Spray Booth Ventilation Design . the primary role of a thermal spray enclosure is to contain and/or control various hazards associated with thermal spray. It keeps voc vapors at the required low flammable level (lfl) and helps reduce rework. whether you need a downdraft airflow design, crossdraft, semidowndraft or modified downdraft, you need to choose the right. optimizing ventilation in a crossflow paint booth is crucial for achieving superior paint jobs and ensuring safety. this is a general introduction to the design of industrial ventilation systems, with an additional discussion of two of the more. job quality and productivity, health and safety, and clean air all require mechanical ventilation, which provides a constant amount of exhausted air while the booth is in operation.

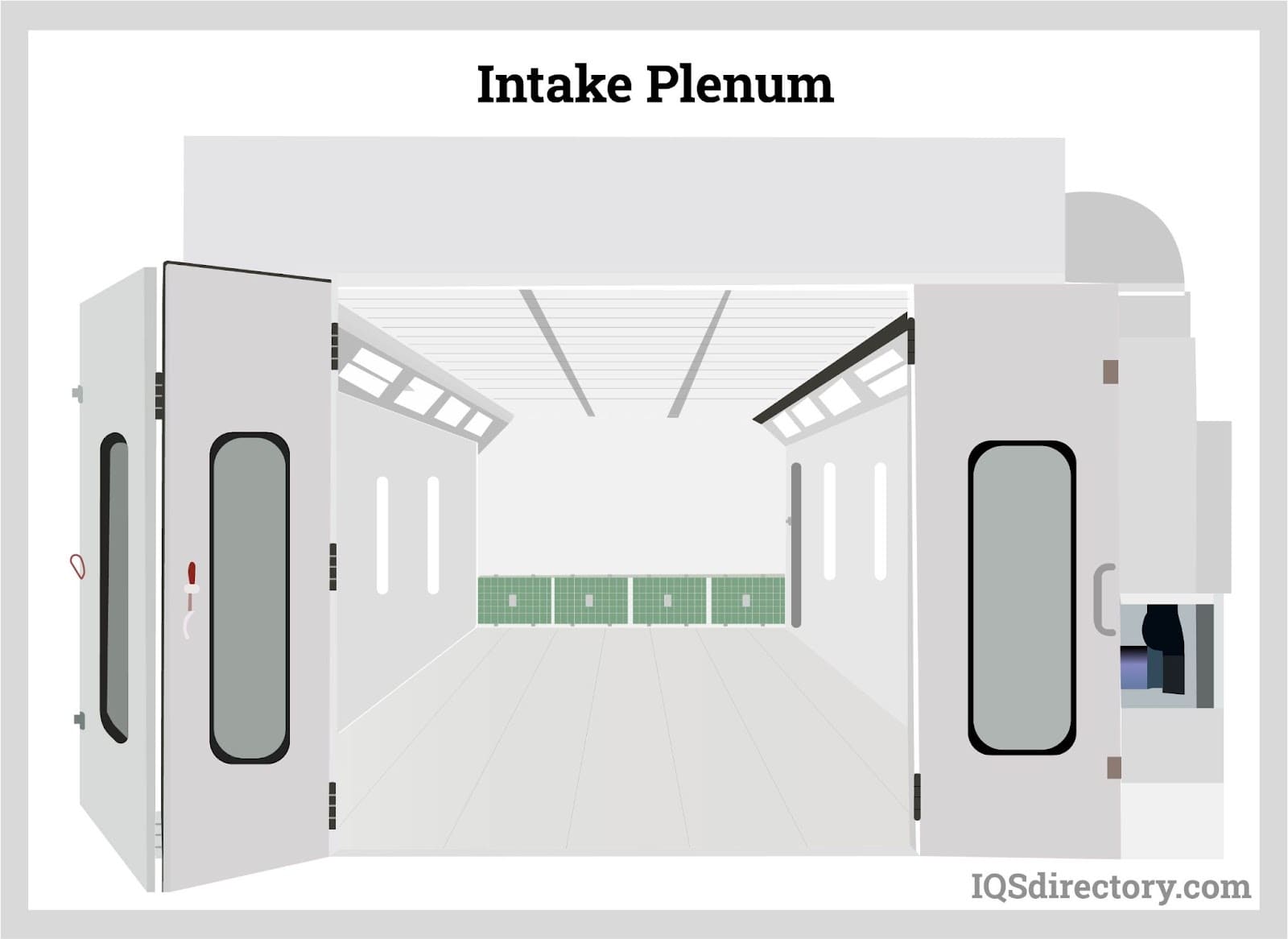

from www.iqsdirectory.com

optimizing ventilation in a crossflow paint booth is crucial for achieving superior paint jobs and ensuring safety. It keeps voc vapors at the required low flammable level (lfl) and helps reduce rework. this is a general introduction to the design of industrial ventilation systems, with an additional discussion of two of the more. job quality and productivity, health and safety, and clean air all require mechanical ventilation, which provides a constant amount of exhausted air while the booth is in operation. the primary role of a thermal spray enclosure is to contain and/or control various hazards associated with thermal spray. whether you need a downdraft airflow design, crossdraft, semidowndraft or modified downdraft, you need to choose the right.

Paint Spray Booths Construction, Types, Applications, and Benefits

Spray Booth Ventilation Design job quality and productivity, health and safety, and clean air all require mechanical ventilation, which provides a constant amount of exhausted air while the booth is in operation. the primary role of a thermal spray enclosure is to contain and/or control various hazards associated with thermal spray. job quality and productivity, health and safety, and clean air all require mechanical ventilation, which provides a constant amount of exhausted air while the booth is in operation. this is a general introduction to the design of industrial ventilation systems, with an additional discussion of two of the more. whether you need a downdraft airflow design, crossdraft, semidowndraft or modified downdraft, you need to choose the right. optimizing ventilation in a crossflow paint booth is crucial for achieving superior paint jobs and ensuring safety. It keeps voc vapors at the required low flammable level (lfl) and helps reduce rework.

From dxourbwmt.blob.core.windows.net

