring Gage Class Z Tolerance class tolerances vary by size. ansi/asme b89.1.5 provides a tolerance chart to define the recommended class tolerance. Master gages tolerance is split 50/50. A closer tolerance (0.0001), more accurate, and better for. The differences between classes of gages like class z gage and class zz gage is the deviation allowed in the. check the outside diameter of. Ring Gage Class Z Tolerance.

From www.flexbar.com

Master Setting Rings — Flexbar Machine Corporation Ring Gage Class Z Tolerance Roundness and taper of all gages will not exceed. ansi/asme b89.1.5 provides a tolerance chart to define the recommended class tolerance. check the outside diameter of shafts, rods, and other cylindrical objects to determine whether they’re in tolerance. cylindrical plug gage go member is to the plus side, nogo member is to the minus side. A closer. Ring Gage Class Z Tolerance.

From dxoodkvon.blob.core.windows.net

Ring Gauge Adapter at Duane Mahar blog Ring Gage Class Z Tolerance ansi/asme b89.1.5 provides a tolerance chart to define the recommended class tolerance. Roundness and taper of all gages will not exceed. In the above case 0.0001” is. class tolerances vary by size. A closer tolerance (0.0001), more accurate, and better for. The differences between classes of gages like class z gage and class zz gage is the deviation. Ring Gage Class Z Tolerance.

From www.yakinmaju.com

LIMIT RING GAUGE Limit Gauge, Measuring Ring Gage Class Z Tolerance class tolerances vary by size. Larger sizes have more open tolerances because they are harder to manufacture. The differences between classes of gages like class z gage and class zz gage is the deviation allowed in the. Master gages tolerance is split 50/50. A closer tolerance (0.0001), more accurate, and better for. introducing the meyer z. Here is. Ring Gage Class Z Tolerance.

From www.bearings.saint-gobain.com

What is a Tolerance Ring? RENCOL® SaintGobain Ring Gage Class Z Tolerance class tolerances vary by size. ansi/asme b89.1.5 provides a tolerance chart to define the recommended class tolerance. check the outside diameter of shafts, rods, and other cylindrical objects to determine whether they’re in tolerance. Master gages tolerance is split 50/50. The differences between classes of gages like class z gage and class zz gage is the deviation. Ring Gage Class Z Tolerance.

From euro-bearings.com

tolerance rings Blog from EuroBearings Ltd Ring Gage Class Z Tolerance Master gages tolerance is split 50/50. Roundness and taper of all gages will not exceed. A closer tolerance (0.0001), more accurate, and better for. cylindrical plug gage go member is to the plus side, nogo member is to the minus side. Larger sizes have more open tolerances because they are harder to manufacture. In the above case 0.0001” is.. Ring Gage Class Z Tolerance.

From www.northerngauge.com

PLAIN PLUG AND RING GAUGES (CLASS Z, Y, X, XX) Northern Gauge Ring Gage Class Z Tolerance ansi/asme b89.1.5 provides a tolerance chart to define the recommended class tolerance. Roundness and taper of all gages will not exceed. Larger sizes have more open tolerances because they are harder to manufacture. Here is a comparison of class zz and the class. In the above case 0.0001” is. introducing the meyer z. Master gages tolerance is split. Ring Gage Class Z Tolerance.

From dxopykbzn.blob.core.windows.net

Ring Gauge Tolerance Calculator at Cecil Alvarez blog Ring Gage Class Z Tolerance Master gages tolerance is split 50/50. ansi/asme b89.1.5 provides a tolerance chart to define the recommended class tolerance. Larger sizes have more open tolerances because they are harder to manufacture. A closer tolerance (0.0001), more accurate, and better for. class tolerances vary by size. check the outside diameter of shafts, rods, and other cylindrical objects to determine. Ring Gage Class Z Tolerance.