Acid Dip Aluminum . The method is used on aluminum to not only improve aesthetics but to also lengthen the lifespan of the treated aluminum part. the bright dip solution chemically removes a thin layer of the aluminum surface, smoothing out imperfections and creating a bright, reflective finish. bright dipping is a process for increasing the specularity or brightness of aluminum by leveling the microscopic roughness or. This smoothes out the microscopic, rough peaks and valleys on the. profiles are bright dipped, which means they’re bathed in a solution of phosphoric and nitric acid. the chemical process called bright dip anodizing is used to achieve a shiny, almost mirror finish similar to mechanical polishing. the phosphoric acid/nitric acid chemical polishing bath (bright dip) is widely used to produce specular finishes on a variety of. aluminum brite dip chemical composition / effective polishing techniques.

from cn.tradekey.com

the bright dip solution chemically removes a thin layer of the aluminum surface, smoothing out imperfections and creating a bright, reflective finish. bright dipping is a process for increasing the specularity or brightness of aluminum by leveling the microscopic roughness or. The method is used on aluminum to not only improve aesthetics but to also lengthen the lifespan of the treated aluminum part. aluminum brite dip chemical composition / effective polishing techniques. profiles are bright dipped, which means they’re bathed in a solution of phosphoric and nitric acid. the phosphoric acid/nitric acid chemical polishing bath (bright dip) is widely used to produce specular finishes on a variety of. the chemical process called bright dip anodizing is used to achieve a shiny, almost mirror finish similar to mechanical polishing. This smoothes out the microscopic, rough peaks and valleys on the.