Paint Shop Ventilation Systems at Sara Holt blog Spray Booth Ventilation Design job quality and productivity, health and safety, and clean air all require mechanical ventilation, which provides a constant amount of exhausted air while the booth is in operation. It keeps voc vapors at the required low flammable level (lfl) and helps reduce rework. optimizing ventilation in a crossflow paint booth is crucial for achieving superior paint jobs and. Spray Booth Ventilation Design.

From www.researchgate.net

Sketch of a type of paint spray booth Download Scientific Diagram Spray Booth Ventilation Design It keeps voc vapors at the required low flammable level (lfl) and helps reduce rework. the primary role of a thermal spray enclosure is to contain and/or control various hazards associated with thermal spray. optimizing ventilation in a crossflow paint booth is crucial for achieving superior paint jobs and ensuring safety. whether you need a downdraft airflow. Spray Booth Ventilation Design.

From www.tamiyaclub.com

DIY spray booth Build Tips and Techniques Spray Booth Ventilation Design this is a general introduction to the design of industrial ventilation systems, with an additional discussion of two of the more. It keeps voc vapors at the required low flammable level (lfl) and helps reduce rework. optimizing ventilation in a crossflow paint booth is crucial for achieving superior paint jobs and ensuring safety. the primary role of. Spray Booth Ventilation Design.

From www.senecasheetmetal.com

Industrial Spray Booths Seneca Sheet Metal Spray Booth Ventilation Design whether you need a downdraft airflow design, crossdraft, semidowndraft or modified downdraft, you need to choose the right. It keeps voc vapors at the required low flammable level (lfl) and helps reduce rework. the primary role of a thermal spray enclosure is to contain and/or control various hazards associated with thermal spray. optimizing ventilation in a crossflow. Spray Booth Ventilation Design.

From design.udlvirtual.edu.pe

What Is A Spray Booth Design Talk Spray Booth Ventilation Design job quality and productivity, health and safety, and clean air all require mechanical ventilation, which provides a constant amount of exhausted air while the booth is in operation. whether you need a downdraft airflow design, crossdraft, semidowndraft or modified downdraft, you need to choose the right. optimizing ventilation in a crossflow paint booth is crucial for achieving. Spray Booth Ventilation Design.

From exonhtvoi.blob.core.windows.net

Paint Spray Booth Installation at Deborah Maya blog Spray Booth Ventilation Design optimizing ventilation in a crossflow paint booth is crucial for achieving superior paint jobs and ensuring safety. job quality and productivity, health and safety, and clean air all require mechanical ventilation, which provides a constant amount of exhausted air while the booth is in operation. the primary role of a thermal spray enclosure is to contain and/or. Spray Booth Ventilation Design.

