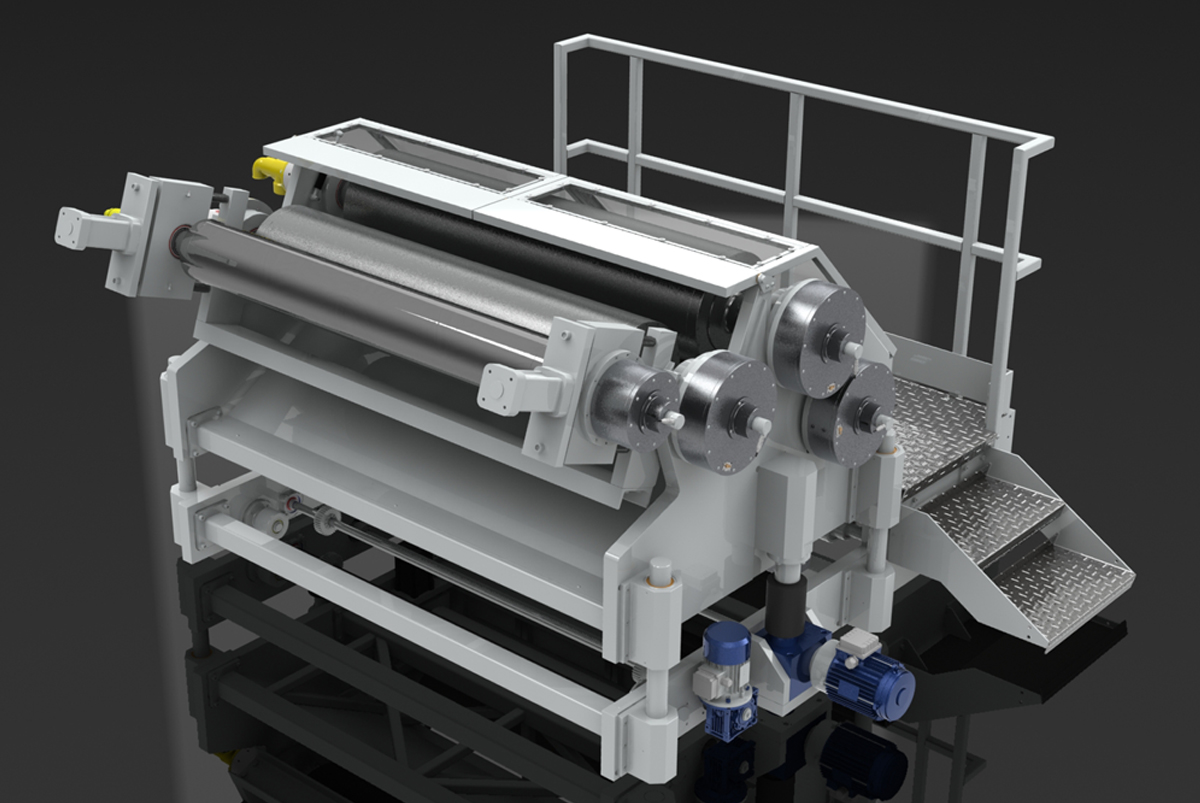

Plastic Extrusion Rolls . this type is used for the extrusion of plastic sheets or films that are too thick to be blown. the resulting product, known as extrudate, is then cooled, often through water baths or cooling rolls, until it solidifies into its final form. After exiting the die, the sheets are pulled. Components of a plastic extruder include a screw, barrel, heaters, cooling fans, and a die. in the sheet extrusion business, one of your most important manufacturing assets is your cooling rolls. The process involves melting plastic, shaping it, and then cooling it to harden.

from www.extrusionroll.com

Components of a plastic extruder include a screw, barrel, heaters, cooling fans, and a die. The process involves melting plastic, shaping it, and then cooling it to harden. in the sheet extrusion business, one of your most important manufacturing assets is your cooling rolls. this type is used for the extrusion of plastic sheets or films that are too thick to be blown. After exiting the die, the sheets are pulled. the resulting product, known as extrudate, is then cooled, often through water baths or cooling rolls, until it solidifies into its final form.

