Hobbing Process Parameters . learn how to use a manufacturing simulation tool to optimize gear hobbing processes based on chip geometries, process forces. (1) start initial hobbing parameter. — the objective presented in this paper is to support the process design by suggesting process parameters. learn about the basics of gear hobbing, a generating process that uses a cutting tool with gashes to form gear teeth. — the optimum hobbing parameter sets obtained from the calculated pareto frontier can provide a feasible solution for manufacturers to solve. — from fig. — the results reveal that (i) a balance can be achieved among machining time, production cost and tool life via. — reliable and reasonable prediction of hobbing parameters can effectively reduce energy consumption.

from www.motorgearengineer.com

— the objective presented in this paper is to support the process design by suggesting process parameters. — the optimum hobbing parameter sets obtained from the calculated pareto frontier can provide a feasible solution for manufacturers to solve. learn about the basics of gear hobbing, a generating process that uses a cutting tool with gashes to form gear teeth. learn how to use a manufacturing simulation tool to optimize gear hobbing processes based on chip geometries, process forces. — the results reveal that (i) a balance can be achieved among machining time, production cost and tool life via. — from fig. — reliable and reasonable prediction of hobbing parameters can effectively reduce energy consumption. (1) start initial hobbing parameter.

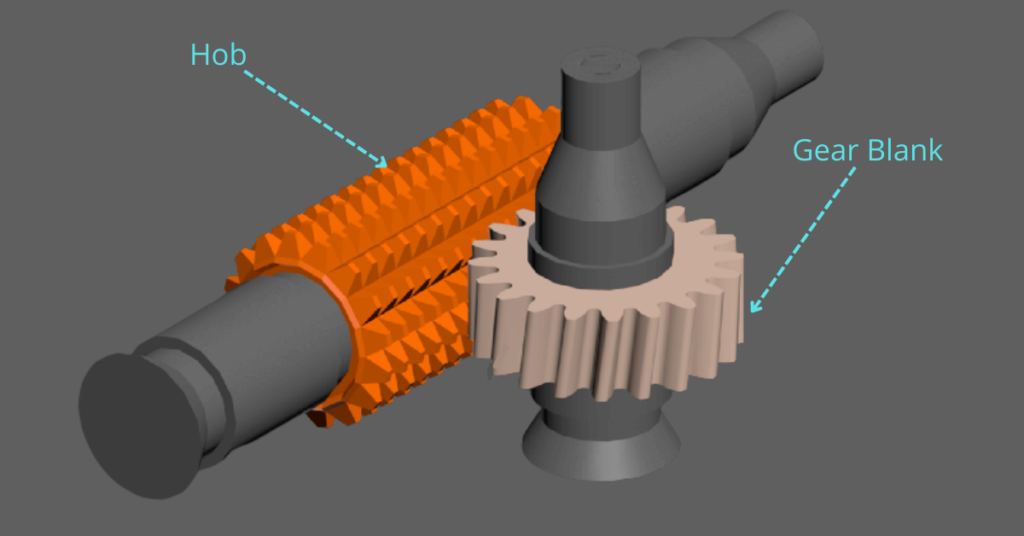

Gear Hobbing Service Introduction, Working, and Applications

Hobbing Process Parameters — reliable and reasonable prediction of hobbing parameters can effectively reduce energy consumption. — from fig. learn how to use a manufacturing simulation tool to optimize gear hobbing processes based on chip geometries, process forces. — the results reveal that (i) a balance can be achieved among machining time, production cost and tool life via. learn about the basics of gear hobbing, a generating process that uses a cutting tool with gashes to form gear teeth. — the objective presented in this paper is to support the process design by suggesting process parameters. — the optimum hobbing parameter sets obtained from the calculated pareto frontier can provide a feasible solution for manufacturers to solve. (1) start initial hobbing parameter. — reliable and reasonable prediction of hobbing parameters can effectively reduce energy consumption.

From www.mdpi.com

Applied Sciences Free FullText A Study on the Effect of Gear Hobbing Process Parameters — the objective presented in this paper is to support the process design by suggesting process parameters. — the results reveal that (i) a balance can be achieved among machining time, production cost and tool life via. (1) start initial hobbing parameter. learn how to use a manufacturing simulation tool to optimize gear hobbing processes based on. Hobbing Process Parameters.

From learnmech.com

Working Of Gear Hobbing ProcessAdvantages and Limitations Hobbing Process Parameters (1) start initial hobbing parameter. learn how to use a manufacturing simulation tool to optimize gear hobbing processes based on chip geometries, process forces. — from fig. — the results reveal that (i) a balance can be achieved among machining time, production cost and tool life via. — reliable and reasonable prediction of hobbing parameters can. Hobbing Process Parameters.

