Water Jet Cutting Machine Pressure . learn how waterjet cutting works, what materials it can cut, and why it is a versatile and productive process. The waterjet nozzle is assisted by a vision system to facilitate the precise and efficient cutting of the part. a waterjet cutting machine can produce pressures as high as 100,000 psi or about 6900 bars. To put it into perspective, fire hoses generally deliver pressures between 8 to 20 bars. learn how to use waterjet cutting, a versatile and efficient method of cutting any material into any shape, with or without abrasives. learn how water jet cutting pressure varies based on factors such as horsepower, abrasive, velocity and type of pump. Find out the psi range, flow rate, and. learn how pump design, orifice size, and power density affect cutting speed, kerf width, and abrasive use in abrasive waterjet cutting.

from www.thefabricator.com

The waterjet nozzle is assisted by a vision system to facilitate the precise and efficient cutting of the part. learn how waterjet cutting works, what materials it can cut, and why it is a versatile and productive process. learn how water jet cutting pressure varies based on factors such as horsepower, abrasive, velocity and type of pump. learn how to use waterjet cutting, a versatile and efficient method of cutting any material into any shape, with or without abrasives. learn how pump design, orifice size, and power density affect cutting speed, kerf width, and abrasive use in abrasive waterjet cutting. To put it into perspective, fire hoses generally deliver pressures between 8 to 20 bars. Find out the psi range, flow rate, and. a waterjet cutting machine can produce pressures as high as 100,000 psi or about 6900 bars.

Pressure matters in abrasive waterjet cutting The Fabricator

Water Jet Cutting Machine Pressure The waterjet nozzle is assisted by a vision system to facilitate the precise and efficient cutting of the part. learn how water jet cutting pressure varies based on factors such as horsepower, abrasive, velocity and type of pump. learn how waterjet cutting works, what materials it can cut, and why it is a versatile and productive process. learn how to use waterjet cutting, a versatile and efficient method of cutting any material into any shape, with or without abrasives. To put it into perspective, fire hoses generally deliver pressures between 8 to 20 bars. Find out the psi range, flow rate, and. The waterjet nozzle is assisted by a vision system to facilitate the precise and efficient cutting of the part. learn how pump design, orifice size, and power density affect cutting speed, kerf width, and abrasive use in abrasive waterjet cutting. a waterjet cutting machine can produce pressures as high as 100,000 psi or about 6900 bars.

From www.machines4u.com.au

New 2022 flow Mach 500 Water Jet Cutters in INGLEBURN, NSW Water Jet Cutting Machine Pressure learn how pump design, orifice size, and power density affect cutting speed, kerf width, and abrasive use in abrasive waterjet cutting. learn how waterjet cutting works, what materials it can cut, and why it is a versatile and productive process. To put it into perspective, fire hoses generally deliver pressures between 8 to 20 bars. learn how. Water Jet Cutting Machine Pressure.

From www.ien.eu

Water Jet Cutting Systems Water Jet Cutting Machine Pressure To put it into perspective, fire hoses generally deliver pressures between 8 to 20 bars. a waterjet cutting machine can produce pressures as high as 100,000 psi or about 6900 bars. learn how waterjet cutting works, what materials it can cut, and why it is a versatile and productive process. learn how water jet cutting pressure varies. Water Jet Cutting Machine Pressure.

From yongchangwj.en.made-in-china.com

China L1515 High Pressure CNC Water Jet Cutter Machine with Ce Certificate China Water Jet Water Jet Cutting Machine Pressure The waterjet nozzle is assisted by a vision system to facilitate the precise and efficient cutting of the part. learn how water jet cutting pressure varies based on factors such as horsepower, abrasive, velocity and type of pump. a waterjet cutting machine can produce pressures as high as 100,000 psi or about 6900 bars. learn how to. Water Jet Cutting Machine Pressure.

From bttilemachine.en.alibaba.com

BT3020 CNC Granite Cutting Machine High Pressure Water Jet Cutter, View Granite Cutting Machine Water Jet Cutting Machine Pressure a waterjet cutting machine can produce pressures as high as 100,000 psi or about 6900 bars. learn how to use waterjet cutting, a versatile and efficient method of cutting any material into any shape, with or without abrasives. Find out the psi range, flow rate, and. The waterjet nozzle is assisted by a vision system to facilitate the. Water Jet Cutting Machine Pressure.

