Press Brake Hem Tooling . With tooling and clamping solutions geared toward decreasing press brake setup times, speeding part flow and optimizing part quality, press brake. The edge of the sheet metal includes either a hem. Material thickness up to 0.118 (3.00mm). Top tools and bottom tools, (punches and dies respectively) work in unison at the business end of your press brake. All of wilson tool’s product lines offer a solution to. Press brake toolings, a guide to punches and dies. They work by folding your workpiece between a matching punch and die and applying force to bend the material (typically sheet metal and metal plate) in to a pre. See how this custom hemming tool, gapped to provide space for material thickness, makes a hem with two hits and one punch and die set in. How to apply the bend functions for a bent and hemmed part. Hemming punch and die sets are used to flatten or hem a part after a 30° bend has been made.

from www.youtube.com

All of wilson tool’s product lines offer a solution to. How to apply the bend functions for a bent and hemmed part. They work by folding your workpiece between a matching punch and die and applying force to bend the material (typically sheet metal and metal plate) in to a pre. Material thickness up to 0.118 (3.00mm). With tooling and clamping solutions geared toward decreasing press brake setup times, speeding part flow and optimizing part quality, press brake. Top tools and bottom tools, (punches and dies respectively) work in unison at the business end of your press brake. Press brake toolings, a guide to punches and dies. Hemming punch and die sets are used to flatten or hem a part after a 30° bend has been made. The edge of the sheet metal includes either a hem. See how this custom hemming tool, gapped to provide space for material thickness, makes a hem with two hits and one punch and die set in.

