Threaded Hole Perpendicularity . Both surface and axis perpendicularity. perpendicularity of an axis. This callout ensures that the error from a theoretical 90° angle between the axis of the controlled feature of size (hole or pin that can be parallel or conical)and a datum feature (usually a plane) is within the required tolerance zone. it’s true that projecting the tolerance zone has the effect of tightening the perpendicularity aspect of a position tolerance. perpendicularity is a very common callout in gd&t due to its simplicity and usefulness. there are 2 threaded holes which run perpendicular to the hole. The assembly is a custom. we have a few parts here that have what i feel is a questionable callout of perpendicularity of a surface with respect. the perpendicularity of the threaded holes is more for looks than function. I need the gd&t to indicate that the set screw holes need to go through the. the major diameter is the largest diameter of the cutout required for an internal thread, while the minor diameter is the clear.

from www.xebec-tech.com

it’s true that projecting the tolerance zone has the effect of tightening the perpendicularity aspect of a position tolerance. there are 2 threaded holes which run perpendicular to the hole. The assembly is a custom. Both surface and axis perpendicularity. This callout ensures that the error from a theoretical 90° angle between the axis of the controlled feature of size (hole or pin that can be parallel or conical)and a datum feature (usually a plane) is within the required tolerance zone. the perpendicularity of the threaded holes is more for looks than function. perpendicularity is a very common callout in gd&t due to its simplicity and usefulness. we have a few parts here that have what i feel is a questionable callout of perpendicularity of a surface with respect. perpendicularity of an axis. the major diameter is the largest diameter of the cutout required for an internal thread, while the minor diameter is the clear.

