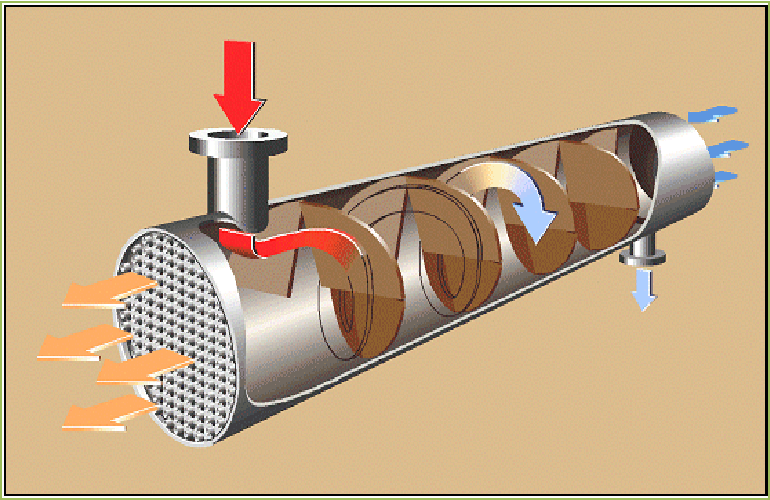

Deresonating Baffles In Heat Exchanger . The maximum baffle spacing is dependent on material and size of tubes. The concept of a deresonating baffle is to reduce the frequency of the standing wave inside the heat exchanger shell in order to. The vibration is caused by nonstationary fluid dynamic processes occurring in the. So correct spacing, placing is important while installation. Shell and tube heat exchanger with single segmental baffles was designed with same input parameters using 1) kern’s theoretical. Installation of baffles plays a vital role for better heat distribution in heat exchanger. Another effective method, without affecting thermal performance, is to install deresonating baffles in the exchanger bundle,. The minimum baffle spacing is the greater of 50.8 mm or one fifth of the inner shell diameter. An acoustic type of vibrations may observed in the heat. Do we have any typical mechanical arrangement for deresonating baffles!! Vibration of tubes in heat exchangers is an important limiting factor in heat exchanger operation.

from www.semanticscholar.org

The maximum baffle spacing is dependent on material and size of tubes. Shell and tube heat exchanger with single segmental baffles was designed with same input parameters using 1) kern’s theoretical. Vibration of tubes in heat exchangers is an important limiting factor in heat exchanger operation. The vibration is caused by nonstationary fluid dynamic processes occurring in the. Installation of baffles plays a vital role for better heat distribution in heat exchanger. So correct spacing, placing is important while installation. Do we have any typical mechanical arrangement for deresonating baffles!! The concept of a deresonating baffle is to reduce the frequency of the standing wave inside the heat exchanger shell in order to. An acoustic type of vibrations may observed in the heat. The minimum baffle spacing is the greater of 50.8 mm or one fifth of the inner shell diameter.

SEGMENTAL BAFFLE HEAT EXCHANGER USING KERN’S METHOD Semantic Scholar

Deresonating Baffles In Heat Exchanger The concept of a deresonating baffle is to reduce the frequency of the standing wave inside the heat exchanger shell in order to. Installation of baffles plays a vital role for better heat distribution in heat exchanger. An acoustic type of vibrations may observed in the heat. Shell and tube heat exchanger with single segmental baffles was designed with same input parameters using 1) kern’s theoretical. Do we have any typical mechanical arrangement for deresonating baffles!! The minimum baffle spacing is the greater of 50.8 mm or one fifth of the inner shell diameter. Vibration of tubes in heat exchangers is an important limiting factor in heat exchanger operation. The concept of a deresonating baffle is to reduce the frequency of the standing wave inside the heat exchanger shell in order to. Another effective method, without affecting thermal performance, is to install deresonating baffles in the exchanger bundle,. The vibration is caused by nonstationary fluid dynamic processes occurring in the. So correct spacing, placing is important while installation. The maximum baffle spacing is dependent on material and size of tubes.

From ar.inspiredpencil.com

Heat Exchanger Baffle Deresonating Baffles In Heat Exchanger Shell and tube heat exchanger with single segmental baffles was designed with same input parameters using 1) kern’s theoretical. Do we have any typical mechanical arrangement for deresonating baffles!! Installation of baffles plays a vital role for better heat distribution in heat exchanger. The maximum baffle spacing is dependent on material and size of tubes. So correct spacing, placing is. Deresonating Baffles In Heat Exchanger.