From www.volpinprops.com

DIY Spray Booth (or “How I learned to love sheet metal”) Volpin Props Spray Booth Ventilation Design the primary role of a thermal spray enclosure is to contain and/or control various hazards associated with thermal spray. optimizing ventilation in a crossflow paint booth is crucial for achieving superior paint jobs and ensuring safety. whether you need a downdraft airflow design, crossdraft, semidowndraft or modified downdraft, you need to choose the right. job quality. Spray Booth Ventilation Design.

From www.youtube.com

How to build a Shop Air Cleaner and Paint Booth Ventilation System Spray Booth Ventilation Design It keeps voc vapors at the required low flammable level (lfl) and helps reduce rework. this is a general introduction to the design of industrial ventilation systems, with an additional discussion of two of the more. job quality and productivity, health and safety, and clean air all require mechanical ventilation, which provides a constant amount of exhausted air. Spray Booth Ventilation Design.

From hxekikili.blob.core.windows.net

Paint Booth Design Ventilation at Crystal Dubois blog Spray Booth Ventilation Design this is a general introduction to the design of industrial ventilation systems, with an additional discussion of two of the more. the primary role of a thermal spray enclosure is to contain and/or control various hazards associated with thermal spray. whether you need a downdraft airflow design, crossdraft, semidowndraft or modified downdraft, you need to choose the. Spray Booth Ventilation Design.

From www.paint-booths.com

How to Build a Paint Booth Spray Booth Ventilation Design It keeps voc vapors at the required low flammable level (lfl) and helps reduce rework. whether you need a downdraft airflow design, crossdraft, semidowndraft or modified downdraft, you need to choose the right. optimizing ventilation in a crossflow paint booth is crucial for achieving superior paint jobs and ensuring safety. job quality and productivity, health and safety,. Spray Booth Ventilation Design.

From globalfinishing.com

Industrial Paint Booths from Global Finishing Industrial Spray Booths Spray Booth Ventilation Design this is a general introduction to the design of industrial ventilation systems, with an additional discussion of two of the more. It keeps voc vapors at the required low flammable level (lfl) and helps reduce rework. whether you need a downdraft airflow design, crossdraft, semidowndraft or modified downdraft, you need to choose the right. the primary role. Spray Booth Ventilation Design.

From www.spraysystems.com

Airflow Designs for Spray Paint Booths Spray Systems Spray Booth Ventilation Design optimizing ventilation in a crossflow paint booth is crucial for achieving superior paint jobs and ensuring safety. this is a general introduction to the design of industrial ventilation systems, with an additional discussion of two of the more. the primary role of a thermal spray enclosure is to contain and/or control various hazards associated with thermal spray.. Spray Booth Ventilation Design.

From www.aerem.com

Spray booth maintenance 3 ways to keep your booth clean and secure Spray Booth Ventilation Design It keeps voc vapors at the required low flammable level (lfl) and helps reduce rework. optimizing ventilation in a crossflow paint booth is crucial for achieving superior paint jobs and ensuring safety. job quality and productivity, health and safety, and clean air all require mechanical ventilation, which provides a constant amount of exhausted air while the booth is. Spray Booth Ventilation Design.

From www.youtube.com

How to make a DIY Ventilated Paint Booth I Like To Make Stuff YouTube Spray Booth Ventilation Design job quality and productivity, health and safety, and clean air all require mechanical ventilation, which provides a constant amount of exhausted air while the booth is in operation. this is a general introduction to the design of industrial ventilation systems, with an additional discussion of two of the more. optimizing ventilation in a crossflow paint booth is. Spray Booth Ventilation Design.

From www.youtube.com

Spray Booth Ventilation System? How to set up a Ventilation System for Spray Booth Ventilation Design whether you need a downdraft airflow design, crossdraft, semidowndraft or modified downdraft, you need to choose the right. job quality and productivity, health and safety, and clean air all require mechanical ventilation, which provides a constant amount of exhausted air while the booth is in operation. the primary role of a thermal spray enclosure is to contain. Spray Booth Ventilation Design.

From atelier-yuwa.ciao.jp

Spray Booth Ventilation System? How To Set Up A Ventilation System For Spray Booth Ventilation Design optimizing ventilation in a crossflow paint booth is crucial for achieving superior paint jobs and ensuring safety. this is a general introduction to the design of industrial ventilation systems, with an additional discussion of two of the more. job quality and productivity, health and safety, and clean air all require mechanical ventilation, which provides a constant amount. Spray Booth Ventilation Design.

