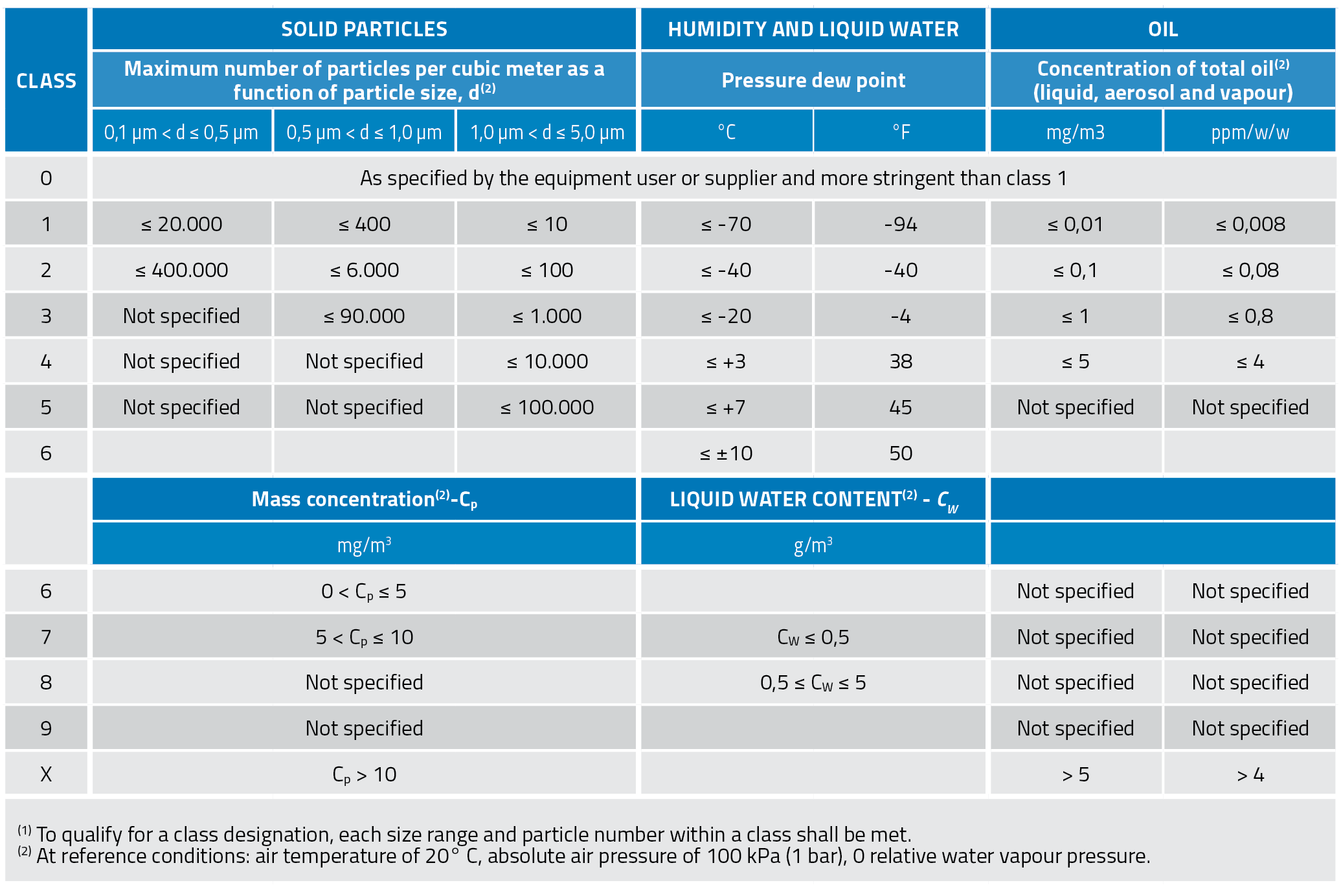

Compressed Air Oil Content . need to understand iso classes for compressed air quality? During operation, lubricating oil is carried over into the compressed air. The right compressed air purity is key to safeguarding production integrity and. the quantification of the oil vapour content in a compressed air system shall be carried out within the following constraints. this document specifies test methods for the sampling and quantitative analysis of liquid oil and oil aerosols that can. most air compressors use oil in the compression stage for sealing, lubrication and cooling. the iso air quality standard measures three types of contaminants present in compressed air:

