How To Make A Circlip Groove . to keep the axial play between the circlip and the bearing to a minimum the following formula can be used as a guide; Made by nickole mini systems, i like them a lot. — cutting circlip grooves in pieces that are too long to be rotated on a rotary table or swung on a lathe, can be a. — i take a standard keyseat cutter and mount the shank on a v block and grind it to the thickness i want (usually i. They have a variety of sizes and thicknesses. — i've got these mini grooving & parting tools that would do the job. — is there some sort of little saw or milling cutter that would be used to make a groove in a bore for an internal circlip?. — i would first find out which brand of circlip that you intend to use.

from advancedathletesperformance.com.au

— cutting circlip grooves in pieces that are too long to be rotated on a rotary table or swung on a lathe, can be a. — is there some sort of little saw or milling cutter that would be used to make a groove in a bore for an internal circlip?. — i would first find out which brand of circlip that you intend to use. — i've got these mini grooving & parting tools that would do the job. — i take a standard keyseat cutter and mount the shank on a v block and grind it to the thickness i want (usually i. They have a variety of sizes and thicknesses. Made by nickole mini systems, i like them a lot. to keep the axial play between the circlip and the bearing to a minimum the following formula can be used as a guide;

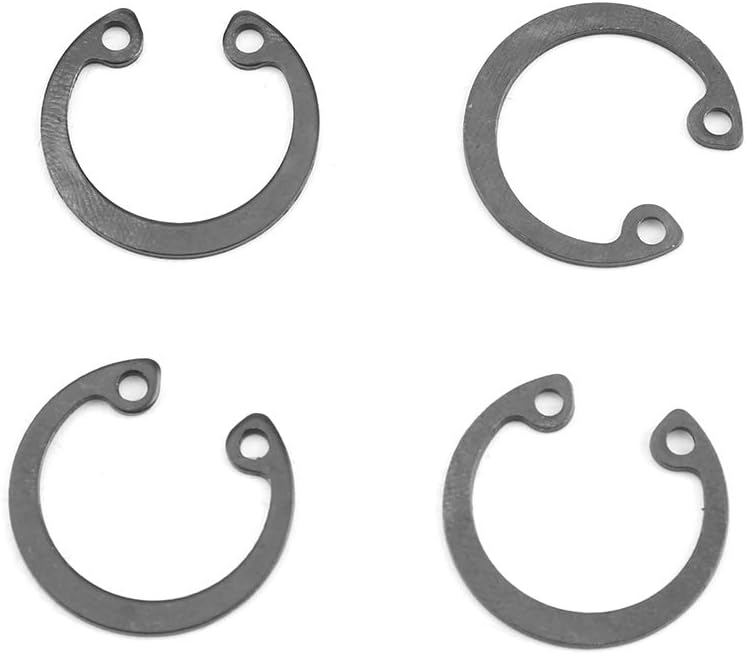

Pins Circlip Assortment Can Be Snapped into a Machined Groove on a

How To Make A Circlip Groove Made by nickole mini systems, i like them a lot. — is there some sort of little saw or milling cutter that would be used to make a groove in a bore for an internal circlip?. They have a variety of sizes and thicknesses. — i've got these mini grooving & parting tools that would do the job. — i take a standard keyseat cutter and mount the shank on a v block and grind it to the thickness i want (usually i. Made by nickole mini systems, i like them a lot. — cutting circlip grooves in pieces that are too long to be rotated on a rotary table or swung on a lathe, can be a. to keep the axial play between the circlip and the bearing to a minimum the following formula can be used as a guide; — i would first find out which brand of circlip that you intend to use.

From www.ifanger.com

Circlip groove tools Internal turning Ifanger How To Make A Circlip Groove They have a variety of sizes and thicknesses. — i've got these mini grooving & parting tools that would do the job. to keep the axial play between the circlip and the bearing to a minimum the following formula can be used as a guide; — cutting circlip grooves in pieces that are too long to be. How To Make A Circlip Groove.

From www.designworldonline.com

Retaining ring basics video Stamped, eared, eclip, and constant section How To Make A Circlip Groove Made by nickole mini systems, i like them a lot. — is there some sort of little saw or milling cutter that would be used to make a groove in a bore for an internal circlip?. — i take a standard keyseat cutter and mount the shank on a v block and grind it to the thickness i. How To Make A Circlip Groove.