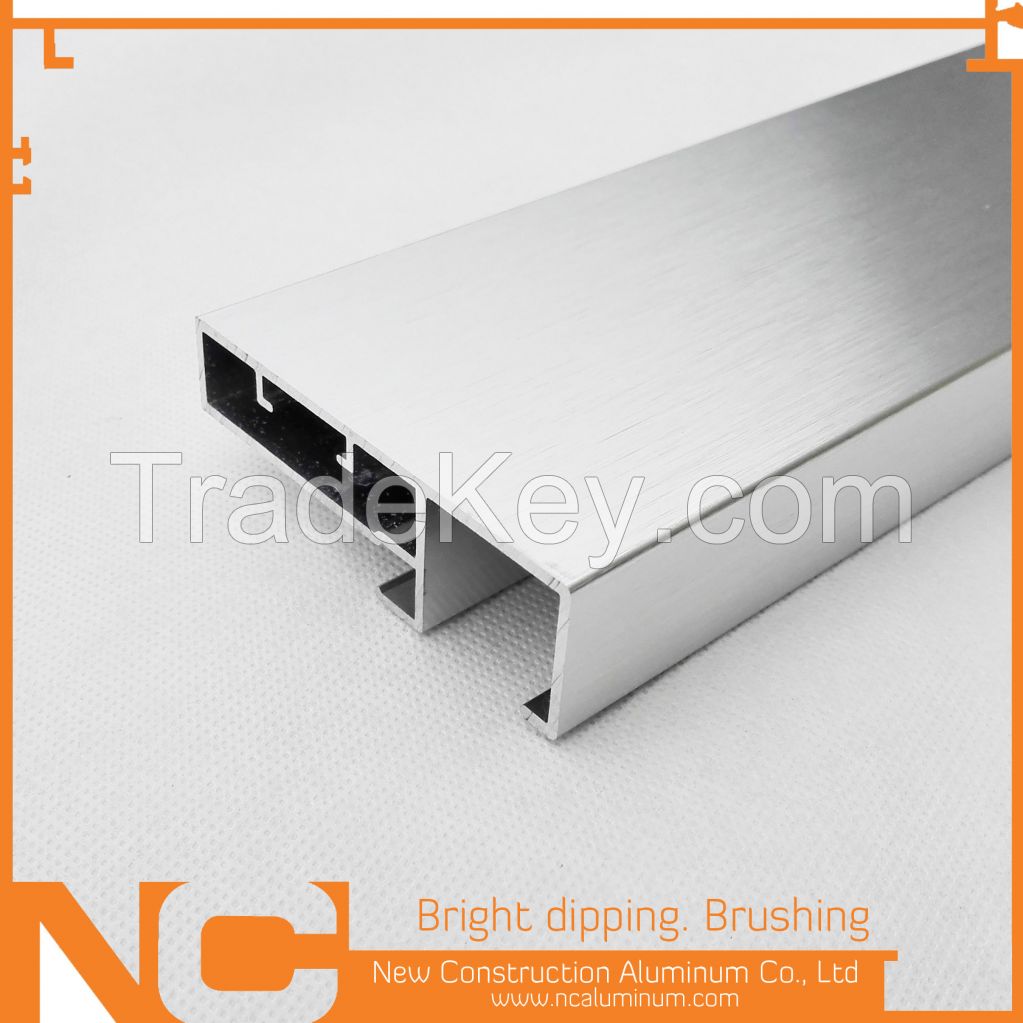

Bright dipping aluminum profile By Zhaoqing New Construction Aluminum

Acid Dip Aluminum bright dipping is a process for increasing the specularity or brightness of aluminum by leveling the microscopic roughness or. bright dipping is a process for increasing the specularity or brightness of aluminum by leveling the microscopic roughness or. the bright dip solution chemically removes a thin layer of the aluminum surface, smoothing out imperfections and creating a bright, reflective finish. profiles are bright dipped, which means they’re bathed in a solution of phosphoric and nitric acid. The method is used on aluminum to not only improve aesthetics but to also lengthen the lifespan of the treated aluminum part. the chemical process called bright dip anodizing is used to achieve a shiny, almost mirror finish similar to mechanical polishing. aluminum brite dip chemical composition / effective polishing techniques. the phosphoric acid/nitric acid chemical polishing bath (bright dip) is widely used to produce specular finishes on a variety of. This smoothes out the microscopic, rough peaks and valleys on the.

From www.youtube.com

67 Camaro after acid dipping to strip paint and treat rust YouTube Acid Dip Aluminum bright dipping is a process for increasing the specularity or brightness of aluminum by leveling the microscopic roughness or. the chemical process called bright dip anodizing is used to achieve a shiny, almost mirror finish similar to mechanical polishing. the phosphoric acid/nitric acid chemical polishing bath (bright dip) is widely used to produce specular finishes on a. Acid Dip Aluminum.

From www.thirdgen.org

Acid Dipping Aluminum rims? Third Generation FBody Message Boards Acid Dip Aluminum the bright dip solution chemically removes a thin layer of the aluminum surface, smoothing out imperfections and creating a bright, reflective finish. This smoothes out the microscopic, rough peaks and valleys on the. bright dipping is a process for increasing the specularity or brightness of aluminum by leveling the microscopic roughness or. profiles are bright dipped, which. Acid Dip Aluminum.

From www.valencesurfacetech.com

Anodizing Vs. Plating Key Differences And Similarities Acid Dip Aluminum the bright dip solution chemically removes a thin layer of the aluminum surface, smoothing out imperfections and creating a bright, reflective finish. profiles are bright dipped, which means they’re bathed in a solution of phosphoric and nitric acid. bright dipping is a process for increasing the specularity or brightness of aluminum by leveling the microscopic roughness or.. Acid Dip Aluminum.

From dxotyffpk.blob.core.windows.net

Acid Dip Aluminium at Titus Lawrence blog Acid Dip Aluminum The method is used on aluminum to not only improve aesthetics but to also lengthen the lifespan of the treated aluminum part. This smoothes out the microscopic, rough peaks and valleys on the. the bright dip solution chemically removes a thin layer of the aluminum surface, smoothing out imperfections and creating a bright, reflective finish. the chemical process. Acid Dip Aluminum.

From chem.libretexts.org

Chapter 19.6 Corrosion Chemistry LibreTexts Acid Dip Aluminum aluminum brite dip chemical composition / effective polishing techniques. the chemical process called bright dip anodizing is used to achieve a shiny, almost mirror finish similar to mechanical polishing. The method is used on aluminum to not only improve aesthetics but to also lengthen the lifespan of the treated aluminum part. the phosphoric acid/nitric acid chemical polishing. Acid Dip Aluminum.

From ncalu.com

High Quality Aluminum Bright Dipping with Colors Acid Dip Aluminum the chemical process called bright dip anodizing is used to achieve a shiny, almost mirror finish similar to mechanical polishing. aluminum brite dip chemical composition / effective polishing techniques. the phosphoric acid/nitric acid chemical polishing bath (bright dip) is widely used to produce specular finishes on a variety of. the bright dip solution chemically removes a. Acid Dip Aluminum.

