End Mill Length To Diameter Ratio . One final topic worth discussing regarding tool geometry is the length of cut (loc) that a tool can achieve. The cutting tests demonstrate changes of 10 and 20 mm diameter end mill in cutting the carbon steel, en24 alloy steel and aluminium by increasing its length from 83.5 mm to 122. Navigating the vast array of end mills available in the market can be a daunting task, especially when precision is paramount. As shown in the figure below, longer end mills are. A tool rotates clockwise is called “right cutting edge”. Long length end mills (aka long flute end mills) have a reduced core diameter from the end of the flutes, all the way up to where the. Some end mills have flutes that terminate at the same diameter as the portion of the. Design milled areas so that the end mill required is limited to 3:1 in length to diameter ratio.

from toolnotes.com

Some end mills have flutes that terminate at the same diameter as the portion of the. As shown in the figure below, longer end mills are. A tool rotates clockwise is called “right cutting edge”. Long length end mills (aka long flute end mills) have a reduced core diameter from the end of the flutes, all the way up to where the. One final topic worth discussing regarding tool geometry is the length of cut (loc) that a tool can achieve. Navigating the vast array of end mills available in the market can be a daunting task, especially when precision is paramount. Design milled areas so that the end mill required is limited to 3:1 in length to diameter ratio. The cutting tests demonstrate changes of 10 and 20 mm diameter end mill in cutting the carbon steel, en24 alloy steel and aluminium by increasing its length from 83.5 mm to 122.

End Mills ToolNotes

End Mill Length To Diameter Ratio One final topic worth discussing regarding tool geometry is the length of cut (loc) that a tool can achieve. One final topic worth discussing regarding tool geometry is the length of cut (loc) that a tool can achieve. Long length end mills (aka long flute end mills) have a reduced core diameter from the end of the flutes, all the way up to where the. Design milled areas so that the end mill required is limited to 3:1 in length to diameter ratio. Some end mills have flutes that terminate at the same diameter as the portion of the. The cutting tests demonstrate changes of 10 and 20 mm diameter end mill in cutting the carbon steel, en24 alloy steel and aluminium by increasing its length from 83.5 mm to 122. As shown in the figure below, longer end mills are. A tool rotates clockwise is called “right cutting edge”. Navigating the vast array of end mills available in the market can be a daunting task, especially when precision is paramount.

From www.mscdirect.com

Harvey Tool Undercutting End Mills; Mill Diameter (Decimal Inch) 0. End Mill Length To Diameter Ratio The cutting tests demonstrate changes of 10 and 20 mm diameter end mill in cutting the carbon steel, en24 alloy steel and aluminium by increasing its length from 83.5 mm to 122. As shown in the figure below, longer end mills are. Navigating the vast array of end mills available in the market can be a daunting task, especially when. End Mill Length To Diameter Ratio.

From www.amazon.ca

Intoolhome 1/8" 3/16" 1/4" 5/16" 3/8" 1/2" high Speed Steel HSS 4 End Mill Length To Diameter Ratio Navigating the vast array of end mills available in the market can be a daunting task, especially when precision is paramount. The cutting tests demonstrate changes of 10 and 20 mm diameter end mill in cutting the carbon steel, en24 alloy steel and aluminium by increasing its length from 83.5 mm to 122. One final topic worth discussing regarding tool. End Mill Length To Diameter Ratio.

