Spur Gear Indexing Calculation . In this section we introduce the basic parts of spur gears (cylindrical gears) and dimensional calculations. Where, blank diameter = (z + 2) m. Perfect for laser cutting, routing, water jet cutting, or importing into your preferred cad package to integrate into. A spur gear calculator is a software program or online tool that helps engineers and designers calculate important parameters of spur gears,. Calculate the gear tooth proportions. Relationship between the involute elements determination of base tooth. Tooth depth = 2.25 m. For metric gears (as adopted by most of the worlds nations) the gear. The gear ratio is proportional to the diameters of the two pitch circles. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. Free variables and constraints are. Tooth width = 1.5708 m. Z = number of teeth required. The lewis equation was used to determine the bending strength and to calculate the material index. Generate a dxf (or svg) profile of your racks, external, and internal spur gears.

from khkgears.net

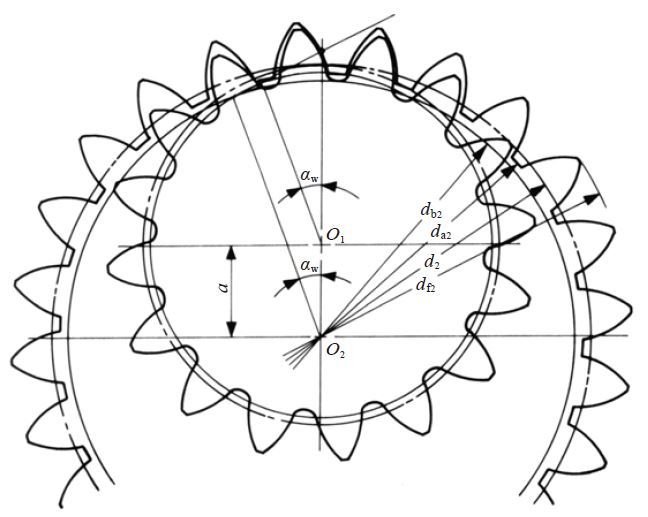

Z = number of teeth required. Relationship between the involute elements determination of base tooth. For metric gears (as adopted by most of the worlds nations) the gear. Where, blank diameter = (z + 2) m. A spur gear calculator is a software program or online tool that helps engineers and designers calculate important parameters of spur gears,. Calculate the gear tooth proportions. Diameter of gears (size) the size. Tooth depth = 2.25 m. Tooth width = 1.5708 m. The lewis equation was used to determine the bending strength and to calculate the material index.

Calculation of Gear Dimensions KHK Gears

Spur Gear Indexing Calculation Tooth width = 1.5708 m. The lewis equation was used to determine the bending strength and to calculate the material index. For metric gears (as adopted by most of the worlds nations) the gear. Tooth width = 1.5708 m. Z = number of teeth required. Generate a dxf (or svg) profile of your racks, external, and internal spur gears. In this section we introduce the basic parts of spur gears (cylindrical gears) and dimensional calculations. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. Relationship between the involute elements determination of base tooth. Where, blank diameter = (z + 2) m. Free variables and constraints are. Calculate the gear tooth proportions. The gear ratio is proportional to the diameters of the two pitch circles. A spur gear calculator is a software program or online tool that helps engineers and designers calculate important parameters of spur gears,. Diameter of gears (size) the size. Perfect for laser cutting, routing, water jet cutting, or importing into your preferred cad package to integrate into.

From getdrawings.com

Spur Gear Drawing at GetDrawings Free download Spur Gear Indexing Calculation Free variables and constraints are. Perfect for laser cutting, routing, water jet cutting, or importing into your preferred cad package to integrate into. The lewis equation was used to determine the bending strength and to calculate the material index. Calculate the gear tooth proportions. Where, blank diameter = (z + 2) m. In this section we introduce the basic parts. Spur Gear Indexing Calculation.

From khkgears.net

Calculation of Gear Dimensions KHK Gears Spur Gear Indexing Calculation The gear ratio is proportional to the diameters of the two pitch circles. Relationship between the involute elements determination of base tooth. Z = number of teeth required. The lewis equation was used to determine the bending strength and to calculate the material index. For metric gears (as adopted by most of the worlds nations) the gear. Tooth width =. Spur Gear Indexing Calculation.

From www.youtube.com

Design Of Spur Gear with Equation in SolidWorks YouTube Spur Gear Indexing Calculation In this section we introduce the basic parts of spur gears (cylindrical gears) and dimensional calculations. Tooth depth = 2.25 m. Diameter of gears (size) the size. The gear ratio is proportional to the diameters of the two pitch circles. Generate a dxf (or svg) profile of your racks, external, and internal spur gears. Tooth width = 1.5708 m. Where,. Spur Gear Indexing Calculation.

