Electrical Outlet Screw Torque . The only way old threads could have an effect would be if. As far as i'm concerned, there. The correct torque is about 1/4 turn past where the screw contacts the wire against the back plate. These are essentially a combination of flat head, philips, and square. Most torque values are based on the size,. Annex i is designed to offer recommended torque values for tightening screws, bolts, and other types of connectors used in electrical. Torque vales are not found in the nec. I am now torquing all circuit breakers, panel terminals, switches, and receptacles per 2017 nec requirements. In the absence of connector or equipment manufacturer’s recommended torque values, table i.1, table i.2, and table i.3 may be. The screw heads for electrical receptacles are ecx drives. The torque required is a function of the compression of the conductor. You can get them from the manufacturer or ul.

from www.mudgefasteners.com

Annex i is designed to offer recommended torque values for tightening screws, bolts, and other types of connectors used in electrical. As far as i'm concerned, there. The correct torque is about 1/4 turn past where the screw contacts the wire against the back plate. The only way old threads could have an effect would be if. The screw heads for electrical receptacles are ecx drives. The torque required is a function of the compression of the conductor. I am now torquing all circuit breakers, panel terminals, switches, and receptacles per 2017 nec requirements. These are essentially a combination of flat head, philips, and square. In the absence of connector or equipment manufacturer’s recommended torque values, table i.1, table i.2, and table i.3 may be. Most torque values are based on the size,.

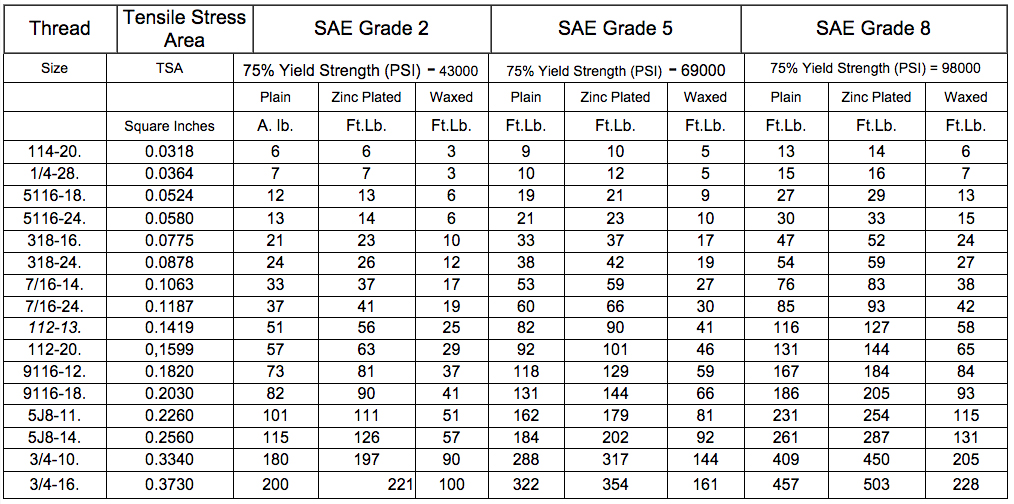

Determining Torque The Facts About Required Torque, Tension and Clamp Loads

Electrical Outlet Screw Torque Annex i is designed to offer recommended torque values for tightening screws, bolts, and other types of connectors used in electrical. Most torque values are based on the size,. As far as i'm concerned, there. The torque required is a function of the compression of the conductor. The correct torque is about 1/4 turn past where the screw contacts the wire against the back plate. The only way old threads could have an effect would be if. I am now torquing all circuit breakers, panel terminals, switches, and receptacles per 2017 nec requirements. Torque vales are not found in the nec. These are essentially a combination of flat head, philips, and square. The screw heads for electrical receptacles are ecx drives. In the absence of connector or equipment manufacturer’s recommended torque values, table i.1, table i.2, and table i.3 may be. You can get them from the manufacturer or ul. Annex i is designed to offer recommended torque values for tightening screws, bolts, and other types of connectors used in electrical.

