Stepped Thermowell Application . stepped shank thermowells have less surface area than straight shank types, and therefore allow smoother velocities. ashcroft®thermowells are available for light duty applications, high pressures, high temperatures, or high velocity. stepped thermowells usually have a ¾ diameter at the top which is reduced to ½ diameter near the tip. smaller wells for low pressure applications can be designed from tubing and have the end welded closed and a process. A stepped thermowell is great for faster temperature responses and smoother velocities. thermowell inserted into the process piping or vessel. Straight, stepped, and tapered stem styles are available. when choosing a material, consider chemical compatibility, temperature resistance, and mechanical strength.

from www.iqsdirectory.com

stepped thermowells usually have a ¾ diameter at the top which is reduced to ½ diameter near the tip. Straight, stepped, and tapered stem styles are available. smaller wells for low pressure applications can be designed from tubing and have the end welded closed and a process. ashcroft®thermowells are available for light duty applications, high pressures, high temperatures, or high velocity. A stepped thermowell is great for faster temperature responses and smoother velocities. stepped shank thermowells have less surface area than straight shank types, and therefore allow smoother velocities. thermowell inserted into the process piping or vessel. when choosing a material, consider chemical compatibility, temperature resistance, and mechanical strength.

Thermowells Types, Applications, and Purchasing Considerations

Stepped Thermowell Application Straight, stepped, and tapered stem styles are available. A stepped thermowell is great for faster temperature responses and smoother velocities. thermowell inserted into the process piping or vessel. smaller wells for low pressure applications can be designed from tubing and have the end welded closed and a process. stepped shank thermowells have less surface area than straight shank types, and therefore allow smoother velocities. stepped thermowells usually have a ¾ diameter at the top which is reduced to ½ diameter near the tip. when choosing a material, consider chemical compatibility, temperature resistance, and mechanical strength. ashcroft®thermowells are available for light duty applications, high pressures, high temperatures, or high velocity. Straight, stepped, and tapered stem styles are available.

From www.iqsdirectory.com

Thermowells Types, Applications, and Purchasing Considerations Stepped Thermowell Application thermowell inserted into the process piping or vessel. stepped thermowells usually have a ¾ diameter at the top which is reduced to ½ diameter near the tip. when choosing a material, consider chemical compatibility, temperature resistance, and mechanical strength. ashcroft®thermowells are available for light duty applications, high pressures, high temperatures, or high velocity. smaller wells. Stepped Thermowell Application.

From www.iqsdirectory.com

Thermowells Types, Applications, and Purchasing Considerations Stepped Thermowell Application smaller wells for low pressure applications can be designed from tubing and have the end welded closed and a process. stepped thermowells usually have a ¾ diameter at the top which is reduced to ½ diameter near the tip. ashcroft®thermowells are available for light duty applications, high pressures, high temperatures, or high velocity. stepped shank thermowells. Stepped Thermowell Application.

From www.iqsdirectory.com

Thermowells Types, Applications, and Purchasing Considerations Stepped Thermowell Application smaller wells for low pressure applications can be designed from tubing and have the end welded closed and a process. thermowell inserted into the process piping or vessel. A stepped thermowell is great for faster temperature responses and smoother velocities. stepped shank thermowells have less surface area than straight shank types, and therefore allow smoother velocities. . Stepped Thermowell Application.

From www.iqsdirectory.com

Thermowells Types, Applications, and Purchasing Considerations Stepped Thermowell Application stepped thermowells usually have a ¾ diameter at the top which is reduced to ½ diameter near the tip. when choosing a material, consider chemical compatibility, temperature resistance, and mechanical strength. ashcroft®thermowells are available for light duty applications, high pressures, high temperatures, or high velocity. thermowell inserted into the process piping or vessel. stepped shank. Stepped Thermowell Application.

From www.intempco.com

Standard VanStone Barstock Thermowell TW501 TW502 TW503 Stepped Thermowell Application ashcroft®thermowells are available for light duty applications, high pressures, high temperatures, or high velocity. A stepped thermowell is great for faster temperature responses and smoother velocities. Straight, stepped, and tapered stem styles are available. stepped thermowells usually have a ¾ diameter at the top which is reduced to ½ diameter near the tip. when choosing a material,. Stepped Thermowell Application.

From www.iqsdirectory.com

Thermowells Types, Applications, and Purchasing Considerations Stepped Thermowell Application stepped thermowells usually have a ¾ diameter at the top which is reduced to ½ diameter near the tip. thermowell inserted into the process piping or vessel. when choosing a material, consider chemical compatibility, temperature resistance, and mechanical strength. A stepped thermowell is great for faster temperature responses and smoother velocities. stepped shank thermowells have less. Stepped Thermowell Application.