From dplasopa513.weebly.com

Fillet Radius Of Spur Gear Formula dplasopa Spur Gear Indexing Calculation Generate a dxf (or svg) profile of your racks, external, and internal spur gears. For metric gears (as adopted by most of the worlds nations) the gear. The lewis equation was used to determine the bending strength and to calculate the material index. Diameter of gears (size) the size. Where, blank diameter = (z + 2) m. In this section. Spur Gear Indexing Calculation.

From mechheart.com

Spur Gear Applications, Design, and Operation MECHHEART Spur Gear Indexing Calculation Relationship between the involute elements determination of base tooth. Tooth width = 1.5708 m. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. Diameter of gears (size) the size. Tooth depth = 2.25 m. A spur gear calculator is a software program or online tool that helps engineers and. Spur Gear Indexing Calculation.

From www.chegg.com

For a "spur spur gear" shown schematically in the Spur Gear Indexing Calculation Z = number of teeth required. Perfect for laser cutting, routing, water jet cutting, or importing into your preferred cad package to integrate into. Tooth width = 1.5708 m. Free variables and constraints are. The lewis equation was used to determine the bending strength and to calculate the material index. Relationship between the involute elements determination of base tooth. Gear. Spur Gear Indexing Calculation.

From www.youtube.com

Spur Gear Calculation and Design (MITCalc03) YouTube Spur Gear Indexing Calculation The lewis equation was used to determine the bending strength and to calculate the material index. The gear ratio is proportional to the diameters of the two pitch circles. Z = number of teeth required. Perfect for laser cutting, routing, water jet cutting, or importing into your preferred cad package to integrate into. Where, blank diameter = (z + 2). Spur Gear Indexing Calculation.

From evolventdesign.com

Spur Gear Calculator Hub Evolvent Design Spur Gear Indexing Calculation In this section we introduce the basic parts of spur gears (cylindrical gears) and dimensional calculations. Tooth depth = 2.25 m. Generate a dxf (or svg) profile of your racks, external, and internal spur gears. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. Perfect for laser cutting, routing,. Spur Gear Indexing Calculation.

From www.mechanicdrive.com

Spur gear calculation Spur Gear Indexing Calculation Z = number of teeth required. Where, blank diameter = (z + 2) m. Perfect for laser cutting, routing, water jet cutting, or importing into your preferred cad package to integrate into. Free variables and constraints are. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. In this section. Spur Gear Indexing Calculation.

From www.mdpi.com

Machines Free FullText Profile Analysis of Spur Gear Shaping Spur Gear Indexing Calculation Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. In this section we introduce the basic parts of spur gears (cylindrical gears) and dimensional calculations. Diameter of gears (size) the size. Relationship between the involute elements determination of base tooth. The gear ratio is proportional to the diameters of. Spur Gear Indexing Calculation.

From khkgears.net

Calculation of Gear Dimensions KHK Gears Spur Gear Indexing Calculation For metric gears (as adopted by most of the worlds nations) the gear. Free variables and constraints are. Diameter of gears (size) the size. Generate a dxf (or svg) profile of your racks, external, and internal spur gears. A spur gear calculator is a software program or online tool that helps engineers and designers calculate important parameters of spur gears,.. Spur Gear Indexing Calculation.

From www.mdpi.com

Machines Free FullText A Numerical Analysis of Hybrid Spur Gears Spur Gear Indexing Calculation Relationship between the involute elements determination of base tooth. Diameter of gears (size) the size. Where, blank diameter = (z + 2) m. A spur gear calculator is a software program or online tool that helps engineers and designers calculate important parameters of spur gears,. Tooth width = 1.5708 m. For metric gears (as adopted by most of the worlds. Spur Gear Indexing Calculation.

From www.youtube.com

Spur Gear Design 2 Involute of the circle YouTube Spur Gear Indexing Calculation Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. Relationship between the involute elements determination of base tooth. Tooth depth = 2.25 m. A spur gear calculator is a software program or online tool that helps engineers and designers calculate important parameters of spur gears,. Free variables and constraints. Spur Gear Indexing Calculation.

From mavink.com

Spur Gear Pitch Diameter Chart Spur Gear Indexing Calculation Relationship between the involute elements determination of base tooth. The gear ratio is proportional to the diameters of the two pitch circles. Z = number of teeth required. Perfect for laser cutting, routing, water jet cutting, or importing into your preferred cad package to integrate into. In this section we introduce the basic parts of spur gears (cylindrical gears) and. Spur Gear Indexing Calculation.

