How To Bevel A Pipe For Welding . There are different ways you can bevel a pipe depending on what you prefer. The standard pipe beveling angle is 37.50. pipe beveling methods. pipe beveling is a pipe fabrication process to create an angle between the edge of the end of metallic pipes and tubes. beveling is the operation for creating a flat angled surface on the end of the pipe. if you want to weld two pieces of pipe together, your pipe must be beveled. to bevel pipe for welding, use a grinder or pipe beveling machine to create a sloping edge along the pipe perimeter to. When joining pipes, beveling is essential, but there are a lot of other. in simpler words, beveling is altering the shape of the pipes before welding, so they fit better. The opening created by the beveling operation. pipe beveling by flame cutting or plasma cutting is a beveling process in which a gas torch or plasma torch is used to remove the edge of the pipe under great.

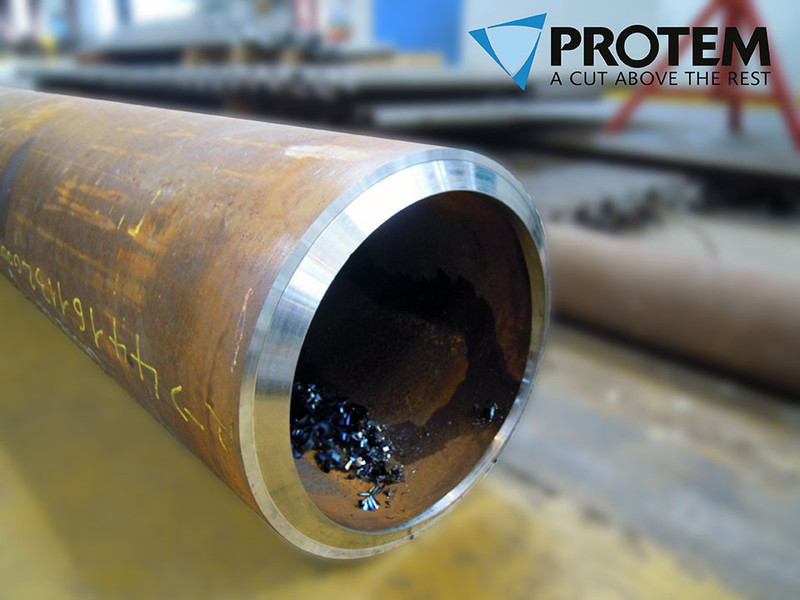

from www.protem.fr

pipe beveling by flame cutting or plasma cutting is a beveling process in which a gas torch or plasma torch is used to remove the edge of the pipe under great. pipe beveling is a pipe fabrication process to create an angle between the edge of the end of metallic pipes and tubes. The standard pipe beveling angle is 37.50. to bevel pipe for welding, use a grinder or pipe beveling machine to create a sloping edge along the pipe perimeter to. When joining pipes, beveling is essential, but there are a lot of other. beveling is the operation for creating a flat angled surface on the end of the pipe. The opening created by the beveling operation. There are different ways you can bevel a pipe depending on what you prefer. if you want to weld two pieces of pipe together, your pipe must be beveled. in simpler words, beveling is altering the shape of the pipes before welding, so they fit better.

Assembling Pipes by ButtWelding The Different Types of Bevels and How

How To Bevel A Pipe For Welding beveling is the operation for creating a flat angled surface on the end of the pipe. beveling is the operation for creating a flat angled surface on the end of the pipe. pipe beveling is a pipe fabrication process to create an angle between the edge of the end of metallic pipes and tubes. pipe beveling by flame cutting or plasma cutting is a beveling process in which a gas torch or plasma torch is used to remove the edge of the pipe under great. pipe beveling methods. if you want to weld two pieces of pipe together, your pipe must be beveled. in simpler words, beveling is altering the shape of the pipes before welding, so they fit better. to bevel pipe for welding, use a grinder or pipe beveling machine to create a sloping edge along the pipe perimeter to. The standard pipe beveling angle is 37.50. When joining pipes, beveling is essential, but there are a lot of other. The opening created by the beveling operation. There are different ways you can bevel a pipe depending on what you prefer.

From landing.morganitech.com

Pipe Beveling Guide How To Bevel A Pipe For Welding There are different ways you can bevel a pipe depending on what you prefer. The standard pipe beveling angle is 37.50. When joining pipes, beveling is essential, but there are a lot of other. if you want to weld two pieces of pipe together, your pipe must be beveled. pipe beveling is a pipe fabrication process to create. How To Bevel A Pipe For Welding.

From www.protem.fr

Assembling Pipes by ButtWelding The Different Types of Bevels and How How To Bevel A Pipe For Welding beveling is the operation for creating a flat angled surface on the end of the pipe. pipe beveling is a pipe fabrication process to create an angle between the edge of the end of metallic pipes and tubes. pipe beveling methods. There are different ways you can bevel a pipe depending on what you prefer. in. How To Bevel A Pipe For Welding.