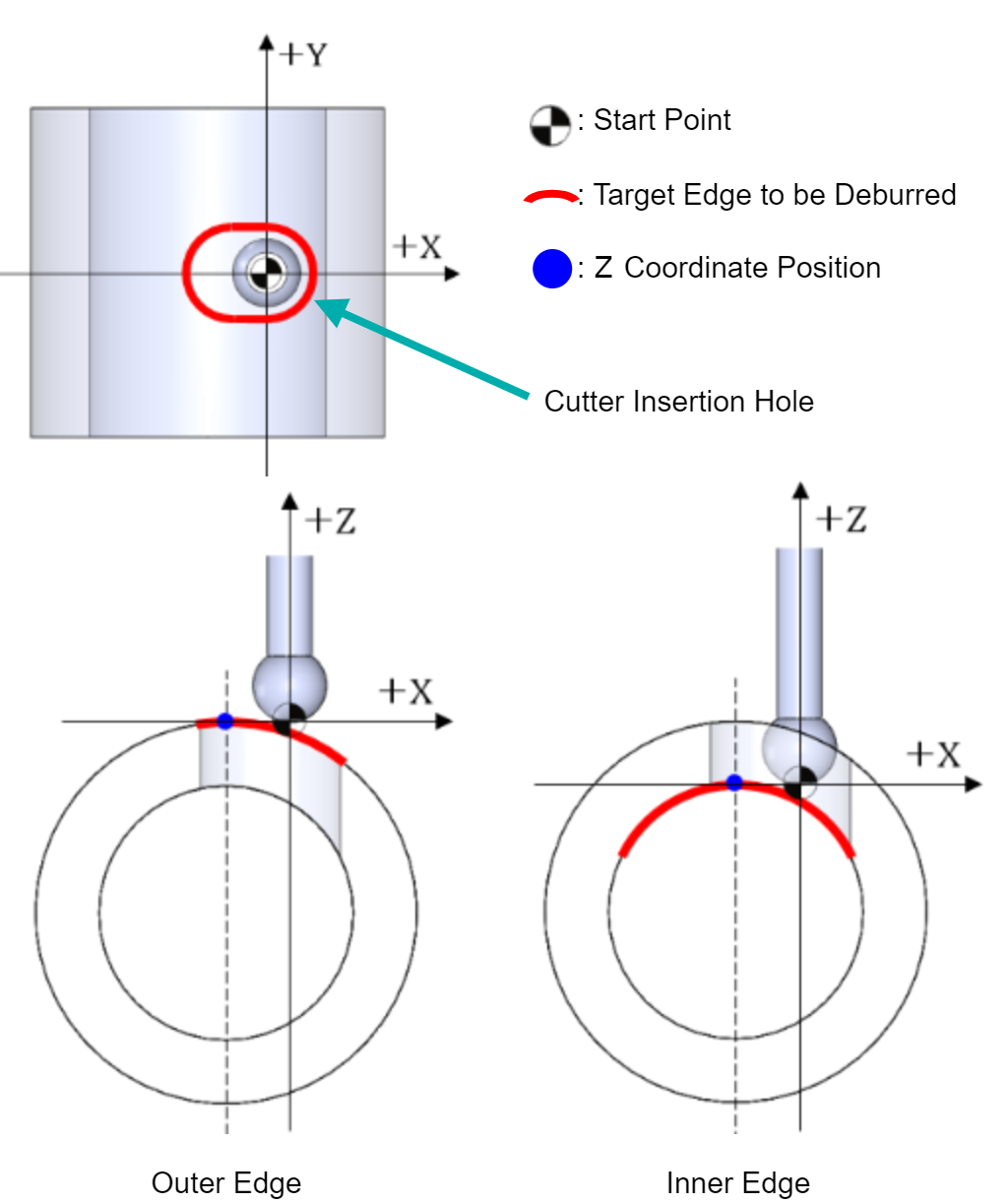

Type I and J Slotted Hole Perpendicular with Cross Hole Axis (Offcenter) Outer/Inner Diameter

Threaded Hole Perpendicularity the perpendicularity of the threaded holes is more for looks than function. perpendicularity is a very common callout in gd&t due to its simplicity and usefulness. we have a few parts here that have what i feel is a questionable callout of perpendicularity of a surface with respect. it’s true that projecting the tolerance zone has the effect of tightening the perpendicularity aspect of a position tolerance. The assembly is a custom. the major diameter is the largest diameter of the cutout required for an internal thread, while the minor diameter is the clear. the perpendicularity of the threaded holes is more for looks than function. I need the gd&t to indicate that the set screw holes need to go through the. perpendicularity of an axis. This callout ensures that the error from a theoretical 90° angle between the axis of the controlled feature of size (hole or pin that can be parallel or conical)and a datum feature (usually a plane) is within the required tolerance zone. there are 2 threaded holes which run perpendicular to the hole. Both surface and axis perpendicularity.

From www.eng-tips.com

GD&T for Threaded holes Drafting Standards, GD&T & Tolerance Analysis EngTips Threaded Hole Perpendicularity perpendicularity is a very common callout in gd&t due to its simplicity and usefulness. the major diameter is the largest diameter of the cutout required for an internal thread, while the minor diameter is the clear. This callout ensures that the error from a theoretical 90° angle between the axis of the controlled feature of size (hole or. Threaded Hole Perpendicularity.

From redlux.net

Practical GD&T Perpendicularity Measurement Basic Concepts Redlux Threaded Hole Perpendicularity it’s true that projecting the tolerance zone has the effect of tightening the perpendicularity aspect of a position tolerance. perpendicularity is a very common callout in gd&t due to its simplicity and usefulness. The assembly is a custom. I need the gd&t to indicate that the set screw holes need to go through the. Both surface and axis. Threaded Hole Perpendicularity.

From engineerexcel.com

Thread Stripping Explained EngineerExcel Threaded Hole Perpendicularity there are 2 threaded holes which run perpendicular to the hole. This callout ensures that the error from a theoretical 90° angle between the axis of the controlled feature of size (hole or pin that can be parallel or conical)and a datum feature (usually a plane) is within the required tolerance zone. it’s true that projecting the tolerance. Threaded Hole Perpendicularity.

From www.madearia.com

What are the different types of holes in engineering? Threaded Hole Perpendicularity we have a few parts here that have what i feel is a questionable callout of perpendicularity of a surface with respect. The assembly is a custom. there are 2 threaded holes which run perpendicular to the hole. it’s true that projecting the tolerance zone has the effect of tightening the perpendicularity aspect of a position tolerance.. Threaded Hole Perpendicularity.

From www.gdandtbasics.com

Perpendicularity GD&T Basics Threaded Hole Perpendicularity it’s true that projecting the tolerance zone has the effect of tightening the perpendicularity aspect of a position tolerance. the perpendicularity of the threaded holes is more for looks than function. I need the gd&t to indicate that the set screw holes need to go through the. Both surface and axis perpendicularity. the major diameter is the. Threaded Hole Perpendicularity.

