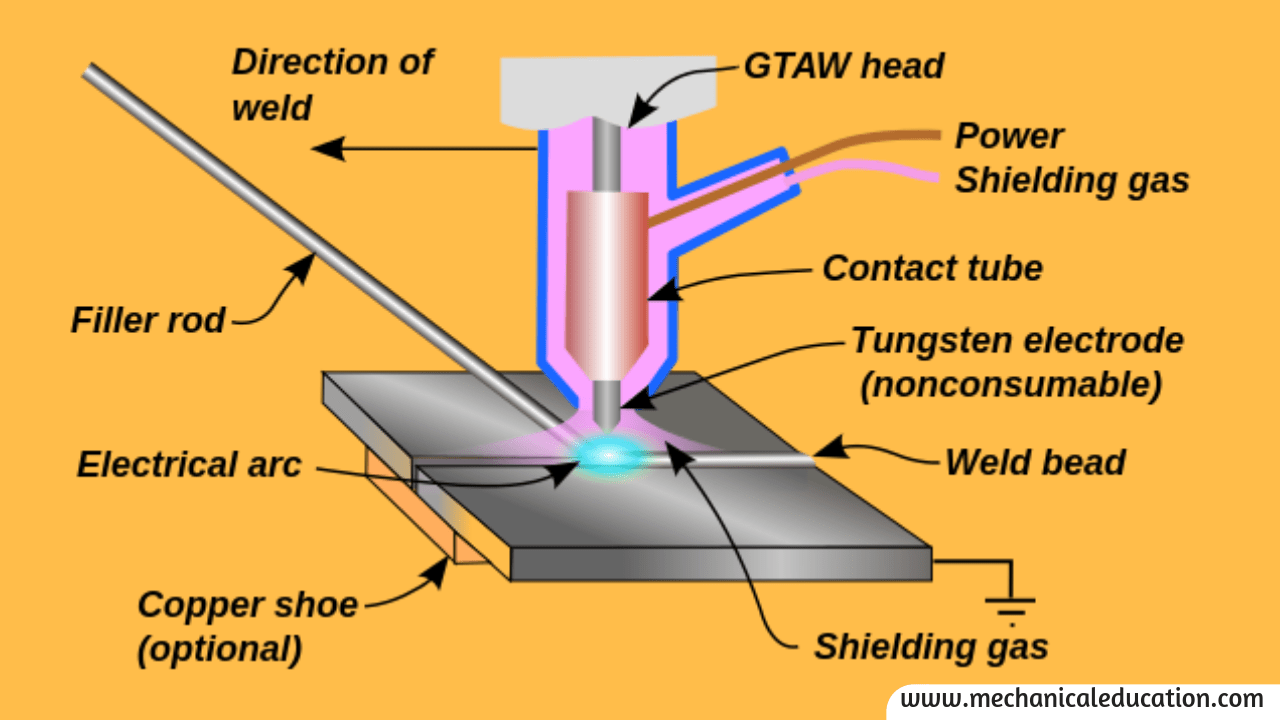

Tungsten Inclusion In Welding . However, tungsten inclusion in welding can be a. By understanding the causes and implementing effective prevention strategies, welders can ensure a strong bond and a robust weld, every time. This article delves into how tungsten inclusions, despite their high melting point, can weaken welding seams and lead to defects. By understanding the causes, such as improper welding techniques and material issues, you can learn to prevent these defects. Tungsten inclusion is a welding defect found in gas tungsten arc welding (gtaw), also known as tungsten inert gas (tig) welding. Tungsten inert gas welding is the best suited welding technique for precision welding in atomic and aircraft industries. Tungsten inclusions are a common yet avoidable issue in tig welding, where particles of the tungsten electrode become embedded in the weld.

from www.mechanicaleducation.com

Tungsten inclusions are a common yet avoidable issue in tig welding, where particles of the tungsten electrode become embedded in the weld. By understanding the causes and implementing effective prevention strategies, welders can ensure a strong bond and a robust weld, every time. However, tungsten inclusion in welding can be a. This article delves into how tungsten inclusions, despite their high melting point, can weaken welding seams and lead to defects. Tungsten inert gas welding is the best suited welding technique for precision welding in atomic and aircraft industries. By understanding the causes, such as improper welding techniques and material issues, you can learn to prevent these defects. Tungsten inclusion is a welding defect found in gas tungsten arc welding (gtaw), also known as tungsten inert gas (tig) welding.

