Welding Rod Material Name . They create a stable arc and are great at shallow penetration. The mig welding electrode is a. These welding rods support both ac and dc current and are ideal for welding with minimal spatter and slag. The rods provide the necessary filler material. These six different types of welding rods are the most uses and quite popular in the welding industry. The most recommended electrode to use while working with dirty metals like having rust or oil and dust on them is the e6010 or e6011. Welding electrode types are consumable metal rods or wires for creating durable bonds between metals in various applications. Each type of flux coating has certain. Tig filler rods are an optional filler material used to fuse two pieces of stock together as a composite. The smaw electrodes are grouped based on their flux coating type into three groups; Welding rod for rusty material? 6010 electrodes used to deliver deep. The main three groups are:

from weldingpros.net

Each type of flux coating has certain. The main three groups are: These six different types of welding rods are the most uses and quite popular in the welding industry. They create a stable arc and are great at shallow penetration. The most recommended electrode to use while working with dirty metals like having rust or oil and dust on them is the e6010 or e6011. 6010 electrodes used to deliver deep. Welding electrode types are consumable metal rods or wires for creating durable bonds between metals in various applications. The rods provide the necessary filler material. The smaw electrodes are grouped based on their flux coating type into three groups; Tig filler rods are an optional filler material used to fuse two pieces of stock together as a composite.

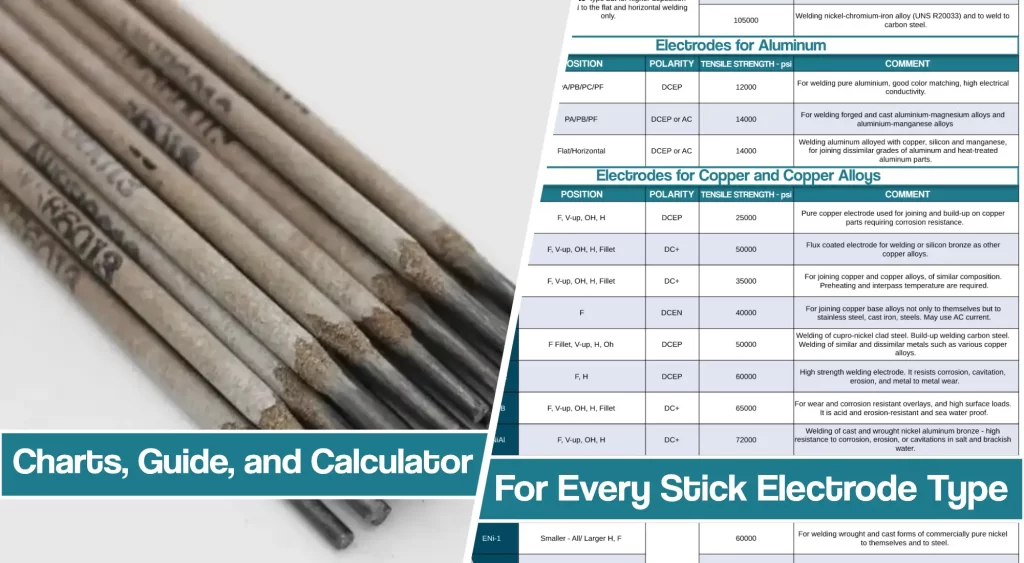

Stick Welding Rod Charts and Calculator Amps, Sizes, Types

Welding Rod Material Name The rods provide the necessary filler material. These welding rods support both ac and dc current and are ideal for welding with minimal spatter and slag. These six different types of welding rods are the most uses and quite popular in the welding industry. Welding electrode types are consumable metal rods or wires for creating durable bonds between metals in various applications. Each type of flux coating has certain. The rods provide the necessary filler material. They create a stable arc and are great at shallow penetration. The most recommended electrode to use while working with dirty metals like having rust or oil and dust on them is the e6010 or e6011. Tig filler rods are an optional filler material used to fuse two pieces of stock together as a composite. 6010 electrodes used to deliver deep. The mig welding electrode is a. The main three groups are: The smaw electrodes are grouped based on their flux coating type into three groups; Welding rod for rusty material?

From www.indiamart.com

Carbon Gouging Torch 800 Amps for Metal Removal and Surface Preparation Welding Rod Material Name They create a stable arc and are great at shallow penetration. Each type of flux coating has certain. The main three groups are: The smaw electrodes are grouped based on their flux coating type into three groups; The most recommended electrode to use while working with dirty metals like having rust or oil and dust on them is the e6010. Welding Rod Material Name.