From blog.tormach.com

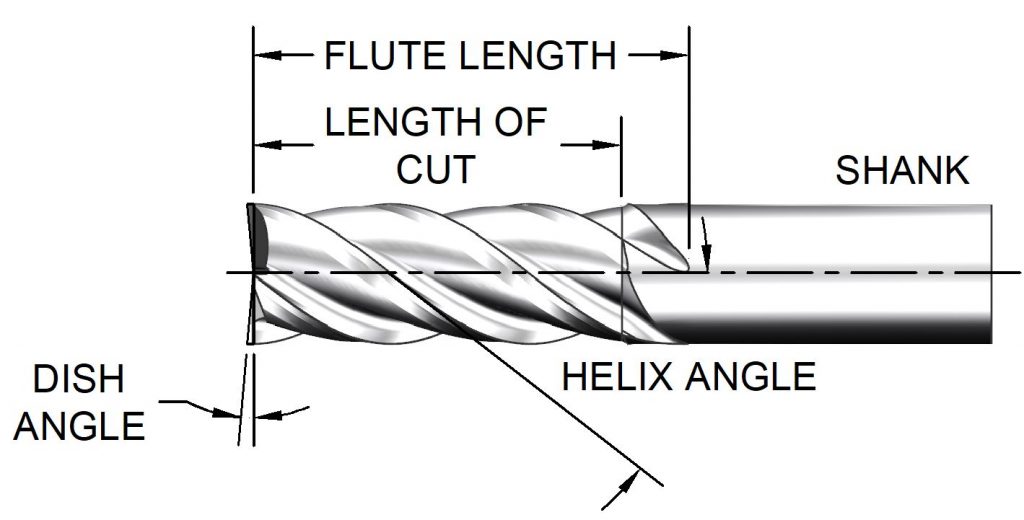

The Anatomy of an End Mill End Mill Length To Diameter Ratio One final topic worth discussing regarding tool geometry is the length of cut (loc) that a tool can achieve. Design milled areas so that the end mill required is limited to 3:1 in length to diameter ratio. Long length end mills (aka long flute end mills) have a reduced core diameter from the end of the flutes, all the way. End Mill Length To Diameter Ratio.

From www.it-tech-uk.com

3 Flute CNC End Mill HSSAl Cutter ITTECH End Mill Length To Diameter Ratio The cutting tests demonstrate changes of 10 and 20 mm diameter end mill in cutting the carbon steel, en24 alloy steel and aluminium by increasing its length from 83.5 mm to 122. Navigating the vast array of end mills available in the market can be a daunting task, especially when precision is paramount. Some end mills have flutes that terminate. End Mill Length To Diameter Ratio.

From samhotool.com

Comprehensive Guide to End Mill Sizes for CNC Machines SAMHO End Mill Length To Diameter Ratio One final topic worth discussing regarding tool geometry is the length of cut (loc) that a tool can achieve. Some end mills have flutes that terminate at the same diameter as the portion of the. A tool rotates clockwise is called “right cutting edge”. Long length end mills (aka long flute end mills) have a reduced core diameter from the. End Mill Length To Diameter Ratio.

From sheffieldtooling.co.uk

Swiss Tech HCO Long Series End Mill (Metric) 20mm Cutting Diameter End Mill Length To Diameter Ratio The cutting tests demonstrate changes of 10 and 20 mm diameter end mill in cutting the carbon steel, en24 alloy steel and aluminium by increasing its length from 83.5 mm to 122. Navigating the vast array of end mills available in the market can be a daunting task, especially when precision is paramount. Some end mills have flutes that terminate. End Mill Length To Diameter Ratio.

From earthasowers.blogspot.com

end mill shank types Eartha Sowers End Mill Length To Diameter Ratio A tool rotates clockwise is called “right cutting edge”. As shown in the figure below, longer end mills are. Some end mills have flutes that terminate at the same diameter as the portion of the. Design milled areas so that the end mill required is limited to 3:1 in length to diameter ratio. One final topic worth discussing regarding tool. End Mill Length To Diameter Ratio.

From www.mscdirect.com

Helical Solutions HighFeed End Mills; Mill Diameter (mm) 8.00 End Mill Length To Diameter Ratio Design milled areas so that the end mill required is limited to 3:1 in length to diameter ratio. A tool rotates clockwise is called “right cutting edge”. Some end mills have flutes that terminate at the same diameter as the portion of the. Long length end mills (aka long flute end mills) have a reduced core diameter from the end. End Mill Length To Diameter Ratio.