from www.industrialair.co.nz

this document specifies test methods for the sampling and quantitative analysis of liquid oil and oil aerosols that can. the iso air quality standard measures three types of contaminants present in compressed air: need to understand iso classes for compressed air quality? the quantification of the oil vapour content in a compressed air system shall be carried out within the following constraints. During operation, lubricating oil is carried over into the compressed air. The right compressed air purity is key to safeguarding production integrity and. most air compressors use oil in the compression stage for sealing, lubrication and cooling.

Compressed air quality standards

Compressed Air Oil Content The right compressed air purity is key to safeguarding production integrity and. During operation, lubricating oil is carried over into the compressed air. The right compressed air purity is key to safeguarding production integrity and. the iso air quality standard measures three types of contaminants present in compressed air: this document specifies test methods for the sampling and quantitative analysis of liquid oil and oil aerosols that can. the quantification of the oil vapour content in a compressed air system shall be carried out within the following constraints. need to understand iso classes for compressed air quality? most air compressors use oil in the compression stage for sealing, lubrication and cooling.

From www.powermotiontech.com

Compressed Air Systems Rely on Proper Filtration Power & Motion Compressed Air Oil Content most air compressors use oil in the compression stage for sealing, lubrication and cooling. need to understand iso classes for compressed air quality? The right compressed air purity is key to safeguarding production integrity and. the iso air quality standard measures three types of contaminants present in compressed air: During operation, lubricating oil is carried over into. Compressed Air Oil Content.

From www.researchgate.net

Oil injected screw compressor [4] Download Scientific Diagram Compressed Air Oil Content During operation, lubricating oil is carried over into the compressed air. the iso air quality standard measures three types of contaminants present in compressed air: this document specifies test methods for the sampling and quantitative analysis of liquid oil and oil aerosols that can. need to understand iso classes for compressed air quality? the quantification of. Compressed Air Oil Content.

From www.industrialair.co.nz

Compressed air quality standards Compressed Air Oil Content need to understand iso classes for compressed air quality? The right compressed air purity is key to safeguarding production integrity and. this document specifies test methods for the sampling and quantitative analysis of liquid oil and oil aerosols that can. the iso air quality standard measures three types of contaminants present in compressed air: the quantification. Compressed Air Oil Content.

From compressorservices.net

5 Ways To Remove Moisture From Your Compressed Air Compressed Air Oil Content this document specifies test methods for the sampling and quantitative analysis of liquid oil and oil aerosols that can. most air compressors use oil in the compression stage for sealing, lubrication and cooling. During operation, lubricating oil is carried over into the compressed air. The right compressed air purity is key to safeguarding production integrity and. the. Compressed Air Oil Content.

From www.youtube.com

Choosing The Right Air Compressor Oil YouTube Compressed Air Oil Content During operation, lubricating oil is carried over into the compressed air. the quantification of the oil vapour content in a compressed air system shall be carried out within the following constraints. the iso air quality standard measures three types of contaminants present in compressed air: need to understand iso classes for compressed air quality? most air. Compressed Air Oil Content.

From www.walmart.com

LUODU Compressed Air Piping System Air Line Kit Air Compressor Oil Air Compressed Air Oil Content the quantification of the oil vapour content in a compressed air system shall be carried out within the following constraints. During operation, lubricating oil is carried over into the compressed air. most air compressors use oil in the compression stage for sealing, lubrication and cooling. the iso air quality standard measures three types of contaminants present in. Compressed Air Oil Content.