From www.weldingcity.com

1/8" x 36" WeldingCity® ER308L Stainless Steel TIG Welding Rods Welding Rod Material Name The rods provide the necessary filler material. The most recommended electrode to use while working with dirty metals like having rust or oil and dust on them is the e6010 or e6011. The main three groups are: The smaw electrodes are grouped based on their flux coating type into three groups; They create a stable arc and are great at. Welding Rod Material Name.

From blog.thepipingmart.com

Stainless Steel Arc Welding Rods Types and Benefits Welding Rod Material Name Welding rod for rusty material? The mig welding electrode is a. Tig filler rods are an optional filler material used to fuse two pieces of stock together as a composite. The smaw electrodes are grouped based on their flux coating type into three groups; These welding rods support both ac and dc current and are ideal for welding with minimal. Welding Rod Material Name.

From www.makro.co.za

Yiad YD57315 Welding Paste Makro Welding Rod Material Name Welding rod for rusty material? They create a stable arc and are great at shallow penetration. These six different types of welding rods are the most uses and quite popular in the welding industry. 6010 electrodes used to deliver deep. The smaw electrodes are grouped based on their flux coating type into three groups; Tig filler rods are an optional. Welding Rod Material Name.

From weldingzilla.com

Types of Welding Rods and Their Applications Welding Rod Material Name The most recommended electrode to use while working with dirty metals like having rust or oil and dust on them is the e6010 or e6011. The rods provide the necessary filler material. They create a stable arc and are great at shallow penetration. Each type of flux coating has certain. These six different types of welding rods are the most. Welding Rod Material Name.

From www.polyvance.com

Welding Rod List Welding Rod Material Name These welding rods support both ac and dc current and are ideal for welding with minimal spatter and slag. Welding electrode types are consumable metal rods or wires for creating durable bonds between metals in various applications. 6010 electrodes used to deliver deep. The most recommended electrode to use while working with dirty metals like having rust or oil and. Welding Rod Material Name.

From www.makro.co.za

Dromex MIIZU300HI Polyester Safety Gloves (Pack of 2) Makro Welding Rod Material Name Welding electrode types are consumable metal rods or wires for creating durable bonds between metals in various applications. These six different types of welding rods are the most uses and quite popular in the welding industry. These welding rods support both ac and dc current and are ideal for welding with minimal spatter and slag. The main three groups are:. Welding Rod Material Name.

From www.makro.co.za

uvex unipur 6639 Nylon Safety Gloves Makro Welding Rod Material Name Welding electrode types are consumable metal rods or wires for creating durable bonds between metals in various applications. The most recommended electrode to use while working with dirty metals like having rust or oil and dust on them is the e6010 or e6011. The rods provide the necessary filler material. They create a stable arc and are great at shallow. Welding Rod Material Name.

From www.zhiliwearparts.com

Roller press rollerZhili New Materials Welding Rod Material Name Welding electrode types are consumable metal rods or wires for creating durable bonds between metals in various applications. Tig filler rods are an optional filler material used to fuse two pieces of stock together as a composite. The main three groups are: The most recommended electrode to use while working with dirty metals like having rust or oil and dust. Welding Rod Material Name.

From www.weldconnect.com.au

4043 ALUMINIUM TIG WELDING RODS Welding Rod Material Name The main three groups are: The smaw electrodes are grouped based on their flux coating type into three groups; Tig filler rods are an optional filler material used to fuse two pieces of stock together as a composite. These six different types of welding rods are the most uses and quite popular in the welding industry. Welding rod for rusty. Welding Rod Material Name.

From weldingtroop.com

What Welding Rod to use for Cast Iron? Guidelines for Welding Cast Iron Welding Rod Material Name They create a stable arc and are great at shallow penetration. Welding electrode types are consumable metal rods or wires for creating durable bonds between metals in various applications. The mig welding electrode is a. The main three groups are: These welding rods support both ac and dc current and are ideal for welding with minimal spatter and slag. 6010. Welding Rod Material Name.

From www.pinterest.com

Pin on dimecsa works Welding Rod Material Name The most recommended electrode to use while working with dirty metals like having rust or oil and dust on them is the e6010 or e6011. They create a stable arc and are great at shallow penetration. Welding rod for rusty material? The rods provide the necessary filler material. 6010 electrodes used to deliver deep. The smaw electrodes are grouped based. Welding Rod Material Name.