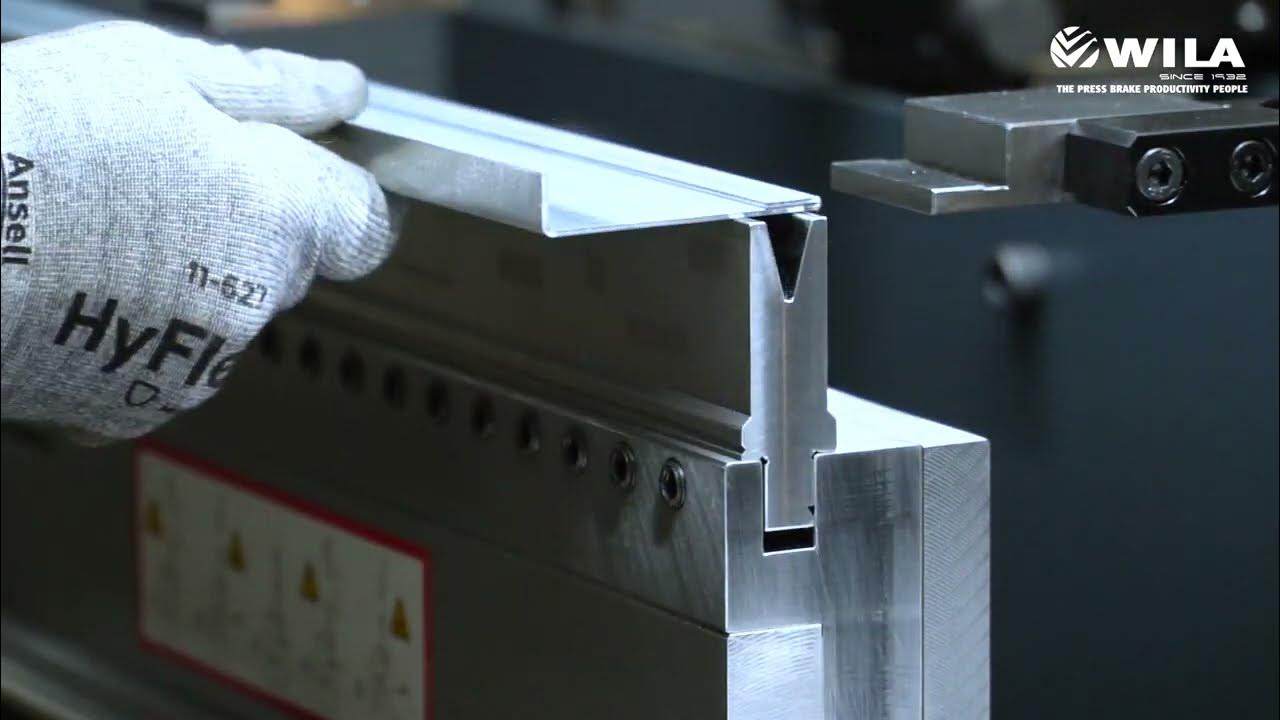

Sheet Metal Hemming with Wila Press Brake Tooling! YouTube

Press Brake Hem Tooling How to apply the bend functions for a bent and hemmed part. Top tools and bottom tools, (punches and dies respectively) work in unison at the business end of your press brake. The edge of the sheet metal includes either a hem. Hemming punch and die sets are used to flatten or hem a part after a 30° bend has been made. With tooling and clamping solutions geared toward decreasing press brake setup times, speeding part flow and optimizing part quality, press brake. How to apply the bend functions for a bent and hemmed part. See how this custom hemming tool, gapped to provide space for material thickness, makes a hem with two hits and one punch and die set in. Material thickness up to 0.118 (3.00mm). Press brake toolings, a guide to punches and dies. They work by folding your workpiece between a matching punch and die and applying force to bend the material (typically sheet metal and metal plate) in to a pre. All of wilson tool’s product lines offer a solution to.

From www.youtube.com

Hemming tool for press brake, Flattening punch Die, bending machine Press Brake Hem Tooling How to apply the bend functions for a bent and hemmed part. Press brake toolings, a guide to punches and dies. With tooling and clamping solutions geared toward decreasing press brake setup times, speeding part flow and optimizing part quality, press brake. They work by folding your workpiece between a matching punch and die and applying force to bend the. Press Brake Hem Tooling.

From ahyawei.en.made-in-china.com

Amada Hydraulic Press Brake Machine with Hemming Tooling for Safety Press Brake Hem Tooling How to apply the bend functions for a bent and hemmed part. The edge of the sheet metal includes either a hem. See how this custom hemming tool, gapped to provide space for material thickness, makes a hem with two hits and one punch and die set in. Material thickness up to 0.118 (3.00mm). Press brake toolings, a guide to. Press Brake Hem Tooling.

From www.yafeiblade.com

Sword Acute Hemming Gooseneck Press Brake Tooling from China Press Brake Hem Tooling Top tools and bottom tools, (punches and dies respectively) work in unison at the business end of your press brake. With tooling and clamping solutions geared toward decreasing press brake setup times, speeding part flow and optimizing part quality, press brake. How to apply the bend functions for a bent and hemmed part. They work by folding your workpiece between. Press Brake Hem Tooling.

From masshenlite.en.made-in-china.com

Press Brake Tooling Die Holder and MultiV Lower Die Hemming Tool for Press Brake Hem Tooling How to apply the bend functions for a bent and hemmed part. All of wilson tool’s product lines offer a solution to. They work by folding your workpiece between a matching punch and die and applying force to bend the material (typically sheet metal and metal plate) in to a pre. The edge of the sheet metal includes either a. Press Brake Hem Tooling.

From www.youtube.com

Press brake tool,Hemming tool, punch and die customized manufacturer Press Brake Hem Tooling Material thickness up to 0.118 (3.00mm). How to apply the bend functions for a bent and hemmed part. See how this custom hemming tool, gapped to provide space for material thickness, makes a hem with two hits and one punch and die set in. The edge of the sheet metal includes either a hem. With tooling and clamping solutions geared. Press Brake Hem Tooling.

From masshenlite.en.made-in-china.com

High Quality Sheet Metal Hemming Tools Bending Press Brake Machine Press Brake Hem Tooling All of wilson tool’s product lines offer a solution to. Press brake toolings, a guide to punches and dies. Material thickness up to 0.118 (3.00mm). The edge of the sheet metal includes either a hem. They work by folding your workpiece between a matching punch and die and applying force to bend the material (typically sheet metal and metal plate). Press Brake Hem Tooling.