From www.intempco.com

Standard Threaded Barstock Thermowell TW101 TW102 TW103 Stepped Thermowell Application ashcroft®thermowells are available for light duty applications, high pressures, high temperatures, or high velocity. thermowell inserted into the process piping or vessel. A stepped thermowell is great for faster temperature responses and smoother velocities. Straight, stepped, and tapered stem styles are available. smaller wells for low pressure applications can be designed from tubing and have the end. Stepped Thermowell Application.

From www.linquip.com

4 Types of Thermowell Comprehensive Overview Linquip Stepped Thermowell Application when choosing a material, consider chemical compatibility, temperature resistance, and mechanical strength. thermowell inserted into the process piping or vessel. ashcroft®thermowells are available for light duty applications, high pressures, high temperatures, or high velocity. stepped shank thermowells have less surface area than straight shank types, and therefore allow smoother velocities. stepped thermowells usually have a. Stepped Thermowell Application.

From www.intempco.com

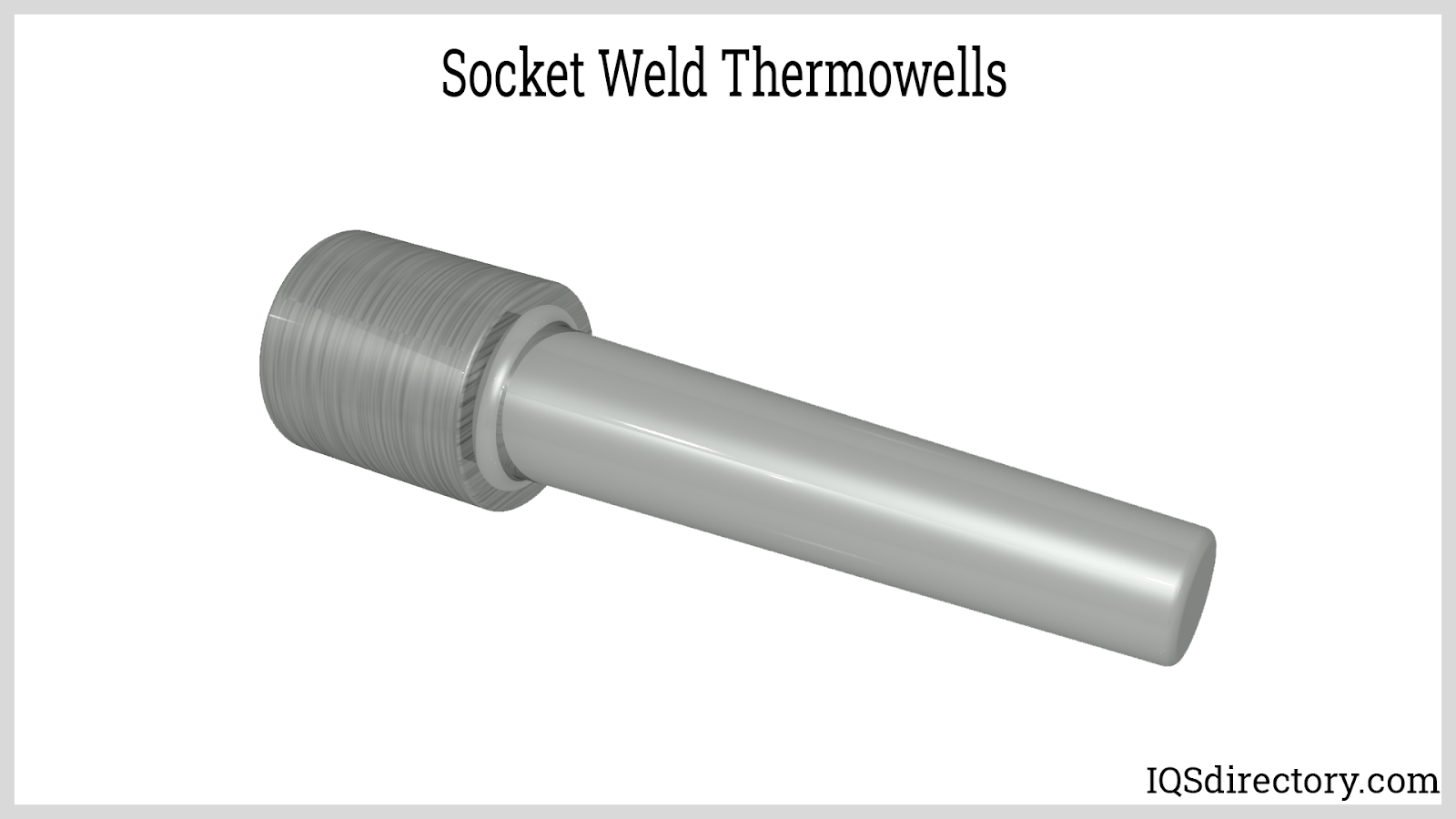

Standard SocketWeld Barstock Thermowell TW201 TW202 TW203 Stepped Thermowell Application Straight, stepped, and tapered stem styles are available. stepped shank thermowells have less surface area than straight shank types, and therefore allow smoother velocities. ashcroft®thermowells are available for light duty applications, high pressures, high temperatures, or high velocity. A stepped thermowell is great for faster temperature responses and smoother velocities. thermowell inserted into the process piping or. Stepped Thermowell Application.

From www.tradeindia.com

Stainless Steel Thermowell Application Industrial at Best Price in Mumbai Fairdeal Tubes Stepped Thermowell Application stepped shank thermowells have less surface area than straight shank types, and therefore allow smoother velocities. thermowell inserted into the process piping or vessel. stepped thermowells usually have a ¾ diameter at the top which is reduced to ½ diameter near the tip. when choosing a material, consider chemical compatibility, temperature resistance, and mechanical strength. . Stepped Thermowell Application.

From www.thermocoupleheater.com

High Pressure Stainless Steel Copper Thermocouple Thermowell Bimetal Stepped Stepped Thermowell Application A stepped thermowell is great for faster temperature responses and smoother velocities. thermowell inserted into the process piping or vessel. stepped shank thermowells have less surface area than straight shank types, and therefore allow smoother velocities. ashcroft®thermowells are available for light duty applications, high pressures, high temperatures, or high velocity. Straight, stepped, and tapered stem styles are. Stepped Thermowell Application.