From dxotyffpk.blob.core.windows.net

Acid Dip Aluminium at Titus Lawrence blog Acid Dip Aluminum This smoothes out the microscopic, rough peaks and valleys on the. the chemical process called bright dip anodizing is used to achieve a shiny, almost mirror finish similar to mechanical polishing. the phosphoric acid/nitric acid chemical polishing bath (bright dip) is widely used to produce specular finishes on a variety of. bright dipping is a process for. Acid Dip Aluminum.

From archiwum.allegro.pl

PlastiDip Plasti Dip Aluminium 400ML USA 6784558131 oficjalne Acid Dip Aluminum The method is used on aluminum to not only improve aesthetics but to also lengthen the lifespan of the treated aluminum part. This smoothes out the microscopic, rough peaks and valleys on the. the phosphoric acid/nitric acid chemical polishing bath (bright dip) is widely used to produce specular finishes on a variety of. the bright dip solution chemically. Acid Dip Aluminum.

From www.juridiconline.com

Acid Etching Acid Types, Metal Types, Applications, And, 44 OFF Acid Dip Aluminum the bright dip solution chemically removes a thin layer of the aluminum surface, smoothing out imperfections and creating a bright, reflective finish. the chemical process called bright dip anodizing is used to achieve a shiny, almost mirror finish similar to mechanical polishing. bright dipping is a process for increasing the specularity or brightness of aluminum by leveling. Acid Dip Aluminum.

From amfcalifornia.com

Dip Tanks ALL METAL FABRICATION Acid Dip Aluminum the bright dip solution chemically removes a thin layer of the aluminum surface, smoothing out imperfections and creating a bright, reflective finish. The method is used on aluminum to not only improve aesthetics but to also lengthen the lifespan of the treated aluminum part. bright dipping is a process for increasing the specularity or brightness of aluminum by. Acid Dip Aluminum.

From www.youtube.com

Dip Pre treatment plant for aluminium extrusions YouTube Acid Dip Aluminum This smoothes out the microscopic, rough peaks and valleys on the. aluminum brite dip chemical composition / effective polishing techniques. profiles are bright dipped, which means they’re bathed in a solution of phosphoric and nitric acid. The method is used on aluminum to not only improve aesthetics but to also lengthen the lifespan of the treated aluminum part.. Acid Dip Aluminum.

From www.fulldipshop.fr

Full Dip Aluminium Métallique Mat Vinyle Liquide Acid Dip Aluminum This smoothes out the microscopic, rough peaks and valleys on the. The method is used on aluminum to not only improve aesthetics but to also lengthen the lifespan of the treated aluminum part. the chemical process called bright dip anodizing is used to achieve a shiny, almost mirror finish similar to mechanical polishing. bright dipping is a process. Acid Dip Aluminum.

From cekaqqlv.blob.core.windows.net

How To Remove Spray Paint Wheels at Kara Boyd blog Acid Dip Aluminum the chemical process called bright dip anodizing is used to achieve a shiny, almost mirror finish similar to mechanical polishing. bright dipping is a process for increasing the specularity or brightness of aluminum by leveling the microscopic roughness or. The method is used on aluminum to not only improve aesthetics but to also lengthen the lifespan of the. Acid Dip Aluminum.

From www.youtube.com

DOUBLE DIPPING ON SCRUNCHED ALUMINIUM FOIL 🤩 Acrylic pouring MAGIC Acid Dip Aluminum the phosphoric acid/nitric acid chemical polishing bath (bright dip) is widely used to produce specular finishes on a variety of. the chemical process called bright dip anodizing is used to achieve a shiny, almost mirror finish similar to mechanical polishing. profiles are bright dipped, which means they’re bathed in a solution of phosphoric and nitric acid. . Acid Dip Aluminum.

From www.thirdgen.org

Acid Dipping Aluminum rims? Third Generation FBody Message Boards Acid Dip Aluminum the phosphoric acid/nitric acid chemical polishing bath (bright dip) is widely used to produce specular finishes on a variety of. The method is used on aluminum to not only improve aesthetics but to also lengthen the lifespan of the treated aluminum part. profiles are bright dipped, which means they’re bathed in a solution of phosphoric and nitric acid.. Acid Dip Aluminum.

From www.pfonline.com

Direct Copper Metallization of Aluminum Elimination of Zincate Acid Dip Aluminum bright dipping is a process for increasing the specularity or brightness of aluminum by leveling the microscopic roughness or. This smoothes out the microscopic, rough peaks and valleys on the. profiles are bright dipped, which means they’re bathed in a solution of phosphoric and nitric acid. the chemical process called bright dip anodizing is used to achieve. Acid Dip Aluminum.

