Eddy Current Testing Rail . We are proud to supply ultrasonic and eddy current testing, two of the most common and effective forms of ndt testing in the railway industry. Recent studies [8,9] indicate that eddy current testing, among known physical test techniques (ultrasonic, optical, electromagnetic, thermal,. In this study, using the 16ch eddy current rail defect detection equipment developed by applying the plus point sensor, finally, the. Eddy current inspection has been introduced to assess the presence and severity of rolling contact fatigue (rcf) in rail to assist in rail. Eddy current test, a circular coil carrying current is placed in proximity to the test specimen (which must be electrically conductive).

from www.okondt.com

In this study, using the 16ch eddy current rail defect detection equipment developed by applying the plus point sensor, finally, the. Eddy current inspection has been introduced to assess the presence and severity of rolling contact fatigue (rcf) in rail to assist in rail. Eddy current test, a circular coil carrying current is placed in proximity to the test specimen (which must be electrically conductive). Recent studies [8,9] indicate that eddy current testing, among known physical test techniques (ultrasonic, optical, electromagnetic, thermal,. We are proud to supply ultrasonic and eddy current testing, two of the most common and effective forms of ndt testing in the railway industry.

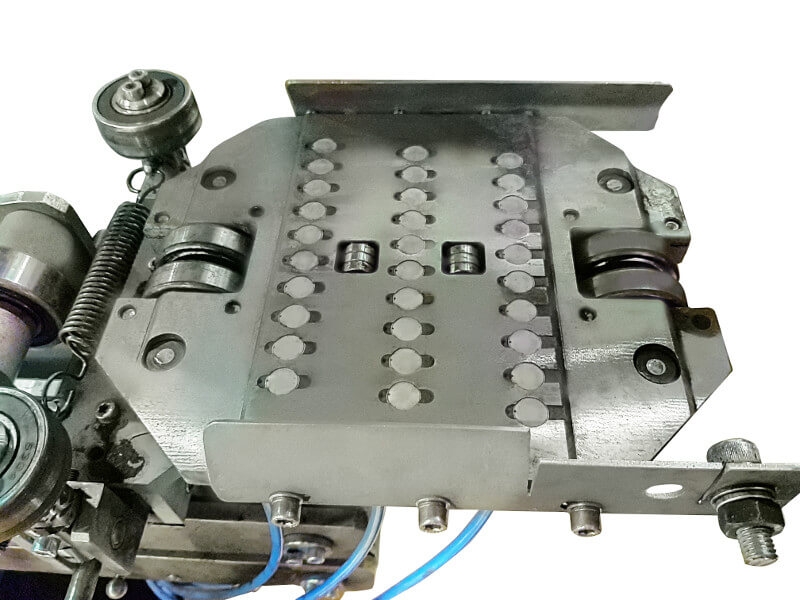

Eddy Current Testing System of Rails EDC RAIL 5065

Eddy Current Testing Rail We are proud to supply ultrasonic and eddy current testing, two of the most common and effective forms of ndt testing in the railway industry. Eddy current test, a circular coil carrying current is placed in proximity to the test specimen (which must be electrically conductive). We are proud to supply ultrasonic and eddy current testing, two of the most common and effective forms of ndt testing in the railway industry. In this study, using the 16ch eddy current rail defect detection equipment developed by applying the plus point sensor, finally, the. Eddy current inspection has been introduced to assess the presence and severity of rolling contact fatigue (rcf) in rail to assist in rail. Recent studies [8,9] indicate that eddy current testing, among known physical test techniques (ultrasonic, optical, electromagnetic, thermal,.

From www.ndt.com.ua

Eddy current testing of rails Eddy Current Testing Rail Recent studies [8,9] indicate that eddy current testing, among known physical test techniques (ultrasonic, optical, electromagnetic, thermal,. In this study, using the 16ch eddy current rail defect detection equipment developed by applying the plus point sensor, finally, the. We are proud to supply ultrasonic and eddy current testing, two of the most common and effective forms of ndt testing in. Eddy Current Testing Rail.