Tungsten Inert Gas Welding Process, Advantages, Disadvantages And

Tungsten Inclusion In Welding This article delves into how tungsten inclusions, despite their high melting point, can weaken welding seams and lead to defects. This article delves into how tungsten inclusions, despite their high melting point, can weaken welding seams and lead to defects. Tungsten inert gas welding is the best suited welding technique for precision welding in atomic and aircraft industries. Tungsten inclusions are a common yet avoidable issue in tig welding, where particles of the tungsten electrode become embedded in the weld. By understanding the causes and implementing effective prevention strategies, welders can ensure a strong bond and a robust weld, every time. Tungsten inclusion is a welding defect found in gas tungsten arc welding (gtaw), also known as tungsten inert gas (tig) welding. However, tungsten inclusion in welding can be a. By understanding the causes, such as improper welding techniques and material issues, you can learn to prevent these defects.

From www.twi-global.com

What is Tungsten Inert Gas (GTAW or TIG) Welding? TWI Tungsten Inclusion In Welding Tungsten inert gas welding is the best suited welding technique for precision welding in atomic and aircraft industries. This article delves into how tungsten inclusions, despite their high melting point, can weaken welding seams and lead to defects. Tungsten inclusion is a welding defect found in gas tungsten arc welding (gtaw), also known as tungsten inert gas (tig) welding. By. Tungsten Inclusion In Welding.

From electricalworkbook.com

What is Tungsten Inert Gas Welding? Process, Diagram, Advantages Tungsten Inclusion In Welding Tungsten inclusions are a common yet avoidable issue in tig welding, where particles of the tungsten electrode become embedded in the weld. By understanding the causes, such as improper welding techniques and material issues, you can learn to prevent these defects. By understanding the causes and implementing effective prevention strategies, welders can ensure a strong bond and a robust weld,. Tungsten Inclusion In Welding.

From www.slideserve.com

PPT Gas Tungsten Arc Welding (GTAW or TIG) PowerPoint Presentation Tungsten Inclusion In Welding Tungsten inert gas welding is the best suited welding technique for precision welding in atomic and aircraft industries. By understanding the causes and implementing effective prevention strategies, welders can ensure a strong bond and a robust weld, every time. Tungsten inclusions are a common yet avoidable issue in tig welding, where particles of the tungsten electrode become embedded in the. Tungsten Inclusion In Welding.

From socalweldtrainingschool.org

Gas Tungsten Arc Welding (TIG) III Weld on Stainless Steel Tungsten Inclusion In Welding Tungsten inert gas welding is the best suited welding technique for precision welding in atomic and aircraft industries. However, tungsten inclusion in welding can be a. By understanding the causes and implementing effective prevention strategies, welders can ensure a strong bond and a robust weld, every time. Tungsten inclusion is a welding defect found in gas tungsten arc welding (gtaw),. Tungsten Inclusion In Welding.

From weldinganswers.com

10 Types of Welding Discontinuities Explained WELDING ANSWERS Tungsten Inclusion In Welding However, tungsten inclusion in welding can be a. Tungsten inert gas welding is the best suited welding technique for precision welding in atomic and aircraft industries. By understanding the causes, such as improper welding techniques and material issues, you can learn to prevent these defects. Tungsten inclusions are a common yet avoidable issue in tig welding, where particles of the. Tungsten Inclusion In Welding.

From tft-pneumatic.com

How to Identify the 7 Most Dangerous Welding Defects TFT Pneumatic Tungsten Inclusion In Welding However, tungsten inclusion in welding can be a. Tungsten inclusion is a welding defect found in gas tungsten arc welding (gtaw), also known as tungsten inert gas (tig) welding. Tungsten inert gas welding is the best suited welding technique for precision welding in atomic and aircraft industries. By understanding the causes and implementing effective prevention strategies, welders can ensure a. Tungsten Inclusion In Welding.

From www.slideserve.com

PPT SHIELDED METAL ARC WELDING (SMAW) PowerPoint Presentation ID Tungsten Inclusion In Welding Tungsten inclusion is a welding defect found in gas tungsten arc welding (gtaw), also known as tungsten inert gas (tig) welding. However, tungsten inclusion in welding can be a. Tungsten inert gas welding is the best suited welding technique for precision welding in atomic and aircraft industries. By understanding the causes, such as improper welding techniques and material issues, you. Tungsten Inclusion In Welding.