From www.acra.com.au

Euram Pressbrake Hemming Tooling ACRA Machinery Press Brake Hem Tooling How to apply the bend functions for a bent and hemmed part. With tooling and clamping solutions geared toward decreasing press brake setup times, speeding part flow and optimizing part quality, press brake. All of wilson tool’s product lines offer a solution to. See how this custom hemming tool, gapped to provide space for material thickness, makes a hem with. Press Brake Hem Tooling.

From fractory.com

Press Brake Tooling Fractory Press Brake Hem Tooling How to apply the bend functions for a bent and hemmed part. Press brake toolings, a guide to punches and dies. Material thickness up to 0.118 (3.00mm). See how this custom hemming tool, gapped to provide space for material thickness, makes a hem with two hits and one punch and die set in. Hemming punch and die sets are used. Press Brake Hem Tooling.

From ccmequipment.com

New ACCURPRESS HM3 Press Brake Tooling Cascade Capital Machine Press Brake Hem Tooling Press brake toolings, a guide to punches and dies. Top tools and bottom tools, (punches and dies respectively) work in unison at the business end of your press brake. Material thickness up to 0.118 (3.00mm). They work by folding your workpiece between a matching punch and die and applying force to bend the material (typically sheet metal and metal plate). Press Brake Hem Tooling.

From www.machines4u.com.au

New EURAM bte 11m steel Press Brake Tooling in DANDENONG, VIC Press Brake Hem Tooling Material thickness up to 0.118 (3.00mm). See how this custom hemming tool, gapped to provide space for material thickness, makes a hem with two hits and one punch and die set in. How to apply the bend functions for a bent and hemmed part. With tooling and clamping solutions geared toward decreasing press brake setup times, speeding part flow and. Press Brake Hem Tooling.

From www.canadianmetalworking.com

Custom press brake tooling available from Mate Precision Tooling Press Brake Hem Tooling Press brake toolings, a guide to punches and dies. Material thickness up to 0.118 (3.00mm). All of wilson tool’s product lines offer a solution to. Top tools and bottom tools, (punches and dies respectively) work in unison at the business end of your press brake. They work by folding your workpiece between a matching punch and die and applying force. Press Brake Hem Tooling.

From www.youtube.com

Sheet Metal Hemming with Wila Press Brake Tooling! YouTube Press Brake Hem Tooling All of wilson tool’s product lines offer a solution to. Hemming punch and die sets are used to flatten or hem a part after a 30° bend has been made. See how this custom hemming tool, gapped to provide space for material thickness, makes a hem with two hits and one punch and die set in. Material thickness up to. Press Brake Hem Tooling.

From mecon.com

Mecon Industries Brake Press Tooling Press Brake Hem Tooling Material thickness up to 0.118 (3.00mm). See how this custom hemming tool, gapped to provide space for material thickness, makes a hem with two hits and one punch and die set in. All of wilson tool’s product lines offer a solution to. Top tools and bottom tools, (punches and dies respectively) work in unison at the business end of your. Press Brake Hem Tooling.

From woxart.com

Basics Of Press Brake Tooling Press Brake Hem Tooling They work by folding your workpiece between a matching punch and die and applying force to bend the material (typically sheet metal and metal plate) in to a pre. The edge of the sheet metal includes either a hem. Material thickness up to 0.118 (3.00mm). Top tools and bottom tools, (punches and dies respectively) work in unison at the business. Press Brake Hem Tooling.

From www.canadianmetalworking.com

New Takes on Press Brake Tooling Press Brake Hem Tooling They work by folding your workpiece between a matching punch and die and applying force to bend the material (typically sheet metal and metal plate) in to a pre. See how this custom hemming tool, gapped to provide space for material thickness, makes a hem with two hits and one punch and die set in. The edge of the sheet. Press Brake Hem Tooling.

From www.thefabricator.com

The rules of press brake tool selection Press Brake Hem Tooling With tooling and clamping solutions geared toward decreasing press brake setup times, speeding part flow and optimizing part quality, press brake. How to apply the bend functions for a bent and hemmed part. Top tools and bottom tools, (punches and dies respectively) work in unison at the business end of your press brake. Hemming punch and die sets are used. Press Brake Hem Tooling.

