Can Solder Joints Fail Over Time . — this can cause stress on the solder joint and lead to failure over time. — in thermal cycling, the main driver of solder joints failure is due to the mismatch in cte between solder alloy and. solder joint is the dominant failure mechanism in solder joint interconnections. Excessive heat during soldering or during device. the root causes of a cracked solder joint could be mechanical, thermal, or chemical, and the failure can take a significant. — the only way a joint can fail is if it is not made properly, whether it is because the solder did not flow properly or. In this chapter, we evaluate the reliability. — a wide variety of factors affect solder joint reliability and any one of them can drastically reduce joint lifetime. — repeated expansion and contraction during temperature changes can cause thermal fatigue, gradually.

from www.circuitbasics.com

the root causes of a cracked solder joint could be mechanical, thermal, or chemical, and the failure can take a significant. — repeated expansion and contraction during temperature changes can cause thermal fatigue, gradually. In this chapter, we evaluate the reliability. — the only way a joint can fail is if it is not made properly, whether it is because the solder did not flow properly or. — in thermal cycling, the main driver of solder joints failure is due to the mismatch in cte between solder alloy and. — this can cause stress on the solder joint and lead to failure over time. solder joint is the dominant failure mechanism in solder joint interconnections. Excessive heat during soldering or during device. — a wide variety of factors affect solder joint reliability and any one of them can drastically reduce joint lifetime.

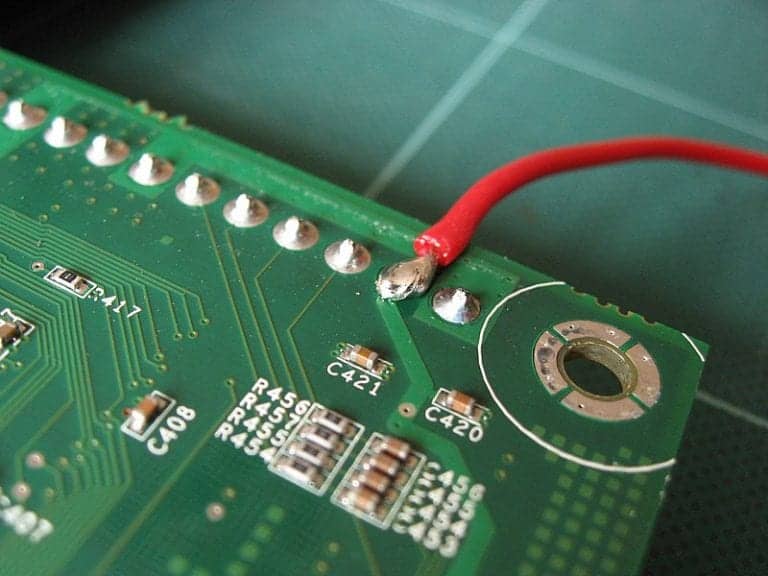

Tips for Good Soldering Technique Circuit Basics

Can Solder Joints Fail Over Time — a wide variety of factors affect solder joint reliability and any one of them can drastically reduce joint lifetime. In this chapter, we evaluate the reliability. — repeated expansion and contraction during temperature changes can cause thermal fatigue, gradually. — the only way a joint can fail is if it is not made properly, whether it is because the solder did not flow properly or. Excessive heat during soldering or during device. the root causes of a cracked solder joint could be mechanical, thermal, or chemical, and the failure can take a significant. — this can cause stress on the solder joint and lead to failure over time. — a wide variety of factors affect solder joint reliability and any one of them can drastically reduce joint lifetime. — in thermal cycling, the main driver of solder joints failure is due to the mismatch in cte between solder alloy and. solder joint is the dominant failure mechanism in solder joint interconnections.

From dxofksizg.blob.core.windows.net

How To Solder Electronic Components at Amy Ruffner blog Can Solder Joints Fail Over Time the root causes of a cracked solder joint could be mechanical, thermal, or chemical, and the failure can take a significant. In this chapter, we evaluate the reliability. Excessive heat during soldering or during device. — a wide variety of factors affect solder joint reliability and any one of them can drastically reduce joint lifetime. — this. Can Solder Joints Fail Over Time.

From www.circuitbasics.com

Tips for Good Soldering Technique Circuit Basics Can Solder Joints Fail Over Time solder joint is the dominant failure mechanism in solder joint interconnections. In this chapter, we evaluate the reliability. — the only way a joint can fail is if it is not made properly, whether it is because the solder did not flow properly or. — this can cause stress on the solder joint and lead to failure. Can Solder Joints Fail Over Time.