From www.youtube.com

[English] Inclusion Welding Defects YouTube Tungsten Inclusion In Welding Tungsten inclusions are a common yet avoidable issue in tig welding, where particles of the tungsten electrode become embedded in the weld. However, tungsten inclusion in welding can be a. By understanding the causes and implementing effective prevention strategies, welders can ensure a strong bond and a robust weld, every time. This article delves into how tungsten inclusions, despite their. Tungsten Inclusion In Welding.

From www.welding.org

Gas Tungsten Arc Welding Hobart Institute of Welding Technology Tungsten Inclusion In Welding Tungsten inclusions are a common yet avoidable issue in tig welding, where particles of the tungsten electrode become embedded in the weld. By understanding the causes and implementing effective prevention strategies, welders can ensure a strong bond and a robust weld, every time. This article delves into how tungsten inclusions, despite their high melting point, can weaken welding seams and. Tungsten Inclusion In Welding.

From www.slideshare.net

Welding Inspection Cswip Tungsten Inclusion In Welding Tungsten inclusions are a common yet avoidable issue in tig welding, where particles of the tungsten electrode become embedded in the weld. Tungsten inert gas welding is the best suited welding technique for precision welding in atomic and aircraft industries. By understanding the causes and implementing effective prevention strategies, welders can ensure a strong bond and a robust weld, every. Tungsten Inclusion In Welding.

From resources.arcmachines.com

Tungsten Inclusions Testing, Prevention, and Mitigation Arc Machines Tungsten Inclusion In Welding By understanding the causes, such as improper welding techniques and material issues, you can learn to prevent these defects. This article delves into how tungsten inclusions, despite their high melting point, can weaken welding seams and lead to defects. Tungsten inert gas welding is the best suited welding technique for precision welding in atomic and aircraft industries. Tungsten inclusions are. Tungsten Inclusion In Welding.

From www.weldingtipsandtricks.com

Tungsten Grind Angles and affects on Tungsten Inclusion In Welding However, tungsten inclusion in welding can be a. Tungsten inert gas welding is the best suited welding technique for precision welding in atomic and aircraft industries. By understanding the causes, such as improper welding techniques and material issues, you can learn to prevent these defects. This article delves into how tungsten inclusions, despite their high melting point, can weaken welding. Tungsten Inclusion In Welding.

From www.youtube.com

TIG Welding (GTAW) Manual Fill Pass Tungsten Inclusion by Electrode Tungsten Inclusion In Welding Tungsten inert gas welding is the best suited welding technique for precision welding in atomic and aircraft industries. This article delves into how tungsten inclusions, despite their high melting point, can weaken welding seams and lead to defects. However, tungsten inclusion in welding can be a. By understanding the causes and implementing effective prevention strategies, welders can ensure a strong. Tungsten Inclusion In Welding.

From www.youtube.com

CMQ GTAW welding Gas tungsten arc welding YouTube Tungsten Inclusion In Welding Tungsten inclusion is a welding defect found in gas tungsten arc welding (gtaw), also known as tungsten inert gas (tig) welding. However, tungsten inclusion in welding can be a. By understanding the causes and implementing effective prevention strategies, welders can ensure a strong bond and a robust weld, every time. By understanding the causes, such as improper welding techniques and. Tungsten Inclusion In Welding.

From www.mechanicwiz.com

Slag Inclusion In Welding Tungsten Inclusion In Welding By understanding the causes, such as improper welding techniques and material issues, you can learn to prevent these defects. By understanding the causes and implementing effective prevention strategies, welders can ensure a strong bond and a robust weld, every time. Tungsten inert gas welding is the best suited welding technique for precision welding in atomic and aircraft industries. However, tungsten. Tungsten Inclusion In Welding.

From engineersblog.net

What is Tungsten inclusions weld defect? how to determine The Tungsten Inclusion In Welding Tungsten inert gas welding is the best suited welding technique for precision welding in atomic and aircraft industries. Tungsten inclusions are a common yet avoidable issue in tig welding, where particles of the tungsten electrode become embedded in the weld. However, tungsten inclusion in welding can be a. By understanding the causes, such as improper welding techniques and material issues,. Tungsten Inclusion In Welding.