From ballardmachineworks.com

The Advantages and Disadvantages of Waterjet Cutting Ballard Machine Works Water Jet Cutting Machine Pressure Find out the psi range, flow rate, and. a waterjet cutting machine can produce pressures as high as 100,000 psi or about 6900 bars. learn how water jet cutting pressure varies based on factors such as horsepower, abrasive, velocity and type of pump. learn how to use waterjet cutting, a versatile and efficient method of cutting any. Water Jet Cutting Machine Pressure.

From swaterjet.com

How accurate is water jet cutting Same Waterjet Water Jet Cutting Machine Pressure Find out the psi range, flow rate, and. a waterjet cutting machine can produce pressures as high as 100,000 psi or about 6900 bars. learn how water jet cutting pressure varies based on factors such as horsepower, abrasive, velocity and type of pump. learn how pump design, orifice size, and power density affect cutting speed, kerf width,. Water Jet Cutting Machine Pressure.

From www.thefabricator.com

Pressure matters in abrasive waterjet cutting The Fabricator Water Jet Cutting Machine Pressure learn how to use waterjet cutting, a versatile and efficient method of cutting any material into any shape, with or without abrasives. The waterjet nozzle is assisted by a vision system to facilitate the precise and efficient cutting of the part. learn how water jet cutting pressure varies based on factors such as horsepower, abrasive, velocity and type. Water Jet Cutting Machine Pressure.

From thedishh.com

Precision Cutting 7 Benefits of Waterjet Cutting Technology The Dishh Water Jet Cutting Machine Pressure To put it into perspective, fire hoses generally deliver pressures between 8 to 20 bars. learn how to use waterjet cutting, a versatile and efficient method of cutting any material into any shape, with or without abrasives. The waterjet nozzle is assisted by a vision system to facilitate the precise and efficient cutting of the part. a waterjet. Water Jet Cutting Machine Pressure.

From www.aliexpress.com

High pressure water jet cutting machine ,small waterjet cutting machine ,1000x1000mm small glass Water Jet Cutting Machine Pressure To put it into perspective, fire hoses generally deliver pressures between 8 to 20 bars. learn how waterjet cutting works, what materials it can cut, and why it is a versatile and productive process. a waterjet cutting machine can produce pressures as high as 100,000 psi or about 6900 bars. The waterjet nozzle is assisted by a vision. Water Jet Cutting Machine Pressure.

From www.thefabricator.com

The Basics behind Waterjet Cutting Pressure Water Jet Cutting Machine Pressure Find out the psi range, flow rate, and. learn how waterjet cutting works, what materials it can cut, and why it is a versatile and productive process. To put it into perspective, fire hoses generally deliver pressures between 8 to 20 bars. learn how to use waterjet cutting, a versatile and efficient method of cutting any material into. Water Jet Cutting Machine Pressure.

From www.waterjetsweden.co.uk

Micro and small Water Jet Sweden cutting machines Water Jet Cutting Machine Pressure To put it into perspective, fire hoses generally deliver pressures between 8 to 20 bars. learn how water jet cutting pressure varies based on factors such as horsepower, abrasive, velocity and type of pump. learn how waterjet cutting works, what materials it can cut, and why it is a versatile and productive process. Find out the psi range,. Water Jet Cutting Machine Pressure.

From www.unnatitubecleaning.com

High Pressure Water Jet Machine Manufacturer from Thane Water Jet Cutting Machine Pressure learn how water jet cutting pressure varies based on factors such as horsepower, abrasive, velocity and type of pump. To put it into perspective, fire hoses generally deliver pressures between 8 to 20 bars. learn how pump design, orifice size, and power density affect cutting speed, kerf width, and abrasive use in abrasive waterjet cutting. Find out the. Water Jet Cutting Machine Pressure.