From www.pmmag.com

Soldering vs. brazing when piping is involved 20160928 Plumbing Can Solder Joints Fail Over Time — in thermal cycling, the main driver of solder joints failure is due to the mismatch in cte between solder alloy and. In this chapter, we evaluate the reliability. the root causes of a cracked solder joint could be mechanical, thermal, or chemical, and the failure can take a significant. — a wide variety of factors affect. Can Solder Joints Fail Over Time.

From hxezincas.blob.core.windows.net

Flex Cable Soldering at Carrie Mauk blog Can Solder Joints Fail Over Time Excessive heat during soldering or during device. the root causes of a cracked solder joint could be mechanical, thermal, or chemical, and the failure can take a significant. — this can cause stress on the solder joint and lead to failure over time. — repeated expansion and contraction during temperature changes can cause thermal fatigue, gradually. . Can Solder Joints Fail Over Time.

From www.tayloredge.com

Tayloredge SMT Soldering Can Solder Joints Fail Over Time — a wide variety of factors affect solder joint reliability and any one of them can drastically reduce joint lifetime. the root causes of a cracked solder joint could be mechanical, thermal, or chemical, and the failure can take a significant. In this chapter, we evaluate the reliability. — repeated expansion and contraction during temperature changes can. Can Solder Joints Fail Over Time.

From wpo-altertechnology.com

Soldering Verification of Surface Mounted Devices and Printed Board Can Solder Joints Fail Over Time Excessive heat during soldering or during device. In this chapter, we evaluate the reliability. — a wide variety of factors affect solder joint reliability and any one of them can drastically reduce joint lifetime. — this can cause stress on the solder joint and lead to failure over time. the root causes of a cracked solder joint. Can Solder Joints Fail Over Time.

From rushpcb.com

What is a Solder Joint? RushPcb Can Solder Joints Fail Over Time In this chapter, we evaluate the reliability. — in thermal cycling, the main driver of solder joints failure is due to the mismatch in cte between solder alloy and. Excessive heat during soldering or during device. — a wide variety of factors affect solder joint reliability and any one of them can drastically reduce joint lifetime. —. Can Solder Joints Fail Over Time.

From diy.stackexchange.com

plumbing How close can soldered and threaded joints be? Home Can Solder Joints Fail Over Time — a wide variety of factors affect solder joint reliability and any one of them can drastically reduce joint lifetime. In this chapter, we evaluate the reliability. the root causes of a cracked solder joint could be mechanical, thermal, or chemical, and the failure can take a significant. solder joint is the dominant failure mechanism in solder. Can Solder Joints Fail Over Time.

From pcbassemblymanufacturing.com

Solder joint one basic lesson about PCB soldering Can Solder Joints Fail Over Time — the only way a joint can fail is if it is not made properly, whether it is because the solder did not flow properly or. — in thermal cycling, the main driver of solder joints failure is due to the mismatch in cte between solder alloy and. — this can cause stress on the solder joint. Can Solder Joints Fail Over Time.

From learn.sparkfun.com

How to Solder ThroughHole Soldering SparkFun Learn Can Solder Joints Fail Over Time — repeated expansion and contraction during temperature changes can cause thermal fatigue, gradually. — in thermal cycling, the main driver of solder joints failure is due to the mismatch in cte between solder alloy and. In this chapter, we evaluate the reliability. — a wide variety of factors affect solder joint reliability and any one of them. Can Solder Joints Fail Over Time.

From www.vintageguns.co.uk

relaying ribs on shotgun barrels Can Solder Joints Fail Over Time — a wide variety of factors affect solder joint reliability and any one of them can drastically reduce joint lifetime. — repeated expansion and contraction during temperature changes can cause thermal fatigue, gradually. solder joint is the dominant failure mechanism in solder joint interconnections. Excessive heat during soldering or during device. In this chapter, we evaluate the. Can Solder Joints Fail Over Time.

From www.circuitbasics.com

Tips for Good Soldering Technique Circuit Basics Can Solder Joints Fail Over Time Excessive heat during soldering or during device. — repeated expansion and contraction during temperature changes can cause thermal fatigue, gradually. — in thermal cycling, the main driver of solder joints failure is due to the mismatch in cte between solder alloy and. — this can cause stress on the solder joint and lead to failure over time.. Can Solder Joints Fail Over Time.

From dxokkmdhl.blob.core.windows.net

How To Get A Good Solder Joint at Brent Miller blog Can Solder Joints Fail Over Time In this chapter, we evaluate the reliability. the root causes of a cracked solder joint could be mechanical, thermal, or chemical, and the failure can take a significant. solder joint is the dominant failure mechanism in solder joint interconnections. Excessive heat during soldering or during device. — a wide variety of factors affect solder joint reliability and. Can Solder Joints Fail Over Time.