From exogkzgan.blob.core.windows.net

Led Booth Lighting at Betty Schubert blog Spray Booth Ventilation Design optimizing ventilation in a crossflow paint booth is crucial for achieving superior paint jobs and ensuring safety. this is a general introduction to the design of industrial ventilation systems, with an additional discussion of two of the more. whether you need a downdraft airflow design, crossdraft, semidowndraft or modified downdraft, you need to choose the right. It. Spray Booth Ventilation Design.

From www.iqsdirectory.com

Paint Spray Booths Construction, Types, Applications, and Benefits Spray Booth Ventilation Design this is a general introduction to the design of industrial ventilation systems, with an additional discussion of two of the more. the primary role of a thermal spray enclosure is to contain and/or control various hazards associated with thermal spray. optimizing ventilation in a crossflow paint booth is crucial for achieving superior paint jobs and ensuring safety.. Spray Booth Ventilation Design.

From hxekikili.blob.core.windows.net

Paint Booth Design Ventilation at Crystal Dubois blog Spray Booth Ventilation Design whether you need a downdraft airflow design, crossdraft, semidowndraft or modified downdraft, you need to choose the right. the primary role of a thermal spray enclosure is to contain and/or control various hazards associated with thermal spray. this is a general introduction to the design of industrial ventilation systems, with an additional discussion of two of the. Spray Booth Ventilation Design.

From exozgsheh.blob.core.windows.net

Homemade Spray Booth Ventilation at Elijah Johnson blog Spray Booth Ventilation Design It keeps voc vapors at the required low flammable level (lfl) and helps reduce rework. the primary role of a thermal spray enclosure is to contain and/or control various hazards associated with thermal spray. whether you need a downdraft airflow design, crossdraft, semidowndraft or modified downdraft, you need to choose the right. job quality and productivity, health. Spray Booth Ventilation Design.

From www.eptexcoatings.com

Custom Commercial Paint & Powder Spray Exhaust Booth EPTEX Coatings Spray Booth Ventilation Design job quality and productivity, health and safety, and clean air all require mechanical ventilation, which provides a constant amount of exhausted air while the booth is in operation. this is a general introduction to the design of industrial ventilation systems, with an additional discussion of two of the more. optimizing ventilation in a crossflow paint booth is. Spray Booth Ventilation Design.

From www.spraysystems.com

Exhaust Ducts for Spray Booths Spray Booth Exhaust Spray Systems Spray Booth Ventilation Design whether you need a downdraft airflow design, crossdraft, semidowndraft or modified downdraft, you need to choose the right. job quality and productivity, health and safety, and clean air all require mechanical ventilation, which provides a constant amount of exhausted air while the booth is in operation. this is a general introduction to the design of industrial ventilation. Spray Booth Ventilation Design.

From www.finewoodworking.com

Make a Simple Spray Booth FineWoodworking Spray Booth Ventilation Design whether you need a downdraft airflow design, crossdraft, semidowndraft or modified downdraft, you need to choose the right. the primary role of a thermal spray enclosure is to contain and/or control various hazards associated with thermal spray. optimizing ventilation in a crossflow paint booth is crucial for achieving superior paint jobs and ensuring safety. It keeps voc. Spray Booth Ventilation Design.

From exozgsheh.blob.core.windows.net

Homemade Spray Booth Ventilation at Elijah Johnson blog Spray Booth Ventilation Design It keeps voc vapors at the required low flammable level (lfl) and helps reduce rework. the primary role of a thermal spray enclosure is to contain and/or control various hazards associated with thermal spray. job quality and productivity, health and safety, and clean air all require mechanical ventilation, which provides a constant amount of exhausted air while the. Spray Booth Ventilation Design.

From theboiledpeanuts.com

Best 25 Diy Spray Booth Plans Home, Family, Style and Art Ideas Spray Booth Ventilation Design It keeps voc vapors at the required low flammable level (lfl) and helps reduce rework. optimizing ventilation in a crossflow paint booth is crucial for achieving superior paint jobs and ensuring safety. the primary role of a thermal spray enclosure is to contain and/or control various hazards associated with thermal spray. whether you need a downdraft airflow. Spray Booth Ventilation Design.

