How To Determine Surface Roughness . This method involves moving a stylus along the surface of the material and measuring the surface variations. Surface roughness is a critical aspect of. Measuring surface roughness allows metrologists to establish the roughness of a surface for quality control or other purposes. Surface roughness value, normally at right angles to the lay of the machining marks. But how exactly is it done? Surface roughness determines sealing capabilities, level of corrosion resistance, heat transfer efficiency, aesthetics, and degree of wear. Surface roughness can be measured using various techniques, including: The measured profile is the profile resulting from scanning the. Surface roughness is the measurement of the relative smoothness of a surface’s profile, calculated via the microscopic deviations in a. Surface roughness is a critical parameter in engineering and manufacturing, influencing the performance and durability of.

from www.suginocorp.com

Surface roughness value, normally at right angles to the lay of the machining marks. The measured profile is the profile resulting from scanning the. Measuring surface roughness allows metrologists to establish the roughness of a surface for quality control or other purposes. Surface roughness can be measured using various techniques, including: Surface roughness is a critical parameter in engineering and manufacturing, influencing the performance and durability of. Surface roughness is the measurement of the relative smoothness of a surface’s profile, calculated via the microscopic deviations in a. Surface roughness determines sealing capabilities, level of corrosion resistance, heat transfer efficiency, aesthetics, and degree of wear. But how exactly is it done? Surface roughness is a critical aspect of. This method involves moving a stylus along the surface of the material and measuring the surface variations.