From www.cutwel.co.uk

Circlip Simmill Grooving Insert Cutwel Groove Milling Tools How To Make A Circlip Groove Made by nickole mini systems, i like them a lot. — i've got these mini grooving & parting tools that would do the job. — i take a standard keyseat cutter and mount the shank on a v block and grind it to the thickness i want (usually i. They have a variety of sizes and thicknesses. . How To Make A Circlip Groove.

From www.wonkeedonkeetools.co.uk

What is a circlip? Wonkee Donkee Tools How To Make A Circlip Groove — i've got these mini grooving & parting tools that would do the job. — i take a standard keyseat cutter and mount the shank on a v block and grind it to the thickness i want (usually i. Made by nickole mini systems, i like them a lot. — cutting circlip grooves in pieces that are. How To Make A Circlip Groove.

From advancedathletesperformance.com.au

Pins Circlip Assortment Can Be Snapped into a Machined Groove on a How To Make A Circlip Groove — cutting circlip grooves in pieces that are too long to be rotated on a rotary table or swung on a lathe, can be a. They have a variety of sizes and thicknesses. — i take a standard keyseat cutter and mount the shank on a v block and grind it to the thickness i want (usually i.. How To Make A Circlip Groove.

From www.youtube.com

Groove MIlling YouTube How To Make A Circlip Groove — i would first find out which brand of circlip that you intend to use. — is there some sort of little saw or milling cutter that would be used to make a groove in a bore for an internal circlip?. to keep the axial play between the circlip and the bearing to a minimum the following. How To Make A Circlip Groove.

From www.youtube.com

Cutting Grooves On A Manual Lathe YouTube How To Make A Circlip Groove — is there some sort of little saw or milling cutter that would be used to make a groove in a bore for an internal circlip?. — i've got these mini grooving & parting tools that would do the job. to keep the axial play between the circlip and the bearing to a minimum the following formula. How To Make A Circlip Groove.

From www.youtube.com

How to draw metric internal circlip din472 with relation and family How To Make A Circlip Groove They have a variety of sizes and thicknesses. — is there some sort of little saw or milling cutter that would be used to make a groove in a bore for an internal circlip?. — i take a standard keyseat cutter and mount the shank on a v block and grind it to the thickness i want (usually. How To Make A Circlip Groove.

From www.turbosport.co.uk

How to machining circlips groove on Mahle piston? How To Make A Circlip Groove They have a variety of sizes and thicknesses. — is there some sort of little saw or milling cutter that would be used to make a groove in a bore for an internal circlip?. — cutting circlip grooves in pieces that are too long to be rotated on a rotary table or swung on a lathe, can be. How To Make A Circlip Groove.

From serviceacsurabaya.me

CIRCLIP DIN 471 PDF How To Make A Circlip Groove — i take a standard keyseat cutter and mount the shank on a v block and grind it to the thickness i want (usually i. — is there some sort of little saw or milling cutter that would be used to make a groove in a bore for an internal circlip?. — cutting circlip grooves in pieces. How To Make A Circlip Groove.

From www.youtube.com

SolidWorks How to make a CIRCLIP YouTube How To Make A Circlip Groove — i've got these mini grooving & parting tools that would do the job. Made by nickole mini systems, i like them a lot. to keep the axial play between the circlip and the bearing to a minimum the following formula can be used as a guide; They have a variety of sizes and thicknesses. — is. How To Make A Circlip Groove.

From www.turbosport.co.uk

How to machining circlips groove on Mahle piston? How To Make A Circlip Groove — i would first find out which brand of circlip that you intend to use. They have a variety of sizes and thicknesses. Made by nickole mini systems, i like them a lot. — i've got these mini grooving & parting tools that would do the job. — is there some sort of little saw or milling. How To Make A Circlip Groove.

From advancedathletesperformance.com.au

Pins Circlip Assortment Can Be Snapped into a Machined Groove on a How To Make A Circlip Groove — is there some sort of little saw or milling cutter that would be used to make a groove in a bore for an internal circlip?. They have a variety of sizes and thicknesses. — i've got these mini grooving & parting tools that would do the job. — i take a standard keyseat cutter and mount. How To Make A Circlip Groove.