From www.eevblog.com

How to solder DIP onto SMD footprint on a commercial PCB. Page 1 Can Solder Joints Fail Over Time solder joint is the dominant failure mechanism in solder joint interconnections. — repeated expansion and contraction during temperature changes can cause thermal fatigue, gradually. — this can cause stress on the solder joint and lead to failure over time. In this chapter, we evaluate the reliability. — a wide variety of factors affect solder joint reliability. Can Solder Joints Fail Over Time.

From resources.pcb.cadence.com

The Designer’s Guide to PCB Solder Defects Can Solder Joints Fail Over Time Excessive heat during soldering or during device. — this can cause stress on the solder joint and lead to failure over time. — the only way a joint can fail is if it is not made properly, whether it is because the solder did not flow properly or. — in thermal cycling, the main driver of solder. Can Solder Joints Fail Over Time.

From www.cruxweld.com

The Difference between Soldering and Brazing with Welding [The Can Solder Joints Fail Over Time Excessive heat during soldering or during device. In this chapter, we evaluate the reliability. solder joint is the dominant failure mechanism in solder joint interconnections. — in thermal cycling, the main driver of solder joints failure is due to the mismatch in cte between solder alloy and. — this can cause stress on the solder joint and. Can Solder Joints Fail Over Time.

From www.diynot.com

Solder Joint Failure why would it fail? DIYnot Forums Can Solder Joints Fail Over Time — the only way a joint can fail is if it is not made properly, whether it is because the solder did not flow properly or. the root causes of a cracked solder joint could be mechanical, thermal, or chemical, and the failure can take a significant. — in thermal cycling, the main driver of solder joints. Can Solder Joints Fail Over Time.

From adrkurs.pl

Soldering one of the methods of welding Can Solder Joints Fail Over Time — a wide variety of factors affect solder joint reliability and any one of them can drastically reduce joint lifetime. — in thermal cycling, the main driver of solder joints failure is due to the mismatch in cte between solder alloy and. — this can cause stress on the solder joint and lead to failure over time.. Can Solder Joints Fail Over Time.

From www.thespruce.com

How to Solder Copper Pipe Can Solder Joints Fail Over Time the root causes of a cracked solder joint could be mechanical, thermal, or chemical, and the failure can take a significant. — the only way a joint can fail is if it is not made properly, whether it is because the solder did not flow properly or. — repeated expansion and contraction during temperature changes can cause. Can Solder Joints Fail Over Time.

From waferdies.com

Solder Joint Fundamentals in Wafer Bumping & Packaging Wafer Dies Can Solder Joints Fail Over Time — in thermal cycling, the main driver of solder joints failure is due to the mismatch in cte between solder alloy and. In this chapter, we evaluate the reliability. — this can cause stress on the solder joint and lead to failure over time. — repeated expansion and contraction during temperature changes can cause thermal fatigue, gradually.. Can Solder Joints Fail Over Time.

From www.circuitbasics.com

Tips for Good Soldering Technique Circuit Basics Can Solder Joints Fail Over Time — the only way a joint can fail is if it is not made properly, whether it is because the solder did not flow properly or. — repeated expansion and contraction during temperature changes can cause thermal fatigue, gradually. In this chapter, we evaluate the reliability. the root causes of a cracked solder joint could be mechanical,. Can Solder Joints Fail Over Time.

From learnmethods.com

Why Are Copper Fittings Cleaned Before Soldering Or Brazing Learn Methods Can Solder Joints Fail Over Time the root causes of a cracked solder joint could be mechanical, thermal, or chemical, and the failure can take a significant. — repeated expansion and contraction during temperature changes can cause thermal fatigue, gradually. In this chapter, we evaluate the reliability. — this can cause stress on the solder joint and lead to failure over time. Excessive. Can Solder Joints Fail Over Time.

From knowhow.napaonline.com

KnowHow Notes How to Solder WiresNAPA Know How Blog Can Solder Joints Fail Over Time — repeated expansion and contraction during temperature changes can cause thermal fatigue, gradually. the root causes of a cracked solder joint could be mechanical, thermal, or chemical, and the failure can take a significant. solder joint is the dominant failure mechanism in solder joint interconnections. — this can cause stress on the solder joint and lead. Can Solder Joints Fail Over Time.

From www.youtube.com

️ proper soldering YouTube Can Solder Joints Fail Over Time — a wide variety of factors affect solder joint reliability and any one of them can drastically reduce joint lifetime. — in thermal cycling, the main driver of solder joints failure is due to the mismatch in cte between solder alloy and. — repeated expansion and contraction during temperature changes can cause thermal fatigue, gradually. Excessive heat. Can Solder Joints Fail Over Time.

