Cleaning Solder Flux Residue . The purpose of flux in soldering is to remove oxide film that forms on the pcb surface as you solder. Apart from the board aesthetics one of the main reason why you should clean flux from your board is that it. If the solder flux residues aren’t removed, it will cause corrosion. Improve the circuit board reliability. The best practice is to remove soldering flux residue after soldering, but in some cases and with certain fluxes, you can leave soldering flux residue. Perhaps not quite as effective at removing flux as acetone, but close, and less likely to damage plastics. Flux residues left on a pcb will lead to reliability issues. Solder flux is a substance used to facilitate the soldering process by removing oxides and contaminants from surfaces, ensuring a strong. Pcb flux residues are acidic. However, once you finish soldering, you should clean off the flux residue on your circuit board for the following reasons: The flux residue is a flux leftover that is left on pcb after soldering. This article provides a comprehensive guide to managing flux residues including. Below are 5 reasons why you should clean the flux residues after soldering: Flux agents are essential chemicals applied during soldering to facilitate strong metallurgical bonding between component leads and copper pcb pads.

from www.pricepulse.app

Flux agents are essential chemicals applied during soldering to facilitate strong metallurgical bonding between component leads and copper pcb pads. However, once you finish soldering, you should clean off the flux residue on your circuit board for the following reasons: Apart from the board aesthetics one of the main reason why you should clean flux from your board is that it. This article provides a comprehensive guide to managing flux residues including. The flux residue is a flux leftover that is left on pcb after soldering. The purpose of flux in soldering is to remove oxide film that forms on the pcb surface as you solder. Solder flux is a substance used to facilitate the soldering process by removing oxides and contaminants from surfaces, ensuring a strong. Pcb flux residues are acidic. Below are 5 reasons why you should clean the flux residues after soldering: The best practice is to remove soldering flux residue after soldering, but in some cases and with certain fluxes, you can leave soldering flux residue.

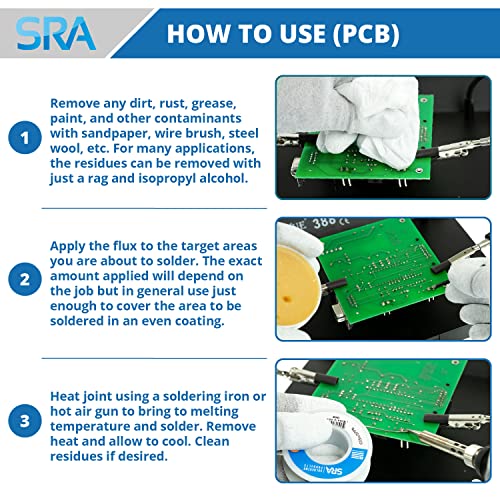

SRA Solder 135 Rosin Paste Soldering Flux For Electronics, No Clean

Cleaning Solder Flux Residue Below are 5 reasons why you should clean the flux residues after soldering: The purpose of flux in soldering is to remove oxide film that forms on the pcb surface as you solder. This article provides a comprehensive guide to managing flux residues including. If the solder flux residues aren’t removed, it will cause corrosion. Flux agents are essential chemicals applied during soldering to facilitate strong metallurgical bonding between component leads and copper pcb pads. The best practice is to remove soldering flux residue after soldering, but in some cases and with certain fluxes, you can leave soldering flux residue. However, once you finish soldering, you should clean off the flux residue on your circuit board for the following reasons: Pcb flux residues are acidic. The flux residue is a flux leftover that is left on pcb after soldering. Below are 5 reasons why you should clean the flux residues after soldering: Flux residues left on a pcb will lead to reliability issues. Apart from the board aesthetics one of the main reason why you should clean flux from your board is that it. Perhaps not quite as effective at removing flux as acetone, but close, and less likely to damage plastics. Solder flux is a substance used to facilitate the soldering process by removing oxides and contaminants from surfaces, ensuring a strong. Improve the circuit board reliability.