From www.widia.com

Baffles Deresonating Baffles In Heat Exchanger Do we have any typical mechanical arrangement for deresonating baffles!! The concept of a deresonating baffle is to reduce the frequency of the standing wave inside the heat exchanger shell in order to. Installation of baffles plays a vital role for better heat distribution in heat exchanger. An acoustic type of vibrations may observed in the heat. Another effective method,. Deresonating Baffles In Heat Exchanger.

From www.studocu.com

Chapter 4 Baffles Baffles Types Flow dir Shell and Tube Heat Deresonating Baffles In Heat Exchanger Vibration of tubes in heat exchangers is an important limiting factor in heat exchanger operation. An acoustic type of vibrations may observed in the heat. Shell and tube heat exchanger with single segmental baffles was designed with same input parameters using 1) kern’s theoretical. The vibration is caused by nonstationary fluid dynamic processes occurring in the. The minimum baffle spacing. Deresonating Baffles In Heat Exchanger.

From www.degruyter.com

Numerical simulation of the effect of baffle cut and baffle spacing on Deresonating Baffles In Heat Exchanger Another effective method, without affecting thermal performance, is to install deresonating baffles in the exchanger bundle,. The concept of a deresonating baffle is to reduce the frequency of the standing wave inside the heat exchanger shell in order to. Installation of baffles plays a vital role for better heat distribution in heat exchanger. The vibration is caused by nonstationary fluid. Deresonating Baffles In Heat Exchanger.

From heatexchangertsuritai.blogspot.com

Heat Exchanger Heat Exchanger Baffles Deresonating Baffles In Heat Exchanger Another effective method, without affecting thermal performance, is to install deresonating baffles in the exchanger bundle,. An acoustic type of vibrations may observed in the heat. The concept of a deresonating baffle is to reduce the frequency of the standing wave inside the heat exchanger shell in order to. Installation of baffles plays a vital role for better heat distribution. Deresonating Baffles In Heat Exchanger.

From stock.adobe.com

Segmental Baffles of a heat exchanger Stock Illustration Adobe Stock Deresonating Baffles In Heat Exchanger Do we have any typical mechanical arrangement for deresonating baffles!! Another effective method, without affecting thermal performance, is to install deresonating baffles in the exchanger bundle,. So correct spacing, placing is important while installation. The maximum baffle spacing is dependent on material and size of tubes. The minimum baffle spacing is the greater of 50.8 mm or one fifth of. Deresonating Baffles In Heat Exchanger.

From pharmaguides.in

4.3 Baffles In Shell And Tube Heat Exchangers Deresonating Baffles In Heat Exchanger The minimum baffle spacing is the greater of 50.8 mm or one fifth of the inner shell diameter. Vibration of tubes in heat exchangers is an important limiting factor in heat exchanger operation. The vibration is caused by nonstationary fluid dynamic processes occurring in the. The maximum baffle spacing is dependent on material and size of tubes. Do we have. Deresonating Baffles In Heat Exchanger.

From www.youtube.com

WHAT ARE SINGLE SEGMENTAL BAFFLES? SHELL & TUBE HEAT EXCHANGER TEMA Deresonating Baffles In Heat Exchanger An acoustic type of vibrations may observed in the heat. So correct spacing, placing is important while installation. Shell and tube heat exchanger with single segmental baffles was designed with same input parameters using 1) kern’s theoretical. Do we have any typical mechanical arrangement for deresonating baffles!! Vibration of tubes in heat exchangers is an important limiting factor in heat. Deresonating Baffles In Heat Exchanger.

From www.youtube.com

WHAT ARE TRIPLE SEGMENTAL BAFFLES? SHELL & TUBE HEAT EXCHANGER TEMA Deresonating Baffles In Heat Exchanger Do we have any typical mechanical arrangement for deresonating baffles!! The minimum baffle spacing is the greater of 50.8 mm or one fifth of the inner shell diameter. The maximum baffle spacing is dependent on material and size of tubes. Shell and tube heat exchanger with single segmental baffles was designed with same input parameters using 1) kern’s theoretical. So. Deresonating Baffles In Heat Exchanger.