Gallery, Extrusion Roll, rolls and cylinders for print industries and

Plastic Extrusion Rolls the resulting product, known as extrudate, is then cooled, often through water baths or cooling rolls, until it solidifies into its final form. in the sheet extrusion business, one of your most important manufacturing assets is your cooling rolls. After exiting the die, the sheets are pulled. The process involves melting plastic, shaping it, and then cooling it to harden. the resulting product, known as extrudate, is then cooled, often through water baths or cooling rolls, until it solidifies into its final form. this type is used for the extrusion of plastic sheets or films that are too thick to be blown. Components of a plastic extruder include a screw, barrel, heaters, cooling fans, and a die.

From www.plastics-extrusion.co.uk

plasticsextrusion.co.uk Tubing and Extrusions Manufacturer Plastic Extrusion Rolls in the sheet extrusion business, one of your most important manufacturing assets is your cooling rolls. The process involves melting plastic, shaping it, and then cooling it to harden. Components of a plastic extruder include a screw, barrel, heaters, cooling fans, and a die. this type is used for the extrusion of plastic sheets or films that are. Plastic Extrusion Rolls.

From www.extrusionroll.com

Gallery, Extrusion Roll, rolls and cylinders for print industries and Plastic Extrusion Rolls Components of a plastic extruder include a screw, barrel, heaters, cooling fans, and a die. in the sheet extrusion business, one of your most important manufacturing assets is your cooling rolls. The process involves melting plastic, shaping it, and then cooling it to harden. this type is used for the extrusion of plastic sheets or films that are. Plastic Extrusion Rolls.

From www.extrusionroll.com

Gallery, Extrusion Roll, rolls and cylinders for print industries and Plastic Extrusion Rolls The process involves melting plastic, shaping it, and then cooling it to harden. the resulting product, known as extrudate, is then cooled, often through water baths or cooling rolls, until it solidifies into its final form. After exiting the die, the sheets are pulled. this type is used for the extrusion of plastic sheets or films that are. Plastic Extrusion Rolls.

From www.extrusionroll.com

Gallery, Extrusion Roll, rolls and cylinders for print industries and Plastic Extrusion Rolls The process involves melting plastic, shaping it, and then cooling it to harden. this type is used for the extrusion of plastic sheets or films that are too thick to be blown. Components of a plastic extruder include a screw, barrel, heaters, cooling fans, and a die. in the sheet extrusion business, one of your most important manufacturing. Plastic Extrusion Rolls.

From www.extrusionroll.com

Gallery, Extrusion Roll, rolls and cylinders for print industries and Plastic Extrusion Rolls Components of a plastic extruder include a screw, barrel, heaters, cooling fans, and a die. After exiting the die, the sheets are pulled. this type is used for the extrusion of plastic sheets or films that are too thick to be blown. The process involves melting plastic, shaping it, and then cooling it to harden. the resulting product,. Plastic Extrusion Rolls.

From www.extrusionroll.com

Gallery, Extrusion Roll, rolls and cylinders for print industries and Plastic Extrusion Rolls in the sheet extrusion business, one of your most important manufacturing assets is your cooling rolls. Components of a plastic extruder include a screw, barrel, heaters, cooling fans, and a die. After exiting the die, the sheets are pulled. this type is used for the extrusion of plastic sheets or films that are too thick to be blown.. Plastic Extrusion Rolls.

From www.youtube.com

A Plastic Extrusion Workspace YouTube Plastic Extrusion Rolls this type is used for the extrusion of plastic sheets or films that are too thick to be blown. Components of a plastic extruder include a screw, barrel, heaters, cooling fans, and a die. After exiting the die, the sheets are pulled. the resulting product, known as extrudate, is then cooled, often through water baths or cooling rolls,. Plastic Extrusion Rolls.