From nxcompressor.com

How to solve the dilemma of compressed air oil? Nanxiang0 Compressed Air Oil Content need to understand iso classes for compressed air quality? The right compressed air purity is key to safeguarding production integrity and. the quantification of the oil vapour content in a compressed air system shall be carried out within the following constraints. During operation, lubricating oil is carried over into the compressed air. the iso air quality standard. Compressed Air Oil Content.

From www.esska-tech.co.uk

ECOLL special compressed air oil 125 ml/ 1 liter VE 20 pcs price Compressed Air Oil Content this document specifies test methods for the sampling and quantitative analysis of liquid oil and oil aerosols that can. most air compressors use oil in the compression stage for sealing, lubrication and cooling. The right compressed air purity is key to safeguarding production integrity and. need to understand iso classes for compressed air quality? the quantification. Compressed Air Oil Content.

From www.engihub.com

Flow How Air and Oil Flow in Screw Air Compressor Engihub Compressed Air Oil Content need to understand iso classes for compressed air quality? this document specifies test methods for the sampling and quantitative analysis of liquid oil and oil aerosols that can. most air compressors use oil in the compression stage for sealing, lubrication and cooling. the quantification of the oil vapour content in a compressed air system shall be. Compressed Air Oil Content.

From www.desertcart.ae

Buy Premium 8000 Hour Rotary Screw Air Compressor Lubricating Oil Compressed Air Oil Content the iso air quality standard measures three types of contaminants present in compressed air: The right compressed air purity is key to safeguarding production integrity and. this document specifies test methods for the sampling and quantitative analysis of liquid oil and oil aerosols that can. During operation, lubricating oil is carried over into the compressed air. most. Compressed Air Oil Content.

From clariancetechnique.com

Compressed Air & Gas Qualifications And Air Quality Testing Clariance Compressed Air Oil Content need to understand iso classes for compressed air quality? most air compressors use oil in the compression stage for sealing, lubrication and cooling. During operation, lubricating oil is carried over into the compressed air. The right compressed air purity is key to safeguarding production integrity and. this document specifies test methods for the sampling and quantitative analysis. Compressed Air Oil Content.

From www.bigrentz.com

How Air Compressors Work An Animated Guide BigRentz Compressed Air Oil Content the iso air quality standard measures three types of contaminants present in compressed air: The right compressed air purity is key to safeguarding production integrity and. the quantification of the oil vapour content in a compressed air system shall be carried out within the following constraints. this document specifies test methods for the sampling and quantitative analysis. Compressed Air Oil Content.

From fluidflow.com

Compressed Air Fluid Flow Compressed Air Oil Content the quantification of the oil vapour content in a compressed air system shall be carried out within the following constraints. the iso air quality standard measures three types of contaminants present in compressed air: most air compressors use oil in the compression stage for sealing, lubrication and cooling. need to understand iso classes for compressed air. Compressed Air Oil Content.

From fluidflow.com

OilFree Vs. OilFlooded Compressed Air Systems Which is Best for Your Compressed Air Oil Content need to understand iso classes for compressed air quality? the quantification of the oil vapour content in a compressed air system shall be carried out within the following constraints. During operation, lubricating oil is carried over into the compressed air. most air compressors use oil in the compression stage for sealing, lubrication and cooling. the iso. Compressed Air Oil Content.

From www.amazon.in

HPDAVV Air Oil Separator Builtin Filter for 7.5KW/10HP 39cfm Screw Air Compressed Air Oil Content most air compressors use oil in the compression stage for sealing, lubrication and cooling. need to understand iso classes for compressed air quality? During operation, lubricating oil is carried over into the compressed air. this document specifies test methods for the sampling and quantitative analysis of liquid oil and oil aerosols that can. The right compressed air. Compressed Air Oil Content.

From yateks.com

YTSW1 Oil Sensor Of Moisture Content is to test the moisture content Compressed Air Oil Content need to understand iso classes for compressed air quality? this document specifies test methods for the sampling and quantitative analysis of liquid oil and oil aerosols that can. the quantification of the oil vapour content in a compressed air system shall be carried out within the following constraints. most air compressors use oil in the compression. Compressed Air Oil Content.