From www.mdpi.com

Applied Sciences Free FullText A Study on the Effect of Gear Hobbing Process Parameters learn how to use a manufacturing simulation tool to optimize gear hobbing processes based on chip geometries, process forces. — from fig. — the optimum hobbing parameter sets obtained from the calculated pareto frontier can provide a feasible solution for manufacturers to solve. learn about the basics of gear hobbing, a generating process that uses a. Hobbing Process Parameters.

From www.slideserve.com

PPT THE INDEXING MECHANISM OF GEAR HOBBING MACHINE PowerPoint Hobbing Process Parameters learn about the basics of gear hobbing, a generating process that uses a cutting tool with gashes to form gear teeth. — reliable and reasonable prediction of hobbing parameters can effectively reduce energy consumption. — the results reveal that (i) a balance can be achieved among machining time, production cost and tool life via. learn how. Hobbing Process Parameters.

From www.researchgate.net

A sketch outline of gear hobbing process Download Scientific Diagram Hobbing Process Parameters — the results reveal that (i) a balance can be achieved among machining time, production cost and tool life via. learn how to use a manufacturing simulation tool to optimize gear hobbing processes based on chip geometries, process forces. — the objective presented in this paper is to support the process design by suggesting process parameters. . Hobbing Process Parameters.

From www.mdpi.com

Applied Sciences Free FullText A Study on the Effect of Gear Hobbing Process Parameters learn about the basics of gear hobbing, a generating process that uses a cutting tool with gashes to form gear teeth. — from fig. (1) start initial hobbing parameter. learn how to use a manufacturing simulation tool to optimize gear hobbing processes based on chip geometries, process forces. — the objective presented in this paper is. Hobbing Process Parameters.

From www.mdpi.com

Applied Sciences Free FullText A Study on the Effect of Gear Hobbing Process Parameters learn about the basics of gear hobbing, a generating process that uses a cutting tool with gashes to form gear teeth. — the optimum hobbing parameter sets obtained from the calculated pareto frontier can provide a feasible solution for manufacturers to solve. — the objective presented in this paper is to support the process design by suggesting. Hobbing Process Parameters.

From www.researchgate.net

Description of hobbing process parameter problem Download Scientific Hobbing Process Parameters — the results reveal that (i) a balance can be achieved among machining time, production cost and tool life via. — reliable and reasonable prediction of hobbing parameters can effectively reduce energy consumption. — the objective presented in this paper is to support the process design by suggesting process parameters. — the optimum hobbing parameter sets. Hobbing Process Parameters.

From gearhobbingsolutions.com

Gear hobbing process Overview CuttingEdge CNC Gear Hobbing Hobbing Process Parameters learn about the basics of gear hobbing, a generating process that uses a cutting tool with gashes to form gear teeth. — the results reveal that (i) a balance can be achieved among machining time, production cost and tool life via. (1) start initial hobbing parameter. — reliable and reasonable prediction of hobbing parameters can effectively reduce. Hobbing Process Parameters.

From www.researchgate.net

Moving path of the hobbing cutter in the gear hobbing process Hobbing Process Parameters — the objective presented in this paper is to support the process design by suggesting process parameters. learn how to use a manufacturing simulation tool to optimize gear hobbing processes based on chip geometries, process forces. — the optimum hobbing parameter sets obtained from the calculated pareto frontier can provide a feasible solution for manufacturers to solve.. Hobbing Process Parameters.

From www.researchgate.net

The schematic diagram of the hobbing process Download Scientific Diagram Hobbing Process Parameters learn how to use a manufacturing simulation tool to optimize gear hobbing processes based on chip geometries, process forces. (1) start initial hobbing parameter. — from fig. — reliable and reasonable prediction of hobbing parameters can effectively reduce energy consumption. learn about the basics of gear hobbing, a generating process that uses a cutting tool with. Hobbing Process Parameters.

From thors.com

Gear Hobbing Cutting Parameters to Optimize the Hobbing Process Hobbing Process Parameters — the results reveal that (i) a balance can be achieved among machining time, production cost and tool life via. — the optimum hobbing parameter sets obtained from the calculated pareto frontier can provide a feasible solution for manufacturers to solve. learn about the basics of gear hobbing, a generating process that uses a cutting tool with. Hobbing Process Parameters.

From geartechnologyindia.com

Key Basic Conditions in the Hobbing Process to Achieve Finish Gear Hobbing Process Parameters — the objective presented in this paper is to support the process design by suggesting process parameters. (1) start initial hobbing parameter. — reliable and reasonable prediction of hobbing parameters can effectively reduce energy consumption. — the optimum hobbing parameter sets obtained from the calculated pareto frontier can provide a feasible solution for manufacturers to solve. . Hobbing Process Parameters.

