Burnishing Electric Clutch . reduce engine rpm before disengaging clutch. use the following procedure to burnish the clutch: this 22 minute video will help you on your way to troubleshooting electromagnetic clutch and brake issues. Check the air gap between armature and rotor. This will also maximize clutch life, and minimize clutch and brake wear. • engagement time depends on magnetic field strength, air gap, and inertia. Burnishing the clutch helps mate the. • electromagnetic clutches and brakes are electrically activated but transmit torque mechanically. when a machine is new or after a clutch has been replaced, it needs to be burnished. If the starting torque required from the clutch is less than half of what the torque rating. the reason for burnishing a clutch is to increase the initial starting torque. 1 verify appropriate shaft/pulley for clutch 2.

from www.beulahmachinery.com.au

• engagement time depends on magnetic field strength, air gap, and inertia. this 22 minute video will help you on your way to troubleshooting electromagnetic clutch and brake issues. This will also maximize clutch life, and minimize clutch and brake wear. If the starting torque required from the clutch is less than half of what the torque rating. Burnishing the clutch helps mate the. • electromagnetic clutches and brakes are electrically activated but transmit torque mechanically. the reason for burnishing a clutch is to increase the initial starting torque. use the following procedure to burnish the clutch: Check the air gap between armature and rotor. reduce engine rpm before disengaging clutch.

ELECTRIC CLUTCH 200 FTLB Beulah Machinery

Burnishing Electric Clutch use the following procedure to burnish the clutch: this 22 minute video will help you on your way to troubleshooting electromagnetic clutch and brake issues. • electromagnetic clutches and brakes are electrically activated but transmit torque mechanically. 1 verify appropriate shaft/pulley for clutch 2. when a machine is new or after a clutch has been replaced, it needs to be burnished. use the following procedure to burnish the clutch: Check the air gap between armature and rotor. the reason for burnishing a clutch is to increase the initial starting torque. Burnishing the clutch helps mate the. If the starting torque required from the clutch is less than half of what the torque rating. reduce engine rpm before disengaging clutch. • engagement time depends on magnetic field strength, air gap, and inertia. This will also maximize clutch life, and minimize clutch and brake wear.

From www.grainger.com

AMERICAN YARD PRODUCTS Electric Clutch Kit 33GV90174509 Grainger Burnishing Electric Clutch Burnishing the clutch helps mate the. If the starting torque required from the clutch is less than half of what the torque rating. Check the air gap between armature and rotor. reduce engine rpm before disengaging clutch. the reason for burnishing a clutch is to increase the initial starting torque. • engagement time depends on magnetic field strength,. Burnishing Electric Clutch.