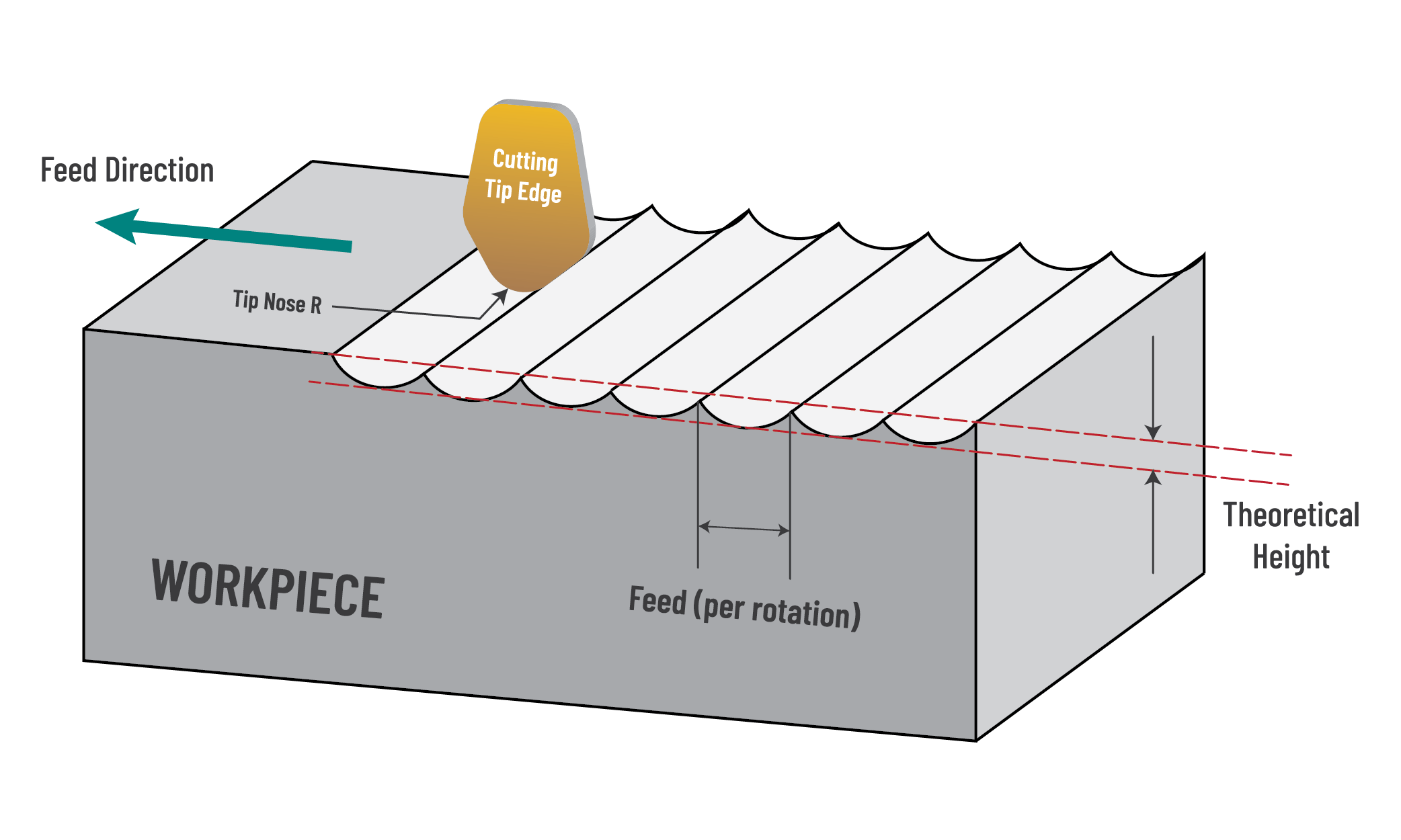

Surface Roughness for Lathe Turning

How To Determine Surface Roughness Surface roughness is the measurement of the relative smoothness of a surface’s profile, calculated via the microscopic deviations in a. Surface roughness determines sealing capabilities, level of corrosion resistance, heat transfer efficiency, aesthetics, and degree of wear. But how exactly is it done? This method involves moving a stylus along the surface of the material and measuring the surface variations. Surface roughness is the measurement of the relative smoothness of a surface’s profile, calculated via the microscopic deviations in a. Measuring surface roughness allows metrologists to establish the roughness of a surface for quality control or other purposes. Surface roughness value, normally at right angles to the lay of the machining marks. Surface roughness can be measured using various techniques, including: The measured profile is the profile resulting from scanning the. Surface roughness is a critical parameter in engineering and manufacturing, influencing the performance and durability of. Surface roughness is a critical aspect of.

From www.researchgate.net

How to calculate surface roughness factor from AFM analysis? ResearchGate How To Determine Surface Roughness This method involves moving a stylus along the surface of the material and measuring the surface variations. Surface roughness is a critical parameter in engineering and manufacturing, influencing the performance and durability of. Measuring surface roughness allows metrologists to establish the roughness of a surface for quality control or other purposes. Surface roughness can be measured using various techniques, including:. How To Determine Surface Roughness.

From www.cpnmestadio3.com

atuação Recorrer Apenas faça surface roughness calculation solicitação How To Determine Surface Roughness Surface roughness is the measurement of the relative smoothness of a surface’s profile, calculated via the microscopic deviations in a. Surface roughness is a critical aspect of. The measured profile is the profile resulting from scanning the. Surface roughness value, normally at right angles to the lay of the machining marks. But how exactly is it done? This method involves. How To Determine Surface Roughness.

From www.slideserve.com

PPT Surface Finish PowerPoint Presentation, free download ID3866407 How To Determine Surface Roughness Surface roughness value, normally at right angles to the lay of the machining marks. Surface roughness can be measured using various techniques, including: Surface roughness determines sealing capabilities, level of corrosion resistance, heat transfer efficiency, aesthetics, and degree of wear. Surface roughness is a critical aspect of. This method involves moving a stylus along the surface of the material and. How To Determine Surface Roughness.

From mavink.com

Surface Roughness Calculation How To Determine Surface Roughness This method involves moving a stylus along the surface of the material and measuring the surface variations. Measuring surface roughness allows metrologists to establish the roughness of a surface for quality control or other purposes. Surface roughness is a critical parameter in engineering and manufacturing, influencing the performance and durability of. Surface roughness value, normally at right angles to the. How To Determine Surface Roughness.

From dxoqmufpl.blob.core.windows.net

Surface Roughness Numbers at Elizabeth Slattery blog How To Determine Surface Roughness Surface roughness is the measurement of the relative smoothness of a surface’s profile, calculated via the microscopic deviations in a. Measuring surface roughness allows metrologists to establish the roughness of a surface for quality control or other purposes. Surface roughness is a critical parameter in engineering and manufacturing, influencing the performance and durability of. Surface roughness determines sealing capabilities, level. How To Determine Surface Roughness.

From www.minaprem.com

Various Sources of Surface Roughness in Conventional Machining How To Determine Surface Roughness Surface roughness is a critical aspect of. This method involves moving a stylus along the surface of the material and measuring the surface variations. Surface roughness can be measured using various techniques, including: But how exactly is it done? Measuring surface roughness allows metrologists to establish the roughness of a surface for quality control or other purposes. Surface roughness is. How To Determine Surface Roughness.