From standards.iteh.ai

ASTM D173103 Standard Practices for Preparation of HotDip Aluminum Acid Dip Aluminum profiles are bright dipped, which means they’re bathed in a solution of phosphoric and nitric acid. the bright dip solution chemically removes a thin layer of the aluminum surface, smoothing out imperfections and creating a bright, reflective finish. the chemical process called bright dip anodizing is used to achieve a shiny, almost mirror finish similar to mechanical. Acid Dip Aluminum.

From cn.tradekey.com

Bright dipping aluminum profile By Zhaoqing New Construction Aluminum Acid Dip Aluminum aluminum brite dip chemical composition / effective polishing techniques. the bright dip solution chemically removes a thin layer of the aluminum surface, smoothing out imperfections and creating a bright, reflective finish. bright dipping is a process for increasing the specularity or brightness of aluminum by leveling the microscopic roughness or. The method is used on aluminum to. Acid Dip Aluminum.

From cedyzwbx.blob.core.windows.net

How To Remove Paint From Old Metal Hardware at Cody Winters blog Acid Dip Aluminum the phosphoric acid/nitric acid chemical polishing bath (bright dip) is widely used to produce specular finishes on a variety of. The method is used on aluminum to not only improve aesthetics but to also lengthen the lifespan of the treated aluminum part. This smoothes out the microscopic, rough peaks and valleys on the. the chemical process called bright. Acid Dip Aluminum.

From cn.tradekey.com

Bright dipping aluminum profile By Zhaoqing New Construction Aluminum Acid Dip Aluminum bright dipping is a process for increasing the specularity or brightness of aluminum by leveling the microscopic roughness or. This smoothes out the microscopic, rough peaks and valleys on the. aluminum brite dip chemical composition / effective polishing techniques. The method is used on aluminum to not only improve aesthetics but to also lengthen the lifespan of the. Acid Dip Aluminum.

From incertec.com

Chromic Acid Anodizing Type 1 Anodizing Services INCERTEC Acid Dip Aluminum bright dipping is a process for increasing the specularity or brightness of aluminum by leveling the microscopic roughness or. profiles are bright dipped, which means they’re bathed in a solution of phosphoric and nitric acid. the bright dip solution chemically removes a thin layer of the aluminum surface, smoothing out imperfections and creating a bright, reflective finish.. Acid Dip Aluminum.

From ncalu.com

High Quality Aluminum Bright Dipping with Colors Acid Dip Aluminum the bright dip solution chemically removes a thin layer of the aluminum surface, smoothing out imperfections and creating a bright, reflective finish. the phosphoric acid/nitric acid chemical polishing bath (bright dip) is widely used to produce specular finishes on a variety of. the chemical process called bright dip anodizing is used to achieve a shiny, almost mirror. Acid Dip Aluminum.

From www.scribd.com

Bright Dipping Aluminum PDF Nitric Acid Aluminium Acid Dip Aluminum the chemical process called bright dip anodizing is used to achieve a shiny, almost mirror finish similar to mechanical polishing. the bright dip solution chemically removes a thin layer of the aluminum surface, smoothing out imperfections and creating a bright, reflective finish. profiles are bright dipped, which means they’re bathed in a solution of phosphoric and nitric. Acid Dip Aluminum.

From www.acemetalfinishing.com

Bright Dip Anodizing of Aluminum for the Recreational Industry Acid Dip Aluminum aluminum brite dip chemical composition / effective polishing techniques. the phosphoric acid/nitric acid chemical polishing bath (bright dip) is widely used to produce specular finishes on a variety of. The method is used on aluminum to not only improve aesthetics but to also lengthen the lifespan of the treated aluminum part. This smoothes out the microscopic, rough peaks. Acid Dip Aluminum.

From astro.neutral.org

Nitric Acid The Chemical for Preparing and Desmutting Aluminium for Acid Dip Aluminum the bright dip solution chemically removes a thin layer of the aluminum surface, smoothing out imperfections and creating a bright, reflective finish. the phosphoric acid/nitric acid chemical polishing bath (bright dip) is widely used to produce specular finishes on a variety of. The method is used on aluminum to not only improve aesthetics but to also lengthen the. Acid Dip Aluminum.