From www.extrusionroll.com

Gallery, Extrusion Roll, rolls and cylinders for print industries and Plastic Extrusion Rolls in the sheet extrusion business, one of your most important manufacturing assets is your cooling rolls. The process involves melting plastic, shaping it, and then cooling it to harden. After exiting the die, the sheets are pulled. Components of a plastic extruder include a screw, barrel, heaters, cooling fans, and a die. the resulting product, known as extrudate,. Plastic Extrusion Rolls.

From continentalroller.com

Plastic Extrusion Continental Roller Plastic Extrusion Rolls After exiting the die, the sheets are pulled. in the sheet extrusion business, one of your most important manufacturing assets is your cooling rolls. the resulting product, known as extrudate, is then cooled, often through water baths or cooling rolls, until it solidifies into its final form. The process involves melting plastic, shaping it, and then cooling it. Plastic Extrusion Rolls.

From www.extrusionroll.com

Gallery, Extrusion Roll, rolls and cylinders for print industries and Plastic Extrusion Rolls the resulting product, known as extrudate, is then cooled, often through water baths or cooling rolls, until it solidifies into its final form. Components of a plastic extruder include a screw, barrel, heaters, cooling fans, and a die. this type is used for the extrusion of plastic sheets or films that are too thick to be blown. . Plastic Extrusion Rolls.

From www.kunghsing.com.tw

3 Layer Co Extrusion Machines Kung Hsing Plastic Machinery 3 layer Plastic Extrusion Rolls the resulting product, known as extrudate, is then cooled, often through water baths or cooling rolls, until it solidifies into its final form. Components of a plastic extruder include a screw, barrel, heaters, cooling fans, and a die. The process involves melting plastic, shaping it, and then cooling it to harden. this type is used for the extrusion. Plastic Extrusion Rolls.

From www.extrusionroll.com

Gallery, Extrusion Roll, rolls and cylinders for print industries and Plastic Extrusion Rolls this type is used for the extrusion of plastic sheets or films that are too thick to be blown. in the sheet extrusion business, one of your most important manufacturing assets is your cooling rolls. After exiting the die, the sheets are pulled. The process involves melting plastic, shaping it, and then cooling it to harden. Components of. Plastic Extrusion Rolls.

From www.evansclarke.com.au

Furniture Plastic Extrusion Strip Quantity of 6 Rolls Plastic Extrusion Rolls After exiting the die, the sheets are pulled. Components of a plastic extruder include a screw, barrel, heaters, cooling fans, and a die. the resulting product, known as extrudate, is then cooled, often through water baths or cooling rolls, until it solidifies into its final form. The process involves melting plastic, shaping it, and then cooling it to harden.. Plastic Extrusion Rolls.

From www.youtube.com

Plastic Extrusion Chill Rolls Cleaning with Autosol YouTube Plastic Extrusion Rolls The process involves melting plastic, shaping it, and then cooling it to harden. this type is used for the extrusion of plastic sheets or films that are too thick to be blown. After exiting the die, the sheets are pulled. Components of a plastic extruder include a screw, barrel, heaters, cooling fans, and a die. the resulting product,. Plastic Extrusion Rolls.

From www.extrusionroll.com

Gallery, Extrusion Roll, rolls and cylinders for print industries and Plastic Extrusion Rolls After exiting the die, the sheets are pulled. The process involves melting plastic, shaping it, and then cooling it to harden. the resulting product, known as extrudate, is then cooled, often through water baths or cooling rolls, until it solidifies into its final form. in the sheet extrusion business, one of your most important manufacturing assets is your. Plastic Extrusion Rolls.

From www.ipfinc.net

Plastic Extrusion Integrated Packaging Film Inc. Plastic Extrusion Rolls After exiting the die, the sheets are pulled. Components of a plastic extruder include a screw, barrel, heaters, cooling fans, and a die. in the sheet extrusion business, one of your most important manufacturing assets is your cooling rolls. the resulting product, known as extrudate, is then cooled, often through water baths or cooling rolls, until it solidifies. Plastic Extrusion Rolls.

From www.rainbowbelts.com

What Is The Profile Extrusion Process? Plastic Extrusion Rolls in the sheet extrusion business, one of your most important manufacturing assets is your cooling rolls. this type is used for the extrusion of plastic sheets or films that are too thick to be blown. the resulting product, known as extrudate, is then cooled, often through water baths or cooling rolls, until it solidifies into its final. Plastic Extrusion Rolls.