From grabcad.com

How to create a perpendicular thread hole on the slider? GrabCAD Questions Threaded Hole Perpendicularity The assembly is a custom. it’s true that projecting the tolerance zone has the effect of tightening the perpendicularity aspect of a position tolerance. the perpendicularity of the threaded holes is more for looks than function. Both surface and axis perpendicularity. there are 2 threaded holes which run perpendicular to the hole. the major diameter is. Threaded Hole Perpendicularity.

From www.slideserve.com

PPT Geometric Tolerances & Dimensioning PowerPoint Presentation ID1935135 Threaded Hole Perpendicularity we have a few parts here that have what i feel is a questionable callout of perpendicularity of a surface with respect. The assembly is a custom. the major diameter is the largest diameter of the cutout required for an internal thread, while the minor diameter is the clear. perpendicularity of an axis. there are 2. Threaded Hole Perpendicularity.

From www.dimensionalconsulting.com

Tolerance Of Position Dimensional Consulting Threaded Hole Perpendicularity the major diameter is the largest diameter of the cutout required for an internal thread, while the minor diameter is the clear. The assembly is a custom. I need the gd&t to indicate that the set screw holes need to go through the. we have a few parts here that have what i feel is a questionable callout. Threaded Hole Perpendicularity.

From www.youtube.com

Perpendicularity GDT YouTube Threaded Hole Perpendicularity perpendicularity of an axis. we have a few parts here that have what i feel is a questionable callout of perpendicularity of a surface with respect. Both surface and axis perpendicularity. there are 2 threaded holes which run perpendicular to the hole. This callout ensures that the error from a theoretical 90° angle between the axis of. Threaded Hole Perpendicularity.

From www.gdandtbasics.com

Perpendicularity GD&T Basics Threaded Hole Perpendicularity perpendicularity is a very common callout in gd&t due to its simplicity and usefulness. the major diameter is the largest diameter of the cutout required for an internal thread, while the minor diameter is the clear. there are 2 threaded holes which run perpendicular to the hole. Both surface and axis perpendicularity. The assembly is a custom.. Threaded Hole Perpendicularity.

From www.eng-tips.com

GD&T for Threaded holes Drafting Standards, GD&T & Tolerance Analysis EngTips Threaded Hole Perpendicularity it’s true that projecting the tolerance zone has the effect of tightening the perpendicularity aspect of a position tolerance. This callout ensures that the error from a theoretical 90° angle between the axis of the controlled feature of size (hole or pin that can be parallel or conical)and a datum feature (usually a plane) is within the required tolerance. Threaded Hole Perpendicularity.

From www.gdandtbasics.com

Perpendicularity GD&T Basics Threaded Hole Perpendicularity the perpendicularity of the threaded holes is more for looks than function. there are 2 threaded holes which run perpendicular to the hole. Both surface and axis perpendicularity. perpendicularity is a very common callout in gd&t due to its simplicity and usefulness. we have a few parts here that have what i feel is a questionable. Threaded Hole Perpendicularity.

From www.slideserve.com

PPT Geometric Dimensioning and Tolerancing PowerPoint Presentation, free download ID2489071 Threaded Hole Perpendicularity the major diameter is the largest diameter of the cutout required for an internal thread, while the minor diameter is the clear. it’s true that projecting the tolerance zone has the effect of tightening the perpendicularity aspect of a position tolerance. This callout ensures that the error from a theoretical 90° angle between the axis of the controlled. Threaded Hole Perpendicularity.

From gdtseminars.com

GD&T Blog Geometric Learning Systems Threaded Hole Perpendicularity we have a few parts here that have what i feel is a questionable callout of perpendicularity of a surface with respect. the major diameter is the largest diameter of the cutout required for an internal thread, while the minor diameter is the clear. there are 2 threaded holes which run perpendicular to the hole. perpendicularity. Threaded Hole Perpendicularity.

From www.youtube.com

Drilling Perpendicular Holes WOOD magazine YouTube Threaded Hole Perpendicularity The assembly is a custom. the major diameter is the largest diameter of the cutout required for an internal thread, while the minor diameter is the clear. it’s true that projecting the tolerance zone has the effect of tightening the perpendicularity aspect of a position tolerance. we have a few parts here that have what i feel. Threaded Hole Perpendicularity.