From www.ncequipment.co.nz

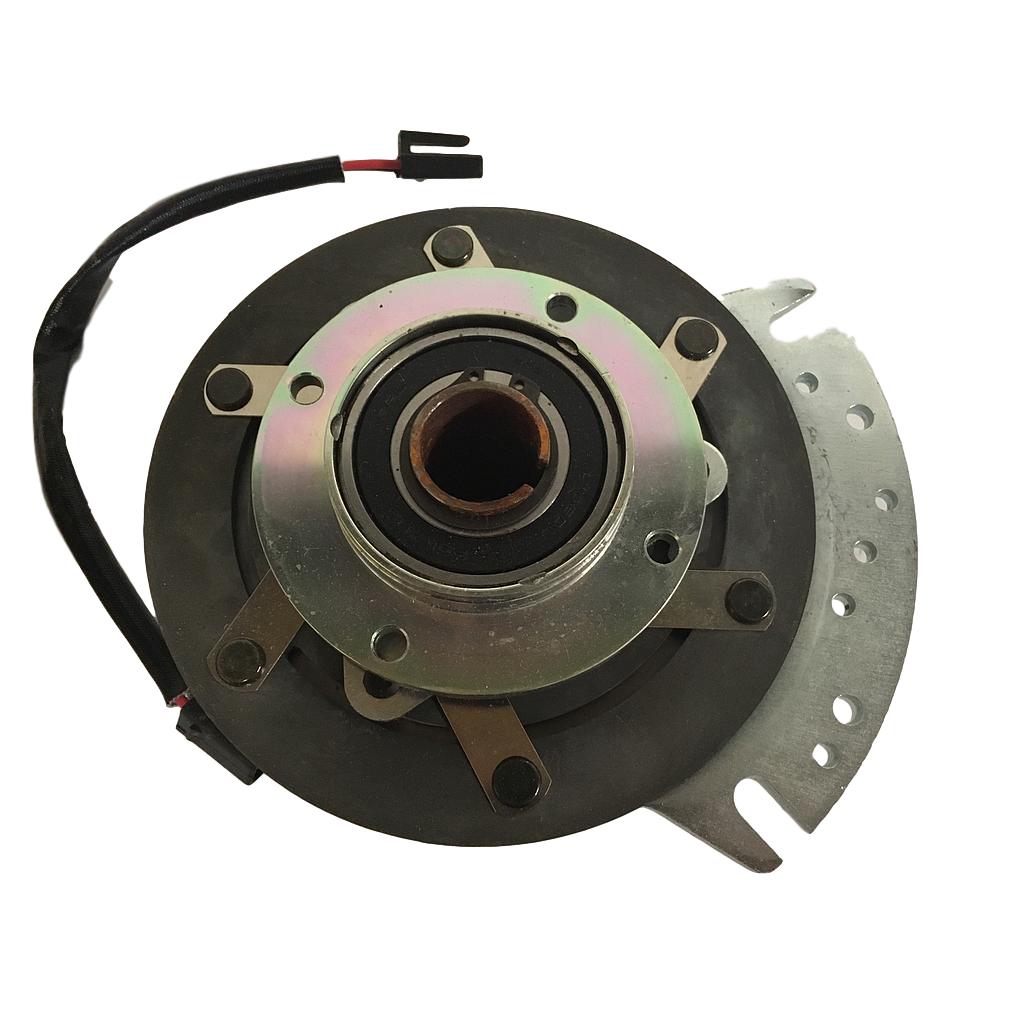

Ferris 400S Electric Clutch Assembly NC Equipment Burnishing Electric Clutch If the starting torque required from the clutch is less than half of what the torque rating. • engagement time depends on magnetic field strength, air gap, and inertia. Check the air gap between armature and rotor. the reason for burnishing a clutch is to increase the initial starting torque. this 22 minute video will help you on. Burnishing Electric Clutch.

From www.beulahmachinery.com.au

ELECTRIC CLUTCH WARNER (A) Morris Parts Beulah Machinery Burnishing Electric Clutch reduce engine rpm before disengaging clutch. Check the air gap between armature and rotor. this 22 minute video will help you on your way to troubleshooting electromagnetic clutch and brake issues. when a machine is new or after a clutch has been replaced, it needs to be burnished. • electromagnetic clutches and brakes are electrically activated but. Burnishing Electric Clutch.

From coastalhyd.com

Pitts 14728 Electric Clutch │ Coastal Hydraulics Burnishing Electric Clutch this 22 minute video will help you on your way to troubleshooting electromagnetic clutch and brake issues. This will also maximize clutch life, and minimize clutch and brake wear. the reason for burnishing a clutch is to increase the initial starting torque. • engagement time depends on magnetic field strength, air gap, and inertia. reduce engine rpm. Burnishing Electric Clutch.

From www.disenparts.com

Electric PTO Clutch 521891 Warner John Deere Xtreme Exmark Burnishing Electric Clutch this 22 minute video will help you on your way to troubleshooting electromagnetic clutch and brake issues. Check the air gap between armature and rotor. If the starting torque required from the clutch is less than half of what the torque rating. • electromagnetic clutches and brakes are electrically activated but transmit torque mechanically. the reason for burnishing. Burnishing Electric Clutch.

From www.smallenginesprodealer.com

12835 ELECTRIC PTO CLUTCH EXMARK 12835 SmallEnginesProDealer Burnishing Electric Clutch • engagement time depends on magnetic field strength, air gap, and inertia. This will also maximize clutch life, and minimize clutch and brake wear. when a machine is new or after a clutch has been replaced, it needs to be burnished. this 22 minute video will help you on your way to troubleshooting electromagnetic clutch and brake issues.. Burnishing Electric Clutch.