From www.extrusionroll.com

Gallery, Extrusion Roll, rolls and cylinders for print industries and Plastic Extrusion Rolls Components of a plastic extruder include a screw, barrel, heaters, cooling fans, and a die. in the sheet extrusion business, one of your most important manufacturing assets is your cooling rolls. After exiting the die, the sheets are pulled. The process involves melting plastic, shaping it, and then cooling it to harden. this type is used for the. Plastic Extrusion Rolls.

From www.youtube.com

Plastic Extrusion Chill Rolls Cleaning with Autosol. Plastic Extrusion Rolls The process involves melting plastic, shaping it, and then cooling it to harden. the resulting product, known as extrudate, is then cooled, often through water baths or cooling rolls, until it solidifies into its final form. this type is used for the extrusion of plastic sheets or films that are too thick to be blown. in the. Plastic Extrusion Rolls.

From www.extrusionroll.com

Gallery, Extrusion Roll, rolls and cylinders for print industries and Plastic Extrusion Rolls Components of a plastic extruder include a screw, barrel, heaters, cooling fans, and a die. The process involves melting plastic, shaping it, and then cooling it to harden. the resulting product, known as extrudate, is then cooled, often through water baths or cooling rolls, until it solidifies into its final form. this type is used for the extrusion. Plastic Extrusion Rolls.

From www.evansclarke.com.au

Furniture Plastic Extrusion Strip Quantity of 6 Rolls Plastic Extrusion Rolls Components of a plastic extruder include a screw, barrel, heaters, cooling fans, and a die. After exiting the die, the sheets are pulled. this type is used for the extrusion of plastic sheets or films that are too thick to be blown. The process involves melting plastic, shaping it, and then cooling it to harden. the resulting product,. Plastic Extrusion Rolls.

From www.extrusionroll.com

Gallery, Extrusion Roll, rolls and cylinders for print industries and Plastic Extrusion Rolls The process involves melting plastic, shaping it, and then cooling it to harden. this type is used for the extrusion of plastic sheets or films that are too thick to be blown. in the sheet extrusion business, one of your most important manufacturing assets is your cooling rolls. Components of a plastic extruder include a screw, barrel, heaters,. Plastic Extrusion Rolls.

From www.plastikcity.co.uk

Getting Critical on Extrusion PlastikCity Blog Plastic Extrusion Rolls The process involves melting plastic, shaping it, and then cooling it to harden. in the sheet extrusion business, one of your most important manufacturing assets is your cooling rolls. the resulting product, known as extrudate, is then cooled, often through water baths or cooling rolls, until it solidifies into its final form. Components of a plastic extruder include. Plastic Extrusion Rolls.

From www.extrusionroll.com

Gallery, Extrusion Roll, rolls and cylinders for print industries and Plastic Extrusion Rolls The process involves melting plastic, shaping it, and then cooling it to harden. After exiting the die, the sheets are pulled. the resulting product, known as extrudate, is then cooled, often through water baths or cooling rolls, until it solidifies into its final form. Components of a plastic extruder include a screw, barrel, heaters, cooling fans, and a die.. Plastic Extrusion Rolls.

From www.extrusionroll.com

Gallery, Extrusion Roll, rolls and cylinders for print industries and Plastic Extrusion Rolls in the sheet extrusion business, one of your most important manufacturing assets is your cooling rolls. this type is used for the extrusion of plastic sheets or films that are too thick to be blown. After exiting the die, the sheets are pulled. The process involves melting plastic, shaping it, and then cooling it to harden. the. Plastic Extrusion Rolls.

From www.boomindustrial.com

Boom Industrial RUBBER EXTRUSION Plastic Extrusion Rolls this type is used for the extrusion of plastic sheets or films that are too thick to be blown. After exiting the die, the sheets are pulled. the resulting product, known as extrudate, is then cooled, often through water baths or cooling rolls, until it solidifies into its final form. Components of a plastic extruder include a screw,. Plastic Extrusion Rolls.