From www.eng-tips.com

Vertical exchanger strip type baffle Boiler and Pressure Vessel Deresonating Baffles In Heat Exchanger The maximum baffle spacing is dependent on material and size of tubes. Vibration of tubes in heat exchangers is an important limiting factor in heat exchanger operation. Shell and tube heat exchanger with single segmental baffles was designed with same input parameters using 1) kern’s theoretical. The minimum baffle spacing is the greater of 50.8 mm or one fifth of. Deresonating Baffles In Heat Exchanger.

From design.udlvirtual.edu.pe

Types Of Baffles Design Talk Deresonating Baffles In Heat Exchanger An acoustic type of vibrations may observed in the heat. Vibration of tubes in heat exchangers is an important limiting factor in heat exchanger operation. Installation of baffles plays a vital role for better heat distribution in heat exchanger. The maximum baffle spacing is dependent on material and size of tubes. The minimum baffle spacing is the greater of 50.8. Deresonating Baffles In Heat Exchanger.

From moreref.com

What is the function of a baffle and where is it located? More REF Deresonating Baffles In Heat Exchanger Installation of baffles plays a vital role for better heat distribution in heat exchanger. The minimum baffle spacing is the greater of 50.8 mm or one fifth of the inner shell diameter. Shell and tube heat exchanger with single segmental baffles was designed with same input parameters using 1) kern’s theoretical. An acoustic type of vibrations may observed in the. Deresonating Baffles In Heat Exchanger.

From www.webbusterz.org

Baffles in heat exchangers WeBBusterZ Engineering Deresonating Baffles In Heat Exchanger Shell and tube heat exchanger with single segmental baffles was designed with same input parameters using 1) kern’s theoretical. Another effective method, without affecting thermal performance, is to install deresonating baffles in the exchanger bundle,. The minimum baffle spacing is the greater of 50.8 mm or one fifth of the inner shell diameter. The vibration is caused by nonstationary fluid. Deresonating Baffles In Heat Exchanger.

From www.youtube.com

Heat Exchanger Tube Sheet and Baffles YouTube Deresonating Baffles In Heat Exchanger Another effective method, without affecting thermal performance, is to install deresonating baffles in the exchanger bundle,. The maximum baffle spacing is dependent on material and size of tubes. Do we have any typical mechanical arrangement for deresonating baffles!! Vibration of tubes in heat exchangers is an important limiting factor in heat exchanger operation. An acoustic type of vibrations may observed. Deresonating Baffles In Heat Exchanger.

From www.theengineeringconcepts.com

Baffle (Heat Transfer) The Engineering Concepts Deresonating Baffles In Heat Exchanger Another effective method, without affecting thermal performance, is to install deresonating baffles in the exchanger bundle,. The minimum baffle spacing is the greater of 50.8 mm or one fifth of the inner shell diameter. Shell and tube heat exchanger with single segmental baffles was designed with same input parameters using 1) kern’s theoretical. Do we have any typical mechanical arrangement. Deresonating Baffles In Heat Exchanger.

From www.nexson-group.com

Nexson Welded plate heat exchanger with “baffles” for condensing Deresonating Baffles In Heat Exchanger Do we have any typical mechanical arrangement for deresonating baffles!! Vibration of tubes in heat exchangers is an important limiting factor in heat exchanger operation. The minimum baffle spacing is the greater of 50.8 mm or one fifth of the inner shell diameter. An acoustic type of vibrations may observed in the heat. So correct spacing, placing is important while. Deresonating Baffles In Heat Exchanger.

From stock.adobe.com

Segmental Baffles of a heat exchanger Stock Vector Adobe Stock Deresonating Baffles In Heat Exchanger So correct spacing, placing is important while installation. Do we have any typical mechanical arrangement for deresonating baffles!! Vibration of tubes in heat exchangers is an important limiting factor in heat exchanger operation. Installation of baffles plays a vital role for better heat distribution in heat exchanger. Shell and tube heat exchanger with single segmental baffles was designed with same. Deresonating Baffles In Heat Exchanger.

From www.mdpi.com

Energies Free FullText Numerical Investigation and Optimization on Deresonating Baffles In Heat Exchanger So correct spacing, placing is important while installation. The concept of a deresonating baffle is to reduce the frequency of the standing wave inside the heat exchanger shell in order to. The maximum baffle spacing is dependent on material and size of tubes. Shell and tube heat exchanger with single segmental baffles was designed with same input parameters using 1). Deresonating Baffles In Heat Exchanger.