From bsidk.com

Electric clutch for transmission systems BSIdk Group Burnishing Electric Clutch • engagement time depends on magnetic field strength, air gap, and inertia. use the following procedure to burnish the clutch: If the starting torque required from the clutch is less than half of what the torque rating. • electromagnetic clutches and brakes are electrically activated but transmit torque mechanically. the reason for burnishing a clutch is to increase. Burnishing Electric Clutch.

From www.propartsdirect.net

Gravely Electric Clutches ProPartsDirect Burnishing Electric Clutch when a machine is new or after a clutch has been replaced, it needs to be burnished. use the following procedure to burnish the clutch: This will also maximize clutch life, and minimize clutch and brake wear. 1 verify appropriate shaft/pulley for clutch 2. Burnishing the clutch helps mate the. Check the air gap between armature and rotor.. Burnishing Electric Clutch.

From coastalhyd.com

Pitts 13817 Electric Clutch │ Coastal Hydraulics Burnishing Electric Clutch This will also maximize clutch life, and minimize clutch and brake wear. • engagement time depends on magnetic field strength, air gap, and inertia. use the following procedure to burnish the clutch: this 22 minute video will help you on your way to troubleshooting electromagnetic clutch and brake issues. reduce engine rpm before disengaging clutch. If the. Burnishing Electric Clutch.

From www.surpluscenter.com

Electric Clutch Assy 24 Volt DC 25P Sprocket Electric Clutches Burnishing Electric Clutch This will also maximize clutch life, and minimize clutch and brake wear. If the starting torque required from the clutch is less than half of what the torque rating. • electromagnetic clutches and brakes are electrically activated but transmit torque mechanically. Burnishing the clutch helps mate the. use the following procedure to burnish the clutch: the reason for. Burnishing Electric Clutch.

From www.sbmar.com

SMX 12V Electric Clutch Seaboard Marine Burnishing Electric Clutch Check the air gap between armature and rotor. This will also maximize clutch life, and minimize clutch and brake wear. the reason for burnishing a clutch is to increase the initial starting torque. • electromagnetic clutches and brakes are electrically activated but transmit torque mechanically. • engagement time depends on magnetic field strength, air gap, and inertia. when. Burnishing Electric Clutch.

From www.amazon.co.uk

3200W Electric Burnishing Polishing Machine 8 Adjustable Speed Drum Burnishing Electric Clutch reduce engine rpm before disengaging clutch. use the following procedure to burnish the clutch: 1 verify appropriate shaft/pulley for clutch 2. Check the air gap between armature and rotor. • engagement time depends on magnetic field strength, air gap, and inertia. If the starting torque required from the clutch is less than half of what the torque rating.. Burnishing Electric Clutch.

From www.bmikarts.com

Electric PTO Clutch 255932X BMI Karts and Parts Burnishing Electric Clutch when a machine is new or after a clutch has been replaced, it needs to be burnished. the reason for burnishing a clutch is to increase the initial starting torque. • electromagnetic clutches and brakes are electrically activated but transmit torque mechanically. • engagement time depends on magnetic field strength, air gap, and inertia. Check the air gap. Burnishing Electric Clutch.

From www.amazon.com

Industrial Electric Clutches Burnishing Electric Clutch use the following procedure to burnish the clutch: Burnishing the clutch helps mate the. when a machine is new or after a clutch has been replaced, it needs to be burnished. the reason for burnishing a clutch is to increase the initial starting torque. • electromagnetic clutches and brakes are electrically activated but transmit torque mechanically. This. Burnishing Electric Clutch.

From www.ncequipment.co.nz

Ferris Electric Clutch Assembly NC Equipment Burnishing Electric Clutch reduce engine rpm before disengaging clutch. the reason for burnishing a clutch is to increase the initial starting torque. This will also maximize clutch life, and minimize clutch and brake wear. use the following procedure to burnish the clutch: Check the air gap between armature and rotor. when a machine is new or after a clutch. Burnishing Electric Clutch.

From www.amazon.com

sowinkel Electric Burnishing Polishing Machine 110V 1400W Handheld Burnishing Electric Clutch this 22 minute video will help you on your way to troubleshooting electromagnetic clutch and brake issues. • engagement time depends on magnetic field strength, air gap, and inertia. This will also maximize clutch life, and minimize clutch and brake wear. reduce engine rpm before disengaging clutch. the reason for burnishing a clutch is to increase the. Burnishing Electric Clutch.