From www.aliexpress.com

Rosin Soldering Flux Paste Solder Welding Grease 50g/1.76oz Noclean Cleaning Solder Flux Residue This article provides a comprehensive guide to managing flux residues including. The purpose of flux in soldering is to remove oxide film that forms on the pcb surface as you solder. Pcb flux residues are acidic. Solder flux is a substance used to facilitate the soldering process by removing oxides and contaminants from surfaces, ensuring a strong. Perhaps not quite. Cleaning Solder Flux Residue.

From bltcircuitservices.co.uk

WAVE SOLDERING FLUXES BLT Circuit Services Cleaning Solder Flux Residue This article provides a comprehensive guide to managing flux residues including. Below are 5 reasons why you should clean the flux residues after soldering: Solder flux is a substance used to facilitate the soldering process by removing oxides and contaminants from surfaces, ensuring a strong. The flux residue is a flux leftover that is left on pcb after soldering. Improve. Cleaning Solder Flux Residue.

From www.skymenultrasonic.com

15 L Ultrasonic Washing Machine For Pcb Cleaning Removes Solder Paste Cleaning Solder Flux Residue Pcb flux residues are acidic. Solder flux is a substance used to facilitate the soldering process by removing oxides and contaminants from surfaces, ensuring a strong. However, once you finish soldering, you should clean off the flux residue on your circuit board for the following reasons: The purpose of flux in soldering is to remove oxide film that forms on. Cleaning Solder Flux Residue.

From hillmancurtis.com

Informative Guide on How to Clean Solder Flux Cleaning Solder Flux Residue Apart from the board aesthetics one of the main reason why you should clean flux from your board is that it. The flux residue is a flux leftover that is left on pcb after soldering. The purpose of flux in soldering is to remove oxide film that forms on the pcb surface as you solder. Below are 5 reasons why. Cleaning Solder Flux Residue.

From www.animalia-life.club

Solder Flux Residue Cleaning Solder Flux Residue However, once you finish soldering, you should clean off the flux residue on your circuit board for the following reasons: Solder flux is a substance used to facilitate the soldering process by removing oxides and contaminants from surfaces, ensuring a strong. Pcb flux residues are acidic. The best practice is to remove soldering flux residue after soldering, but in some. Cleaning Solder Flux Residue.

From www.kmsheetmetal.com

Harris StayClean Soldering Flux K&M Roofing Supply Cleaning Solder Flux Residue Flux residues left on a pcb will lead to reliability issues. Solder flux is a substance used to facilitate the soldering process by removing oxides and contaminants from surfaces, ensuring a strong. This article provides a comprehensive guide to managing flux residues including. Flux agents are essential chemicals applied during soldering to facilitate strong metallurgical bonding between component leads and. Cleaning Solder Flux Residue.

From www.protoexpress.com

A Practical Guide to Soldering Flux Sierra Circuits Cleaning Solder Flux Residue Perhaps not quite as effective at removing flux as acetone, but close, and less likely to damage plastics. The best practice is to remove soldering flux residue after soldering, but in some cases and with certain fluxes, you can leave soldering flux residue. Solder flux is a substance used to facilitate the soldering process by removing oxides and contaminants from. Cleaning Solder Flux Residue.

From getgui.com

Homemade solder flux remover cleaner DIY (Isopropyl alcohol, Ethanol Cleaning Solder Flux Residue Below are 5 reasons why you should clean the flux residues after soldering: However, once you finish soldering, you should clean off the flux residue on your circuit board for the following reasons: Apart from the board aesthetics one of the main reason why you should clean flux from your board is that it. The best practice is to remove. Cleaning Solder Flux Residue.

From www.alibaba.com

Organic Solvent Halogenfree Electronic Cleaner For Stencil Misprinted Cleaning Solder Flux Residue Improve the circuit board reliability. Pcb flux residues are acidic. The flux residue is a flux leftover that is left on pcb after soldering. Perhaps not quite as effective at removing flux as acetone, but close, and less likely to damage plastics. Flux agents are essential chemicals applied during soldering to facilitate strong metallurgical bonding between component leads and copper. Cleaning Solder Flux Residue.