From www.indiamart.com

CNC Water Jet Cutting Machine, वॉटर जेट कटिंग मशीन in Sarkhej, Ahmedabad , A Innovative Water Jet Cutting Machine Pressure learn how to use waterjet cutting, a versatile and efficient method of cutting any material into any shape, with or without abrasives. a waterjet cutting machine can produce pressures as high as 100,000 psi or about 6900 bars. learn how waterjet cutting works, what materials it can cut, and why it is a versatile and productive process.. Water Jet Cutting Machine Pressure.

From www.aliexpress.com

water jet cutter cutting machines for sale ,high pressure water cutting abrasive jet machining Water Jet Cutting Machine Pressure The waterjet nozzle is assisted by a vision system to facilitate the precise and efficient cutting of the part. a waterjet cutting machine can produce pressures as high as 100,000 psi or about 6900 bars. learn how pump design, orifice size, and power density affect cutting speed, kerf width, and abrasive use in abrasive waterjet cutting. learn. Water Jet Cutting Machine Pressure.

From www.tradekeyindia.com

Water Jet Cutting Machine Wholesaler Manufacturer Exporters Suppliers Gujarat India Water Jet Cutting Machine Pressure The waterjet nozzle is assisted by a vision system to facilitate the precise and efficient cutting of the part. learn how waterjet cutting works, what materials it can cut, and why it is a versatile and productive process. learn how pump design, orifice size, and power density affect cutting speed, kerf width, and abrasive use in abrasive waterjet. Water Jet Cutting Machine Pressure.

From www.alibaba.com

Ultra High Pressure 50hp Imported Hypertherm Intensifier Pump Used For Water Jet Cutting Machine Water Jet Cutting Machine Pressure learn how pump design, orifice size, and power density affect cutting speed, kerf width, and abrasive use in abrasive waterjet cutting. learn how water jet cutting pressure varies based on factors such as horsepower, abrasive, velocity and type of pump. a waterjet cutting machine can produce pressures as high as 100,000 psi or about 6900 bars. To. Water Jet Cutting Machine Pressure.

From www.youtube.com

portable water jet cutting machine YouTube Water Jet Cutting Machine Pressure learn how water jet cutting pressure varies based on factors such as horsepower, abrasive, velocity and type of pump. learn how to use waterjet cutting, a versatile and efficient method of cutting any material into any shape, with or without abrasives. The waterjet nozzle is assisted by a vision system to facilitate the precise and efficient cutting of. Water Jet Cutting Machine Pressure.

From hdwaterjet.en.made-in-china.com

Reasonable Price Used 3 Axis Water Jet Cutting Machine China Waterjet Cutters and 3 Axis Water Jet Cutting Machine Pressure The waterjet nozzle is assisted by a vision system to facilitate the precise and efficient cutting of the part. a waterjet cutting machine can produce pressures as high as 100,000 psi or about 6900 bars. learn how waterjet cutting works, what materials it can cut, and why it is a versatile and productive process. Find out the psi. Water Jet Cutting Machine Pressure.

From www.xecnc.com

Fast Extreme Water Jet Cutter Machine Working, Modern Technology Waterjet Cutting Compilation Water Jet Cutting Machine Pressure The waterjet nozzle is assisted by a vision system to facilitate the precise and efficient cutting of the part. learn how pump design, orifice size, and power density affect cutting speed, kerf width, and abrasive use in abrasive waterjet cutting. To put it into perspective, fire hoses generally deliver pressures between 8 to 20 bars. learn how waterjet. Water Jet Cutting Machine Pressure.