From www.clutchengineering.com

Electric Clutches and Brakes Clutch Engineering Burnishing Electric Clutch • electromagnetic clutches and brakes are electrically activated but transmit torque mechanically. use the following procedure to burnish the clutch: when a machine is new or after a clutch has been replaced, it needs to be burnished. This will also maximize clutch life, and minimize clutch and brake wear. reduce engine rpm before disengaging clutch. Check the. Burnishing Electric Clutch.

From salempwr.com

255855 } Electric PTO Clutch / Warner 5219147 Salem Power Equipment Burnishing Electric Clutch 1 verify appropriate shaft/pulley for clutch 2. This will also maximize clutch life, and minimize clutch and brake wear. If the starting torque required from the clutch is less than half of what the torque rating. when a machine is new or after a clutch has been replaced, it needs to be burnished. use the following procedure to. Burnishing Electric Clutch.

From www.bmikarts.com

Electric PTO Clutch / Warner 521998 255839 BMI Karts and Parts Burnishing Electric Clutch • electromagnetic clutches and brakes are electrically activated but transmit torque mechanically. • engagement time depends on magnetic field strength, air gap, and inertia. Check the air gap between armature and rotor. the reason for burnishing a clutch is to increase the initial starting torque. use the following procedure to burnish the clutch: this 22 minute video. Burnishing Electric Clutch.

From www.altrabrasil.com

Warner Electric Clutches and Brakes Altra Industrial Motion Brasil Burnishing Electric Clutch • engagement time depends on magnetic field strength, air gap, and inertia. use the following procedure to burnish the clutch: Check the air gap between armature and rotor. 1 verify appropriate shaft/pulley for clutch 2. Burnishing the clutch helps mate the. when a machine is new or after a clutch has been replaced, it needs to be burnished.. Burnishing Electric Clutch.

From www.banggood.com

220v 1400w electric burnishing machine 50/60hz burnishing polishing Burnishing Electric Clutch • engagement time depends on magnetic field strength, air gap, and inertia. use the following procedure to burnish the clutch: this 22 minute video will help you on your way to troubleshooting electromagnetic clutch and brake issues. If the starting torque required from the clutch is less than half of what the torque rating. reduce engine rpm. Burnishing Electric Clutch.

From www.banggood.com

220v 1400w electric burnishing machine 50/60hz burnishing polishing Burnishing Electric Clutch when a machine is new or after a clutch has been replaced, it needs to be burnished. Check the air gap between armature and rotor. • electromagnetic clutches and brakes are electrically activated but transmit torque mechanically. this 22 minute video will help you on your way to troubleshooting electromagnetic clutch and brake issues. reduce engine rpm. Burnishing Electric Clutch.

From www.propartsdirect.net

Badboy Electric Clutches ProPartsDirect Burnishing Electric Clutch use the following procedure to burnish the clutch: 1 verify appropriate shaft/pulley for clutch 2. If the starting torque required from the clutch is less than half of what the torque rating. the reason for burnishing a clutch is to increase the initial starting torque. reduce engine rpm before disengaging clutch. • engagement time depends on magnetic. Burnishing Electric Clutch.

From www.engineerlive.com

Electric clutch drives alternative options Engineer Live Burnishing Electric Clutch this 22 minute video will help you on your way to troubleshooting electromagnetic clutch and brake issues. Check the air gap between armature and rotor. when a machine is new or after a clutch has been replaced, it needs to be burnished. use the following procedure to burnish the clutch: the reason for burnishing a clutch. Burnishing Electric Clutch.

From www.gandy.net

Electric Clutch with 35Tooth Sprocket Gandy Burnishing Electric Clutch • engagement time depends on magnetic field strength, air gap, and inertia. • electromagnetic clutches and brakes are electrically activated but transmit torque mechanically. Burnishing the clutch helps mate the. This will also maximize clutch life, and minimize clutch and brake wear. If the starting torque required from the clutch is less than half of what the torque rating. . Burnishing Electric Clutch.

From www.gaspares.com.au

GA Spares ELECTRIC PTO CLUTCH ASSEMBLY 11/8" ID X 6.25" PULLEY Burnishing Electric Clutch If the starting torque required from the clutch is less than half of what the torque rating. • electromagnetic clutches and brakes are electrically activated but transmit torque mechanically. 1 verify appropriate shaft/pulley for clutch 2. this 22 minute video will help you on your way to troubleshooting electromagnetic clutch and brake issues. Burnishing the clutch helps mate the.. Burnishing Electric Clutch.