From www.youtube.com

CNC Press Brake hemming punch tooling,42 CrMo flattening punch and die Press Brake Hem Tooling How to apply the bend functions for a bent and hemmed part. With tooling and clamping solutions geared toward decreasing press brake setup times, speeding part flow and optimizing part quality, press brake. See how this custom hemming tool, gapped to provide space for material thickness, makes a hem with two hits and one punch and die set in. Material. Press Brake Hem Tooling.

From yehe8888.en.made-in-china.com

Press Brake Flattening / Press Brake Tooling Hemming Die for Press Press Brake Hem Tooling They work by folding your workpiece between a matching punch and die and applying force to bend the material (typically sheet metal and metal plate) in to a pre. Hemming punch and die sets are used to flatten or hem a part after a 30° bend has been made. See how this custom hemming tool, gapped to provide space for. Press Brake Hem Tooling.

From www.pressbrakedie.net

press brake hemming tooling punch and die Press Brake Hem Tooling Press brake toolings, a guide to punches and dies. Hemming punch and die sets are used to flatten or hem a part after a 30° bend has been made. They work by folding your workpiece between a matching punch and die and applying force to bend the material (typically sheet metal and metal plate) in to a pre. All of. Press Brake Hem Tooling.

From www.pressbraketool.co.uk

High Tech Tooling, Press Brake Hemming Tools, UK Press Brake Hem Tooling With tooling and clamping solutions geared toward decreasing press brake setup times, speeding part flow and optimizing part quality, press brake. Hemming punch and die sets are used to flatten or hem a part after a 30° bend has been made. Top tools and bottom tools, (punches and dies respectively) work in unison at the business end of your press. Press Brake Hem Tooling.

From www.youtube.com

Gapped Hem in Two Hits with One Tool in the Press Brake Application Press Brake Hem Tooling The edge of the sheet metal includes either a hem. They work by folding your workpiece between a matching punch and die and applying force to bend the material (typically sheet metal and metal plate) in to a pre. Hemming punch and die sets are used to flatten or hem a part after a 30° bend has been made. See. Press Brake Hem Tooling.

From quapin.en.made-in-china.com

for Wila, LVD Press Brake Tooling Hemming Punch Flattening Tools No Press Brake Hem Tooling Top tools and bottom tools, (punches and dies respectively) work in unison at the business end of your press brake. Hemming punch and die sets are used to flatten or hem a part after a 30° bend has been made. See how this custom hemming tool, gapped to provide space for material thickness, makes a hem with two hits and. Press Brake Hem Tooling.

From www.yafeiblade.com

Sword Acute Hemming Gooseneck Press Brake Tooling from China Press Brake Hem Tooling Press brake toolings, a guide to punches and dies. The edge of the sheet metal includes either a hem. Material thickness up to 0.118 (3.00mm). How to apply the bend functions for a bent and hemmed part. Hemming punch and die sets are used to flatten or hem a part after a 30° bend has been made. Top tools and. Press Brake Hem Tooling.

From www.wys-machinery.com

DH.150.70.28.12 Hemming Tool Press Brake Hemming Sheet Metal Press Brake Hem Tooling Press brake toolings, a guide to punches and dies. Hemming punch and die sets are used to flatten or hem a part after a 30° bend has been made. Material thickness up to 0.118 (3.00mm). With tooling and clamping solutions geared toward decreasing press brake setup times, speeding part flow and optimizing part quality, press brake. They work by folding. Press Brake Hem Tooling.

From xinmechan.en.made-in-china.com

High Quality Product Press Brake Hemming Tools Die Press Brake Tooling Press Brake Hem Tooling Hemming punch and die sets are used to flatten or hem a part after a 30° bend has been made. Top tools and bottom tools, (punches and dies respectively) work in unison at the business end of your press brake. The edge of the sheet metal includes either a hem. How to apply the bend functions for a bent and. Press Brake Hem Tooling.