From www.presto-tools.co.uk

2 Flute Solid Carbide End Mills Presto International UK Limited End Mill Length To Diameter Ratio Long length end mills (aka long flute end mills) have a reduced core diameter from the end of the flutes, all the way up to where the. As shown in the figure below, longer end mills are. Navigating the vast array of end mills available in the market can be a daunting task, especially when precision is paramount. One final. End Mill Length To Diameter Ratio.

From www.qualitytechtool.com

General Purpose End Mills Inch Quality Tech Tool End Mill Length To Diameter Ratio Design milled areas so that the end mill required is limited to 3:1 in length to diameter ratio. As shown in the figure below, longer end mills are. A tool rotates clockwise is called “right cutting edge”. One final topic worth discussing regarding tool geometry is the length of cut (loc) that a tool can achieve. Some end mills have. End Mill Length To Diameter Ratio.

From www.mscdirect.com

Union Tool Square End Mills; Mill Diameter (mm) 10.00; Number Of End Mill Length To Diameter Ratio Some end mills have flutes that terminate at the same diameter as the portion of the. One final topic worth discussing regarding tool geometry is the length of cut (loc) that a tool can achieve. As shown in the figure below, longer end mills are. Navigating the vast array of end mills available in the market can be a daunting. End Mill Length To Diameter Ratio.

From www.toolmex.com

Solid Carbide End Mills, Ball Nose, 4 Flute, Standard Length, Metric End Mill Length To Diameter Ratio Long length end mills (aka long flute end mills) have a reduced core diameter from the end of the flutes, all the way up to where the. As shown in the figure below, longer end mills are. The cutting tests demonstrate changes of 10 and 20 mm diameter end mill in cutting the carbon steel, en24 alloy steel and aluminium. End Mill Length To Diameter Ratio.

From toolnotes.com

End Mills ToolNotes End Mill Length To Diameter Ratio A tool rotates clockwise is called “right cutting edge”. Design milled areas so that the end mill required is limited to 3:1 in length to diameter ratio. Navigating the vast array of end mills available in the market can be a daunting task, especially when precision is paramount. As shown in the figure below, longer end mills are. Some end. End Mill Length To Diameter Ratio.

From www.redlinetools.com

Endmill Selection Guide RedLine Tools Redline Tools End Mill Length To Diameter Ratio Some end mills have flutes that terminate at the same diameter as the portion of the. As shown in the figure below, longer end mills are. Design milled areas so that the end mill required is limited to 3:1 in length to diameter ratio. Long length end mills (aka long flute end mills) have a reduced core diameter from the. End Mill Length To Diameter Ratio.

From www.qualitytechtool.com

General Purpose End Mills Inch Quality Tech Tool End Mill Length To Diameter Ratio Navigating the vast array of end mills available in the market can be a daunting task, especially when precision is paramount. Design milled areas so that the end mill required is limited to 3:1 in length to diameter ratio. Long length end mills (aka long flute end mills) have a reduced core diameter from the end of the flutes, all. End Mill Length To Diameter Ratio.

From www.youtube.com

How to Measure the Outside Diameter 3 Fluted End Mill YouTube End Mill Length To Diameter Ratio As shown in the figure below, longer end mills are. Long length end mills (aka long flute end mills) have a reduced core diameter from the end of the flutes, all the way up to where the. A tool rotates clockwise is called “right cutting edge”. One final topic worth discussing regarding tool geometry is the length of cut (loc). End Mill Length To Diameter Ratio.

From www.mscdirect.com

Harvey Tool Square End Mills; Mill Diameter (Decimal Inch) 0.0300 End Mill Length To Diameter Ratio Some end mills have flutes that terminate at the same diameter as the portion of the. One final topic worth discussing regarding tool geometry is the length of cut (loc) that a tool can achieve. As shown in the figure below, longer end mills are. Design milled areas so that the end mill required is limited to 3:1 in length. End Mill Length To Diameter Ratio.