From at-machining.com

Surface Finish Chart A Guide to Understanding Surface Finishing Chart How To Determine Surface Roughness Surface roughness can be measured using various techniques, including: Surface roughness is a critical parameter in engineering and manufacturing, influencing the performance and durability of. Surface roughness value, normally at right angles to the lay of the machining marks. This method involves moving a stylus along the surface of the material and measuring the surface variations. Surface roughness determines sealing. How To Determine Surface Roughness.

From ceccewld.blob.core.windows.net

Surface Roughness Calculation Excel at Bennie Weaver blog How To Determine Surface Roughness This method involves moving a stylus along the surface of the material and measuring the surface variations. But how exactly is it done? Surface roughness can be measured using various techniques, including: Surface roughness is the measurement of the relative smoothness of a surface’s profile, calculated via the microscopic deviations in a. The measured profile is the profile resulting from. How To Determine Surface Roughness.

From www.researchgate.net

Calculation of the average surface roughness, R a , and the mean How To Determine Surface Roughness Surface roughness is a critical aspect of. Surface roughness is the measurement of the relative smoothness of a surface’s profile, calculated via the microscopic deviations in a. Surface roughness determines sealing capabilities, level of corrosion resistance, heat transfer efficiency, aesthetics, and degree of wear. But how exactly is it done? Measuring surface roughness allows metrologists to establish the roughness of. How To Determine Surface Roughness.

From www.slideserve.com

PPT LIMITS, FITS, TOLERANCES & SURFACE ROUGHNESS PowerPoint How To Determine Surface Roughness Surface roughness is a critical parameter in engineering and manufacturing, influencing the performance and durability of. Surface roughness is the measurement of the relative smoothness of a surface’s profile, calculated via the microscopic deviations in a. Surface roughness is a critical aspect of. Measuring surface roughness allows metrologists to establish the roughness of a surface for quality control or other. How To Determine Surface Roughness.

From klaseomhk.blob.core.windows.net

Measurement Of The Roughness Of Surfaces Physics at Renee Clark blog How To Determine Surface Roughness Surface roughness value, normally at right angles to the lay of the machining marks. The measured profile is the profile resulting from scanning the. Surface roughness can be measured using various techniques, including: Surface roughness is a critical aspect of. Surface roughness is a critical parameter in engineering and manufacturing, influencing the performance and durability of. Surface roughness determines sealing. How To Determine Surface Roughness.

From www.youtube.com

Quantify Surface Roughness YouTube How To Determine Surface Roughness But how exactly is it done? Measuring surface roughness allows metrologists to establish the roughness of a surface for quality control or other purposes. Surface roughness is a critical aspect of. Surface roughness is a critical parameter in engineering and manufacturing, influencing the performance and durability of. This method involves moving a stylus along the surface of the material and. How To Determine Surface Roughness.

From wa.nlcs.gov.bt

Surface roughness chart How To Determine Surface Roughness Surface roughness value, normally at right angles to the lay of the machining marks. Surface roughness determines sealing capabilities, level of corrosion resistance, heat transfer efficiency, aesthetics, and degree of wear. Surface roughness is the measurement of the relative smoothness of a surface’s profile, calculated via the microscopic deviations in a. But how exactly is it done? This method involves. How To Determine Surface Roughness.

From mavink.com

Ra Roughness Chart How To Determine Surface Roughness Surface roughness is the measurement of the relative smoothness of a surface’s profile, calculated via the microscopic deviations in a. Surface roughness is a critical aspect of. The measured profile is the profile resulting from scanning the. This method involves moving a stylus along the surface of the material and measuring the surface variations. But how exactly is it done?. How To Determine Surface Roughness.

From www.researchgate.net

Joint Roughness Coefficient (JRC) for different surface roughness How To Determine Surface Roughness Surface roughness is a critical parameter in engineering and manufacturing, influencing the performance and durability of. Surface roughness can be measured using various techniques, including: Surface roughness determines sealing capabilities, level of corrosion resistance, heat transfer efficiency, aesthetics, and degree of wear. Surface roughness value, normally at right angles to the lay of the machining marks. The measured profile is. How To Determine Surface Roughness.