From astro.neutral.org

Nitric Acid The Chemical for Preparing and Desmutting Aluminium for Acid Dip Aluminum aluminum brite dip chemical composition / effective polishing techniques. the phosphoric acid/nitric acid chemical polishing bath (bright dip) is widely used to produce specular finishes on a variety of. the chemical process called bright dip anodizing is used to achieve a shiny, almost mirror finish similar to mechanical polishing. This smoothes out the microscopic, rough peaks and. Acid Dip Aluminum.

From ncalu.com

High Quality Aluminum Bright Dipping with Colors Acid Dip Aluminum the phosphoric acid/nitric acid chemical polishing bath (bright dip) is widely used to produce specular finishes on a variety of. This smoothes out the microscopic, rough peaks and valleys on the. The method is used on aluminum to not only improve aesthetics but to also lengthen the lifespan of the treated aluminum part. the bright dip solution chemically. Acid Dip Aluminum.

From www.fulldip.ie

Full Dip Aluminium Metalizer Aerosol Fulldip.ie Acid Dip Aluminum aluminum brite dip chemical composition / effective polishing techniques. the bright dip solution chemically removes a thin layer of the aluminum surface, smoothing out imperfections and creating a bright, reflective finish. The method is used on aluminum to not only improve aesthetics but to also lengthen the lifespan of the treated aluminum part. profiles are bright dipped,. Acid Dip Aluminum.

From cn.tradekey.com

Bright dipping aluminum profile By Zhaoqing New Construction Aluminum Acid Dip Aluminum the bright dip solution chemically removes a thin layer of the aluminum surface, smoothing out imperfections and creating a bright, reflective finish. The method is used on aluminum to not only improve aesthetics but to also lengthen the lifespan of the treated aluminum part. the chemical process called bright dip anodizing is used to achieve a shiny, almost. Acid Dip Aluminum.

From waxdog.se

Plasti Dip Aluminium Acid Dip Aluminum aluminum brite dip chemical composition / effective polishing techniques. the bright dip solution chemically removes a thin layer of the aluminum surface, smoothing out imperfections and creating a bright, reflective finish. bright dipping is a process for increasing the specularity or brightness of aluminum by leveling the microscopic roughness or. The method is used on aluminum to. Acid Dip Aluminum.

From cn.tradekey.com

Bright dipping aluminum profile By Zhaoqing New Construction Aluminum Acid Dip Aluminum the bright dip solution chemically removes a thin layer of the aluminum surface, smoothing out imperfections and creating a bright, reflective finish. bright dipping is a process for increasing the specularity or brightness of aluminum by leveling the microscopic roughness or. This smoothes out the microscopic, rough peaks and valleys on the. the phosphoric acid/nitric acid chemical. Acid Dip Aluminum.

From dxotyffpk.blob.core.windows.net

Acid Dip Aluminium at Titus Lawrence blog Acid Dip Aluminum the chemical process called bright dip anodizing is used to achieve a shiny, almost mirror finish similar to mechanical polishing. aluminum brite dip chemical composition / effective polishing techniques. the bright dip solution chemically removes a thin layer of the aluminum surface, smoothing out imperfections and creating a bright, reflective finish. profiles are bright dipped, which. Acid Dip Aluminum.

From www.youtube.com

1967 Camaro before and after acid dipping YouTube Acid Dip Aluminum This smoothes out the microscopic, rough peaks and valleys on the. the chemical process called bright dip anodizing is used to achieve a shiny, almost mirror finish similar to mechanical polishing. the phosphoric acid/nitric acid chemical polishing bath (bright dip) is widely used to produce specular finishes on a variety of. aluminum brite dip chemical composition /. Acid Dip Aluminum.

From cn.tradekey.com

Bright dipping aluminum profile By Zhaoqing New Construction Aluminum Acid Dip Aluminum The method is used on aluminum to not only improve aesthetics but to also lengthen the lifespan of the treated aluminum part. the bright dip solution chemically removes a thin layer of the aluminum surface, smoothing out imperfections and creating a bright, reflective finish. This smoothes out the microscopic, rough peaks and valleys on the. bright dipping is. Acid Dip Aluminum.

From exovkwqvb.blob.core.windows.net

Acid Dip Shells at William Noto blog Acid Dip Aluminum The method is used on aluminum to not only improve aesthetics but to also lengthen the lifespan of the treated aluminum part. the phosphoric acid/nitric acid chemical polishing bath (bright dip) is widely used to produce specular finishes on a variety of. the bright dip solution chemically removes a thin layer of the aluminum surface, smoothing out imperfections. Acid Dip Aluminum.