From kristlehartmann.blogspot.com

ball end mill size chart Kristle Hartmann End Mill Length To Diameter Ratio One final topic worth discussing regarding tool geometry is the length of cut (loc) that a tool can achieve. The cutting tests demonstrate changes of 10 and 20 mm diameter end mill in cutting the carbon steel, en24 alloy steel and aluminium by increasing its length from 83.5 mm to 122. As shown in the figure below, longer end mills. End Mill Length To Diameter Ratio.

From rdbarrett.co.uk

Mastermill VX Standard Length Corner Radius End Mill By Europa 179323 End Mill Length To Diameter Ratio The cutting tests demonstrate changes of 10 and 20 mm diameter end mill in cutting the carbon steel, en24 alloy steel and aluminium by increasing its length from 83.5 mm to 122. Navigating the vast array of end mills available in the market can be a daunting task, especially when precision is paramount. A tool rotates clockwise is called “right. End Mill Length To Diameter Ratio.

From www.qualitytechtool.com

Premium Class End Mills Metric Quality Tech Tool End Mill Length To Diameter Ratio The cutting tests demonstrate changes of 10 and 20 mm diameter end mill in cutting the carbon steel, en24 alloy steel and aluminium by increasing its length from 83.5 mm to 122. Some end mills have flutes that terminate at the same diameter as the portion of the. Design milled areas so that the end mill required is limited to. End Mill Length To Diameter Ratio.

From indotech-group.co.id

End Mill Ketahui Jenis Jenis End Mill Indotech Trimitra Abadi End Mill Length To Diameter Ratio Long length end mills (aka long flute end mills) have a reduced core diameter from the end of the flutes, all the way up to where the. Design milled areas so that the end mill required is limited to 3:1 in length to diameter ratio. Navigating the vast array of end mills available in the market can be a daunting. End Mill Length To Diameter Ratio.

From www.mscdirect.com

Harvey Tool Square End Mill 1/8" Dia, 3/16" LOC, 3 Flute, Solid End Mill Length To Diameter Ratio One final topic worth discussing regarding tool geometry is the length of cut (loc) that a tool can achieve. As shown in the figure below, longer end mills are. A tool rotates clockwise is called “right cutting edge”. Long length end mills (aka long flute end mills) have a reduced core diameter from the end of the flutes, all the. End Mill Length To Diameter Ratio.

From www.clortech.com

Request a Quote for a Tool Designed to Your Specifications Clortech End Mill Length To Diameter Ratio One final topic worth discussing regarding tool geometry is the length of cut (loc) that a tool can achieve. Navigating the vast array of end mills available in the market can be a daunting task, especially when precision is paramount. Design milled areas so that the end mill required is limited to 3:1 in length to diameter ratio. Long length. End Mill Length To Diameter Ratio.

From www.davehylands.com

Charts End Mill Length To Diameter Ratio Design milled areas so that the end mill required is limited to 3:1 in length to diameter ratio. The cutting tests demonstrate changes of 10 and 20 mm diameter end mill in cutting the carbon steel, en24 alloy steel and aluminium by increasing its length from 83.5 mm to 122. Long length end mills (aka long flute end mills) have. End Mill Length To Diameter Ratio.

From www.alibaba.com

End Mill Cutter Sizes;2flute Flattened End Mills With Straight Shank End Mill Length To Diameter Ratio Design milled areas so that the end mill required is limited to 3:1 in length to diameter ratio. As shown in the figure below, longer end mills are. Navigating the vast array of end mills available in the market can be a daunting task, especially when precision is paramount. One final topic worth discussing regarding tool geometry is the length. End Mill Length To Diameter Ratio.

From www.speedtigertools.com

End Mill Size Standards Chart & IntroductionSPEED TIGER End Mill Length To Diameter Ratio The cutting tests demonstrate changes of 10 and 20 mm diameter end mill in cutting the carbon steel, en24 alloy steel and aluminium by increasing its length from 83.5 mm to 122. A tool rotates clockwise is called “right cutting edge”. Navigating the vast array of end mills available in the market can be a daunting task, especially when precision. End Mill Length To Diameter Ratio.