From www.chegg.com

Solved For a given Spur gear of 30 teeth, Calculate the Spur Gear Indexing Calculation Free variables and constraints are. Tooth width = 1.5708 m. For metric gears (as adopted by most of the worlds nations) the gear. Relationship between the involute elements determination of base tooth. Tooth depth = 2.25 m. The lewis equation was used to determine the bending strength and to calculate the material index. Generate a dxf (or svg) profile of. Spur Gear Indexing Calculation.

From qlerobh.weebly.com

Spur gear formulas qlerobh Spur Gear Indexing Calculation Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. A spur gear calculator is a software program or online tool that helps engineers and designers calculate important parameters of spur gears,. Free variables and constraints are. Z = number of teeth required. The lewis equation was used to determine. Spur Gear Indexing Calculation.

From www.zhygear.com

Verification of calculation accuracy of spur gear stiffness model ZHY Spur Gear Indexing Calculation Generate a dxf (or svg) profile of your racks, external, and internal spur gears. For metric gears (as adopted by most of the worlds nations) the gear. Tooth depth = 2.25 m. A spur gear calculator is a software program or online tool that helps engineers and designers calculate important parameters of spur gears,. Relationship between the involute elements determination. Spur Gear Indexing Calculation.

From present5.com

CALCULATION OF STRAIGHT SPUR GEARS FOR STRENGTH FORCES Spur Gear Indexing Calculation Calculate the gear tooth proportions. Perfect for laser cutting, routing, water jet cutting, or importing into your preferred cad package to integrate into. In this section we introduce the basic parts of spur gears (cylindrical gears) and dimensional calculations. A spur gear calculator is a software program or online tool that helps engineers and designers calculate important parameters of spur. Spur Gear Indexing Calculation.

From www.youtube.com

How to use the dividing head and calculations YouTube Spur Gear Indexing Calculation Perfect for laser cutting, routing, water jet cutting, or importing into your preferred cad package to integrate into. The gear ratio is proportional to the diameters of the two pitch circles. Relationship between the involute elements determination of base tooth. Tooth depth = 2.25 m. In this section we introduce the basic parts of spur gears (cylindrical gears) and dimensional. Spur Gear Indexing Calculation.

From www.pinterest.cl

Image result for internal gear design calculation Engrenagens, Torno Spur Gear Indexing Calculation Calculate the gear tooth proportions. Free variables and constraints are. Relationship between the involute elements determination of base tooth. Tooth width = 1.5708 m. The gear ratio is proportional to the diameters of the two pitch circles. The lewis equation was used to determine the bending strength and to calculate the material index. Perfect for laser cutting, routing, water jet. Spur Gear Indexing Calculation.

From getdrawings.com

Spur Gear Drawing at GetDrawings Free download Spur Gear Indexing Calculation A spur gear calculator is a software program or online tool that helps engineers and designers calculate important parameters of spur gears,. Tooth depth = 2.25 m. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. In this section we introduce the basic parts of spur gears (cylindrical gears). Spur Gear Indexing Calculation.

From www.iqsdirectory.com

Spur Gears Types, Uses, Benefits, and Manufacturing Spur Gear Indexing Calculation Diameter of gears (size) the size. Relationship between the involute elements determination of base tooth. Perfect for laser cutting, routing, water jet cutting, or importing into your preferred cad package to integrate into. Calculate the gear tooth proportions. A spur gear calculator is a software program or online tool that helps engineers and designers calculate important parameters of spur gears,.. Spur Gear Indexing Calculation.

From www.mechical.com

Terminology of Spur Gear and Their Formulas Spur Gear Indexing Calculation Z = number of teeth required. Tooth depth = 2.25 m. The gear ratio is proportional to the diameters of the two pitch circles. For metric gears (as adopted by most of the worlds nations) the gear. Free variables and constraints are. Where, blank diameter = (z + 2) m. The lewis equation was used to determine the bending strength. Spur Gear Indexing Calculation.

From ar.inspiredpencil.com

Simple Gear Train Driven Gear Spur Gear Indexing Calculation Generate a dxf (or svg) profile of your racks, external, and internal spur gears. Calculate the gear tooth proportions. Z = number of teeth required. Free variables and constraints are. Where, blank diameter = (z + 2) m. The gear ratio is proportional to the diameters of the two pitch circles. Gear dimensions are determined in accordance with their specifications,. Spur Gear Indexing Calculation.

From www.mdpi.com

Machines Free FullText Dynamic Modeling, Optimization and Spur Gear Indexing Calculation A spur gear calculator is a software program or online tool that helps engineers and designers calculate important parameters of spur gears,. Calculate the gear tooth proportions. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. For metric gears (as adopted by most of the worlds nations) the gear.. Spur Gear Indexing Calculation.