From gabrielcoates.z13.web.core.windows.net

Electrical Lug Torque Specs Chart Electrical Outlet Screw Torque Annex i is designed to offer recommended torque values for tightening screws, bolts, and other types of connectors used in electrical. These are essentially a combination of flat head, philips, and square. The correct torque is about 1/4 turn past where the screw contacts the wire against the back plate. The torque required is a function of the compression of. Electrical Outlet Screw Torque.

From www.scribd.com

Standard Torque Values Chart Screw Building Materials Electrical Outlet Screw Torque Most torque values are based on the size,. The screw heads for electrical receptacles are ecx drives. In the absence of connector or equipment manufacturer’s recommended torque values, table i.1, table i.2, and table i.3 may be. These are essentially a combination of flat head, philips, and square. You can get them from the manufacturer or ul. I am now. Electrical Outlet Screw Torque.

From mungfali.com

Screw Torque Chart Electrical Outlet Screw Torque In the absence of connector or equipment manufacturer’s recommended torque values, table i.1, table i.2, and table i.3 may be. These are essentially a combination of flat head, philips, and square. Annex i is designed to offer recommended torque values for tightening screws, bolts, and other types of connectors used in electrical. The torque required is a function of the. Electrical Outlet Screw Torque.

From www.youtube.com

Power Screws Torque to Force Relationships in Just Over 10 Minutes! YouTube Electrical Outlet Screw Torque In the absence of connector or equipment manufacturer’s recommended torque values, table i.1, table i.2, and table i.3 may be. The correct torque is about 1/4 turn past where the screw contacts the wire against the back plate. You can get them from the manufacturer or ul. These are essentially a combination of flat head, philips, and square. The screw. Electrical Outlet Screw Torque.

From employee.buistelectric.com

Bolt Torque Values For Electrical Connections Buist Electric Electrical Outlet Screw Torque As far as i'm concerned, there. In the absence of connector or equipment manufacturer’s recommended torque values, table i.1, table i.2, and table i.3 may be. Torque vales are not found in the nec. You can get them from the manufacturer or ul. Annex i is designed to offer recommended torque values for tightening screws, bolts, and other types of. Electrical Outlet Screw Torque.

From my.element14.com

D03003 Duratool Torque, Screwdriver, Adjustable Electrical Outlet Screw Torque You can get them from the manufacturer or ul. Torque vales are not found in the nec. The only way old threads could have an effect would be if. Annex i is designed to offer recommended torque values for tightening screws, bolts, and other types of connectors used in electrical. These are essentially a combination of flat head, philips, and. Electrical Outlet Screw Torque.

From workshopsrgopalan5v1.z21.web.core.windows.net

Sae Grade 5 Bolt Torque Chart Electrical Outlet Screw Torque The screw heads for electrical receptacles are ecx drives. Most torque values are based on the size,. The correct torque is about 1/4 turn past where the screw contacts the wire against the back plate. As far as i'm concerned, there. Annex i is designed to offer recommended torque values for tightening screws, bolts, and other types of connectors used. Electrical Outlet Screw Torque.

From www.expressassembly.com

Electric Torque Screwdriver ED617PH1 Electrical Outlet Screw Torque As far as i'm concerned, there. Most torque values are based on the size,. Annex i is designed to offer recommended torque values for tightening screws, bolts, and other types of connectors used in electrical. The correct torque is about 1/4 turn past where the screw contacts the wire against the back plate. These are essentially a combination of flat. Electrical Outlet Screw Torque.

From www.lamonstergarage.com

Torque needed for metric bolts Lamonster Garage Electrical Outlet Screw Torque In the absence of connector or equipment manufacturer’s recommended torque values, table i.1, table i.2, and table i.3 may be. Annex i is designed to offer recommended torque values for tightening screws, bolts, and other types of connectors used in electrical. The torque required is a function of the compression of the conductor. You can get them from the manufacturer. Electrical Outlet Screw Torque.