From www.makro.co.za

Pioneer 100004 Latex Safety Gloves (Pack of 2) Makro Welding Rod Material Name They create a stable arc and are great at shallow penetration. Welding electrode types are consumable metal rods or wires for creating durable bonds between metals in various applications. These six different types of welding rods are the most uses and quite popular in the welding industry. The smaw electrodes are grouped based on their flux coating type into three. Welding Rod Material Name.

From www.thefabricator.com

Stick welding basics How to stick weld Welding Rod Material Name 6010 electrodes used to deliver deep. The smaw electrodes are grouped based on their flux coating type into three groups; Welding electrode types are consumable metal rods or wires for creating durable bonds between metals in various applications. The most recommended electrode to use while working with dirty metals like having rust or oil and dust on them is the. Welding Rod Material Name.

From www.pinterest.co.uk

tigchart2 Welding rod chart, Welding rods, Welding and fabrication Welding Rod Material Name Tig filler rods are an optional filler material used to fuse two pieces of stock together as a composite. Welding electrode types are consumable metal rods or wires for creating durable bonds between metals in various applications. They create a stable arc and are great at shallow penetration. Welding rod for rusty material? The main three groups are: These six. Welding Rod Material Name.

From www.indiamart.com

Mangalam 350 mm Mild Steel Welding Rods, Size 3.15 mm, Model Name Welding Rod Material Name Tig filler rods are an optional filler material used to fuse two pieces of stock together as a composite. Welding rod for rusty material? They create a stable arc and are great at shallow penetration. The rods provide the necessary filler material. These welding rods support both ac and dc current and are ideal for welding with minimal spatter and. Welding Rod Material Name.

From weldingrods.com

Welding Rod Chart Welding Rod Material Name The mig welding electrode is a. The most recommended electrode to use while working with dirty metals like having rust or oil and dust on them is the e6010 or e6011. The rods provide the necessary filler material. Tig filler rods are an optional filler material used to fuse two pieces of stock together as a composite. These six different. Welding Rod Material Name.

From shopee.ph

dailylife1.ph ️4mm Multimeter Probes Silicone Banana Socket Quick Test Welding Rod Material Name The most recommended electrode to use while working with dirty metals like having rust or oil and dust on them is the e6010 or e6011. Each type of flux coating has certain. 6010 electrodes used to deliver deep. The rods provide the necessary filler material. The smaw electrodes are grouped based on their flux coating type into three groups; The. Welding Rod Material Name.

From www.makro.co.za

Golden Hands NGB002 Nitrile Safety Gloves Makro Welding Rod Material Name They create a stable arc and are great at shallow penetration. Tig filler rods are an optional filler material used to fuse two pieces of stock together as a composite. The main three groups are: The most recommended electrode to use while working with dirty metals like having rust or oil and dust on them is the e6010 or e6011.. Welding Rod Material Name.

From exommtwxx.blob.core.windows.net

Material Group For Welding at Benjamin Leon blog Welding Rod Material Name These welding rods support both ac and dc current and are ideal for welding with minimal spatter and slag. The most recommended electrode to use while working with dirty metals like having rust or oil and dust on them is the e6010 or e6011. Tig filler rods are an optional filler material used to fuse two pieces of stock together. Welding Rod Material Name.

From www.indiamart.com

Welding Rod at best price in Ahmedabad by Aadinath Tools Traders ID Welding Rod Material Name Each type of flux coating has certain. Tig filler rods are an optional filler material used to fuse two pieces of stock together as a composite. They create a stable arc and are great at shallow penetration. The smaw electrodes are grouped based on their flux coating type into three groups; The main three groups are: The most recommended electrode. Welding Rod Material Name.

From www.cnwearparts.com

Roller press rollerZhili New Materials Welding Rod Material Name Welding electrode types are consumable metal rods or wires for creating durable bonds between metals in various applications. The main three groups are: Welding rod for rusty material? Tig filler rods are an optional filler material used to fuse two pieces of stock together as a composite. These welding rods support both ac and dc current and are ideal for. Welding Rod Material Name.

From www.wcwelding.com

Arc Welding Rods Guide Welding Rod Material Name Each type of flux coating has certain. The smaw electrodes are grouped based on their flux coating type into three groups; They create a stable arc and are great at shallow penetration. The mig welding electrode is a. The most recommended electrode to use while working with dirty metals like having rust or oil and dust on them is the. Welding Rod Material Name.

From www.makro.co.za

Yiad YD57320 Welding Paste Makro Welding Rod Material Name These six different types of welding rods are the most uses and quite popular in the welding industry. These welding rods support both ac and dc current and are ideal for welding with minimal spatter and slag. Welding rod for rusty material? The main three groups are: The most recommended electrode to use while working with dirty metals like having. Welding Rod Material Name.