From www.mdpi.com

Applied Sciences Free FullText A Study on the Effect of Gear Hobbing Process Parameters — from fig. learn about the basics of gear hobbing, a generating process that uses a cutting tool with gashes to form gear teeth. — reliable and reasonable prediction of hobbing parameters can effectively reduce energy consumption. — the results reveal that (i) a balance can be achieved among machining time, production cost and tool life. Hobbing Process Parameters.

From www.mdpi.com

Applied Sciences Free FullText A Study on the Effect of Gear Hobbing Process Parameters (1) start initial hobbing parameter. learn about the basics of gear hobbing, a generating process that uses a cutting tool with gashes to form gear teeth. — the optimum hobbing parameter sets obtained from the calculated pareto frontier can provide a feasible solution for manufacturers to solve. — from fig. — the objective presented in this. Hobbing Process Parameters.

From www.liebherr.com

LC 300 500 Gear hobbing machines Liebherr Liebherr Hobbing Process Parameters learn about the basics of gear hobbing, a generating process that uses a cutting tool with gashes to form gear teeth. learn how to use a manufacturing simulation tool to optimize gear hobbing processes based on chip geometries, process forces. — reliable and reasonable prediction of hobbing parameters can effectively reduce energy consumption. — the optimum. Hobbing Process Parameters.

From thors.com

Gear Hobbing Cutting Parameters to Optimize the Hobbing Process Hobbing Process Parameters — the results reveal that (i) a balance can be achieved among machining time, production cost and tool life via. — reliable and reasonable prediction of hobbing parameters can effectively reduce energy consumption. (1) start initial hobbing parameter. — from fig. learn about the basics of gear hobbing, a generating process that uses a cutting tool. Hobbing Process Parameters.

From www.researchgate.net

The hobbing process parameter optimization model Download Scientific Hobbing Process Parameters learn about the basics of gear hobbing, a generating process that uses a cutting tool with gashes to form gear teeth. (1) start initial hobbing parameter. learn how to use a manufacturing simulation tool to optimize gear hobbing processes based on chip geometries, process forces. — the results reveal that (i) a balance can be achieved among. Hobbing Process Parameters.

From www.youtube.com

The process of Gear Hobbing. Engineer's Academy YouTube Hobbing Process Parameters — the objective presented in this paper is to support the process design by suggesting process parameters. learn how to use a manufacturing simulation tool to optimize gear hobbing processes based on chip geometries, process forces. (1) start initial hobbing parameter. — the optimum hobbing parameter sets obtained from the calculated pareto frontier can provide a feasible. Hobbing Process Parameters.

From www.semanticscholar.org

Figure 1 from Analysis method of importance degree of hobbing process Hobbing Process Parameters — the objective presented in this paper is to support the process design by suggesting process parameters. (1) start initial hobbing parameter. — reliable and reasonable prediction of hobbing parameters can effectively reduce energy consumption. learn about the basics of gear hobbing, a generating process that uses a cutting tool with gashes to form gear teeth. . Hobbing Process Parameters.

From www.researchgate.net

Basic kinematics and essential parameters of gear hobbing Download Hobbing Process Parameters — the results reveal that (i) a balance can be achieved among machining time, production cost and tool life via. — reliable and reasonable prediction of hobbing parameters can effectively reduce energy consumption. (1) start initial hobbing parameter. — the objective presented in this paper is to support the process design by suggesting process parameters. learn. Hobbing Process Parameters.

From www.mdpi.com

Energies Free FullText An Intelligent Deep Learning Technique for Hobbing Process Parameters — the results reveal that (i) a balance can be achieved among machining time, production cost and tool life via. learn how to use a manufacturing simulation tool to optimize gear hobbing processes based on chip geometries, process forces. — the optimum hobbing parameter sets obtained from the calculated pareto frontier can provide a feasible solution for. Hobbing Process Parameters.

From www.motorgearengineer.com

Gear Hobbing Service Introduction, Working, and Applications Hobbing Process Parameters (1) start initial hobbing parameter. — the objective presented in this paper is to support the process design by suggesting process parameters. — the optimum hobbing parameter sets obtained from the calculated pareto frontier can provide a feasible solution for manufacturers to solve. — from fig. learn about the basics of gear hobbing, a generating process. Hobbing Process Parameters.

From www.scribd.com

Productivity Improvement of Gear Hobbing Process by Analysing Process Hobbing Process Parameters — the optimum hobbing parameter sets obtained from the calculated pareto frontier can provide a feasible solution for manufacturers to solve. — from fig. (1) start initial hobbing parameter. — the objective presented in this paper is to support the process design by suggesting process parameters. — reliable and reasonable prediction of hobbing parameters can effectively. Hobbing Process Parameters.