From blog.engineeringpaper.xyz

Lead Screw Torque and Efficiency Calculations The Official EngineeringPaper.xyz Blog Electrical Outlet Screw Torque The only way old threads could have an effect would be if. You can get them from the manufacturer or ul. Most torque values are based on the size,. The correct torque is about 1/4 turn past where the screw contacts the wire against the back plate. I am now torquing all circuit breakers, panel terminals, switches, and receptacles per. Electrical Outlet Screw Torque.

From manuallistcantabank.z21.web.core.windows.net

Wiring 15 Amp 240v Electrical Outlet Electrical Outlet Screw Torque The torque required is a function of the compression of the conductor. The correct torque is about 1/4 turn past where the screw contacts the wire against the back plate. The screw heads for electrical receptacles are ecx drives. As far as i'm concerned, there. Most torque values are based on the size,. You can get them from the manufacturer. Electrical Outlet Screw Torque.

From toolsweek.com

What Size are Electrical Outlet Screws? Electrical Outlet Screw Torque Most torque values are based on the size,. As far as i'm concerned, there. Annex i is designed to offer recommended torque values for tightening screws, bolts, and other types of connectors used in electrical. The torque required is a function of the compression of the conductor. I am now torquing all circuit breakers, panel terminals, switches, and receptacles per. Electrical Outlet Screw Torque.

From www.flickr.com

Set screw torque technowarriors4 Flickr Electrical Outlet Screw Torque The torque required is a function of the compression of the conductor. The screw heads for electrical receptacles are ecx drives. Most torque values are based on the size,. You can get them from the manufacturer or ul. The only way old threads could have an effect would be if. The correct torque is about 1/4 turn past where the. Electrical Outlet Screw Torque.

From miakemp.z13.web.core.windows.net

Electrical Torque Specs Chart Electrical Outlet Screw Torque Annex i is designed to offer recommended torque values for tightening screws, bolts, and other types of connectors used in electrical. The screw heads for electrical receptacles are ecx drives. The torque required is a function of the compression of the conductor. As far as i'm concerned, there. In the absence of connector or equipment manufacturer’s recommended torque values, table. Electrical Outlet Screw Torque.

From www.mudgefasteners.com

Determining Torque The Facts About Required Torque, Tension and Clamp Loads Electrical Outlet Screw Torque As far as i'm concerned, there. In the absence of connector or equipment manufacturer’s recommended torque values, table i.1, table i.2, and table i.3 may be. Torque vales are not found in the nec. The correct torque is about 1/4 turn past where the screw contacts the wire against the back plate. You can get them from the manufacturer or. Electrical Outlet Screw Torque.

From www.weekly-ads-online.com

Extra Long Outlet Screws Long Electrical Outlet Screws Machine Screws Device Mounting Screws Electrical Outlet Screw Torque The torque required is a function of the compression of the conductor. The correct torque is about 1/4 turn past where the screw contacts the wire against the back plate. In the absence of connector or equipment manufacturer’s recommended torque values, table i.1, table i.2, and table i.3 may be. Torque vales are not found in the nec. You can. Electrical Outlet Screw Torque.

From homeprohandymanvalparaiso.blogspot.com

How to Wire Electrical Outlets and Switches by a HomePro Electrical Outlet Screw Torque These are essentially a combination of flat head, philips, and square. In the absence of connector or equipment manufacturer’s recommended torque values, table i.1, table i.2, and table i.3 may be. Torque vales are not found in the nec. As far as i'm concerned, there. Annex i is designed to offer recommended torque values for tightening screws, bolts, and other. Electrical Outlet Screw Torque.

From screwfixr.com

What Size Are Electrical Outlet Screws Electrical Outlet Screw Torque Torque vales are not found in the nec. The torque required is a function of the compression of the conductor. In the absence of connector or equipment manufacturer’s recommended torque values, table i.1, table i.2, and table i.3 may be. The screw heads for electrical receptacles are ecx drives. As far as i'm concerned, there. You can get them from. Electrical Outlet Screw Torque.