From ronnalopes.blogspot.com

ball end mill sizes Ronna Lopes End Mill Length To Diameter Ratio As shown in the figure below, longer end mills are. A tool rotates clockwise is called “right cutting edge”. The cutting tests demonstrate changes of 10 and 20 mm diameter end mill in cutting the carbon steel, en24 alloy steel and aluminium by increasing its length from 83.5 mm to 122. Navigating the vast array of end mills available in. End Mill Length To Diameter Ratio.

From www.peaktoolworks.com

Standard Length Endmills (Ball End) Peak Toolworks End Mill Length To Diameter Ratio Navigating the vast array of end mills available in the market can be a daunting task, especially when precision is paramount. As shown in the figure below, longer end mills are. The cutting tests demonstrate changes of 10 and 20 mm diameter end mill in cutting the carbon steel, en24 alloy steel and aluminium by increasing its length from 83.5. End Mill Length To Diameter Ratio.

From tillescenter.org

1/8 Dia A62656Z 4 Flute Square Long Solid Carbide AlTiN Coated End End Mill Length To Diameter Ratio As shown in the figure below, longer end mills are. Design milled areas so that the end mill required is limited to 3:1 in length to diameter ratio. One final topic worth discussing regarding tool geometry is the length of cut (loc) that a tool can achieve. Long length end mills (aka long flute end mills) have a reduced core. End Mill Length To Diameter Ratio.

From blog.naver.com

엔드밀의 종류 및 각부의 명칭.. 네이버 블로그 End Mill Length To Diameter Ratio One final topic worth discussing regarding tool geometry is the length of cut (loc) that a tool can achieve. A tool rotates clockwise is called “right cutting edge”. Some end mills have flutes that terminate at the same diameter as the portion of the. Design milled areas so that the end mill required is limited to 3:1 in length to. End Mill Length To Diameter Ratio.

From mavink.com

Standard End Mill Sizes Chart End Mill Length To Diameter Ratio Some end mills have flutes that terminate at the same diameter as the portion of the. Long length end mills (aka long flute end mills) have a reduced core diameter from the end of the flutes, all the way up to where the. The cutting tests demonstrate changes of 10 and 20 mm diameter end mill in cutting the carbon. End Mill Length To Diameter Ratio.

From www.harveyperformance.com

The Anatomy of an End Mill In The Loupe Machinist Blog End Mill Length To Diameter Ratio One final topic worth discussing regarding tool geometry is the length of cut (loc) that a tool can achieve. A tool rotates clockwise is called “right cutting edge”. The cutting tests demonstrate changes of 10 and 20 mm diameter end mill in cutting the carbon steel, en24 alloy steel and aluminium by increasing its length from 83.5 mm to 122.. End Mill Length To Diameter Ratio.

From www.qualitytechtool.com

General Purpose End Mills Metric Quality Tech Tool End Mill Length To Diameter Ratio Some end mills have flutes that terminate at the same diameter as the portion of the. One final topic worth discussing regarding tool geometry is the length of cut (loc) that a tool can achieve. The cutting tests demonstrate changes of 10 and 20 mm diameter end mill in cutting the carbon steel, en24 alloy steel and aluminium by increasing. End Mill Length To Diameter Ratio.

From huanatools.com

The difference between metric and inch end mill sizes Huana Tools End Mill Length To Diameter Ratio One final topic worth discussing regarding tool geometry is the length of cut (loc) that a tool can achieve. Navigating the vast array of end mills available in the market can be a daunting task, especially when precision is paramount. The cutting tests demonstrate changes of 10 and 20 mm diameter end mill in cutting the carbon steel, en24 alloy. End Mill Length To Diameter Ratio.

From www.youtube.com

How to Measure Tool Diameters on a CNC Mill YouTube End Mill Length To Diameter Ratio A tool rotates clockwise is called “right cutting edge”. As shown in the figure below, longer end mills are. Some end mills have flutes that terminate at the same diameter as the portion of the. One final topic worth discussing regarding tool geometry is the length of cut (loc) that a tool can achieve. Design milled areas so that the. End Mill Length To Diameter Ratio.