From www.mechanicaleducation.com

Tungsten Inert Gas Welding Process, Advantages, Disadvantages And Tungsten Inclusion In Welding Tungsten inert gas welding is the best suited welding technique for precision welding in atomic and aircraft industries. Tungsten inclusion is a welding defect found in gas tungsten arc welding (gtaw), also known as tungsten inert gas (tig) welding. By understanding the causes, such as improper welding techniques and material issues, you can learn to prevent these defects. By understanding. Tungsten Inclusion In Welding.

From materialwelding.com

Tungsten Inclusion in Welding Tungsten Inclusion In Welding This article delves into how tungsten inclusions, despite their high melting point, can weaken welding seams and lead to defects. By understanding the causes, such as improper welding techniques and material issues, you can learn to prevent these defects. Tungsten inclusion is a welding defect found in gas tungsten arc welding (gtaw), also known as tungsten inert gas (tig) welding.. Tungsten Inclusion In Welding.

From www.slideserve.com

PPT Arc Welding Continued PowerPoint Presentation, free download ID Tungsten Inclusion In Welding By understanding the causes, such as improper welding techniques and material issues, you can learn to prevent these defects. However, tungsten inclusion in welding can be a. Tungsten inert gas welding is the best suited welding technique for precision welding in atomic and aircraft industries. This article delves into how tungsten inclusions, despite their high melting point, can weaken welding. Tungsten Inclusion In Welding.

From www.weldingtipsandtricks.com

Tungsten Grind Angles and affects on Tungsten Inclusion In Welding By understanding the causes and implementing effective prevention strategies, welders can ensure a strong bond and a robust weld, every time. However, tungsten inclusion in welding can be a. Tungsten inert gas welding is the best suited welding technique for precision welding in atomic and aircraft industries. This article delves into how tungsten inclusions, despite their high melting point, can. Tungsten Inclusion In Welding.

From www.youtube.com

Gas Tungsten Arc Welding YouTube Tungsten Inclusion In Welding Tungsten inclusion is a welding defect found in gas tungsten arc welding (gtaw), also known as tungsten inert gas (tig) welding. By understanding the causes and implementing effective prevention strategies, welders can ensure a strong bond and a robust weld, every time. Tungsten inclusions are a common yet avoidable issue in tig welding, where particles of the tungsten electrode become. Tungsten Inclusion In Welding.

From yeswelder.com

How To Shape Tungsten Electrode For TIG Welding YesWelder Tungsten Inclusion In Welding By understanding the causes and implementing effective prevention strategies, welders can ensure a strong bond and a robust weld, every time. Tungsten inclusions are a common yet avoidable issue in tig welding, where particles of the tungsten electrode become embedded in the weld. However, tungsten inclusion in welding can be a. Tungsten inert gas welding is the best suited welding. Tungsten Inclusion In Welding.

From stainless-welding-fabrication.com

Benefits of TIG (Tungsten Inert Gas) Welding Stainless Welding Tungsten Inclusion In Welding Tungsten inclusion is a welding defect found in gas tungsten arc welding (gtaw), also known as tungsten inert gas (tig) welding. Tungsten inclusions are a common yet avoidable issue in tig welding, where particles of the tungsten electrode become embedded in the weld. By understanding the causes, such as improper welding techniques and material issues, you can learn to prevent. Tungsten Inclusion In Welding.

From www.youtube.com

Tungsten preparation and circuit selection for tig welding different Tungsten Inclusion In Welding Tungsten inclusions are a common yet avoidable issue in tig welding, where particles of the tungsten electrode become embedded in the weld. By understanding the causes and implementing effective prevention strategies, welders can ensure a strong bond and a robust weld, every time. By understanding the causes, such as improper welding techniques and material issues, you can learn to prevent. Tungsten Inclusion In Welding.

From www.machinemfg.com

10 Essential Welding Tips for Steel Structures Boost Your Welding Tungsten Inclusion In Welding By understanding the causes, such as improper welding techniques and material issues, you can learn to prevent these defects. This article delves into how tungsten inclusions, despite their high melting point, can weaken welding seams and lead to defects. However, tungsten inclusion in welding can be a. Tungsten inclusions are a common yet avoidable issue in tig welding, where particles. Tungsten Inclusion In Welding.

From www.facebook.com

Welding ideas Dipping Tungsten during your TIG... Tungsten Inclusion In Welding However, tungsten inclusion in welding can be a. By understanding the causes, such as improper welding techniques and material issues, you can learn to prevent these defects. Tungsten inclusions are a common yet avoidable issue in tig welding, where particles of the tungsten electrode become embedded in the weld. By understanding the causes and implementing effective prevention strategies, welders can. Tungsten Inclusion In Welding.