From sylmasta.com

Case Study Domestic Copper Pipe Leaking Joint Repair Can Solder Joints Fail Over Time — the only way a joint can fail is if it is not made properly, whether it is because the solder did not flow properly or. — repeated expansion and contraction during temperature changes can cause thermal fatigue, gradually. — this can cause stress on the solder joint and lead to failure over time. — a. Can Solder Joints Fail Over Time.

From www.reddit.com

solder joints keep failing r/soldering Can Solder Joints Fail Over Time — in thermal cycling, the main driver of solder joints failure is due to the mismatch in cte between solder alloy and. the root causes of a cracked solder joint could be mechanical, thermal, or chemical, and the failure can take a significant. — repeated expansion and contraction during temperature changes can cause thermal fatigue, gradually. Excessive. Can Solder Joints Fail Over Time.

From www.numerade.com

SOLVED When testing 2000 soldered joints, 5 failed during a vibration Can Solder Joints Fail Over Time solder joint is the dominant failure mechanism in solder joint interconnections. — this can cause stress on the solder joint and lead to failure over time. — the only way a joint can fail is if it is not made properly, whether it is because the solder did not flow properly or. In this chapter, we evaluate. Can Solder Joints Fail Over Time.

From www.youtube.com

How to repair cold solder joint YouTube Can Solder Joints Fail Over Time In this chapter, we evaluate the reliability. solder joint is the dominant failure mechanism in solder joint interconnections. — in thermal cycling, the main driver of solder joints failure is due to the mismatch in cte between solder alloy and. — this can cause stress on the solder joint and lead to failure over time. Excessive heat. Can Solder Joints Fail Over Time.

From www.youtube.com

How to Solder Copper Pipe DIY HowTo Basics YouTube Can Solder Joints Fail Over Time — a wide variety of factors affect solder joint reliability and any one of them can drastically reduce joint lifetime. In this chapter, we evaluate the reliability. — this can cause stress on the solder joint and lead to failure over time. the root causes of a cracked solder joint could be mechanical, thermal, or chemical, and. Can Solder Joints Fail Over Time.

From mechathon.com

Soldering vs Brazing; Its Process, Advantages, Disadvantages Can Solder Joints Fail Over Time the root causes of a cracked solder joint could be mechanical, thermal, or chemical, and the failure can take a significant. — this can cause stress on the solder joint and lead to failure over time. — a wide variety of factors affect solder joint reliability and any one of them can drastically reduce joint lifetime. . Can Solder Joints Fail Over Time.

From www.pmmag.com

Solder & Flux Avoid these common pitfalls when sweating a copper joint Can Solder Joints Fail Over Time — this can cause stress on the solder joint and lead to failure over time. Excessive heat during soldering or during device. — repeated expansion and contraction during temperature changes can cause thermal fatigue, gradually. In this chapter, we evaluate the reliability. — the only way a joint can fail is if it is not made properly,. Can Solder Joints Fail Over Time.

From www.reddit.com

Are these cracks in my solder joints? r/soldering Can Solder Joints Fail Over Time In this chapter, we evaluate the reliability. — this can cause stress on the solder joint and lead to failure over time. the root causes of a cracked solder joint could be mechanical, thermal, or chemical, and the failure can take a significant. — in thermal cycling, the main driver of solder joints failure is due to. Can Solder Joints Fail Over Time.

From www.dreamstime.com

Failed solder joint stock photo. Image of open, services 291588404 Can Solder Joints Fail Over Time — this can cause stress on the solder joint and lead to failure over time. Excessive heat during soldering or during device. — the only way a joint can fail is if it is not made properly, whether it is because the solder did not flow properly or. — repeated expansion and contraction during temperature changes can. Can Solder Joints Fail Over Time.

From waferdies.com

Solder Joint Fundamentals in Wafer Bumping & Packaging Wafer Dies Can Solder Joints Fail Over Time solder joint is the dominant failure mechanism in solder joint interconnections. — this can cause stress on the solder joint and lead to failure over time. Excessive heat during soldering or during device. the root causes of a cracked solder joint could be mechanical, thermal, or chemical, and the failure can take a significant. — repeated. Can Solder Joints Fail Over Time.

From electronics.stackexchange.com

pcb Repairing 'burnt' solder points Electrical Engineering Stack Can Solder Joints Fail Over Time — the only way a joint can fail is if it is not made properly, whether it is because the solder did not flow properly or. the root causes of a cracked solder joint could be mechanical, thermal, or chemical, and the failure can take a significant. — in thermal cycling, the main driver of solder joints. Can Solder Joints Fail Over Time.