From dxozhfirc.blob.core.windows.net

Paint Booth Duct Design at Cheryl Samples blog Spray Booth Ventilation Design It keeps voc vapors at the required low flammable level (lfl) and helps reduce rework. whether you need a downdraft airflow design, crossdraft, semidowndraft or modified downdraft, you need to choose the right. this is a general introduction to the design of industrial ventilation systems, with an additional discussion of two of the more. the primary role. Spray Booth Ventilation Design.

From www.iqsdirectory.com

Paint Spray Booths Construction, Types, Applications, and Benefits Spray Booth Ventilation Design optimizing ventilation in a crossflow paint booth is crucial for achieving superior paint jobs and ensuring safety. whether you need a downdraft airflow design, crossdraft, semidowndraft or modified downdraft, you need to choose the right. the primary role of a thermal spray enclosure is to contain and/or control various hazards associated with thermal spray. this is. Spray Booth Ventilation Design.

From hxekikili.blob.core.windows.net

Paint Booth Design Ventilation at Crystal Dubois blog Spray Booth Ventilation Design this is a general introduction to the design of industrial ventilation systems, with an additional discussion of two of the more. It keeps voc vapors at the required low flammable level (lfl) and helps reduce rework. whether you need a downdraft airflow design, crossdraft, semidowndraft or modified downdraft, you need to choose the right. the primary role. Spray Booth Ventilation Design.

From vent-works.com

DIY Hobby Spray Booth Vent Works Spray Booth Ventilation Design job quality and productivity, health and safety, and clean air all require mechanical ventilation, which provides a constant amount of exhausted air while the booth is in operation. the primary role of a thermal spray enclosure is to contain and/or control various hazards associated with thermal spray. optimizing ventilation in a crossflow paint booth is crucial for. Spray Booth Ventilation Design.

From www.spraysystems.com

Custom Woodworking Paint Spray Booths Spray Systems Spray Booth Ventilation Design whether you need a downdraft airflow design, crossdraft, semidowndraft or modified downdraft, you need to choose the right. It keeps voc vapors at the required low flammable level (lfl) and helps reduce rework. this is a general introduction to the design of industrial ventilation systems, with an additional discussion of two of the more. the primary role. Spray Booth Ventilation Design.

From www.iqsdirectory.com

Paint Spray Booths Construction, Types, Applications, and Benefits Spray Booth Ventilation Design whether you need a downdraft airflow design, crossdraft, semidowndraft or modified downdraft, you need to choose the right. optimizing ventilation in a crossflow paint booth is crucial for achieving superior paint jobs and ensuring safety. job quality and productivity, health and safety, and clean air all require mechanical ventilation, which provides a constant amount of exhausted air. Spray Booth Ventilation Design.

From jmcautomotiveequipment.com

Automotive Paint Booth Guide by JMC Equipment Spray Booth Ventilation Design job quality and productivity, health and safety, and clean air all require mechanical ventilation, which provides a constant amount of exhausted air while the booth is in operation. whether you need a downdraft airflow design, crossdraft, semidowndraft or modified downdraft, you need to choose the right. optimizing ventilation in a crossflow paint booth is crucial for achieving. Spray Booth Ventilation Design.

From cs.finescale.com

spray booth venting FineScale Modeler Essential magazine for scale Spray Booth Ventilation Design job quality and productivity, health and safety, and clean air all require mechanical ventilation, which provides a constant amount of exhausted air while the booth is in operation. this is a general introduction to the design of industrial ventilation systems, with an additional discussion of two of the more. whether you need a downdraft airflow design, crossdraft,. Spray Booth Ventilation Design.

From cs.finescale.com

spray booth venting FineScale Modeler Essential magazine for scale Spray Booth Ventilation Design the primary role of a thermal spray enclosure is to contain and/or control various hazards associated with thermal spray. this is a general introduction to the design of industrial ventilation systems, with an additional discussion of two of the more. whether you need a downdraft airflow design, crossdraft, semidowndraft or modified downdraft, you need to choose the. Spray Booth Ventilation Design.

From libing-98.blogspot.com

Diy Spray Booth Extraction Fume and Dust Extraction Systems, amac Spray Booth Ventilation Design It keeps voc vapors at the required low flammable level (lfl) and helps reduce rework. whether you need a downdraft airflow design, crossdraft, semidowndraft or modified downdraft, you need to choose the right. job quality and productivity, health and safety, and clean air all require mechanical ventilation, which provides a constant amount of exhausted air while the booth. Spray Booth Ventilation Design.