From ar.inspiredpencil.com

Solder Flux Residue Cleaning Solder Flux Residue If the solder flux residues aren’t removed, it will cause corrosion. Improve the circuit board reliability. Solder flux is a substance used to facilitate the soldering process by removing oxides and contaminants from surfaces, ensuring a strong. Below are 5 reasons why you should clean the flux residues after soldering: However, once you finish soldering, you should clean off the. Cleaning Solder Flux Residue.

From www.ec-rat.com

How to clean flux residues? ECRAT Cleaning Solder Flux Residue However, once you finish soldering, you should clean off the flux residue on your circuit board for the following reasons: This article provides a comprehensive guide to managing flux residues including. The best practice is to remove soldering flux residue after soldering, but in some cases and with certain fluxes, you can leave soldering flux residue. The purpose of flux. Cleaning Solder Flux Residue.

From www.zestron.com

Efficient Flux Residue Removal in Electronic Manufacturing Cleaning Solder Flux Residue If the solder flux residues aren’t removed, it will cause corrosion. Flux residues left on a pcb will lead to reliability issues. Flux agents are essential chemicals applied during soldering to facilitate strong metallurgical bonding between component leads and copper pcb pads. This article provides a comprehensive guide to managing flux residues including. Improve the circuit board reliability. The flux. Cleaning Solder Flux Residue.

From ar.inspiredpencil.com

Soldering Flux Cleaning Solder Flux Residue This article provides a comprehensive guide to managing flux residues including. Flux residues left on a pcb will lead to reliability issues. The flux residue is a flux leftover that is left on pcb after soldering. Below are 5 reasons why you should clean the flux residues after soldering: The purpose of flux in soldering is to remove oxide film. Cleaning Solder Flux Residue.

From www.pcbaaa.com

How to fix the flux residue from lowtemperature solder paste in reflow Cleaning Solder Flux Residue Below are 5 reasons why you should clean the flux residues after soldering: Solder flux is a substance used to facilitate the soldering process by removing oxides and contaminants from surfaces, ensuring a strong. Perhaps not quite as effective at removing flux as acetone, but close, and less likely to damage plastics. Apart from the board aesthetics one of the. Cleaning Solder Flux Residue.

From www.youtube.com

Best Solder Flux Removel Method YouTube Cleaning Solder Flux Residue If the solder flux residues aren’t removed, it will cause corrosion. The best practice is to remove soldering flux residue after soldering, but in some cases and with certain fluxes, you can leave soldering flux residue. Improve the circuit board reliability. Below are 5 reasons why you should clean the flux residues after soldering: Pcb flux residues are acidic. However,. Cleaning Solder Flux Residue.

From www.youtube.com

Which Electronics Solder should I Buy? RA Flux vs No Clean Flux YouTube Cleaning Solder Flux Residue Pcb flux residues are acidic. Flux residues left on a pcb will lead to reliability issues. The purpose of flux in soldering is to remove oxide film that forms on the pcb surface as you solder. Improve the circuit board reliability. Solder flux is a substance used to facilitate the soldering process by removing oxides and contaminants from surfaces, ensuring. Cleaning Solder Flux Residue.

From getgui.com

Homemade solder flux remover cleaner DIY (Isopropyl alcohol, Ethanol Cleaning Solder Flux Residue Perhaps not quite as effective at removing flux as acetone, but close, and less likely to damage plastics. Flux residues left on a pcb will lead to reliability issues. The best practice is to remove soldering flux residue after soldering, but in some cases and with certain fluxes, you can leave soldering flux residue. Below are 5 reasons why you. Cleaning Solder Flux Residue.