From www.youtube.com

TIG welding Tungsten Inert Gas welding GTAW welding Gas tungsten Tungsten Inclusion In Welding This article delves into how tungsten inclusions, despite their high melting point, can weaken welding seams and lead to defects. Tungsten inclusion is a welding defect found in gas tungsten arc welding (gtaw), also known as tungsten inert gas (tig) welding. Tungsten inert gas welding is the best suited welding technique for precision welding in atomic and aircraft industries. By. Tungsten Inclusion In Welding.

From www.youtube.com

Welding Defect Watch How Slag Inclusion Happens! YouTube Tungsten Inclusion In Welding Tungsten inclusions are a common yet avoidable issue in tig welding, where particles of the tungsten electrode become embedded in the weld. Tungsten inert gas welding is the best suited welding technique for precision welding in atomic and aircraft industries. By understanding the causes and implementing effective prevention strategies, welders can ensure a strong bond and a robust weld, every. Tungsten Inclusion In Welding.

From www.thefabricator.com

Guidelines for tungsten electrodes An Update Tungsten Inclusion In Welding Tungsten inclusions are a common yet avoidable issue in tig welding, where particles of the tungsten electrode become embedded in the weld. This article delves into how tungsten inclusions, despite their high melting point, can weaken welding seams and lead to defects. By understanding the causes, such as improper welding techniques and material issues, you can learn to prevent these. Tungsten Inclusion In Welding.

From tdrtraining.co.uk

Tungsten Inert Gas Welding (TIG) TDR Training Tungsten Inclusion In Welding Tungsten inclusion is a welding defect found in gas tungsten arc welding (gtaw), also known as tungsten inert gas (tig) welding. This article delves into how tungsten inclusions, despite their high melting point, can weaken welding seams and lead to defects. By understanding the causes and implementing effective prevention strategies, welders can ensure a strong bond and a robust weld,. Tungsten Inclusion In Welding.

From kavithamizhan.blogspot.com

Weld Imperfection Solid Inclusions Tungsten Inclusion In Welding Tungsten inclusions are a common yet avoidable issue in tig welding, where particles of the tungsten electrode become embedded in the weld. Tungsten inclusion is a welding defect found in gas tungsten arc welding (gtaw), also known as tungsten inert gas (tig) welding. Tungsten inert gas welding is the best suited welding technique for precision welding in atomic and aircraft. Tungsten Inclusion In Welding.

From www.aedmetals.com

TIG Welding Defects Tungsten Inclusion In Welding This article delves into how tungsten inclusions, despite their high melting point, can weaken welding seams and lead to defects. By understanding the causes and implementing effective prevention strategies, welders can ensure a strong bond and a robust weld, every time. Tungsten inert gas welding is the best suited welding technique for precision welding in atomic and aircraft industries. By. Tungsten Inclusion In Welding.

From materialwelding.com

How to correctly grind Tungsten Electrode for TIG Welding Tungsten Inclusion In Welding Tungsten inert gas welding is the best suited welding technique for precision welding in atomic and aircraft industries. By understanding the causes, such as improper welding techniques and material issues, you can learn to prevent these defects. Tungsten inclusions are a common yet avoidable issue in tig welding, where particles of the tungsten electrode become embedded in the weld. By. Tungsten Inclusion In Welding.

From www.instructables.com

Perfectly Sharpen Tungsten for TIG Welding! 3 Steps Instructables Tungsten Inclusion In Welding Tungsten inclusions are a common yet avoidable issue in tig welding, where particles of the tungsten electrode become embedded in the weld. Tungsten inert gas welding is the best suited welding technique for precision welding in atomic and aircraft industries. Tungsten inclusion is a welding defect found in gas tungsten arc welding (gtaw), also known as tungsten inert gas (tig). Tungsten Inclusion In Welding.

From www.weldingandndt.com

Inclusion Welding & NDT Tungsten Inclusion In Welding By understanding the causes and implementing effective prevention strategies, welders can ensure a strong bond and a robust weld, every time. By understanding the causes, such as improper welding techniques and material issues, you can learn to prevent these defects. However, tungsten inclusion in welding can be a. Tungsten inclusions are a common yet avoidable issue in tig welding, where. Tungsten Inclusion In Welding.