From weldzone.org

How to Bevel a Pipe 4 Methods and 5 Techniques How To Bevel A Pipe For Welding There are different ways you can bevel a pipe depending on what you prefer. beveling is the operation for creating a flat angled surface on the end of the pipe. to bevel pipe for welding, use a grinder or pipe beveling machine to create a sloping edge along the pipe perimeter to. When joining pipes, beveling is essential,. How To Bevel A Pipe For Welding.

From www.youtube.com

37.5 Pipe Bevel Calculation & Marking Method YouTube How To Bevel A Pipe For Welding if you want to weld two pieces of pipe together, your pipe must be beveled. to bevel pipe for welding, use a grinder or pipe beveling machine to create a sloping edge along the pipe perimeter to. pipe beveling methods. The opening created by the beveling operation. The standard pipe beveling angle is 37.50. pipe beveling. How To Bevel A Pipe For Welding.

From www.mactechonsite.com

Pipe Beveling Mactech OnSite Solutions How To Bevel A Pipe For Welding The opening created by the beveling operation. pipe beveling methods. The standard pipe beveling angle is 37.50. in simpler words, beveling is altering the shape of the pipes before welding, so they fit better. if you want to weld two pieces of pipe together, your pipe must be beveled. to bevel pipe for welding, use a. How To Bevel A Pipe For Welding.

From blog.thepipingmart.com

How to Weld Pipe to Plate A Complete Guide How To Bevel A Pipe For Welding When joining pipes, beveling is essential, but there are a lot of other. beveling is the operation for creating a flat angled surface on the end of the pipe. pipe beveling is a pipe fabrication process to create an angle between the edge of the end of metallic pipes and tubes. in simpler words, beveling is altering. How To Bevel A Pipe For Welding.

From fittertraining.com

how to check pipe bevel degree 37.5 degree pipe bevel formula How To Bevel A Pipe For Welding pipe beveling by flame cutting or plasma cutting is a beveling process in which a gas torch or plasma torch is used to remove the edge of the pipe under great. The opening created by the beveling operation. The standard pipe beveling angle is 37.50. in simpler words, beveling is altering the shape of the pipes before welding,. How To Bevel A Pipe For Welding.

From materialwelding.com

Welding Bevel Types and Symbols you NEED to know! How To Bevel A Pipe For Welding When joining pipes, beveling is essential, but there are a lot of other. beveling is the operation for creating a flat angled surface on the end of the pipe. if you want to weld two pieces of pipe together, your pipe must be beveled. in simpler words, beveling is altering the shape of the pipes before welding,. How To Bevel A Pipe For Welding.

From www.shutterstock.com

Fabrication Pipe Welding Preparing Singer Bevel Stock Photo 1361754218 How To Bevel A Pipe For Welding The standard pipe beveling angle is 37.50. The opening created by the beveling operation. pipe beveling methods. pipe beveling by flame cutting or plasma cutting is a beveling process in which a gas torch or plasma torch is used to remove the edge of the pipe under great. There are different ways you can bevel a pipe depending. How To Bevel A Pipe For Welding.

From weldzone.org

How to Bevel a Pipe 4 Methods and 5 Techniques How To Bevel A Pipe For Welding When joining pipes, beveling is essential, but there are a lot of other. pipe beveling is a pipe fabrication process to create an angle between the edge of the end of metallic pipes and tubes. pipe beveling methods. if you want to weld two pieces of pipe together, your pipe must be beveled. There are different ways. How To Bevel A Pipe For Welding.

From www.youtube.com

Mastering Steel Tube Fabrication Prep, Bevel, Weld, and Finish YouTube How To Bevel A Pipe For Welding if you want to weld two pieces of pipe together, your pipe must be beveled. in simpler words, beveling is altering the shape of the pipes before welding, so they fit better. There are different ways you can bevel a pipe depending on what you prefer. pipe beveling methods. The standard pipe beveling angle is 37.50. When. How To Bevel A Pipe For Welding.

From www.allaboutpiping.com

What Is Beveling? Types, Preparation, Hazards ALL ABOUT PIPING How To Bevel A Pipe For Welding The opening created by the beveling operation. pipe beveling methods. if you want to weld two pieces of pipe together, your pipe must be beveled. There are different ways you can bevel a pipe depending on what you prefer. beveling is the operation for creating a flat angled surface on the end of the pipe. When joining. How To Bevel A Pipe For Welding.

From www.protem.fr

Assembling Pipes by ButtWelding The Different Types of Bevels and How How To Bevel A Pipe For Welding There are different ways you can bevel a pipe depending on what you prefer. pipe beveling is a pipe fabrication process to create an angle between the edge of the end of metallic pipes and tubes. beveling is the operation for creating a flat angled surface on the end of the pipe. The opening created by the beveling. How To Bevel A Pipe For Welding.