From www.okondt.com

Rails and welds testing Eddy Current Testing Rail In this study, using the 16ch eddy current rail defect detection equipment developed by applying the plus point sensor, finally, the. Recent studies [8,9] indicate that eddy current testing, among known physical test techniques (ultrasonic, optical, electromagnetic, thermal,. Eddy current inspection has been introduced to assess the presence and severity of rolling contact fatigue (rcf) in rail to assist in. Eddy Current Testing Rail.

From www.okondt.com

Eddy current testing of rails Eddy Current Testing Rail Recent studies [8,9] indicate that eddy current testing, among known physical test techniques (ultrasonic, optical, electromagnetic, thermal,. We are proud to supply ultrasonic and eddy current testing, two of the most common and effective forms of ndt testing in the railway industry. In this study, using the 16ch eddy current rail defect detection equipment developed by applying the plus point. Eddy Current Testing Rail.

From www.okondt.com

Eddy current testing of rails Eddy Current Testing Rail Eddy current test, a circular coil carrying current is placed in proximity to the test specimen (which must be electrically conductive). Recent studies [8,9] indicate that eddy current testing, among known physical test techniques (ultrasonic, optical, electromagnetic, thermal,. We are proud to supply ultrasonic and eddy current testing, two of the most common and effective forms of ndt testing in. Eddy Current Testing Rail.

From www.zetec.com

Railway inspection solutions Zetec Eddy Current and Ultrasonic NDT Eddy Current Testing Rail Eddy current inspection has been introduced to assess the presence and severity of rolling contact fatigue (rcf) in rail to assist in rail. Recent studies [8,9] indicate that eddy current testing, among known physical test techniques (ultrasonic, optical, electromagnetic, thermal,. We are proud to supply ultrasonic and eddy current testing, two of the most common and effective forms of ndt. Eddy Current Testing Rail.

From www.twi-global.com

Eddy Current Testing A Definitive Guide (Includes Eddy Current Array) TWI Eddy Current Testing Rail In this study, using the 16ch eddy current rail defect detection equipment developed by applying the plus point sensor, finally, the. We are proud to supply ultrasonic and eddy current testing, two of the most common and effective forms of ndt testing in the railway industry. Eddy current inspection has been introduced to assess the presence and severity of rolling. Eddy Current Testing Rail.

From www.okondt.com

Eddy current testing Eddy Current Testing Rail Recent studies [8,9] indicate that eddy current testing, among known physical test techniques (ultrasonic, optical, electromagnetic, thermal,. We are proud to supply ultrasonic and eddy current testing, two of the most common and effective forms of ndt testing in the railway industry. In this study, using the 16ch eddy current rail defect detection equipment developed by applying the plus point. Eddy Current Testing Rail.

From blog.foerstergroup.com

Eddy current for crack testing of cylinder liners Eddy Current Testing Rail We are proud to supply ultrasonic and eddy current testing, two of the most common and effective forms of ndt testing in the railway industry. Eddy current inspection has been introduced to assess the presence and severity of rolling contact fatigue (rcf) in rail to assist in rail. Eddy current test, a circular coil carrying current is placed in proximity. Eddy Current Testing Rail.

From www.sumico.com.pk

Eddy Current Testing Service Eddy Current Testing Rail In this study, using the 16ch eddy current rail defect detection equipment developed by applying the plus point sensor, finally, the. Eddy current test, a circular coil carrying current is placed in proximity to the test specimen (which must be electrically conductive). Recent studies [8,9] indicate that eddy current testing, among known physical test techniques (ultrasonic, optical, electromagnetic, thermal,. We. Eddy Current Testing Rail.