From edu.svet.gob.gt

Standard External Circlip Groove Dimensions edu.svet.gob.gt How To Make A Circlip Groove to keep the axial play between the circlip and the bearing to a minimum the following formula can be used as a guide; — i take a standard keyseat cutter and mount the shank on a v block and grind it to the thickness i want (usually i. — i would first find out which brand of. How To Make A Circlip Groove.

From www.brtmotorsport.co.uk

M10x1 Female Circlip Groove With Milled Flat How To Make A Circlip Groove They have a variety of sizes and thicknesses. — i would first find out which brand of circlip that you intend to use. — i've got these mini grooving & parting tools that would do the job. to keep the axial play between the circlip and the bearing to a minimum the following formula can be used. How To Make A Circlip Groove.

From www.wonkeedonkeetools.co.uk

What is a circlip? Wonkee Donkee Tools How To Make A Circlip Groove — i would first find out which brand of circlip that you intend to use. — i've got these mini grooving & parting tools that would do the job. — i take a standard keyseat cutter and mount the shank on a v block and grind it to the thickness i want (usually i. — cutting. How To Make A Circlip Groove.

From advancedathletesperformance.com.au

Pins Circlip Assortment Can Be Snapped into a Machined Groove on a How To Make A Circlip Groove — i would first find out which brand of circlip that you intend to use. — i've got these mini grooving & parting tools that would do the job. — cutting circlip grooves in pieces that are too long to be rotated on a rotary table or swung on a lathe, can be a. to keep. How To Make A Circlip Groove.

From nwb.uk.com

NWB Circlips How To Make A Circlip Groove — cutting circlip grooves in pieces that are too long to be rotated on a rotary table or swung on a lathe, can be a. — is there some sort of little saw or milling cutter that would be used to make a groove in a bore for an internal circlip?. to keep the axial play between. How To Make A Circlip Groove.

From www.youtube.com

Creation of Circlip grooves and Circlips SolidGenius for Creo YouTube How To Make A Circlip Groove — cutting circlip grooves in pieces that are too long to be rotated on a rotary table or swung on a lathe, can be a. Made by nickole mini systems, i like them a lot. — i take a standard keyseat cutter and mount the shank on a v block and grind it to the thickness i want. How To Make A Circlip Groove.

From www.youtube.com

Cutting Grease Grooves on cnc lathe. YouTube How To Make A Circlip Groove — i've got these mini grooving & parting tools that would do the job. — is there some sort of little saw or milling cutter that would be used to make a groove in a bore for an internal circlip?. — i would first find out which brand of circlip that you intend to use. —. How To Make A Circlip Groove.

From advancedathletesperformance.com.au

Pins Circlip Assortment Can Be Snapped into a Machined Groove on a How To Make A Circlip Groove — is there some sort of little saw or milling cutter that would be used to make a groove in a bore for an internal circlip?. — i would first find out which brand of circlip that you intend to use. to keep the axial play between the circlip and the bearing to a minimum the following. How To Make A Circlip Groove.

From dokumen.tips

(PDF) EXTERNAL CIRCLIPS DIN 471 IS How To Make A Circlip Groove — i would first find out which brand of circlip that you intend to use. to keep the axial play between the circlip and the bearing to a minimum the following formula can be used as a guide; — i've got these mini grooving & parting tools that would do the job. — is there some. How To Make A Circlip Groove.

From diyquickly.com

How to Install Circlips Without Pliers 10 Easy Ways (2024) How To Make A Circlip Groove to keep the axial play between the circlip and the bearing to a minimum the following formula can be used as a guide; — cutting circlip grooves in pieces that are too long to be rotated on a rotary table or swung on a lathe, can be a. — i take a standard keyseat cutter and mount. How To Make A Circlip Groove.

From www.thumpertalk.com

Is my secondary shaft made correctly? circlip jumped out of its groove How To Make A Circlip Groove to keep the axial play between the circlip and the bearing to a minimum the following formula can be used as a guide; They have a variety of sizes and thicknesses. — i take a standard keyseat cutter and mount the shank on a v block and grind it to the thickness i want (usually i. —. How To Make A Circlip Groove.