From www.fabricatingandmetalworking.com

Fabricating & Metalworking How To Bevel A Pipe For Welding if you want to weld two pieces of pipe together, your pipe must be beveled. The opening created by the beveling operation. pipe beveling methods. to bevel pipe for welding, use a grinder or pipe beveling machine to create a sloping edge along the pipe perimeter to. When joining pipes, beveling is essential, but there are a. How To Bevel A Pipe For Welding.

From www.protem.fr

Assembling Pipes by ButtWelding The Different Types of Bevels and How How To Bevel A Pipe For Welding pipe beveling methods. if you want to weld two pieces of pipe together, your pipe must be beveled. There are different ways you can bevel a pipe depending on what you prefer. to bevel pipe for welding, use a grinder or pipe beveling machine to create a sloping edge along the pipe perimeter to. beveling is. How To Bevel A Pipe For Welding.

From weldingheadquarters.com

How to Bevel Pipe for Welding How To Bevel A Pipe For Welding pipe beveling methods. When joining pipes, beveling is essential, but there are a lot of other. to bevel pipe for welding, use a grinder or pipe beveling machine to create a sloping edge along the pipe perimeter to. The opening created by the beveling operation. if you want to weld two pieces of pipe together, your pipe. How To Bevel A Pipe For Welding.

From www.westermans.com

Weld Preparation Techniques Plate Bevelling Westermans Blog How To Bevel A Pipe For Welding if you want to weld two pieces of pipe together, your pipe must be beveled. When joining pipes, beveling is essential, but there are a lot of other. in simpler words, beveling is altering the shape of the pipes before welding, so they fit better. There are different ways you can bevel a pipe depending on what you. How To Bevel A Pipe For Welding.

From www.irvon.co.uk

Steel Plate Bevelling for Weld Preparation Tube & Pipe Curving How To Bevel A Pipe For Welding pipe beveling is a pipe fabrication process to create an angle between the edge of the end of metallic pipes and tubes. if you want to weld two pieces of pipe together, your pipe must be beveled. When joining pipes, beveling is essential, but there are a lot of other. The standard pipe beveling angle is 37.50. There. How To Bevel A Pipe For Welding.

From www.youtube.com

How to Bevel pipe on lathe YouTube How To Bevel A Pipe For Welding beveling is the operation for creating a flat angled surface on the end of the pipe. pipe beveling is a pipe fabrication process to create an angle between the edge of the end of metallic pipes and tubes. The standard pipe beveling angle is 37.50. pipe beveling by flame cutting or plasma cutting is a beveling process. How To Bevel A Pipe For Welding.

From blog.morganitech.com

J Bevel The Key to MultiPass Orbital Pipe Welding How To Bevel A Pipe For Welding pipe beveling is a pipe fabrication process to create an angle between the edge of the end of metallic pipes and tubes. in simpler words, beveling is altering the shape of the pipes before welding, so they fit better. if you want to weld two pieces of pipe together, your pipe must be beveled. The opening created. How To Bevel A Pipe For Welding.

From www.eastern-steels.com

Pipe Beveling How To Bevel A Pipe For Welding pipe beveling methods. The standard pipe beveling angle is 37.50. There are different ways you can bevel a pipe depending on what you prefer. When joining pipes, beveling is essential, but there are a lot of other. The opening created by the beveling operation. pipe beveling is a pipe fabrication process to create an angle between the edge. How To Bevel A Pipe For Welding.

From resources.arcmachines.com

Pipe Welding Joint Preparation After Machining Arc Machines How To Bevel A Pipe For Welding The opening created by the beveling operation. if you want to weld two pieces of pipe together, your pipe must be beveled. There are different ways you can bevel a pipe depending on what you prefer. pipe beveling is a pipe fabrication process to create an angle between the edge of the end of metallic pipes and tubes.. How To Bevel A Pipe For Welding.

From waterwelders.com

How to Bevel Pipe for Welding A Pipe Beveling Guide WaterWelders How To Bevel A Pipe For Welding pipe beveling is a pipe fabrication process to create an angle between the edge of the end of metallic pipes and tubes. beveling is the operation for creating a flat angled surface on the end of the pipe. The opening created by the beveling operation. to bevel pipe for welding, use a grinder or pipe beveling machine. How To Bevel A Pipe For Welding.

From weldzone.org

How to Bevel a Pipe 4 Methods and 5 Techniques How To Bevel A Pipe For Welding There are different ways you can bevel a pipe depending on what you prefer. pipe beveling methods. beveling is the operation for creating a flat angled surface on the end of the pipe. if you want to weld two pieces of pipe together, your pipe must be beveled. to bevel pipe for welding, use a grinder. How To Bevel A Pipe For Welding.