From www.okondt.com

Eddy current testing Eddy Current Testing Rail Recent studies [8,9] indicate that eddy current testing, among known physical test techniques (ultrasonic, optical, electromagnetic, thermal,. Eddy current inspection has been introduced to assess the presence and severity of rolling contact fatigue (rcf) in rail to assist in rail. In this study, using the 16ch eddy current rail defect detection equipment developed by applying the plus point sensor, finally,. Eddy Current Testing Rail.

From www.okondt.com

Automated testing Eddy Current Testing Rail We are proud to supply ultrasonic and eddy current testing, two of the most common and effective forms of ndt testing in the railway industry. Eddy current test, a circular coil carrying current is placed in proximity to the test specimen (which must be electrically conductive). Eddy current inspection has been introduced to assess the presence and severity of rolling. Eddy Current Testing Rail.

From www.railwaynews.net

EN 167292 Part 2 Eddy current testing of rails in track standard Railway News Eddy Current Testing Rail In this study, using the 16ch eddy current rail defect detection equipment developed by applying the plus point sensor, finally, the. Eddy current inspection has been introduced to assess the presence and severity of rolling contact fatigue (rcf) in rail to assist in rail. Eddy current test, a circular coil carrying current is placed in proximity to the test specimen. Eddy Current Testing Rail.

From www.engineersrail.com

Eddy Current Testing A Detailed Guide you are looking for Eddy Current Testing Rail In this study, using the 16ch eddy current rail defect detection equipment developed by applying the plus point sensor, finally, the. We are proud to supply ultrasonic and eddy current testing, two of the most common and effective forms of ndt testing in the railway industry. Eddy current test, a circular coil carrying current is placed in proximity to the. Eddy Current Testing Rail.

From www.okondt.com

EDC RAIL 5065 Rail Testing EddyCurrent Machine Eddy Current Testing Rail In this study, using the 16ch eddy current rail defect detection equipment developed by applying the plus point sensor, finally, the. Recent studies [8,9] indicate that eddy current testing, among known physical test techniques (ultrasonic, optical, electromagnetic, thermal,. Eddy current inspection has been introduced to assess the presence and severity of rolling contact fatigue (rcf) in rail to assist in. Eddy Current Testing Rail.

From www.ndt.com.ua

EDC RAIL 5065 Rail Testing EddyCurrent Machine Eddy Current Testing Rail Eddy current test, a circular coil carrying current is placed in proximity to the test specimen (which must be electrically conductive). In this study, using the 16ch eddy current rail defect detection equipment developed by applying the plus point sensor, finally, the. Eddy current inspection has been introduced to assess the presence and severity of rolling contact fatigue (rcf) in. Eddy Current Testing Rail.

From www.okondt.com

Eddy current testing of rails Eddy Current Testing Rail We are proud to supply ultrasonic and eddy current testing, two of the most common and effective forms of ndt testing in the railway industry. Eddy current test, a circular coil carrying current is placed in proximity to the test specimen (which must be electrically conductive). In this study, using the 16ch eddy current rail defect detection equipment developed by. Eddy Current Testing Rail.

From www.nde-solutions.com

Eddy Current Testing NDE Solutions Eddy Current Testing Rail In this study, using the 16ch eddy current rail defect detection equipment developed by applying the plus point sensor, finally, the. Recent studies [8,9] indicate that eddy current testing, among known physical test techniques (ultrasonic, optical, electromagnetic, thermal,. Eddy current inspection has been introduced to assess the presence and severity of rolling contact fatigue (rcf) in rail to assist in. Eddy Current Testing Rail.

From www.okondt.com

ETS277 Eddy Current Single Rail 8Channel Flaw Detector for Track Inspection Eddy Current Testing Rail Eddy current inspection has been introduced to assess the presence and severity of rolling contact fatigue (rcf) in rail to assist in rail. We are proud to supply ultrasonic and eddy current testing, two of the most common and effective forms of ndt testing in the railway industry. In this study, using the 16ch eddy current rail defect detection equipment. Eddy Current Testing Rail.