From www.researchgate.net

Schematic diagram of hobbing process Download Scientific Diagram Hobbing Process Parameters — the optimum hobbing parameter sets obtained from the calculated pareto frontier can provide a feasible solution for manufacturers to solve. — reliable and reasonable prediction of hobbing parameters can effectively reduce energy consumption. — from fig. learn about the basics of gear hobbing, a generating process that uses a cutting tool with gashes to form. Hobbing Process Parameters.

From www.researchgate.net

(PDF) A Study on the Effect of Gear Hobbing Process Parameters on the Hobbing Process Parameters — the optimum hobbing parameter sets obtained from the calculated pareto frontier can provide a feasible solution for manufacturers to solve. learn about the basics of gear hobbing, a generating process that uses a cutting tool with gashes to form gear teeth. — reliable and reasonable prediction of hobbing parameters can effectively reduce energy consumption. —. Hobbing Process Parameters.

From www.researchgate.net

Relationship flow between process parameters and hobbing performance Hobbing Process Parameters learn how to use a manufacturing simulation tool to optimize gear hobbing processes based on chip geometries, process forces. (1) start initial hobbing parameter. — the optimum hobbing parameter sets obtained from the calculated pareto frontier can provide a feasible solution for manufacturers to solve. learn about the basics of gear hobbing, a generating process that uses. Hobbing Process Parameters.

From www.mdpi.com

Applied Sciences Free FullText A Study on the Effect of Gear Hobbing Process Parameters — the optimum hobbing parameter sets obtained from the calculated pareto frontier can provide a feasible solution for manufacturers to solve. — the results reveal that (i) a balance can be achieved among machining time, production cost and tool life via. learn how to use a manufacturing simulation tool to optimize gear hobbing processes based on chip. Hobbing Process Parameters.

From www.scribd.com

Analysis of Process Parameters in Hobbing Using PDF Gear Industries Hobbing Process Parameters learn how to use a manufacturing simulation tool to optimize gear hobbing processes based on chip geometries, process forces. — from fig. — the optimum hobbing parameter sets obtained from the calculated pareto frontier can provide a feasible solution for manufacturers to solve. learn about the basics of gear hobbing, a generating process that uses a. Hobbing Process Parameters.

From www.researchgate.net

(PDF) Analysis of Process Parameters in Hobbing using Optimization Hobbing Process Parameters — the objective presented in this paper is to support the process design by suggesting process parameters. — from fig. — the results reveal that (i) a balance can be achieved among machining time, production cost and tool life via. learn about the basics of gear hobbing, a generating process that uses a cutting tool with. Hobbing Process Parameters.

From www.semanticscholar.org

Figure 1.1 from A Review on Gear Hobbing Process Semantic Scholar Hobbing Process Parameters (1) start initial hobbing parameter. learn about the basics of gear hobbing, a generating process that uses a cutting tool with gashes to form gear teeth. — from fig. — reliable and reasonable prediction of hobbing parameters can effectively reduce energy consumption. — the results reveal that (i) a balance can be achieved among machining time,. Hobbing Process Parameters.

From www.researchgate.net

(PDF) Gear Hobbing Cutting Process Simulation and Tool Wear Prediction Hobbing Process Parameters — from fig. — the objective presented in this paper is to support the process design by suggesting process parameters. — the results reveal that (i) a balance can be achieved among machining time, production cost and tool life via. learn how to use a manufacturing simulation tool to optimize gear hobbing processes based on chip. Hobbing Process Parameters.

From www.thelibraryofmanufacturing.com

Metal Hobbing Hobbing Process Parameters — the optimum hobbing parameter sets obtained from the calculated pareto frontier can provide a feasible solution for manufacturers to solve. learn about the basics of gear hobbing, a generating process that uses a cutting tool with gashes to form gear teeth. learn how to use a manufacturing simulation tool to optimize gear hobbing processes based on. Hobbing Process Parameters.

From www.youtube.com

Gear Hobbing Process Compilation Kompilasi Proses Gear Hobbing Hobbing Process Parameters — the optimum hobbing parameter sets obtained from the calculated pareto frontier can provide a feasible solution for manufacturers to solve. learn how to use a manufacturing simulation tool to optimize gear hobbing processes based on chip geometries, process forces. learn about the basics of gear hobbing, a generating process that uses a cutting tool with gashes. Hobbing Process Parameters.

From www.mdpi.com

Algorithms Free FullText InProcess Monitoring of Hobbing Process Hobbing Process Parameters — the results reveal that (i) a balance can be achieved among machining time, production cost and tool life via. — from fig. — the optimum hobbing parameter sets obtained from the calculated pareto frontier can provide a feasible solution for manufacturers to solve. — reliable and reasonable prediction of hobbing parameters can effectively reduce energy. Hobbing Process Parameters.