From www.meetyoucarbide.com

How To Calculate the Surface Roughness in Ballend Milling Meetyou How To Determine Surface Roughness Surface roughness is the measurement of the relative smoothness of a surface’s profile, calculated via the microscopic deviations in a. Surface roughness is a critical aspect of. But how exactly is it done? Surface roughness can be measured using various techniques, including: This method involves moving a stylus along the surface of the material and measuring the surface variations. The. How To Determine Surface Roughness.

From wa.nlcs.gov.bt

Surface roughness chart How To Determine Surface Roughness This method involves moving a stylus along the surface of the material and measuring the surface variations. Surface roughness determines sealing capabilities, level of corrosion resistance, heat transfer efficiency, aesthetics, and degree of wear. But how exactly is it done? Measuring surface roughness allows metrologists to establish the roughness of a surface for quality control or other purposes. Surface roughness. How To Determine Surface Roughness.

From thereviewlog.com

Surface Roughness The Teeth in Copper Jaw (Details of Surface How To Determine Surface Roughness Surface roughness can be measured using various techniques, including: Surface roughness is the measurement of the relative smoothness of a surface’s profile, calculated via the microscopic deviations in a. The measured profile is the profile resulting from scanning the. But how exactly is it done? Surface roughness value, normally at right angles to the lay of the machining marks. This. How To Determine Surface Roughness.

From www.sigmatest.org

How do Surface Roughness Measurements Improve Profits? How To Determine Surface Roughness Surface roughness is a critical aspect of. Surface roughness is the measurement of the relative smoothness of a surface’s profile, calculated via the microscopic deviations in a. Measuring surface roughness allows metrologists to establish the roughness of a surface for quality control or other purposes. Surface roughness can be measured using various techniques, including: Surface roughness is a critical parameter. How To Determine Surface Roughness.

From imagesee.biz

Surface Roughness Ra Scale IMAGESEE How To Determine Surface Roughness Measuring surface roughness allows metrologists to establish the roughness of a surface for quality control or other purposes. Surface roughness is a critical parameter in engineering and manufacturing, influencing the performance and durability of. Surface roughness value, normally at right angles to the lay of the machining marks. Surface roughness can be measured using various techniques, including: Surface roughness is. How To Determine Surface Roughness.

From forum.image.sc

How to calculate 2D surface roughness? Development Image.sc Forum How To Determine Surface Roughness Surface roughness value, normally at right angles to the lay of the machining marks. Surface roughness is the measurement of the relative smoothness of a surface’s profile, calculated via the microscopic deviations in a. Measuring surface roughness allows metrologists to establish the roughness of a surface for quality control or other purposes. Surface roughness can be measured using various techniques,. How To Determine Surface Roughness.

From www.amazon.com

30PCS Roughness Test Block, Surface Roughness Comparison How To Determine Surface Roughness Surface roughness is a critical parameter in engineering and manufacturing, influencing the performance and durability of. The measured profile is the profile resulting from scanning the. Surface roughness can be measured using various techniques, including: Surface roughness is a critical aspect of. But how exactly is it done? Surface roughness determines sealing capabilities, level of corrosion resistance, heat transfer efficiency,. How To Determine Surface Roughness.

From www.suginocorp.com

Surface Roughness for Lathe Turning How To Determine Surface Roughness Surface roughness value, normally at right angles to the lay of the machining marks. Measuring surface roughness allows metrologists to establish the roughness of a surface for quality control or other purposes. This method involves moving a stylus along the surface of the material and measuring the surface variations. Surface roughness is the measurement of the relative smoothness of a. How To Determine Surface Roughness.

From mungfali.com

RMS Surface Roughness How To Determine Surface Roughness The measured profile is the profile resulting from scanning the. Surface roughness is a critical aspect of. Surface roughness is the measurement of the relative smoothness of a surface’s profile, calculated via the microscopic deviations in a. But how exactly is it done? Surface roughness can be measured using various techniques, including: Surface roughness value, normally at right angles to. How To Determine Surface Roughness.

From www.kemalmfg.com

A Comprehensive Guide to Surface Roughness, its Measurement, Standards How To Determine Surface Roughness Surface roughness value, normally at right angles to the lay of the machining marks. Measuring surface roughness allows metrologists to establish the roughness of a surface for quality control or other purposes. Surface roughness is a critical parameter in engineering and manufacturing, influencing the performance and durability of. This method involves moving a stylus along the surface of the material. How To Determine Surface Roughness.