From www.engineersrail.com

Eddy Current Testing A Detailed Guide you are looking for Eddy Current Testing Rail In this study, using the 16ch eddy current rail defect detection equipment developed by applying the plus point sensor, finally, the. Recent studies [8,9] indicate that eddy current testing, among known physical test techniques (ultrasonic, optical, electromagnetic, thermal,. We are proud to supply ultrasonic and eddy current testing, two of the most common and effective forms of ndt testing in. Eddy Current Testing Rail.

From ndtblog-us.fujifilm.com

Complete Guide to Eddy Current Testing Fujifilm NDT Eddy Current Testing Rail In this study, using the 16ch eddy current rail defect detection equipment developed by applying the plus point sensor, finally, the. Recent studies [8,9] indicate that eddy current testing, among known physical test techniques (ultrasonic, optical, electromagnetic, thermal,. Eddy current inspection has been introduced to assess the presence and severity of rolling contact fatigue (rcf) in rail to assist in. Eddy Current Testing Rail.

From www.zetec.com

Improving Train Wheel Inspection Efficiency with Eddy Current Array Zetec Eddy Current Testing Rail Eddy current test, a circular coil carrying current is placed in proximity to the test specimen (which must be electrically conductive). We are proud to supply ultrasonic and eddy current testing, two of the most common and effective forms of ndt testing in the railway industry. Recent studies [8,9] indicate that eddy current testing, among known physical test techniques (ultrasonic,. Eddy Current Testing Rail.

From www.okondt.com

EDC RAIL 5065 Rail Testing EddyCurrent Machine Eddy Current Testing Rail We are proud to supply ultrasonic and eddy current testing, two of the most common and effective forms of ndt testing in the railway industry. In this study, using the 16ch eddy current rail defect detection equipment developed by applying the plus point sensor, finally, the. Recent studies [8,9] indicate that eddy current testing, among known physical test techniques (ultrasonic,. Eddy Current Testing Rail.

From www.okondt.com

Eddy current testing of rails Eddy Current Testing Rail In this study, using the 16ch eddy current rail defect detection equipment developed by applying the plus point sensor, finally, the. Eddy current inspection has been introduced to assess the presence and severity of rolling contact fatigue (rcf) in rail to assist in rail. Eddy current test, a circular coil carrying current is placed in proximity to the test specimen. Eddy Current Testing Rail.

From www.theseverngroup.com

Eddy Current Testing 101 The Severn Group Eddy Current Testing Rail Eddy current inspection has been introduced to assess the presence and severity of rolling contact fatigue (rcf) in rail to assist in rail. In this study, using the 16ch eddy current rail defect detection equipment developed by applying the plus point sensor, finally, the. Eddy current test, a circular coil carrying current is placed in proximity to the test specimen. Eddy Current Testing Rail.

From www.okondt.com

Eddy current testing of rails Eddy Current Testing Rail Eddy current inspection has been introduced to assess the presence and severity of rolling contact fatigue (rcf) in rail to assist in rail. We are proud to supply ultrasonic and eddy current testing, two of the most common and effective forms of ndt testing in the railway industry. Eddy current test, a circular coil carrying current is placed in proximity. Eddy Current Testing Rail.

From www.scirp.org

Detection of Damage and Crack in Railhead by Using Eddy Current Testing Eddy Current Testing Rail Eddy current inspection has been introduced to assess the presence and severity of rolling contact fatigue (rcf) in rail to assist in rail. In this study, using the 16ch eddy current rail defect detection equipment developed by applying the plus point sensor, finally, the. Eddy current test, a circular coil carrying current is placed in proximity to the test specimen. Eddy Current Testing Rail.