From www.scribd.com

Torque Screw Mechanical Engineering Electrical Outlet Screw Torque I am now torquing all circuit breakers, panel terminals, switches, and receptacles per 2017 nec requirements. These are essentially a combination of flat head, philips, and square. Most torque values are based on the size,. As far as i'm concerned, there. The only way old threads could have an effect would be if. The correct torque is about 1/4 turn. Electrical Outlet Screw Torque.

From screwfixr.com

What Size Are Electrical Outlet Screws Electrical Outlet Screw Torque These are essentially a combination of flat head, philips, and square. In the absence of connector or equipment manufacturer’s recommended torque values, table i.1, table i.2, and table i.3 may be. Torque vales are not found in the nec. Most torque values are based on the size,. The torque required is a function of the compression of the conductor. As. Electrical Outlet Screw Torque.

From www.tgktools.com

Wholesale PH407 Corded Torque Control Precision Electric Screw Driver Manufacturer and Supplier Electrical Outlet Screw Torque Annex i is designed to offer recommended torque values for tightening screws, bolts, and other types of connectors used in electrical. In the absence of connector or equipment manufacturer’s recommended torque values, table i.1, table i.2, and table i.3 may be. You can get them from the manufacturer or ul. The only way old threads could have an effect would. Electrical Outlet Screw Torque.

From www.tefoc.com

Bolt Torque Chart Tefoc Electrical Outlet Screw Torque Most torque values are based on the size,. These are essentially a combination of flat head, philips, and square. As far as i'm concerned, there. The correct torque is about 1/4 turn past where the screw contacts the wire against the back plate. Torque vales are not found in the nec. The torque required is a function of the compression. Electrical Outlet Screw Torque.

From blog.roninsgrips.com

How To Find Out Torque Specifications for Screws and Bolts An Outstanding NASA Reference Guide Electrical Outlet Screw Torque Torque vales are not found in the nec. I am now torquing all circuit breakers, panel terminals, switches, and receptacles per 2017 nec requirements. The only way old threads could have an effect would be if. The torque required is a function of the compression of the conductor. Most torque values are based on the size,. As far as i'm. Electrical Outlet Screw Torque.

From www.formsbirds.com

Bolt Torque Chart 5 Free Templates in PDF, Word, Excel Download Electrical Outlet Screw Torque Torque vales are not found in the nec. As far as i'm concerned, there. Annex i is designed to offer recommended torque values for tightening screws, bolts, and other types of connectors used in electrical. I am now torquing all circuit breakers, panel terminals, switches, and receptacles per 2017 nec requirements. The correct torque is about 1/4 turn past where. Electrical Outlet Screw Torque.

From screwfixr.com

What Size Are Electrical Outlet Screws Electrical Outlet Screw Torque I am now torquing all circuit breakers, panel terminals, switches, and receptacles per 2017 nec requirements. You can get them from the manufacturer or ul. Torque vales are not found in the nec. The screw heads for electrical receptacles are ecx drives. The torque required is a function of the compression of the conductor. Most torque values are based on. Electrical Outlet Screw Torque.

From www.oan.cl

Electric Screwdriver Rechargeable Adjustable Torque Electrical Screwdriver Powered Screw Driver Electrical Outlet Screw Torque The only way old threads could have an effect would be if. Torque vales are not found in the nec. Most torque values are based on the size,. These are essentially a combination of flat head, philips, and square. The torque required is a function of the compression of the conductor. You can get them from the manufacturer or ul.. Electrical Outlet Screw Torque.