From www.compair.com

À propos de la technologie des compresseurs lubrifiés Compressed Air Oil Content the quantification of the oil vapour content in a compressed air system shall be carried out within the following constraints. the iso air quality standard measures three types of contaminants present in compressed air: this document specifies test methods for the sampling and quantitative analysis of liquid oil and oil aerosols that can. During operation, lubricating oil. Compressed Air Oil Content.

From www.airchecklab.com

How to Designate ISO 85731 Purity Classes Trace Analytics, the Compressed Air Oil Content The right compressed air purity is key to safeguarding production integrity and. most air compressors use oil in the compression stage for sealing, lubrication and cooling. this document specifies test methods for the sampling and quantitative analysis of liquid oil and oil aerosols that can. During operation, lubricating oil is carried over into the compressed air. the. Compressed Air Oil Content.

From jhfoster.com

Ensure Compressed Air Purity Levels Using ISO JHFOSTER Compressed Air Oil Content this document specifies test methods for the sampling and quantitative analysis of liquid oil and oil aerosols that can. most air compressors use oil in the compression stage for sealing, lubrication and cooling. need to understand iso classes for compressed air quality? During operation, lubricating oil is carried over into the compressed air. the quantification of. Compressed Air Oil Content.

From www.oilfree-air.eu

Why use oil free compressed air ? Oil Free Air Compressed Air Oil Content the quantification of the oil vapour content in a compressed air system shall be carried out within the following constraints. The right compressed air purity is key to safeguarding production integrity and. need to understand iso classes for compressed air quality? this document specifies test methods for the sampling and quantitative analysis of liquid oil and oil. Compressed Air Oil Content.

From www.ifsqn.com

Compressed Air How Clean is Yours? International Food Safety and Compressed Air Oil Content need to understand iso classes for compressed air quality? During operation, lubricating oil is carried over into the compressed air. most air compressors use oil in the compression stage for sealing, lubrication and cooling. the quantification of the oil vapour content in a compressed air system shall be carried out within the following constraints. the iso. Compressed Air Oil Content.

From owlcation.com

Making Crude Oil Useful Fractional Distillation and Cracking Owlcation Compressed Air Oil Content The right compressed air purity is key to safeguarding production integrity and. need to understand iso classes for compressed air quality? most air compressors use oil in the compression stage for sealing, lubrication and cooling. the iso air quality standard measures three types of contaminants present in compressed air: During operation, lubricating oil is carried over into. Compressed Air Oil Content.

From www.britannica.com

Compressed air Energy Efficiency, Industrial Uses & Safety Britannica Compressed Air Oil Content the iso air quality standard measures three types of contaminants present in compressed air: most air compressors use oil in the compression stage for sealing, lubrication and cooling. need to understand iso classes for compressed air quality? this document specifies test methods for the sampling and quantitative analysis of liquid oil and oil aerosols that can.. Compressed Air Oil Content.

From understanding-air-compressors.com

How Much Oil Does My Air Compressor Need? Understanding Air Compressors Compressed Air Oil Content The right compressed air purity is key to safeguarding production integrity and. need to understand iso classes for compressed air quality? the quantification of the oil vapour content in a compressed air system shall be carried out within the following constraints. this document specifies test methods for the sampling and quantitative analysis of liquid oil and oil. Compressed Air Oil Content.

From rockoil.co.uk

AIRGUARD 5000 High performance synthetic compressor oils ISO VG 32 Compressed Air Oil Content The right compressed air purity is key to safeguarding production integrity and. this document specifies test methods for the sampling and quantitative analysis of liquid oil and oil aerosols that can. During operation, lubricating oil is carried over into the compressed air. the iso air quality standard measures three types of contaminants present in compressed air: most. Compressed Air Oil Content.