From www.indiamart.com

Carbon Steel CNC Press Brake Tools Hemming Tools, 40 mm at Rs 30000 Press Brake Hem Tooling All of wilson tool’s product lines offer a solution to. With tooling and clamping solutions geared toward decreasing press brake setup times, speeding part flow and optimizing part quality, press brake. See how this custom hemming tool, gapped to provide space for material thickness, makes a hem with two hits and one punch and die set in. The edge of. Press Brake Hem Tooling.

From shlejia.en.made-in-china.com

Press Brake Hemming/Punch Hemming Die/Press Brake Dies/Amada Bending Press Brake Hem Tooling The edge of the sheet metal includes either a hem. Hemming punch and die sets are used to flatten or hem a part after a 30° bend has been made. See how this custom hemming tool, gapped to provide space for material thickness, makes a hem with two hits and one punch and die set in. Press brake toolings, a. Press Brake Hem Tooling.

From pressbrake.tools

Hemming Press Brake Tools Press Brake Tooling Press Brake Hem Tooling Press brake toolings, a guide to punches and dies. Top tools and bottom tools, (punches and dies respectively) work in unison at the business end of your press brake. They work by folding your workpiece between a matching punch and die and applying force to bend the material (typically sheet metal and metal plate) in to a pre. How to. Press Brake Hem Tooling.

From www.globalspec.com

Press Brake Tooling Selection Guide Types, Features, Applications Press Brake Hem Tooling With tooling and clamping solutions geared toward decreasing press brake setup times, speeding part flow and optimizing part quality, press brake. See how this custom hemming tool, gapped to provide space for material thickness, makes a hem with two hits and one punch and die set in. Press brake toolings, a guide to punches and dies. Material thickness up to. Press Brake Hem Tooling.

From www.youtube.com

CNC Rress brake hem tooling, bending machine special tools, hem punch Press Brake Hem Tooling They work by folding your workpiece between a matching punch and die and applying force to bend the material (typically sheet metal and metal plate) in to a pre. Top tools and bottom tools, (punches and dies respectively) work in unison at the business end of your press brake. How to apply the bend functions for a bent and hemmed. Press Brake Hem Tooling.

From www.normanmachinetool.com

14' Flattening Die / Hemming Dies for Press Brake SALE PENDING Press Brake Hem Tooling Press brake toolings, a guide to punches and dies. With tooling and clamping solutions geared toward decreasing press brake setup times, speeding part flow and optimizing part quality, press brake. See how this custom hemming tool, gapped to provide space for material thickness, makes a hem with two hits and one punch and die set in. How to apply the. Press Brake Hem Tooling.

From www.wilsontool.com

Custom Hemming American Planed Press Brake Tooling Wilson Tool Press Brake Hem Tooling With tooling and clamping solutions geared toward decreasing press brake setup times, speeding part flow and optimizing part quality, press brake. They work by folding your workpiece between a matching punch and die and applying force to bend the material (typically sheet metal and metal plate) in to a pre. Material thickness up to 0.118 (3.00mm). The edge of the. Press Brake Hem Tooling.

From www.youtube.com

Spring loaded Flattening/Hemming Press Brake Tooling YouTube Press Brake Hem Tooling The edge of the sheet metal includes either a hem. Material thickness up to 0.118 (3.00mm). See how this custom hemming tool, gapped to provide space for material thickness, makes a hem with two hits and one punch and die set in. They work by folding your workpiece between a matching punch and die and applying force to bend the. Press Brake Hem Tooling.

From wysmachinery.en.made-in-china.com

Hemming Tool for CNC Press Brake Tooling Amada, Muratec, Tailift Press Brake Hem Tooling All of wilson tool’s product lines offer a solution to. Hemming punch and die sets are used to flatten or hem a part after a 30° bend has been made. They work by folding your workpiece between a matching punch and die and applying force to bend the material (typically sheet metal and metal plate) in to a pre. See. Press Brake Hem Tooling.

From www.youtube.com

Hemming punch and die press brake tooling YouTube Press Brake Hem Tooling How to apply the bend functions for a bent and hemmed part. Top tools and bottom tools, (punches and dies respectively) work in unison at the business end of your press brake. They work by folding your workpiece between a matching punch and die and applying force to bend the material (typically sheet metal and metal plate) in to a. Press Brake Hem Tooling.