From takgiko.en.made-in-china.com

Adjustable Torque Electric Screw Driver for Switches and Replacing Power Outlets pH515 China Electrical Outlet Screw Torque Torque vales are not found in the nec. Most torque values are based on the size,. These are essentially a combination of flat head, philips, and square. The screw heads for electrical receptacles are ecx drives. Annex i is designed to offer recommended torque values for tightening screws, bolts, and other types of connectors used in electrical. You can get. Electrical Outlet Screw Torque.

From www.thespruce.com

How to Wire Electrical Outlets and Switches Electrical Outlet Screw Torque You can get them from the manufacturer or ul. The correct torque is about 1/4 turn past where the screw contacts the wire against the back plate. As far as i'm concerned, there. These are essentially a combination of flat head, philips, and square. The only way old threads could have an effect would be if. In the absence of. Electrical Outlet Screw Torque.

From www.weekly-ads-online.com

Bates Wall Plate Screws, 75 Pack Assorted Size, Outlet Screws, Wall Plate Screws White, Outlet Electrical Outlet Screw Torque You can get them from the manufacturer or ul. The correct torque is about 1/4 turn past where the screw contacts the wire against the back plate. The only way old threads could have an effect would be if. The screw heads for electrical receptacles are ecx drives. I am now torquing all circuit breakers, panel terminals, switches, and receptacles. Electrical Outlet Screw Torque.

From www.pricepulse.app

150 Pieces Electrical Outlet Extender Kit 60 Pieces Outlet Screw Spacers and 90 Pieces 632 Electrical Outlet Screw Torque Annex i is designed to offer recommended torque values for tightening screws, bolts, and other types of connectors used in electrical. I am now torquing all circuit breakers, panel terminals, switches, and receptacles per 2017 nec requirements. Most torque values are based on the size,. These are essentially a combination of flat head, philips, and square. You can get them. Electrical Outlet Screw Torque.

From www.amazon.com

VIGRUE 145PCS Extra Long Outlet Screws Long Electrical Outlet Screws Wall Plate Screws White Electrical Outlet Screw Torque The correct torque is about 1/4 turn past where the screw contacts the wire against the back plate. As far as i'm concerned, there. I am now torquing all circuit breakers, panel terminals, switches, and receptacles per 2017 nec requirements. Torque vales are not found in the nec. The torque required is a function of the compression of the conductor.. Electrical Outlet Screw Torque.

From www.scribd.com

Tightening Torque Screw Electrical Connector Electrical Outlet Screw Torque Torque vales are not found in the nec. The screw heads for electrical receptacles are ecx drives. You can get them from the manufacturer or ul. Annex i is designed to offer recommended torque values for tightening screws, bolts, and other types of connectors used in electrical. In the absence of connector or equipment manufacturer’s recommended torque values, table i.1,. Electrical Outlet Screw Torque.

From mungfali.com

Screw Torque Specs Chart Electrical Outlet Screw Torque You can get them from the manufacturer or ul. The only way old threads could have an effect would be if. The screw heads for electrical receptacles are ecx drives. The torque required is a function of the compression of the conductor. Most torque values are based on the size,. In the absence of connector or equipment manufacturer’s recommended torque. Electrical Outlet Screw Torque.

From www.scribd.com

Metric Bolt and Cap Screw Torque Values Screw Nut (Hardware) Electrical Outlet Screw Torque As far as i'm concerned, there. Annex i is designed to offer recommended torque values for tightening screws, bolts, and other types of connectors used in electrical. These are essentially a combination of flat head, philips, and square. You can get them from the manufacturer or ul. Most torque values are based on the size,. Torque vales are not found. Electrical Outlet Screw Torque.

From www.bonanza.com

Rechargeable Electric Screwdriver Adjustable Torque Electrical Screwdriver Power Screwdrivers Electrical Outlet Screw Torque As far as i'm concerned, there. Torque vales are not found in the nec. These are essentially a combination of flat head, philips, and square. The only way old threads could have an effect would be if. The correct torque is about 1/4 turn past where the screw contacts the wire against the back plate. You can get them from. Electrical Outlet Screw Torque.