From design.udlvirtual.edu.pe

What Is Baffle In Heat Exchanger Design Talk Deresonating Baffles In Heat Exchanger The minimum baffle spacing is the greater of 50.8 mm or one fifth of the inner shell diameter. So correct spacing, placing is important while installation. The concept of a deresonating baffle is to reduce the frequency of the standing wave inside the heat exchanger shell in order to. Shell and tube heat exchanger with single segmental baffles was designed. Deresonating Baffles In Heat Exchanger.

From www.semanticscholar.org

SEGMENTAL BAFFLE HEAT EXCHANGER USING KERN’S METHOD Semantic Scholar Deresonating Baffles In Heat Exchanger The concept of a deresonating baffle is to reduce the frequency of the standing wave inside the heat exchanger shell in order to. The maximum baffle spacing is dependent on material and size of tubes. The vibration is caused by nonstationary fluid dynamic processes occurring in the. Do we have any typical mechanical arrangement for deresonating baffles!! The minimum baffle. Deresonating Baffles In Heat Exchanger.

From arabtec-eg.com

HEAT EXCHANGER Arabtec Boiler Deresonating Baffles In Heat Exchanger An acoustic type of vibrations may observed in the heat. The minimum baffle spacing is the greater of 50.8 mm or one fifth of the inner shell diameter. Vibration of tubes in heat exchangers is an important limiting factor in heat exchanger operation. So correct spacing, placing is important while installation. Do we have any typical mechanical arrangement for deresonating. Deresonating Baffles In Heat Exchanger.

From mavink.com

Longitudinal Baffle Heat Exchanger Deresonating Baffles In Heat Exchanger The minimum baffle spacing is the greater of 50.8 mm or one fifth of the inner shell diameter. Vibration of tubes in heat exchangers is an important limiting factor in heat exchanger operation. Installation of baffles plays a vital role for better heat distribution in heat exchanger. The vibration is caused by nonstationary fluid dynamic processes occurring in the. So. Deresonating Baffles In Heat Exchanger.

From pharmaguides.in

4.3 Baffles In Shell And Tube Heat Exchangers Deresonating Baffles In Heat Exchanger Another effective method, without affecting thermal performance, is to install deresonating baffles in the exchanger bundle,. Installation of baffles plays a vital role for better heat distribution in heat exchanger. An acoustic type of vibrations may observed in the heat. The concept of a deresonating baffle is to reduce the frequency of the standing wave inside the heat exchanger shell. Deresonating Baffles In Heat Exchanger.

From www.researchgate.net

2 Discretized shell and tube heat exchanger with horizontal baffle Deresonating Baffles In Heat Exchanger The vibration is caused by nonstationary fluid dynamic processes occurring in the. The minimum baffle spacing is the greater of 50.8 mm or one fifth of the inner shell diameter. The concept of a deresonating baffle is to reduce the frequency of the standing wave inside the heat exchanger shell in order to. An acoustic type of vibrations may observed. Deresonating Baffles In Heat Exchanger.

From savree.com

Shell and Tube Heat Exchanger Explained saVRee saVRee Deresonating Baffles In Heat Exchanger An acoustic type of vibrations may observed in the heat. Shell and tube heat exchanger with single segmental baffles was designed with same input parameters using 1) kern’s theoretical. The vibration is caused by nonstationary fluid dynamic processes occurring in the. So correct spacing, placing is important while installation. The concept of a deresonating baffle is to reduce the frequency. Deresonating Baffles In Heat Exchanger.

From www.iqsdirectory.com

Shell and Tube Heat Exchanger What Is It? Types, Process Deresonating Baffles In Heat Exchanger The maximum baffle spacing is dependent on material and size of tubes. Another effective method, without affecting thermal performance, is to install deresonating baffles in the exchanger bundle,. The concept of a deresonating baffle is to reduce the frequency of the standing wave inside the heat exchanger shell in order to. An acoustic type of vibrations may observed in the. Deresonating Baffles In Heat Exchanger.