From edmontonrealestateinvestmentblog.com

Surface Roughness Explained Get It Made (2022) How To Determine Surface Roughness Measuring surface roughness allows metrologists to establish the roughness of a surface for quality control or other purposes. Surface roughness value, normally at right angles to the lay of the machining marks. Surface roughness is a critical aspect of. Surface roughness is a critical parameter in engineering and manufacturing, influencing the performance and durability of. Surface roughness can be measured. How To Determine Surface Roughness.

From www.engineeringchoice.com

What Is Surface Roughness? Unit, Chart, Measurement How To Determine Surface Roughness Surface roughness is a critical parameter in engineering and manufacturing, influencing the performance and durability of. Surface roughness can be measured using various techniques, including: The measured profile is the profile resulting from scanning the. But how exactly is it done? Measuring surface roughness allows metrologists to establish the roughness of a surface for quality control or other purposes. Surface. How To Determine Surface Roughness.

From www.suginocorp.com

Surface Roughness for Lathe Turning How To Determine Surface Roughness Surface roughness can be measured using various techniques, including: This method involves moving a stylus along the surface of the material and measuring the surface variations. Surface roughness is a critical aspect of. Surface roughness is a critical parameter in engineering and manufacturing, influencing the performance and durability of. Measuring surface roughness allows metrologists to establish the roughness of a. How To Determine Surface Roughness.

From www.youtube.com

Surface Roughness YouTube How To Determine Surface Roughness Surface roughness determines sealing capabilities, level of corrosion resistance, heat transfer efficiency, aesthetics, and degree of wear. This method involves moving a stylus along the surface of the material and measuring the surface variations. Surface roughness is a critical aspect of. Measuring surface roughness allows metrologists to establish the roughness of a surface for quality control or other purposes. The. How To Determine Surface Roughness.

From loecchpug.blob.core.windows.net

How To Determine Surface Finish at Don Ritchey blog How To Determine Surface Roughness Surface roughness can be measured using various techniques, including: But how exactly is it done? Surface roughness determines sealing capabilities, level of corrosion resistance, heat transfer efficiency, aesthetics, and degree of wear. Measuring surface roughness allows metrologists to establish the roughness of a surface for quality control or other purposes. Surface roughness value, normally at right angles to the lay. How To Determine Surface Roughness.

From www.meetyoucarbide.com

How To Calculate the Surface Roughness in Ballend Milling Meetyou How To Determine Surface Roughness Surface roughness can be measured using various techniques, including: Surface roughness is the measurement of the relative smoothness of a surface’s profile, calculated via the microscopic deviations in a. Surface roughness is a critical aspect of. The measured profile is the profile resulting from scanning the. This method involves moving a stylus along the surface of the material and measuring. How To Determine Surface Roughness.

From www.flexbar.com

Surface Roughness Standards Set 30 Specimens — Flexbar Machine How To Determine Surface Roughness Measuring surface roughness allows metrologists to establish the roughness of a surface for quality control or other purposes. Surface roughness value, normally at right angles to the lay of the machining marks. Surface roughness is a critical parameter in engineering and manufacturing, influencing the performance and durability of. Surface roughness is the measurement of the relative smoothness of a surface’s. How To Determine Surface Roughness.

From ceqkkqeq.blob.core.windows.net

How Is Surface Roughness Measured at Fern Teran blog How To Determine Surface Roughness This method involves moving a stylus along the surface of the material and measuring the surface variations. Surface roughness is the measurement of the relative smoothness of a surface’s profile, calculated via the microscopic deviations in a. Measuring surface roughness allows metrologists to establish the roughness of a surface for quality control or other purposes. Surface roughness is a critical. How To Determine Surface Roughness.

From everipedia.org

Surface roughness Wiki Everipedia How To Determine Surface Roughness Surface roughness value, normally at right angles to the lay of the machining marks. Surface roughness is a critical parameter in engineering and manufacturing, influencing the performance and durability of. This method involves moving a stylus along the surface of the material and measuring the surface variations. Surface roughness is the measurement of the relative smoothness of a surface’s profile,. How To Determine Surface Roughness.

From www.gdandtbasics.com

The Basics of Surface Finish GD&T Basics How To Determine Surface Roughness But how exactly is it done? This method involves moving a stylus along the surface of the material and measuring the surface variations. Surface roughness value, normally at right angles to the lay of the machining marks. Surface roughness determines sealing capabilities, level of corrosion resistance, heat transfer efficiency, aesthetics, and degree of wear. Surface roughness can be measured using. How To Determine Surface Roughness.