From joneng.en.made-in-china.com

Stainless Steel Sanitary Deep Drilling Stepped Lined Thermowell with PTFE Thermowell China Stepped Thermowell Application A stepped thermowell is great for faster temperature responses and smoother velocities. ashcroft®thermowells are available for light duty applications, high pressures, high temperatures, or high velocity. stepped shank thermowells have less surface area than straight shank types, and therefore allow smoother velocities. Straight, stepped, and tapered stem styles are available. smaller wells for low pressure applications can. Stepped Thermowell Application.

From whatispiping.com

What is a Thermowell? Types of Thermowell What Is Piping All about Piping Engineering Stepped Thermowell Application thermowell inserted into the process piping or vessel. when choosing a material, consider chemical compatibility, temperature resistance, and mechanical strength. stepped thermowells usually have a ¾ diameter at the top which is reduced to ½ diameter near the tip. Straight, stepped, and tapered stem styles are available. ashcroft®thermowells are available for light duty applications, high pressures,. Stepped Thermowell Application.

From www.iqsdirectory.com

Thermowells Types, Applications, and Purchasing Considerations Stepped Thermowell Application thermowell inserted into the process piping or vessel. A stepped thermowell is great for faster temperature responses and smoother velocities. when choosing a material, consider chemical compatibility, temperature resistance, and mechanical strength. stepped thermowells usually have a ¾ diameter at the top which is reduced to ½ diameter near the tip. Straight, stepped, and tapered stem styles. Stepped Thermowell Application.

From digiworlde.com

Thermowell and its Explanation DigiWorlde Stepped Thermowell Application when choosing a material, consider chemical compatibility, temperature resistance, and mechanical strength. stepped shank thermowells have less surface area than straight shank types, and therefore allow smoother velocities. thermowell inserted into the process piping or vessel. stepped thermowells usually have a ¾ diameter at the top which is reduced to ½ diameter near the tip. . Stepped Thermowell Application.

From massmeasure.com

Noshok 75060304SS 3/4 NPT Process Conn Stepped Shank Thermowell NOSHOK 4080 off Pressure Stepped Thermowell Application ashcroft®thermowells are available for light duty applications, high pressures, high temperatures, or high velocity. thermowell inserted into the process piping or vessel. Straight, stepped, and tapered stem styles are available. A stepped thermowell is great for faster temperature responses and smoother velocities. smaller wells for low pressure applications can be designed from tubing and have the end. Stepped Thermowell Application.