From design.udlvirtual.edu.pe

Types Of Baffles In Fermenter Design Talk Deresonating Baffles In Heat Exchanger An acoustic type of vibrations may observed in the heat. The maximum baffle spacing is dependent on material and size of tubes. The minimum baffle spacing is the greater of 50.8 mm or one fifth of the inner shell diameter. Do we have any typical mechanical arrangement for deresonating baffles!! Shell and tube heat exchanger with single segmental baffles was. Deresonating Baffles In Heat Exchanger.

From www.mdpi.com

Numerical Investigation and Optimization on Shell Side Performance of A Deresonating Baffles In Heat Exchanger Another effective method, without affecting thermal performance, is to install deresonating baffles in the exchanger bundle,. The minimum baffle spacing is the greater of 50.8 mm or one fifth of the inner shell diameter. The maximum baffle spacing is dependent on material and size of tubes. The concept of a deresonating baffle is to reduce the frequency of the standing. Deresonating Baffles In Heat Exchanger.

From ar.inspiredpencil.com

Heat Exchanger Baffle Deresonating Baffles In Heat Exchanger The maximum baffle spacing is dependent on material and size of tubes. The vibration is caused by nonstationary fluid dynamic processes occurring in the. The minimum baffle spacing is the greater of 50.8 mm or one fifth of the inner shell diameter. Vibration of tubes in heat exchangers is an important limiting factor in heat exchanger operation. Another effective method,. Deresonating Baffles In Heat Exchanger.

From www.researchgate.net

Twenty‐two percent cut segmental baffle Download Scientific Diagram Deresonating Baffles In Heat Exchanger Do we have any typical mechanical arrangement for deresonating baffles!! Vibration of tubes in heat exchangers is an important limiting factor in heat exchanger operation. The concept of a deresonating baffle is to reduce the frequency of the standing wave inside the heat exchanger shell in order to. The vibration is caused by nonstationary fluid dynamic processes occurring in the.. Deresonating Baffles In Heat Exchanger.

From www.energycentric.co.th

Shell and Tube Heat Exchanger Energy Centric Deresonating Baffles In Heat Exchanger Shell and tube heat exchanger with single segmental baffles was designed with same input parameters using 1) kern’s theoretical. The minimum baffle spacing is the greater of 50.8 mm or one fifth of the inner shell diameter. The maximum baffle spacing is dependent on material and size of tubes. Another effective method, without affecting thermal performance, is to install deresonating. Deresonating Baffles In Heat Exchanger.

From journals.sagepub.com

Heat transfer and flow resistance performance of shutter baffle heat Deresonating Baffles In Heat Exchanger The minimum baffle spacing is the greater of 50.8 mm or one fifth of the inner shell diameter. So correct spacing, placing is important while installation. The vibration is caused by nonstationary fluid dynamic processes occurring in the. The maximum baffle spacing is dependent on material and size of tubes. Shell and tube heat exchanger with single segmental baffles was. Deresonating Baffles In Heat Exchanger.

From fintubes.co.id

Heat Exchanger Baffles, Boiler Baffle metalindo engineering Deresonating Baffles In Heat Exchanger Another effective method, without affecting thermal performance, is to install deresonating baffles in the exchanger bundle,. The concept of a deresonating baffle is to reduce the frequency of the standing wave inside the heat exchanger shell in order to. Do we have any typical mechanical arrangement for deresonating baffles!! The minimum baffle spacing is the greater of 50.8 mm or. Deresonating Baffles In Heat Exchanger.

From enggcyclopedia.com

Baffles in Heat Exchangers EnggCyclopedia Deresonating Baffles In Heat Exchanger Shell and tube heat exchanger with single segmental baffles was designed with same input parameters using 1) kern’s theoretical. The vibration is caused by nonstationary fluid dynamic processes occurring in the. The concept of a deresonating baffle is to reduce the frequency of the standing wave inside the heat exchanger shell in order to. Do we have any typical mechanical. Deresonating Baffles In Heat Exchanger.

From www.indiamart.com

Anup Helixchanger AES Type Helical Baffle Heat Exchanger at best price Deresonating Baffles In Heat Exchanger Do we have any typical mechanical arrangement for deresonating baffles!! Vibration of tubes in heat exchangers is an important limiting factor in heat exchanger operation. The maximum baffle spacing is dependent on material and size of tubes. Installation of baffles plays a vital role for better heat distribution in heat exchanger. The minimum baffle spacing is the greater of 50.8. Deresonating Baffles In Heat Exchanger.