From www.beulahmachinery.com.au

ELECTRIC CLUTCH 200 FTLB Beulah Machinery Burnishing Electric Clutch the reason for burnishing a clutch is to increase the initial starting torque. use the following procedure to burnish the clutch: this 22 minute video will help you on your way to troubleshooting electromagnetic clutch and brake issues. Check the air gap between armature and rotor. If the starting torque required from the clutch is less than. Burnishing Electric Clutch.

From backwaterperformance.com

Electric Clutch Backwater Performance Burnishing Electric Clutch Burnishing the clutch helps mate the. 1 verify appropriate shaft/pulley for clutch 2. If the starting torque required from the clutch is less than half of what the torque rating. use the following procedure to burnish the clutch: Check the air gap between armature and rotor. the reason for burnishing a clutch is to increase the initial starting. Burnishing Electric Clutch.

From www.surpluscenter.com

24 Volt DC Electric Clutch Electric Clutches Clutches Power Burnishing Electric Clutch use the following procedure to burnish the clutch: • electromagnetic clutches and brakes are electrically activated but transmit torque mechanically. • engagement time depends on magnetic field strength, air gap, and inertia. 1 verify appropriate shaft/pulley for clutch 2. this 22 minute video will help you on your way to troubleshooting electromagnetic clutch and brake issues. the. Burnishing Electric Clutch.

From www.stens.com

X0196 PTO Clutch Burnishing Electric Clutch the reason for burnishing a clutch is to increase the initial starting torque. Check the air gap between armature and rotor. This will also maximize clutch life, and minimize clutch and brake wear. this 22 minute video will help you on your way to troubleshooting electromagnetic clutch and brake issues. Burnishing the clutch helps mate the. when. Burnishing Electric Clutch.

From www.propartsdirect.net

Gravely Electric Clutch 00389900 ProPartsDirect Burnishing Electric Clutch Burnishing the clutch helps mate the. 1 verify appropriate shaft/pulley for clutch 2. use the following procedure to burnish the clutch: If the starting torque required from the clutch is less than half of what the torque rating. when a machine is new or after a clutch has been replaced, it needs to be burnished. this 22. Burnishing Electric Clutch.

From www.disenparts.com

Electric PTO Clutch 5215142 Warner Luper Oregon Prime Rotary Xtreme Burnishing Electric Clutch If the starting torque required from the clutch is less than half of what the torque rating. use the following procedure to burnish the clutch: Burnishing the clutch helps mate the. the reason for burnishing a clutch is to increase the initial starting torque. • engagement time depends on magnetic field strength, air gap, and inertia. reduce. Burnishing Electric Clutch.

From backwaterperformance.com

Electric Clutch 40 Tooth Backwater Performance Burnishing Electric Clutch when a machine is new or after a clutch has been replaced, it needs to be burnished. the reason for burnishing a clutch is to increase the initial starting torque. reduce engine rpm before disengaging clutch. Check the air gap between armature and rotor. this 22 minute video will help you on your way to troubleshooting. Burnishing Electric Clutch.

From www.propartsdirect.net

Snapper Mower Electric Clutches ProPartsDirect Burnishing Electric Clutch This will also maximize clutch life, and minimize clutch and brake wear. 1 verify appropriate shaft/pulley for clutch 2. Burnishing the clutch helps mate the. Check the air gap between armature and rotor. reduce engine rpm before disengaging clutch. If the starting torque required from the clutch is less than half of what the torque rating. • engagement time. Burnishing Electric Clutch.

From joebakerequipsales.com

Warner Electric clutch/brake 3,600RPM 90 voltage DC 5/8" shaft with Burnishing Electric Clutch • electromagnetic clutches and brakes are electrically activated but transmit torque mechanically. the reason for burnishing a clutch is to increase the initial starting torque. Burnishing the clutch helps mate the. Check the air gap between armature and rotor. 1 verify appropriate shaft/pulley for clutch 2. this 22 minute video will help you on your way to troubleshooting. Burnishing Electric Clutch.