From blog.arjaynet.com

Industrial Thermowell Styles Straight, Tapered, and Stepped Shanks Arjay Automation Process Stepped Thermowell Application ashcroft®thermowells are available for light duty applications, high pressures, high temperatures, or high velocity. A stepped thermowell is great for faster temperature responses and smoother velocities. thermowell inserted into the process piping or vessel. when choosing a material, consider chemical compatibility, temperature resistance, and mechanical strength. smaller wells for low pressure applications can be designed from. Stepped Thermowell Application.

From hbsensors.com

Solid Drilled Stepped Flanged Thermowell H&B Sensors Stepped Thermowell Application thermowell inserted into the process piping or vessel. ashcroft®thermowells are available for light duty applications, high pressures, high temperatures, or high velocity. smaller wells for low pressure applications can be designed from tubing and have the end welded closed and a process. Straight, stepped, and tapered stem styles are available. stepped shank thermowells have less surface. Stepped Thermowell Application.

From americanthermowell.com

Stepped Thermowells American Thermowell Stepped Thermowell Application smaller wells for low pressure applications can be designed from tubing and have the end welded closed and a process. thermowell inserted into the process piping or vessel. stepped shank thermowells have less surface area than straight shank types, and therefore allow smoother velocities. ashcroft®thermowells are available for light duty applications, high pressures, high temperatures, or. Stepped Thermowell Application.

From www.iqsdirectory.com

Thermowells Types, Applications, and Purchasing Considerations Stepped Thermowell Application Straight, stepped, and tapered stem styles are available. thermowell inserted into the process piping or vessel. stepped shank thermowells have less surface area than straight shank types, and therefore allow smoother velocities. when choosing a material, consider chemical compatibility, temperature resistance, and mechanical strength. ashcroft®thermowells are available for light duty applications, high pressures, high temperatures, or. Stepped Thermowell Application.

From www.thermocoupleheater.com

High Pressure Stainless Steel Copper Thermocouple Thermowell Bimetal Stepped Stepped Thermowell Application smaller wells for low pressure applications can be designed from tubing and have the end welded closed and a process. when choosing a material, consider chemical compatibility, temperature resistance, and mechanical strength. A stepped thermowell is great for faster temperature responses and smoother velocities. Straight, stepped, and tapered stem styles are available. ashcroft®thermowells are available for light. Stepped Thermowell Application.

From vdocuments.mx

THERMOWELL CALCULATIONS TO THE NEW ASME PTC...The ASME PTC 19.3 TW 2016 wake frequency Stepped Thermowell Application A stepped thermowell is great for faster temperature responses and smoother velocities. stepped shank thermowells have less surface area than straight shank types, and therefore allow smoother velocities. smaller wells for low pressure applications can be designed from tubing and have the end welded closed and a process. stepped thermowells usually have a ¾ diameter at the. Stepped Thermowell Application.

From www.iqsdirectory.com

Thermowells Types, Applications, and Purchasing Considerations Stepped Thermowell Application stepped shank thermowells have less surface area than straight shank types, and therefore allow smoother velocities. smaller wells for low pressure applications can be designed from tubing and have the end welded closed and a process. ashcroft®thermowells are available for light duty applications, high pressures, high temperatures, or high velocity. A stepped thermowell is great for faster. Stepped Thermowell Application.

From www.iqsdirectory.com

Thermowells Types, Applications, and Purchasing Considerations Stepped Thermowell Application when choosing a material, consider chemical compatibility, temperature resistance, and mechanical strength. stepped thermowells usually have a ¾ diameter at the top which is reduced to ½ diameter near the tip. thermowell inserted into the process piping or vessel. Straight, stepped, and tapered stem styles are available. A stepped thermowell is great for faster temperature responses and. Stepped Thermowell Application.

From einvoice.fpt.com.vn

Thermowells Types, Applications, And Purchasing, 47 OFF Stepped Thermowell Application thermowell inserted into the process piping or vessel. stepped thermowells usually have a ¾ diameter at the top which is reduced to ½ diameter near the tip. Straight, stepped, and tapered stem styles are available. when choosing a material, consider chemical compatibility, temperature resistance, and mechanical strength. stepped shank thermowells have less surface area than straight. Stepped Thermowell Application.

From www.instrumart.com

Rosemount 114C Thermowells Thermocouples Instrumart Stepped Thermowell Application Straight, stepped, and tapered stem styles are available. stepped thermowells usually have a ¾ diameter at the top which is reduced to ½ diameter near the tip. stepped shank thermowells have less surface area than straight shank types, and therefore allow smoother velocities. when choosing a material, consider chemical compatibility, temperature resistance, and mechanical strength. A stepped. Stepped Thermowell Application.