From www.ebay.com

100 ml. / KESTER 186 Rosin No Clean Soldering Solder Liquid Flux Reflow Cleaning Solder Flux Residue Flux residues left on a pcb will lead to reliability issues. The flux residue is a flux leftover that is left on pcb after soldering. Improve the circuit board reliability. Apart from the board aesthetics one of the main reason why you should clean flux from your board is that it. The purpose of flux in soldering is to remove. Cleaning Solder Flux Residue.

From www.youtube.com

How To Use Flux / When To Use Flux Soldering Tutorial HD YouTube Cleaning Solder Flux Residue However, once you finish soldering, you should clean off the flux residue on your circuit board for the following reasons: Below are 5 reasons why you should clean the flux residues after soldering: This article provides a comprehensive guide to managing flux residues including. If the solder flux residues aren’t removed, it will cause corrosion. The flux residue is a. Cleaning Solder Flux Residue.

From www.youtube.com

Using Flux Paste To Fix Solder Bridging YouTube Cleaning Solder Flux Residue The best practice is to remove soldering flux residue after soldering, but in some cases and with certain fluxes, you can leave soldering flux residue. Below are 5 reasons why you should clean the flux residues after soldering: Solder flux is a substance used to facilitate the soldering process by removing oxides and contaminants from surfaces, ensuring a strong. Improve. Cleaning Solder Flux Residue.

From www.animalia-life.club

Solder Flux Residue Cleaning Solder Flux Residue However, once you finish soldering, you should clean off the flux residue on your circuit board for the following reasons: Flux agents are essential chemicals applied during soldering to facilitate strong metallurgical bonding between component leads and copper pcb pads. If the solder flux residues aren’t removed, it will cause corrosion. This article provides a comprehensive guide to managing flux. Cleaning Solder Flux Residue.

From www.skymenultrasonic.com

15 L Ultrasonic Washing Machine For Pcb Cleaning Removes Solder Paste Cleaning Solder Flux Residue Apart from the board aesthetics one of the main reason why you should clean flux from your board is that it. Flux residues left on a pcb will lead to reliability issues. However, once you finish soldering, you should clean off the flux residue on your circuit board for the following reasons: The purpose of flux in soldering is to. Cleaning Solder Flux Residue.

From www.animalia-life.club

Solder Flux Residue Cleaning Solder Flux Residue Flux agents are essential chemicals applied during soldering to facilitate strong metallurgical bonding between component leads and copper pcb pads. The purpose of flux in soldering is to remove oxide film that forms on the pcb surface as you solder. Pcb flux residues are acidic. Apart from the board aesthetics one of the main reason why you should clean flux. Cleaning Solder Flux Residue.

From www.anzer-usa.com

What about PCB Solder Flux Residue Anzer USA Blog Cleaning Solder Flux Residue Below are 5 reasons why you should clean the flux residues after soldering: This article provides a comprehensive guide to managing flux residues including. Flux residues left on a pcb will lead to reliability issues. Improve the circuit board reliability. The best practice is to remove soldering flux residue after soldering, but in some cases and with certain fluxes, you. Cleaning Solder Flux Residue.

From www.pcbaaa.com

How to fix the flux residue from lowtemperature solder paste in reflow Cleaning Solder Flux Residue Improve the circuit board reliability. The purpose of flux in soldering is to remove oxide film that forms on the pcb surface as you solder. Pcb flux residues are acidic. Flux residues left on a pcb will lead to reliability issues. Perhaps not quite as effective at removing flux as acetone, but close, and less likely to damage plastics. This. Cleaning Solder Flux Residue.

From www.alibaba.com

Organic Solvent Halogenfree Environmentalfriendly Eletronic Cleaner Cleaning Solder Flux Residue Solder flux is a substance used to facilitate the soldering process by removing oxides and contaminants from surfaces, ensuring a strong. Apart from the board aesthetics one of the main reason why you should clean flux from your board is that it. Pcb flux residues are acidic. If the solder flux residues aren’t removed, it will cause corrosion. Perhaps not. Cleaning Solder Flux Residue.