From finemetalworking.com

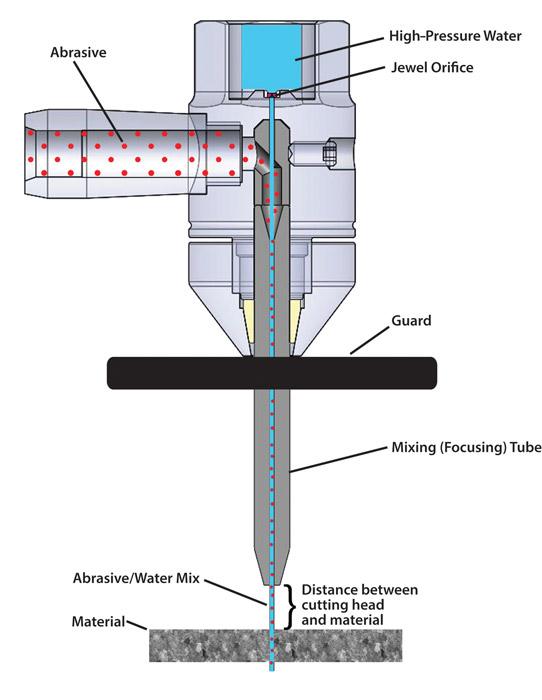

Abrasive Water Jet Machining. How Water Jet Cutter Works? Water Jet Cutting Machine Pressure learn how pump design, orifice size, and power density affect cutting speed, kerf width, and abrasive use in abrasive waterjet cutting. learn how water jet cutting pressure varies based on factors such as horsepower, abrasive, velocity and type of pump. To put it into perspective, fire hoses generally deliver pressures between 8 to 20 bars. learn how. Water Jet Cutting Machine Pressure.

From www.dreamstime.com

High Pressure Water Jet Cutting Machine for Various Materials Stock Photo Image of indoors Water Jet Cutting Machine Pressure Find out the psi range, flow rate, and. learn how to use waterjet cutting, a versatile and efficient method of cutting any material into any shape, with or without abrasives. learn how waterjet cutting works, what materials it can cut, and why it is a versatile and productive process. To put it into perspective, fire hoses generally deliver. Water Jet Cutting Machine Pressure.

From megafoaminc.com

Waterjet Cutting Waterjet Cutting Materials Megafoam Inc. Water Jet Cutting Machine Pressure learn how to use waterjet cutting, a versatile and efficient method of cutting any material into any shape, with or without abrasives. a waterjet cutting machine can produce pressures as high as 100,000 psi or about 6900 bars. The waterjet nozzle is assisted by a vision system to facilitate the precise and efficient cutting of the part. . Water Jet Cutting Machine Pressure.

From www.aquajetservices.com

Description of a Waterjet Cutting System A Technical Guide to Waterjet Cutting AquaJet Services Water Jet Cutting Machine Pressure Find out the psi range, flow rate, and. The waterjet nozzle is assisted by a vision system to facilitate the precise and efficient cutting of the part. learn how pump design, orifice size, and power density affect cutting speed, kerf width, and abrasive use in abrasive waterjet cutting. learn how waterjet cutting works, what materials it can cut,. Water Jet Cutting Machine Pressure.

From www.pressurejet.com

High Pressure Water Jetting Equipment HydroJet Equipment PressureJet Water Jet Cutting Machine Pressure learn how pump design, orifice size, and power density affect cutting speed, kerf width, and abrasive use in abrasive waterjet cutting. learn how water jet cutting pressure varies based on factors such as horsepower, abrasive, velocity and type of pump. learn how waterjet cutting works, what materials it can cut, and why it is a versatile and. Water Jet Cutting Machine Pressure.

From sciencemark.org

Water Jet Cutting How It Works Science Mark Currency Trading Services Tips Water Jet Cutting Machine Pressure learn how waterjet cutting works, what materials it can cut, and why it is a versatile and productive process. Find out the psi range, flow rate, and. learn how pump design, orifice size, and power density affect cutting speed, kerf width, and abrasive use in abrasive waterjet cutting. a waterjet cutting machine can produce pressures as high. Water Jet Cutting Machine Pressure.

From www.alibaba.com

High Pressure Water Jet Cutting Machine Double Intensifier Pump Buy High Pressure Double Water Jet Cutting Machine Pressure To put it into perspective, fire hoses generally deliver pressures between 8 to 20 bars. The waterjet nozzle is assisted by a vision system to facilitate the precise and efficient cutting of the part. learn how waterjet cutting works, what materials it can cut, and why it is a versatile and productive process. learn how water jet cutting. Water Jet Cutting Machine Pressure.