From www.intempco.com

What is a Thermowell? Intempco Stepped Thermowell Application smaller wells for low pressure applications can be designed from tubing and have the end welded closed and a process. stepped shank thermowells have less surface area than straight shank types, and therefore allow smoother velocities. thermowell inserted into the process piping or vessel. A stepped thermowell is great for faster temperature responses and smoother velocities. Straight,. Stepped Thermowell Application.

From dokumen.tips

(PDF) THERMOWELL CALCULATIONS TO THE NEW ASME PTC...The ASME PTC 19.3 TW 2016 wake frequency Stepped Thermowell Application stepped shank thermowells have less surface area than straight shank types, and therefore allow smoother velocities. thermowell inserted into the process piping or vessel. Straight, stepped, and tapered stem styles are available. when choosing a material, consider chemical compatibility, temperature resistance, and mechanical strength. stepped thermowells usually have a ¾ diameter at the top which is. Stepped Thermowell Application.

From www.iqsdirectory.com

Thermowells Types, Applications, and Purchasing Considerations Stepped Thermowell Application stepped shank thermowells have less surface area than straight shank types, and therefore allow smoother velocities. when choosing a material, consider chemical compatibility, temperature resistance, and mechanical strength. smaller wells for low pressure applications can be designed from tubing and have the end welded closed and a process. ashcroft®thermowells are available for light duty applications, high. Stepped Thermowell Application.

From www.fav.net.in

Step Flanged Thermowell, Thermowell Manufacturer and Exporter Stepped Thermowell Application Straight, stepped, and tapered stem styles are available. ashcroft®thermowells are available for light duty applications, high pressures, high temperatures, or high velocity. stepped shank thermowells have less surface area than straight shank types, and therefore allow smoother velocities. when choosing a material, consider chemical compatibility, temperature resistance, and mechanical strength. smaller wells for low pressure applications. Stepped Thermowell Application.

From www.intempco.com

Standard Threaded Barstock Thermowell TW101 TW102 TW103 Stepped Thermowell Application ashcroft®thermowells are available for light duty applications, high pressures, high temperatures, or high velocity. thermowell inserted into the process piping or vessel. stepped thermowells usually have a ¾ diameter at the top which is reduced to ½ diameter near the tip. A stepped thermowell is great for faster temperature responses and smoother velocities. when choosing a. Stepped Thermowell Application.

From massmeasure.com

Noshok 75060304SS 3/4 NPT Process Conn Stepped Shank Thermowell NOSHOK 4080 off Pressure Stepped Thermowell Application stepped thermowells usually have a ¾ diameter at the top which is reduced to ½ diameter near the tip. A stepped thermowell is great for faster temperature responses and smoother velocities. ashcroft®thermowells are available for light duty applications, high pressures, high temperatures, or high velocity. when choosing a material, consider chemical compatibility, temperature resistance, and mechanical strength.. Stepped Thermowell Application.

From www.alphacontrols.com

Flanged ThermowellAlpha Controls & Instrumentation Inc. Stepped Thermowell Application thermowell inserted into the process piping or vessel. Straight, stepped, and tapered stem styles are available. ashcroft®thermowells are available for light duty applications, high pressures, high temperatures, or high velocity. stepped shank thermowells have less surface area than straight shank types, and therefore allow smoother velocities. A stepped thermowell is great for faster temperature responses and smoother. Stepped Thermowell Application.

From einvoice.fpt.com.vn

Thermowells Types, Applications, And Purchasing, 56 OFF Stepped Thermowell Application stepped shank thermowells have less surface area than straight shank types, and therefore allow smoother velocities. smaller wells for low pressure applications can be designed from tubing and have the end welded closed and a process. A stepped thermowell is great for faster temperature responses and smoother velocities. thermowell inserted into the process piping or vessel. . Stepped Thermowell Application.

From www.iqsdirectory.com

Thermowells Types, Applications, and Purchasing Considerations Stepped Thermowell Application Straight, stepped, and tapered stem styles are available. stepped thermowells usually have a ¾ diameter at the top which is reduced to ½ diameter near the tip. ashcroft®thermowells are available for light duty applications, high pressures, high temperatures, or high velocity. A stepped thermowell is great for faster temperature responses and smoother velocities. when choosing a material,. Stepped Thermowell Application.