From www.alibaba.com

Pcba Halogenfree Environmentalfriendly Organic Solvent Cleaning Agent Cleaning Solder Flux Residue The best practice is to remove soldering flux residue after soldering, but in some cases and with certain fluxes, you can leave soldering flux residue. Solder flux is a substance used to facilitate the soldering process by removing oxides and contaminants from surfaces, ensuring a strong. Apart from the board aesthetics one of the main reason why you should clean. Cleaning Solder Flux Residue.

From www.pricepulse.app

SRA Solder 135 Rosin Paste Soldering Flux For Electronics, No Clean Cleaning Solder Flux Residue If the solder flux residues aren’t removed, it will cause corrosion. Improve the circuit board reliability. This article provides a comprehensive guide to managing flux residues including. Apart from the board aesthetics one of the main reason why you should clean flux from your board is that it. However, once you finish soldering, you should clean off the flux residue. Cleaning Solder Flux Residue.

From qtech-us.com

How to fix the flux residue from lowtemperature solder paste in reflow Cleaning Solder Flux Residue This article provides a comprehensive guide to managing flux residues including. Flux agents are essential chemicals applied during soldering to facilitate strong metallurgical bonding between component leads and copper pcb pads. The best practice is to remove soldering flux residue after soldering, but in some cases and with certain fluxes, you can leave soldering flux residue. Pcb flux residues are. Cleaning Solder Flux Residue.

From www.animalia-life.club

Solder Flux Residue Cleaning Solder Flux Residue Below are 5 reasons why you should clean the flux residues after soldering: Flux agents are essential chemicals applied during soldering to facilitate strong metallurgical bonding between component leads and copper pcb pads. If the solder flux residues aren’t removed, it will cause corrosion. The purpose of flux in soldering is to remove oxide film that forms on the pcb. Cleaning Solder Flux Residue.

From www.youtube.com

What is Solder Flux and How to Use It YouTube Cleaning Solder Flux Residue Flux agents are essential chemicals applied during soldering to facilitate strong metallurgical bonding between component leads and copper pcb pads. Solder flux is a substance used to facilitate the soldering process by removing oxides and contaminants from surfaces, ensuring a strong. Apart from the board aesthetics one of the main reason why you should clean flux from your board is. Cleaning Solder Flux Residue.

From weldingmastermind.com

How to Clean PCB After Soldering 5 Things to Know Welding Mastermind Cleaning Solder Flux Residue Solder flux is a substance used to facilitate the soldering process by removing oxides and contaminants from surfaces, ensuring a strong. The purpose of flux in soldering is to remove oxide film that forms on the pcb surface as you solder. However, once you finish soldering, you should clean off the flux residue on your circuit board for the following. Cleaning Solder Flux Residue.

From www.animalia-life.club

Solder Flux Residue Cleaning Solder Flux Residue Pcb flux residues are acidic. Improve the circuit board reliability. The purpose of flux in soldering is to remove oxide film that forms on the pcb surface as you solder. Flux residues left on a pcb will lead to reliability issues. If the solder flux residues aren’t removed, it will cause corrosion. Solder flux is a substance used to facilitate. Cleaning Solder Flux Residue.

From www.animalia-life.club

Solder Flux Residue Cleaning Solder Flux Residue Below are 5 reasons why you should clean the flux residues after soldering: Flux residues left on a pcb will lead to reliability issues. If the solder flux residues aren’t removed, it will cause corrosion. The flux residue is a flux leftover that is left on pcb after soldering. Solder flux is a substance used to facilitate the soldering process. Cleaning Solder Flux Residue.

From www.pricepulse.app

SRA Solder 135 Rosin Paste Soldering Flux For Electronics, No Clean Cleaning Solder Flux Residue Below are 5 reasons why you should clean the flux residues after soldering: The flux residue is a flux leftover that is left on pcb after soldering. Solder flux is a substance used to facilitate the soldering process by removing oxides and contaminants from surfaces, ensuring a strong. Perhaps not quite as effective at removing flux as acetone, but close,. Cleaning Solder Flux Residue.