From www.weldingmania.com

What Is Bevel In Welding And When It Is Used? WeldingMania How To Bevel A Pipe For Welding to bevel pipe for welding, use a grinder or pipe beveling machine to create a sloping edge along the pipe perimeter to. The opening created by the beveling operation. pipe beveling by flame cutting or plasma cutting is a beveling process in which a gas torch or plasma torch is used to remove the edge of the pipe. How To Bevel A Pipe For Welding.

From www.pittsburghpipe.com

What Are the Different Types of Beveling? Pittsburgh Pipe How To Bevel A Pipe For Welding pipe beveling methods. There are different ways you can bevel a pipe depending on what you prefer. beveling is the operation for creating a flat angled surface on the end of the pipe. pipe beveling by flame cutting or plasma cutting is a beveling process in which a gas torch or plasma torch is used to remove. How To Bevel A Pipe For Welding.

From www.thefabricator.com

The next generation of portable beveling How To Bevel A Pipe For Welding beveling is the operation for creating a flat angled surface on the end of the pipe. in simpler words, beveling is altering the shape of the pipes before welding, so they fit better. pipe beveling is a pipe fabrication process to create an angle between the edge of the end of metallic pipes and tubes. The standard. How To Bevel A Pipe For Welding.

From www.canadianmetalworking.com

Bevel Booster How to Bevel Pipe How To Bevel A Pipe For Welding beveling is the operation for creating a flat angled surface on the end of the pipe. The standard pipe beveling angle is 37.50. if you want to weld two pieces of pipe together, your pipe must be beveled. There are different ways you can bevel a pipe depending on what you prefer. When joining pipes, beveling is essential,. How To Bevel A Pipe For Welding.

From waterwelders.com

How to Bevel Pipe for Welding A Pipe Beveling Guide WaterWelders How To Bevel A Pipe For Welding pipe beveling by flame cutting or plasma cutting is a beveling process in which a gas torch or plasma torch is used to remove the edge of the pipe under great. The standard pipe beveling angle is 37.50. When joining pipes, beveling is essential, but there are a lot of other. pipe beveling methods. to bevel pipe. How To Bevel A Pipe For Welding.

From waterwelders.com

How to Bevel Pipe for Welding A Pipe Beveling Guide WaterWelders How To Bevel A Pipe For Welding in simpler words, beveling is altering the shape of the pipes before welding, so they fit better. pipe beveling is a pipe fabrication process to create an angle between the edge of the end of metallic pipes and tubes. if you want to weld two pieces of pipe together, your pipe must be beveled. The standard pipe. How To Bevel A Pipe For Welding.

From www.copiermachinery.com

What is Pipe Beveling? How to Bevel a Pipe? How To Bevel A Pipe For Welding The opening created by the beveling operation. beveling is the operation for creating a flat angled surface on the end of the pipe. There are different ways you can bevel a pipe depending on what you prefer. The standard pipe beveling angle is 37.50. When joining pipes, beveling is essential, but there are a lot of other. if. How To Bevel A Pipe For Welding.

From waterwelders.com

How to Bevel Pipe for Welding A Pipe Beveling Guide WaterWelders How To Bevel A Pipe For Welding if you want to weld two pieces of pipe together, your pipe must be beveled. When joining pipes, beveling is essential, but there are a lot of other. There are different ways you can bevel a pipe depending on what you prefer. pipe beveling is a pipe fabrication process to create an angle between the edge of the. How To Bevel A Pipe For Welding.

From www.dwt-pipetools.com

FAQ Pipe Beveling You have the question? DWT PipeTools How To Bevel A Pipe For Welding The standard pipe beveling angle is 37.50. in simpler words, beveling is altering the shape of the pipes before welding, so they fit better. There are different ways you can bevel a pipe depending on what you prefer. When joining pipes, beveling is essential, but there are a lot of other. pipe beveling is a pipe fabrication process. How To Bevel A Pipe For Welding.

From www.youtube.com

PIpe Beveling Machine for Weld Prep and Fabrication YouTube How To Bevel A Pipe For Welding pipe beveling by flame cutting or plasma cutting is a beveling process in which a gas torch or plasma torch is used to remove the edge of the pipe under great. beveling is the operation for creating a flat angled surface on the end of the pipe. in simpler words, beveling is altering the shape of the. How To Bevel A Pipe For Welding.

From www.protem.fr

Assembling Pipes by ButtWelding The Different Types of Bevels and How How To Bevel A Pipe For Welding in simpler words, beveling is altering the shape of the pipes before welding, so they fit better. The opening created by the beveling operation. When joining pipes, beveling is essential, but there are a lot of other. to bevel pipe for welding, use a grinder or pipe beveling machine to create a sloping edge along the pipe perimeter. How To Bevel A Pipe For Welding.