From www.atravis.ch

Extrusion Plastic Extrusion Rolls in the sheet extrusion business, one of your most important manufacturing assets is your cooling rolls. the resulting product, known as extrudate, is then cooled, often through water baths or cooling rolls, until it solidifies into its final form. After exiting the die, the sheets are pulled. Components of a plastic extruder include a screw, barrel, heaters, cooling. Plastic Extrusion Rolls.

From www.extrusionroll.com

Gallery, Extrusion Roll, rolls and cylinders for print industries and Plastic Extrusion Rolls After exiting the die, the sheets are pulled. Components of a plastic extruder include a screw, barrel, heaters, cooling fans, and a die. The process involves melting plastic, shaping it, and then cooling it to harden. the resulting product, known as extrudate, is then cooled, often through water baths or cooling rolls, until it solidifies into its final form.. Plastic Extrusion Rolls.

From www.extrusionroll.com

Gallery, Extrusion Roll, rolls and cylinders for print industries and Plastic Extrusion Rolls this type is used for the extrusion of plastic sheets or films that are too thick to be blown. The process involves melting plastic, shaping it, and then cooling it to harden. After exiting the die, the sheets are pulled. in the sheet extrusion business, one of your most important manufacturing assets is your cooling rolls. the. Plastic Extrusion Rolls.

From www.extrusionroll.com

Gallery, Extrusion Roll, rolls and cylinders for print industries and Plastic Extrusion Rolls Components of a plastic extruder include a screw, barrel, heaters, cooling fans, and a die. in the sheet extrusion business, one of your most important manufacturing assets is your cooling rolls. The process involves melting plastic, shaping it, and then cooling it to harden. the resulting product, known as extrudate, is then cooled, often through water baths or. Plastic Extrusion Rolls.

From www.extrusionroll.com

Gallery, Extrusion Roll, rolls and cylinders for print industries and Plastic Extrusion Rolls The process involves melting plastic, shaping it, and then cooling it to harden. the resulting product, known as extrudate, is then cooled, often through water baths or cooling rolls, until it solidifies into its final form. this type is used for the extrusion of plastic sheets or films that are too thick to be blown. Components of a. Plastic Extrusion Rolls.

From www.extrusionroll.com

Gallery, Extrusion Roll, rolls and cylinders for print industries and Plastic Extrusion Rolls this type is used for the extrusion of plastic sheets or films that are too thick to be blown. the resulting product, known as extrudate, is then cooled, often through water baths or cooling rolls, until it solidifies into its final form. Components of a plastic extruder include a screw, barrel, heaters, cooling fans, and a die. . Plastic Extrusion Rolls.

From www.extrusionroll.com

Gallery, Extrusion Roll, rolls and cylinders for print industries and Plastic Extrusion Rolls The process involves melting plastic, shaping it, and then cooling it to harden. Components of a plastic extruder include a screw, barrel, heaters, cooling fans, and a die. in the sheet extrusion business, one of your most important manufacturing assets is your cooling rolls. the resulting product, known as extrudate, is then cooled, often through water baths or. Plastic Extrusion Rolls.

From www.extrusionroll.com

Gallery, Extrusion Roll, rolls and cylinders for print industries and Plastic Extrusion Rolls this type is used for the extrusion of plastic sheets or films that are too thick to be blown. the resulting product, known as extrudate, is then cooled, often through water baths or cooling rolls, until it solidifies into its final form. in the sheet extrusion business, one of your most important manufacturing assets is your cooling. Plastic Extrusion Rolls.

From www.evansclarke.com.au

Rolls of Furniture Plastic Extrusion Strip Quantity of 6 Rolls Plastic Extrusion Rolls the resulting product, known as extrudate, is then cooled, often through water baths or cooling rolls, until it solidifies into its final form. The process involves melting plastic, shaping it, and then cooling it to harden. Components of a plastic extruder include a screw, barrel, heaters, cooling fans, and a die. in the sheet extrusion business, one of. Plastic Extrusion Rolls.