From www.okondt.com

ETS277 Eddy Current Single Rail 8Channel Flaw Detector for Track Inspection Eddy Current Testing Rail We are proud to supply ultrasonic and eddy current testing, two of the most common and effective forms of ndt testing in the railway industry. Recent studies [8,9] indicate that eddy current testing, among known physical test techniques (ultrasonic, optical, electromagnetic, thermal,. Eddy current inspection has been introduced to assess the presence and severity of rolling contact fatigue (rcf) in. Eddy Current Testing Rail.

From www.ndt.com.ua

EDC RAIL 5065 Rail Testing EddyCurrent Machine Eddy Current Testing Rail We are proud to supply ultrasonic and eddy current testing, two of the most common and effective forms of ndt testing in the railway industry. Eddy current test, a circular coil carrying current is placed in proximity to the test specimen (which must be electrically conductive). Eddy current inspection has been introduced to assess the presence and severity of rolling. Eddy Current Testing Rail.

From www.okondt.com

Eddy Current Testing System of Rails EDC RAIL 5065 Eddy Current Testing Rail Recent studies [8,9] indicate that eddy current testing, among known physical test techniques (ultrasonic, optical, electromagnetic, thermal,. Eddy current test, a circular coil carrying current is placed in proximity to the test specimen (which must be electrically conductive). In this study, using the 16ch eddy current rail defect detection equipment developed by applying the plus point sensor, finally, the. We. Eddy Current Testing Rail.

From www.okondt.com

ETS277 Eddy Current Single Rail 8Channel Flaw Detector for Track Inspection Eddy Current Testing Rail Eddy current test, a circular coil carrying current is placed in proximity to the test specimen (which must be electrically conductive). Recent studies [8,9] indicate that eddy current testing, among known physical test techniques (ultrasonic, optical, electromagnetic, thermal,. We are proud to supply ultrasonic and eddy current testing, two of the most common and effective forms of ndt testing in. Eddy Current Testing Rail.

From www.okondt.com

Eddy current testing of rails Eddy Current Testing Rail Eddy current inspection has been introduced to assess the presence and severity of rolling contact fatigue (rcf) in rail to assist in rail. In this study, using the 16ch eddy current rail defect detection equipment developed by applying the plus point sensor, finally, the. Eddy current test, a circular coil carrying current is placed in proximity to the test specimen. Eddy Current Testing Rail.

From www.ndt.com.ua

Eddy current testing of rails Eddy Current Testing Rail Eddy current test, a circular coil carrying current is placed in proximity to the test specimen (which must be electrically conductive). In this study, using the 16ch eddy current rail defect detection equipment developed by applying the plus point sensor, finally, the. Eddy current inspection has been introduced to assess the presence and severity of rolling contact fatigue (rcf) in. Eddy Current Testing Rail.

From www.okondt.com

Eddy Current Testing System of Rails EDC RAIL 5065 Eddy Current Testing Rail Recent studies [8,9] indicate that eddy current testing, among known physical test techniques (ultrasonic, optical, electromagnetic, thermal,. We are proud to supply ultrasonic and eddy current testing, two of the most common and effective forms of ndt testing in the railway industry. In this study, using the 16ch eddy current rail defect detection equipment developed by applying the plus point. Eddy Current Testing Rail.

From tiat.nl

Eddy Current Testing Tiat Europe B.V. Eddy Current Testing Rail We are proud to supply ultrasonic and eddy current testing, two of the most common and effective forms of ndt testing in the railway industry. In this study, using the 16ch eddy current rail defect detection equipment developed by applying the plus point sensor, finally, the. Eddy current inspection has been introduced to assess the presence and severity of rolling. Eddy Current Testing Rail.

From www.ndt.com.ua

Eddycurrent testing equipment Eddy Current Testing Rail We are proud to supply ultrasonic and eddy current testing, two of the most common and effective forms of ndt testing in the railway industry. In this study, using the 16ch eddy current rail defect detection equipment developed by applying the plus point sensor, finally, the. Eddy current test, a circular coil carrying current is placed in proximity to the. Eddy Current Testing Rail.