From mavink.com

Different Types Of Welding Rods Welding Rod Material Name 6010 electrodes used to deliver deep. These six different types of welding rods are the most uses and quite popular in the welding industry. Each type of flux coating has certain. The rods provide the necessary filler material. The smaw electrodes are grouped based on their flux coating type into three groups; These welding rods support both ac and dc. Welding Rod Material Name.

From www.zhiliwearparts.com

Roller press rollerZhili New Materials Welding Rod Material Name These welding rods support both ac and dc current and are ideal for welding with minimal spatter and slag. The most recommended electrode to use while working with dirty metals like having rust or oil and dust on them is the e6010 or e6011. The rods provide the necessary filler material. The main three groups are: The smaw electrodes are. Welding Rod Material Name.

From www.mechanicwiz.com

Welding Rod Chart & Classification Welding Rod Material Name Each type of flux coating has certain. The most recommended electrode to use while working with dirty metals like having rust or oil and dust on them is the e6010 or e6011. Welding electrode types are consumable metal rods or wires for creating durable bonds between metals in various applications. The mig welding electrode is a. 6010 electrodes used to. Welding Rod Material Name.

From www.indiamart.com

Mild Steel MS Welding Rod, Rs 105 /kg RND Welding ID 23155176830 Welding Rod Material Name 6010 electrodes used to deliver deep. These six different types of welding rods are the most uses and quite popular in the welding industry. They create a stable arc and are great at shallow penetration. The main three groups are: These welding rods support both ac and dc current and are ideal for welding with minimal spatter and slag. Welding. Welding Rod Material Name.

From www.zhiliwearparts.com

Roller press rollerZhili New Materials Welding Rod Material Name They create a stable arc and are great at shallow penetration. These six different types of welding rods are the most uses and quite popular in the welding industry. The mig welding electrode is a. Tig filler rods are an optional filler material used to fuse two pieces of stock together as a composite. The main three groups are: 6010. Welding Rod Material Name.

From weldingpros.net

Stick Welding Rod Charts and Calculator Amps, Sizes, Types Welding Rod Material Name The smaw electrodes are grouped based on their flux coating type into three groups; The main three groups are: The rods provide the necessary filler material. Each type of flux coating has certain. Welding electrode types are consumable metal rods or wires for creating durable bonds between metals in various applications. They create a stable arc and are great at. Welding Rod Material Name.

From blog.thepipingmart.com

Best Welding Rod for En19 Material Welding Rod Material Name 6010 electrodes used to deliver deep. The smaw electrodes are grouped based on their flux coating type into three groups; The rods provide the necessary filler material. Tig filler rods are an optional filler material used to fuse two pieces of stock together as a composite. They create a stable arc and are great at shallow penetration. Each type of. Welding Rod Material Name.

From blog.thepipingmart.com

Best Welding Rod For Manganese Welding Rod Material Name The most recommended electrode to use while working with dirty metals like having rust or oil and dust on them is the e6010 or e6011. Each type of flux coating has certain. These six different types of welding rods are the most uses and quite popular in the welding industry. These welding rods support both ac and dc current and. Welding Rod Material Name.

From www.makro.co.za

GC CORP LatexPowderFree100 Latex Safety Gloves Makro Welding Rod Material Name The most recommended electrode to use while working with dirty metals like having rust or oil and dust on them is the e6010 or e6011. Welding electrode types are consumable metal rods or wires for creating durable bonds between metals in various applications. 6010 electrodes used to deliver deep. These welding rods support both ac and dc current and are. Welding Rod Material Name.

From www.myxxgirl.com

Arc Welding Rod Chart My XXX Hot Girl Welding Rod Material Name Each type of flux coating has certain. They create a stable arc and are great at shallow penetration. The smaw electrodes are grouped based on their flux coating type into three groups; The most recommended electrode to use while working with dirty metals like having rust or oil and dust on them is the e6010 or e6011. The main three. Welding Rod Material Name.

From www.makro.co.za

GC CORP BLUELARGE Nitrile Safety Gloves (Pack of 100) Makro Welding Rod Material Name These six different types of welding rods are the most uses and quite popular in the welding industry. Tig filler rods are an optional filler material used to fuse two pieces of stock together as a composite. These welding rods support both ac and dc current and are ideal for welding with minimal spatter and slag. Each type of flux. Welding Rod Material Name.