From www.researchgate.net

(Test 2) Spur gear calculation user interface (see online version for Spur Gear Indexing Calculation Free variables and constraints are. The gear ratio is proportional to the diameters of the two pitch circles. A spur gear calculator is a software program or online tool that helps engineers and designers calculate important parameters of spur gears,. For metric gears (as adopted by most of the worlds nations) the gear. Where, blank diameter = (z + 2). Spur Gear Indexing Calculation.

From www.youtube.com

Spur gear calculation, Design Details Spur Gear Formula spur gear Spur Gear Indexing Calculation Perfect for laser cutting, routing, water jet cutting, or importing into your preferred cad package to integrate into. Generate a dxf (or svg) profile of your racks, external, and internal spur gears. Tooth width = 1.5708 m. The gear ratio is proportional to the diameters of the two pitch circles. Relationship between the involute elements determination of base tooth. Diameter. Spur Gear Indexing Calculation.

From www.youtube.com

SimpleIndexing Simple Indexing Gear Cutting Milling Machine (Hindi Spur Gear Indexing Calculation The lewis equation was used to determine the bending strength and to calculate the material index. Calculate the gear tooth proportions. In this section we introduce the basic parts of spur gears (cylindrical gears) and dimensional calculations. Free variables and constraints are. Tooth width = 1.5708 m. Z = number of teeth required. The gear ratio is proportional to the. Spur Gear Indexing Calculation.

From www.pinterest.es

Gears General Gearing Arrangements Mechanical engineering, Gears Spur Gear Indexing Calculation Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. Generate a dxf (or svg) profile of your racks, external, and internal spur gears. In this section we introduce the basic parts of spur gears (cylindrical gears) and dimensional calculations. Relationship between the involute elements determination of base tooth. Free. Spur Gear Indexing Calculation.

From azgardsci.weebly.com

Pitch Diameter Gear Calculator azgardsci Spur Gear Indexing Calculation The gear ratio is proportional to the diameters of the two pitch circles. Tooth depth = 2.25 m. Calculate the gear tooth proportions. In this section we introduce the basic parts of spur gears (cylindrical gears) and dimensional calculations. Generate a dxf (or svg) profile of your racks, external, and internal spur gears. Perfect for laser cutting, routing, water jet. Spur Gear Indexing Calculation.

From mavink.com

Rack Gear Design Formulas Spur Gear Indexing Calculation Diameter of gears (size) the size. Tooth width = 1.5708 m. For metric gears (as adopted by most of the worlds nations) the gear. Z = number of teeth required. Generate a dxf (or svg) profile of your racks, external, and internal spur gears. The gear ratio is proportional to the diameters of the two pitch circles. In this section. Spur Gear Indexing Calculation.

From khkgears.net

Basic Gear Terminology and Calculation KHK Gears Spur Gear Indexing Calculation Calculate the gear tooth proportions. Relationship between the involute elements determination of base tooth. Free variables and constraints are. The lewis equation was used to determine the bending strength and to calculate the material index. Tooth width = 1.5708 m. Perfect for laser cutting, routing, water jet cutting, or importing into your preferred cad package to integrate into. In this. Spur Gear Indexing Calculation.

From www.chegg.com

Solved A spur gear has 47 teeth with 12 DP and 14.5° Spur Gear Indexing Calculation A spur gear calculator is a software program or online tool that helps engineers and designers calculate important parameters of spur gears,. Generate a dxf (or svg) profile of your racks, external, and internal spur gears. In this section we introduce the basic parts of spur gears (cylindrical gears) and dimensional calculations. Relationship between the involute elements determination of base. Spur Gear Indexing Calculation.

From paulbupejr.com

Wood Clock Gears with Motor Drive Part 1 of 3 Paul Bupe, Jr Spur Gear Indexing Calculation Relationship between the involute elements determination of base tooth. Diameter of gears (size) the size. The gear ratio is proportional to the diameters of the two pitch circles. Generate a dxf (or svg) profile of your racks, external, and internal spur gears. Calculate the gear tooth proportions. Where, blank diameter = (z + 2) m. In this section we introduce. Spur Gear Indexing Calculation.

From khkgears.net

Surface Durability of Spur and Helical Gears KHK Gears Spur Gear Indexing Calculation In this section we introduce the basic parts of spur gears (cylindrical gears) and dimensional calculations. The lewis equation was used to determine the bending strength and to calculate the material index. Diameter of gears (size) the size. Tooth depth = 2.25 m. Z = number of teeth required. Relationship between the involute elements determination of base tooth. Free variables. Spur Gear Indexing Calculation.