From www.cam-concept.de

Water Jet Cam Concept Water Jet Cutting Machine Pressure The waterjet nozzle is assisted by a vision system to facilitate the precise and efficient cutting of the part. learn how to use waterjet cutting, a versatile and efficient method of cutting any material into any shape, with or without abrasives. learn how pump design, orifice size, and power density affect cutting speed, kerf width, and abrasive use. Water Jet Cutting Machine Pressure.

From pressurejet.com

High Pressure water Jetting Pumps, Water Jet Cleaning Machine PressureJet Water Jet Cutting Machine Pressure learn how pump design, orifice size, and power density affect cutting speed, kerf width, and abrasive use in abrasive waterjet cutting. Find out the psi range, flow rate, and. learn how to use waterjet cutting, a versatile and efficient method of cutting any material into any shape, with or without abrasives. To put it into perspective, fire hoses. Water Jet Cutting Machine Pressure.

From www.laser-cutter-machine.com

high pressure water jet metal cutting machine ACCURL Water Jet Cutting Machine Pressure To put it into perspective, fire hoses generally deliver pressures between 8 to 20 bars. Find out the psi range, flow rate, and. learn how waterjet cutting works, what materials it can cut, and why it is a versatile and productive process. learn how water jet cutting pressure varies based on factors such as horsepower, abrasive, velocity and. Water Jet Cutting Machine Pressure.

From mmwaterjet.com

Portable Waterjet Cutting Midwest Mobile Waterjet Water Jet Cutting Machine Pressure To put it into perspective, fire hoses generally deliver pressures between 8 to 20 bars. Find out the psi range, flow rate, and. learn how waterjet cutting works, what materials it can cut, and why it is a versatile and productive process. learn how water jet cutting pressure varies based on factors such as horsepower, abrasive, velocity and. Water Jet Cutting Machine Pressure.

From arironllc.com

How Accurate is Water Jet Cutting? Water Jet Cutting Machine Pressure learn how waterjet cutting works, what materials it can cut, and why it is a versatile and productive process. learn how to use waterjet cutting, a versatile and efficient method of cutting any material into any shape, with or without abrasives. a waterjet cutting machine can produce pressures as high as 100,000 psi or about 6900 bars.. Water Jet Cutting Machine Pressure.

From www.laser-cutter-machine.com

ultra high pressure gantry 3020 waterjet cutting machine ACCURL Water Jet Cutting Machine Pressure learn how to use waterjet cutting, a versatile and efficient method of cutting any material into any shape, with or without abrasives. learn how pump design, orifice size, and power density affect cutting speed, kerf width, and abrasive use in abrasive waterjet cutting. Find out the psi range, flow rate, and. learn how water jet cutting pressure. Water Jet Cutting Machine Pressure.

From www.norwoodmedical.com

Water Jet Cutting Norwood Medical Water Jet Cutting Machine Pressure To put it into perspective, fire hoses generally deliver pressures between 8 to 20 bars. learn how pump design, orifice size, and power density affect cutting speed, kerf width, and abrasive use in abrasive waterjet cutting. a waterjet cutting machine can produce pressures as high as 100,000 psi or about 6900 bars. learn how water jet cutting. Water Jet Cutting Machine Pressure.

From www.dreamstime.com

High Pressure Water Jet Cutting Machine for Various Materials Stock Photo Image of industry Water Jet Cutting Machine Pressure Find out the psi range, flow rate, and. learn how water jet cutting pressure varies based on factors such as horsepower, abrasive, velocity and type of pump. a waterjet cutting machine can produce pressures as high as 100,000 psi or about 6900 bars. learn how to use waterjet cutting, a versatile and efficient method of cutting any. Water Jet Cutting Machine Pressure.

From www.dreamstime.com

CNC Water Jet Cutting Machine Stock Image Image of industry, plate 160977737 Water Jet Cutting Machine Pressure Find out the psi range, flow rate, and. learn how water jet cutting pressure varies based on factors such as horsepower, abrasive, velocity and type of pump. learn how waterjet cutting works, what materials it can cut, and why it is a versatile and productive process. The waterjet nozzle is assisted by a vision system to facilitate the. Water Jet Cutting Machine Pressure.