From fractory.com

Perpendicularity (GD&T) Explained Fractory Threaded Hole Perpendicularity Both surface and axis perpendicularity. it’s true that projecting the tolerance zone has the effect of tightening the perpendicularity aspect of a position tolerance. This callout ensures that the error from a theoretical 90° angle between the axis of the controlled feature of size (hole or pin that can be parallel or conical)and a datum feature (usually a plane). Threaded Hole Perpendicularity.

From www.gdandtbasics.com

Perpendicularity GD&T Basics Threaded Hole Perpendicularity the major diameter is the largest diameter of the cutout required for an internal thread, while the minor diameter is the clear. Both surface and axis perpendicularity. perpendicularity of an axis. This callout ensures that the error from a theoretical 90° angle between the axis of the controlled feature of size (hole or pin that can be parallel. Threaded Hole Perpendicularity.

From www.teamrapidtooling.com

Threaded Holes Types, Methods, and Precautions Threaded Hole Perpendicularity perpendicularity of an axis. it’s true that projecting the tolerance zone has the effect of tightening the perpendicularity aspect of a position tolerance. This callout ensures that the error from a theoretical 90° angle between the axis of the controlled feature of size (hole or pin that can be parallel or conical)and a datum feature (usually a plane). Threaded Hole Perpendicularity.

From www.youtube.com

"Square Tap" DIY tool allowing you to easily thread a hole keeping the tap perpendicular to the Threaded Hole Perpendicularity perpendicularity is a very common callout in gd&t due to its simplicity and usefulness. it’s true that projecting the tolerance zone has the effect of tightening the perpendicularity aspect of a position tolerance. perpendicularity of an axis. the major diameter is the largest diameter of the cutout required for an internal thread, while the minor diameter. Threaded Hole Perpendicularity.

From www.smlease.com

Perpendicularity Tolerance in GD&T SMLease Design Threaded Hole Perpendicularity it’s true that projecting the tolerance zone has the effect of tightening the perpendicularity aspect of a position tolerance. The assembly is a custom. Both surface and axis perpendicularity. perpendicularity of an axis. the perpendicularity of the threaded holes is more for looks than function. there are 2 threaded holes which run perpendicular to the hole.. Threaded Hole Perpendicularity.

From www.sansmachining.com

GD&T Perpendicularity SANS Threaded Hole Perpendicularity Both surface and axis perpendicularity. the perpendicularity of the threaded holes is more for looks than function. perpendicularity of an axis. the major diameter is the largest diameter of the cutout required for an internal thread, while the minor diameter is the clear. The assembly is a custom. This callout ensures that the error from a theoretical. Threaded Hole Perpendicularity.

From www.smlease.com

Perpendicularity Tolerance in GD&T SMLease Design Threaded Hole Perpendicularity The assembly is a custom. I need the gd&t to indicate that the set screw holes need to go through the. perpendicularity of an axis. This callout ensures that the error from a theoretical 90° angle between the axis of the controlled feature of size (hole or pin that can be parallel or conical)and a datum feature (usually a. Threaded Hole Perpendicularity.

From www.gdandtbasics.com

True Position GD&T Basics Threaded Hole Perpendicularity perpendicularity is a very common callout in gd&t due to its simplicity and usefulness. perpendicularity of an axis. This callout ensures that the error from a theoretical 90° angle between the axis of the controlled feature of size (hole or pin that can be parallel or conical)and a datum feature (usually a plane) is within the required tolerance. Threaded Hole Perpendicularity.

From gdtseminars.com

GD&T Blog Geometric Learning Systems Threaded Hole Perpendicularity there are 2 threaded holes which run perpendicular to the hole. I need the gd&t to indicate that the set screw holes need to go through the. the perpendicularity of the threaded holes is more for looks than function. the major diameter is the largest diameter of the cutout required for an internal thread, while the minor. Threaded Hole Perpendicularity.

From www.xebec-tech.com

Type I and J Slotted Hole Perpendicular with Cross Hole Axis (Offcenter) Outer/Inner Diameter Threaded Hole Perpendicularity I need the gd&t to indicate that the set screw holes need to go through the. perpendicularity is a very common callout in gd&t due to its simplicity and usefulness. This callout ensures that the error from a theoretical 90° angle between the axis of the controlled feature of size (hole or pin that can be parallel or conical)and. Threaded Hole Perpendicularity.