From www.youtube.com

Circlip groove using narex indexing head YouTube How To Make A Circlip Groove — cutting circlip grooves in pieces that are too long to be rotated on a rotary table or swung on a lathe, can be a. — is there some sort of little saw or milling cutter that would be used to make a groove in a bore for an internal circlip?. — i've got these mini grooving. How To Make A Circlip Groove.

From www.youtube.com

Solid Edge Week 5 exercises How to create a Circlip YouTube How To Make A Circlip Groove — i would first find out which brand of circlip that you intend to use. — is there some sort of little saw or milling cutter that would be used to make a groove in a bore for an internal circlip?. They have a variety of sizes and thicknesses. Made by nickole mini systems, i like them a. How To Make A Circlip Groove.

From www.youtube.com

Cutting the circlip groove YouTube How To Make A Circlip Groove They have a variety of sizes and thicknesses. — cutting circlip grooves in pieces that are too long to be rotated on a rotary table or swung on a lathe, can be a. Made by nickole mini systems, i like them a lot. — i take a standard keyseat cutter and mount the shank on a v block. How To Make A Circlip Groove.

From www.youtube.com

How to create a Circlip YouTube How To Make A Circlip Groove — is there some sort of little saw or milling cutter that would be used to make a groove in a bore for an internal circlip?. Made by nickole mini systems, i like them a lot. They have a variety of sizes and thicknesses. to keep the axial play between the circlip and the bearing to a minimum. How To Make A Circlip Groove.

From ifanger.com

Circlip groove cutters Turning Ifanger How To Make A Circlip Groove Made by nickole mini systems, i like them a lot. to keep the axial play between the circlip and the bearing to a minimum the following formula can be used as a guide; — is there some sort of little saw or milling cutter that would be used to make a groove in a bore for an internal. How To Make A Circlip Groove.

From www.scribd.com

Internal Circlip For Semi Circular Groove PDF How To Make A Circlip Groove — cutting circlip grooves in pieces that are too long to be rotated on a rotary table or swung on a lathe, can be a. — i take a standard keyseat cutter and mount the shank on a v block and grind it to the thickness i want (usually i. — is there some sort of little. How To Make A Circlip Groove.

From www.wonkeedonkeetools.co.uk

What is a circlip? Wonkee Donkee Tools How To Make A Circlip Groove Made by nickole mini systems, i like them a lot. — i would first find out which brand of circlip that you intend to use. — is there some sort of little saw or milling cutter that would be used to make a groove in a bore for an internal circlip?. — i've got these mini grooving. How To Make A Circlip Groove.

From www.youtube.com

Solidworks Circlip YouTube How To Make A Circlip Groove Made by nickole mini systems, i like them a lot. to keep the axial play between the circlip and the bearing to a minimum the following formula can be used as a guide; They have a variety of sizes and thicknesses. — i would first find out which brand of circlip that you intend to use. —. How To Make A Circlip Groove.

From www.indiamart.com

Carbide Circlip Groove Insert For Industrial, Rs 300 /piece R.K How To Make A Circlip Groove Made by nickole mini systems, i like them a lot. — is there some sort of little saw or milling cutter that would be used to make a groove in a bore for an internal circlip?. — i've got these mini grooving & parting tools that would do the job. — cutting circlip grooves in pieces that. How To Make A Circlip Groove.

From diyquickly.com

How to Install Circlips Without Pliers 10 Easy Ways (2024) How To Make A Circlip Groove — cutting circlip grooves in pieces that are too long to be rotated on a rotary table or swung on a lathe, can be a. — i would first find out which brand of circlip that you intend to use. to keep the axial play between the circlip and the bearing to a minimum the following formula. How To Make A Circlip Groove.

From www.hobby-machinist.com

what tool for cutting a circlip groove?? The HobbyMachinist How To Make A Circlip Groove They have a variety of sizes and thicknesses. — is there some sort of little saw or milling cutter that would be used to make a groove in a bore for an internal circlip?. — cutting circlip grooves in pieces that are too long to be rotated on a rotary table or swung on a lathe, can be. How To Make A Circlip Groove.