From compressedairservices.com

Air Compressor Oils For Air Compressors In Hagerstown, MD Compressed Air Oil Content the quantification of the oil vapour content in a compressed air system shall be carried out within the following constraints. most air compressors use oil in the compression stage for sealing, lubrication and cooling. this document specifies test methods for the sampling and quantitative analysis of liquid oil and oil aerosols that can. The right compressed air. Compressed Air Oil Content.

From www.youtube.com

Oil free Compressed Air projects for industry YouTube Compressed Air Oil Content most air compressors use oil in the compression stage for sealing, lubrication and cooling. need to understand iso classes for compressed air quality? The right compressed air purity is key to safeguarding production integrity and. the iso air quality standard measures three types of contaminants present in compressed air: During operation, lubricating oil is carried over into. Compressed Air Oil Content.

From mavaindustrial.com

How compressed air is treated MAVA Industrial SA Compressed Air Oil Content the quantification of the oil vapour content in a compressed air system shall be carried out within the following constraints. this document specifies test methods for the sampling and quantitative analysis of liquid oil and oil aerosols that can. During operation, lubricating oil is carried over into the compressed air. most air compressors use oil in the. Compressed Air Oil Content.

From www.atlascopco.com

Compressed Air Quality Class 130 is perfect for Food and Beverage Compressed Air Oil Content need to understand iso classes for compressed air quality? the iso air quality standard measures three types of contaminants present in compressed air: this document specifies test methods for the sampling and quantitative analysis of liquid oil and oil aerosols that can. most air compressors use oil in the compression stage for sealing, lubrication and cooling.. Compressed Air Oil Content.

From dxowfwccx.blob.core.windows.net

Oil Water Separator Compressed Air Systems at Nellie Silva blog Compressed Air Oil Content The right compressed air purity is key to safeguarding production integrity and. this document specifies test methods for the sampling and quantitative analysis of liquid oil and oil aerosols that can. need to understand iso classes for compressed air quality? the quantification of the oil vapour content in a compressed air system shall be carried out within. Compressed Air Oil Content.

From www.air4ultd.co.uk

What is an Air Compressor Oil Separator? Air 4U Compressed Air Oil Content During operation, lubricating oil is carried over into the compressed air. the iso air quality standard measures three types of contaminants present in compressed air: most air compressors use oil in the compression stage for sealing, lubrication and cooling. this document specifies test methods for the sampling and quantitative analysis of liquid oil and oil aerosols that. Compressed Air Oil Content.

From ourfutureenergy.com

Energy Storage OurFuture.Energy Compressed Air Oil Content this document specifies test methods for the sampling and quantitative analysis of liquid oil and oil aerosols that can. the iso air quality standard measures three types of contaminants present in compressed air: need to understand iso classes for compressed air quality? The right compressed air purity is key to safeguarding production integrity and. most air. Compressed Air Oil Content.

From www.airpowereast.co.uk

SOLVED How to Remove Moisture Content in Compressed Air Systems Compressed Air Oil Content During operation, lubricating oil is carried over into the compressed air. the quantification of the oil vapour content in a compressed air system shall be carried out within the following constraints. need to understand iso classes for compressed air quality? this document specifies test methods for the sampling and quantitative analysis of liquid oil and oil aerosols. Compressed Air Oil Content.

From www.12eleven.com

The Importance of Clean Instrument Air Used in the Oil and Gas Industry Compressed Air Oil Content this document specifies test methods for the sampling and quantitative analysis of liquid oil and oil aerosols that can. During operation, lubricating oil is carried over into the compressed air. most air compressors use oil in the compression stage for sealing, lubrication and cooling. the quantification of the oil vapour content in a compressed air system shall. Compressed Air Oil Content.

From www.directair.co.uk

Compressed Air Duties for Breathing Air Direct Air Compressed Air Oil Content the quantification of the oil vapour content in a compressed air system shall be carried out within the following constraints. During operation, lubricating oil is carried over into the compressed air. this document specifies test methods for the sampling and quantitative analysis of liquid oil and oil aerosols that can. most air compressors use oil in the. Compressed Air Oil Content.