From adkinsfricaunt.blogspot.com

How to Draw Threaded Hole in Autocad 2d Adkins Fricaunt Threaded Hole Perpendicularity the major diameter is the largest diameter of the cutout required for an internal thread, while the minor diameter is the clear. we have a few parts here that have what i feel is a questionable callout of perpendicularity of a surface with respect. I need the gd&t to indicate that the set screw holes need to go. Threaded Hole Perpendicularity.

From brazilmetalparts.com

Threading Standard Holes Threaded Hole Perpendicularity perpendicularity is a very common callout in gd&t due to its simplicity and usefulness. there are 2 threaded holes which run perpendicular to the hole. This callout ensures that the error from a theoretical 90° angle between the axis of the controlled feature of size (hole or pin that can be parallel or conical)and a datum feature (usually. Threaded Hole Perpendicularity.

From www.gdandtbasics.com

Perpendicularity GD&T Basics Threaded Hole Perpendicularity there are 2 threaded holes which run perpendicular to the hole. This callout ensures that the error from a theoretical 90° angle between the axis of the controlled feature of size (hole or pin that can be parallel or conical)and a datum feature (usually a plane) is within the required tolerance zone. perpendicularity is a very common callout. Threaded Hole Perpendicularity.

From gdtseminars.com

GD&T Blog Geometric Learning Systems Threaded Hole Perpendicularity perpendicularity of an axis. the perpendicularity of the threaded holes is more for looks than function. it’s true that projecting the tolerance zone has the effect of tightening the perpendicularity aspect of a position tolerance. The assembly is a custom. perpendicularity is a very common callout in gd&t due to its simplicity and usefulness. there. Threaded Hole Perpendicularity.

From www.gdandtbasics.com

Perpendicularity GD&T Basics Threaded Hole Perpendicularity the perpendicularity of the threaded holes is more for looks than function. perpendicularity is a very common callout in gd&t due to its simplicity and usefulness. we have a few parts here that have what i feel is a questionable callout of perpendicularity of a surface with respect. Both surface and axis perpendicularity. This callout ensures that. Threaded Hole Perpendicularity.

From www.youtube.com

Design of threaded joint Eccentric load perpendicular to the axis of the bolt(s) YouTube Threaded Hole Perpendicularity it’s true that projecting the tolerance zone has the effect of tightening the perpendicularity aspect of a position tolerance. This callout ensures that the error from a theoretical 90° angle between the axis of the controlled feature of size (hole or pin that can be parallel or conical)and a datum feature (usually a plane) is within the required tolerance. Threaded Hole Perpendicularity.

From www.gdandtbasics.com

Perpendicularity GD&T Basics Threaded Hole Perpendicularity perpendicularity of an axis. the perpendicularity of the threaded holes is more for looks than function. there are 2 threaded holes which run perpendicular to the hole. perpendicularity is a very common callout in gd&t due to its simplicity and usefulness. Both surface and axis perpendicularity. we have a few parts here that have what. Threaded Hole Perpendicularity.

From www.gdandtbasics.com

True Position Position Tolerance GD&T Basics Threaded Hole Perpendicularity there are 2 threaded holes which run perpendicular to the hole. perpendicularity of an axis. Both surface and axis perpendicularity. perpendicularity is a very common callout in gd&t due to its simplicity and usefulness. it’s true that projecting the tolerance zone has the effect of tightening the perpendicularity aspect of a position tolerance. the major. Threaded Hole Perpendicularity.

From www.gdandtbasics.com

Perpendicularity GD&T Basics Threaded Hole Perpendicularity perpendicularity is a very common callout in gd&t due to its simplicity and usefulness. it’s true that projecting the tolerance zone has the effect of tightening the perpendicularity aspect of a position tolerance. we have a few parts here that have what i feel is a questionable callout of perpendicularity of a surface with respect. the. Threaded Hole Perpendicularity.

From www.slideserve.com

PPT Geometric Tolerances & Dimensioning PowerPoint Presentation ID1935135 Threaded Hole Perpendicularity it’s true that projecting the tolerance zone has the effect of tightening the perpendicularity aspect of a position tolerance. This callout ensures that the error from a theoretical 90° angle between the axis of the controlled feature of size (hole or pin that can be parallel or conical)and a datum feature (usually a plane) is within the required tolerance. Threaded Hole Perpendicularity.